14 years one-stop China custom CNC machining parts factory

Home / Resources / Material / Aluminum CNC Machining /

Expert Aluminum Machining Team

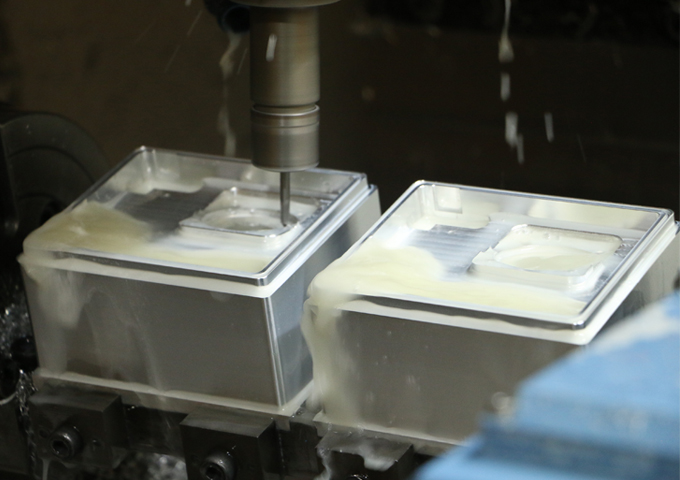

24/7 CNC Machining Facility with Samples Ready in 7-10 Days

With the rising popularity of lightweight metals, aluminum machined parts have become the preferred choice across various industries. Backed by extensive machining expertise, VMT has specialized in CNC aluminum machining for many years.

We specialize in producing high-precision, complex custom CNC machined aluminum parts, covering every stage from prototyping to mass production. Our advanced equipment and expert team ensure exceptional product quality and consistency. We are capable of machining a wide range of aluminum alloy components to meet strict tolerance requirements, delivering efficient production and outstanding solutions for your projects.

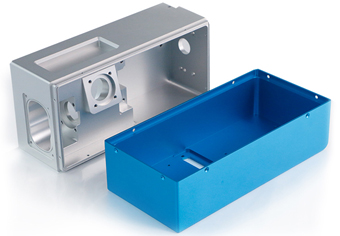

CNC Machined Aluminum Prototypes

Aluminum CNC prototyping is a critical step before mass production of aluminum parts, enabling effective validation of complex designs and pre-production testing to help you quickly identify and solve potential issues.

Our internal processes are efficient, precise, and cost-competitive, ensuring high-quality aluminum prototypes. Our engineering team carefully reviews each project and customizes the most suitable machining solutions based on your design requirements, such as extrusion, die casting, welding, electrical discharge machining (EDM), or wire EDM. This ensures that the process is efficient and meets your budget, timeline, and material specifications.

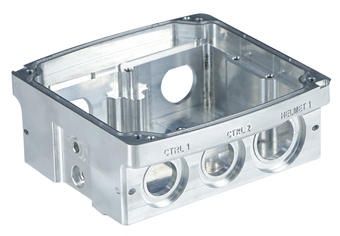

Custom Aluminum Parts Machining and Manufacturing

If you are looking for custom aluminum machining services, we are your ideal choice. With our advanced technology, extensive experience, and professional expertise, we offer cost-effective production solutions. Since 2015, we have been ISO 9001:2015 certified, along with IATF 16949 and SGS factory audits. We adhere to ISO 9001 quality standards, combining efficient production with flexible customization to ensure fast delivery of complex projects with exceptional quality.

We also provide comprehensive surface treatments for aluminum parts, including anodizing, sandblasting, shot peening, polishing, electrophoresis, chrome plating, powder coating, PVD, and painting.

Aluminum Alloy CNC Machining

In CNC machining, raw aluminum blocks are precisely cut into the desired shapes using CNC machines, allowing the production of various complex aluminum parts. Aluminum alloys are highly machinable, ductile, and offer an excellent strength-to-weight ratio. They also exhibit outstanding thermal and electrical conductivity, low density, and natural corrosion resistance. Through anodizing, their protective qualities can be further enhanced.

With a high strength-to-weight ratio, aluminum alloys are ideal for applications requiring both metal strength and lightweight properties. Custom aluminum machining is a top choice for meeting precise and versatile requirements.

Aluminum Materials: 6061, 2024, 5052, 5083, 6061-T6, 6063, 6082, 7075, 7075-T6, ADC12 (A380)

Advantages

Disadvantages

Price: $$

Delivery Time: < 10 days

Wall Thickness: 0.75 mm

Tolerance: ±0.125 mm (±0.005 inches)

Maximum Part Size: 200 x 80 x 100 cm

Applications

CNC machining enables the production of high-performance, high-precision, and highly repeatable metal and plastic parts. It supports both 3-axis and 5-axis CNC milling services and finds extensive applications across industries such as aerospace, automotive, and electronics. CNC machining delivers high-quality custom parts tailored to diverse requirements.

6061 Aluminum

A versatile and widely used alloy, renowned for its excellent machinability, weldability, and corrosion resistance. It is an ideal choice for structural applications, bicycle frames, aerospace components, and automotive parts.

Yield Tensile Strength (MPa): 276

Fatigue Strength (MPa): 96

Elongation at Break (%): 17

Hardness (Brinell): 95

Density (g/cm³): 2.70

Melting Point: 580–652°C

2024 Aluminum

This high-performance alloy is commonly used in aerospace due to its exceptional fatigue resistance and high strength-to-weight ratio. It is ideal for manufacturing aircraft structures, truck wheels, and automotive components.

Yield Tensile Strength (MPa): 325

Fatigue Strength (MPa): 140

Elongation at Break (%): 20

Hardness (Brinell):120

Density (g/cm³):2.78

Melting Point: 630–650°C

5052 Aluminum

This alloy is renowned for its excellent corrosion resistance, making it widely used in marine structures, chemical containers, and the construction industry. Its high malleability also makes it a preferred material for CNC machining.

Yield Tensile Strength (MPa): 193

Fatigue Strength (MPa): 115

Elongation at Break (%): 12

Hardness (Brinell):60

Density (g/cm³):2.68

Melting Point: 607°C–650°C

5083 Aluminum

This aluminum alloy offers high strength and excellent corrosion resistance, making it ideal for marine applications, high-pressure vessels, and low-temperature environments. Its superior fatigue resistance ensures outstanding performance under extreme conditions.

Yield Tensile Strength (MPa): 275

Fatigue Strength (MPa): 125

Elongation at Break (%): 12

Hardness (Brinell):75

Density (g/cm³):2.66

Melting Point: 660°C

6061-T6 Aluminum

An upgraded heat-treated version of 6061, this alloy offers enhanced strength while maintaining excellent machinability and weldability. It is ideal for high-pressure environments, such as aircraft, automotive components, and structural applications.

Yield Tensile Strength (MPa): 276

Fatigue Strength (MPa): 96

Elongation at Break (%): 10–12

Hardness (Brinell):95

Density (g/cm³):2.70

Melting Point: 582–652°C

6063 Aluminum

This alloy is widely favored in the construction industry for its excellent surface finish, strong corrosion resistance, and ease of forming. It is commonly used for manufacturing window frames, irrigation pipes, and decorative trims.

Yield Tensile Strength (MPa): 214

Fatigue Strength (MPa): 65

Elongation at Break (%): 12

Hardness (Brinell):73

Density (g/cm³):2.70

Melting Point: 600–655°C

6082 Aluminum

The 6082 alloy is strong and durable, offering exceptional mechanical properties and corrosion resistance. It is ideal for high-strength applications such as bridges, cranes, and trusses, and is also widely used in marine engineering and construction industries.

Yield Tensile Strength (MPa): 260

Fatigue Strength (MPa): 7

Elongation at Break (%): 10–12

Hardness (Brinell):95

Density (g/cm³):2.70

Melting Point: 600–660°C

7075 Aluminum

This high-strength alloy exhibits excellent fatigue resistance, making it widely used in aerospace and military applications. It is ideal for manufacturing aircraft components, gears, and high-stress structural elements.

Yield Tensile Strength (MPa): 503

Fatigue Strength (MPa): 160

Elongation at Break (%): 11

Hardness (Brinell):150

Density (g/cm³):2.81

Melting Point: 475–635°C

7075-T6 Aluminum

7075-T6 aluminum is widely used in aerospace, military, automotive, and mold processing industries due to its high strength, high hardness, excellent mechanical properties, and corrosion resistance.

Yield Tensile Strength (MPa): 503

Fatigue Strength (MPa): 159

Elongation at Break (%): 11

Hardness (Brinell):150

Density (g/cm³):2.81

Melting Point: 475–635°C

ADC12 (A380) Aluminum

This alloy is a common material for die-cast parts, renowned for its excellent castability, balanced strength, and corrosion resistance. Its durability and precision casting capabilities make it a popular choice among machinists for manufacturing automotive components, electronic device enclosures, and industrial machinery parts.

Yield Tensile Strength (MPa): 160

Fatigue Strength (MPa): 130

Elongation at Break (%): 3.5

Hardness (Brinell):80

Density (g/cm³):2.74

Melting Point: 660.32°C

6060 Aluminum

6060 aluminum alloy is a high-strength, heat-treatable alloy known for its excellent mechanical properties, resistance to deformation after machining, and good weldability. It is widely used in applications such as aircraft components, couplings, brake pistons, valves, magnetic heads, and electronic accessories.

Yield Tensile Strength (MPa): 190

Fatigue Strength (MPa): 215

Elongation at Break (%): 8

Hardness (Brinell):75

Density (g/cm³):2.71

Melting Point: 585–630°C

7050 Aluminum

7050 aluminum is widely used in aerospace, mold processing, and mechanical equipment due to its high strength, excellent corrosion resistance, and heat-treatability. It is particularly suitable for manufacturing high-strength components such as aircraft structural parts, medium and thick plate extrusions, open die forgings, and die forgings.

Yield Tensile Strength (MPa): 510

Fatigue Strength (MPa): 159

Elongation at Break (%): 6

Hardness (Brinell):135

Density (g/cm³):2.83

Melting Point: 477–635°C

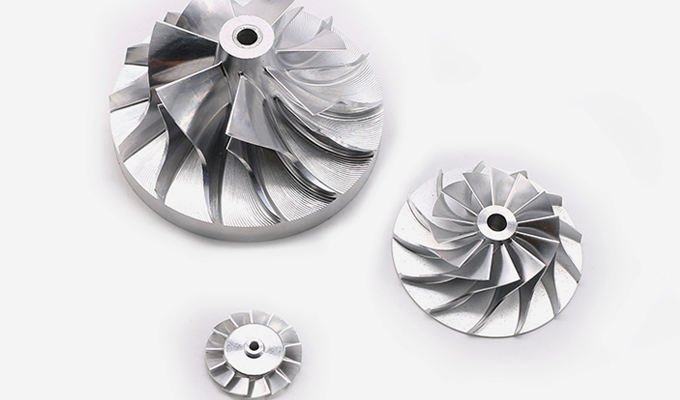

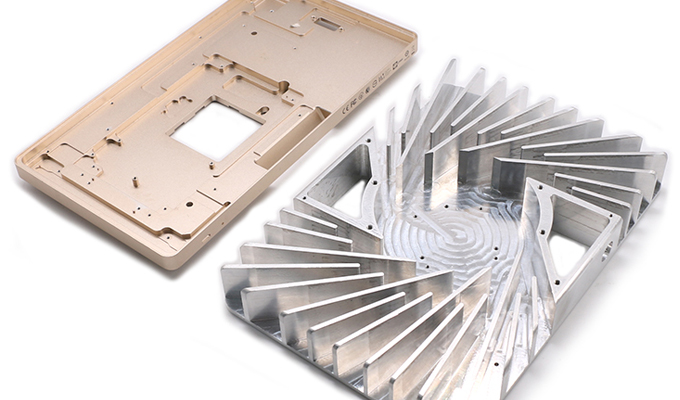

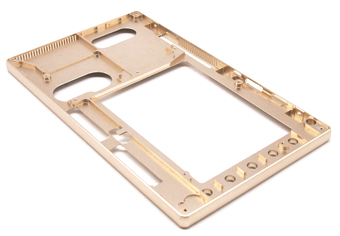

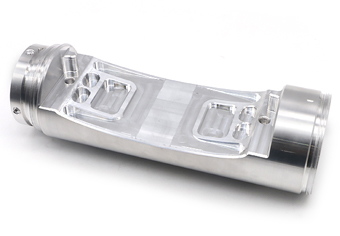

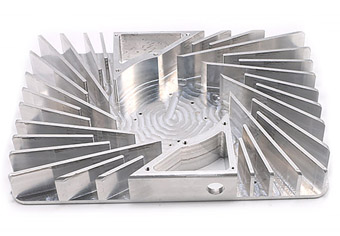

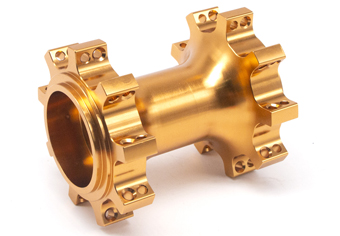

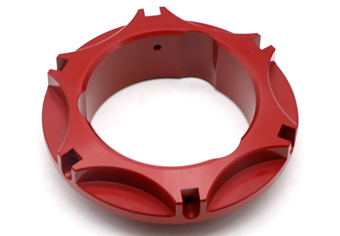

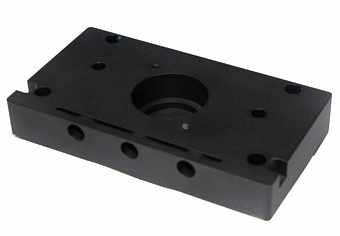

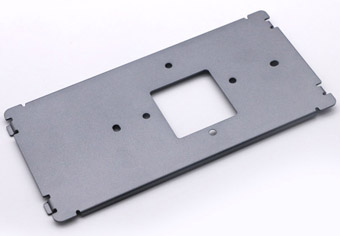

Aluminum CNC Machined Parts Gallery

Aluminum CNC Machining Capabilities

VMT is dedicated to providing customers with high-precision, complex component production and machining solutions, covering the entire process from prototype development to mass production. Below are our core machining capabilities:

Multi-Axis Machining (3-axis, 4-axis, 5-axis CNC): Our multi-axis CNC machining centers provide efficient cutting for multi-angle, complex surfaces, achieving exceptional precision. Ideal for manufacturing parts with intricate geometries and stringent tolerance requirements.

CNC Milling: High-precision CNC milling services for complex parts with strict tolerance demands.

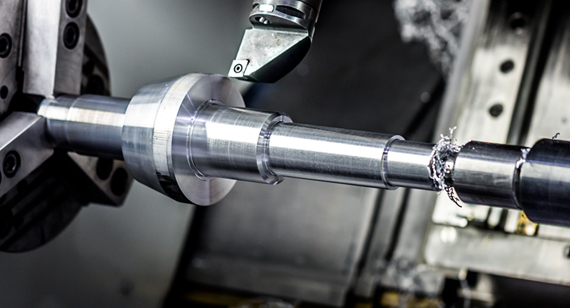

CNC Turning: CNC turning for cylindrical parts, delivering smooth surfaces and precise dimensions.

Rapid Prototyping: From design to prototype, we offer fast machining services that utilize CNC technology to deliver high-precision parts with short lead times. This accelerates product development and helps clients bring products to market faster.

Precision Machining: VMT excels in micrometer-level precision machining, achieving tolerances within 0.01mm. Perfect for components requiring high dimensional accuracy and surface finish, such as those used in medical, aerospace, and electronics applications.

Wide Range of Materials: We specialize in machining various metals (aluminum, titanium, stainless steel, copper) and engineering plastics. Our expertise ensures optimal adjustment of machining parameters based on material characteristics, guaranteeing product quality and performance.

Customized Small-Batch and Mass Production: Whether small-batch customization or large-scale production, we adapt our manufacturing solutions to meet client needs, ensuring timely delivery and consistent quality.

Quality Control: Adhering to ISO quality management standards, we employ advanced equipment such as coordinate measuring machines (CMM) and laser scanners to monitor quality at every step, ensuring precision and consistency in every product.

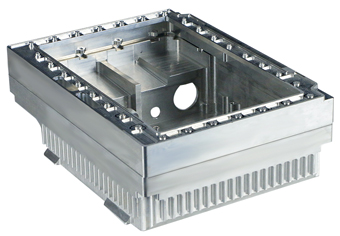

Aluminum Parts Surface Finishing Options

VMT offers a variety of surface treatments for aluminum CNC machining, ensuring exceptional product quality for every part. Each surface treatment is customized based on the characteristics of the aluminum components. Among these, anodizing is the most popular, including both standard and hard anodizing. Other options, such as electroplating, sandblasting, and polishing, are also available to enhance the alloy's wear resistance, corrosion resistance, mechanical properties, and appearance.

As Machined

Anodizing

Electroplating

Sandblasting

Polishing

Electrophoresis

Painting

Powder coating

Flexible Turnaround Time

We customize production schedules for various projects to ensure we meet your aluminum CNC machining needs.

Project Type

Urgent high-Precision Samples

Aluminum Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Advantages and Disadvantages of Aluminum Alloy CNC Machining

Aluminum alloys have significant advantages and disadvantages in CNC machining. The following are the advantages and limitations of aluminum alloys in CNC machining:

Advantages

Disadvantages

Application of CNC Machining Aluminum Parts

The excellent properties of aluminum alloys make them widely used in many fields, including but not limited to:

Frequently Asked Questions

What is the Best Aluminum for CNC Machining?

The best aluminum for CNC machining is 6061 aluminum alloy, known for its excellent machinability, moderate strength, strong corrosion resistance, and cost-effectiveness. Additionally, 7075 aluminum alloy is highly suitable for applications requiring high strength.

What is the Minimum Thickness for CNC Aluminum?

The minimum thickness for CNC machined aluminum generally depends on the equipment and process requirements. Typically, 0.5mm is a common minimum thickness, but high-precision equipment is required to prevent deformation and breakage.

What is CNC Machined Aluminum?

CNC machined aluminum refers to the process of cutting, engraving, or drilling aluminum materials using computer numerical control (CNC) equipment. By programming and controlling the cutting tools, high-precision machining of aluminum is achieved. This process is widely used for prototyping, part production, and large-scale manufacturing.

What is the Difference Between CNC 7075 and 6061 Aluminum?

7075 Aluminum Alloy: Known for its high strength and excellent fatigue resistance, but it has relatively lower corrosion resistance. It is commonly used in aerospace applications and other high-strength environments.

6061 Aluminum Alloy: Offers moderate strength, better corrosion resistance, and superior machinability. It is suitable for mechanical parts, structural components, and general industrial applications.

Summary:

7075: Ideal for high-strength requirements.

6061: Versatile for a wide range of industrial applications due to its balanced properties.

What is the Most Common Machined Aluminum?

6061 aluminum alloy is the most common CNC machined aluminum due to its reasonable cost, excellent machinability, good strength, and corrosion resistance.

Which Aluminum Has the Best Bendability and Strength?

Best Bendability: 5052 aluminum alloy, known for its high ductility and excellent bending properties.

Highest Strength: 7075 aluminum alloy, famous for its high strength but with slightly inferior bending performance.

What Causes Pitting and Holes in Machined Aluminum Surfaces?

Material Issues: Impurities or air pockets in the aluminum.

Casting Defects: Uneven cooling during casting leading to trapped gases.

Machining Problems: Dull cutting tools or improper feed rates.

Processing Environment: Contaminated coolant or air pollutants.

How to Reduce Burrs in CNC Machined Aluminum Parts?

Optimize Tool Selection: Use sharp tools and choose appropriate tool materials based on aluminum hardness.

Adjust Cutting Parameters: Reduce feed rates and optimize cutting depth.

Enhance Cooling: Use suitable coolant to prevent heat buildup, which can cause burrs.

Deburring Process: Post-processing with manual deburring tools or mechanical deburring equipment.

What is the Typical Lead Time for Aluminum Machining Projects?

Lead times depend on project size and complexity:

Clear requirements and advanced planning can further optimize lead times.

CNC Machining Resources

CNC Machining Stainless Steel: Challenges, Tips, Types, Advantages, and Disadvantages

Read this article to learn about the challenges, tips, types, advantages, and disadvantages of CNC machining stainless steel. It will help you make informed decisions for your stainless steel parts projects, improving ...

Custom Shaft Machining: Types, Manufacturing Processes, and Techniques

Aluminum is a versatile and widely used material in CNC machining, valued for its lightweight, corrosion resistance, and adaptability. However, untreated aluminum is prone to ...

Why Choose Brass for CNC Machining: A Comprehensive Guide to Custom Brass Parts

Read this article to understand the unique properties of brass, how to select the right brass alloy, and apply the correct machining techniques to ensure high-quality, durable results for your ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red