14 years one-stop China custom CNC machining parts factory

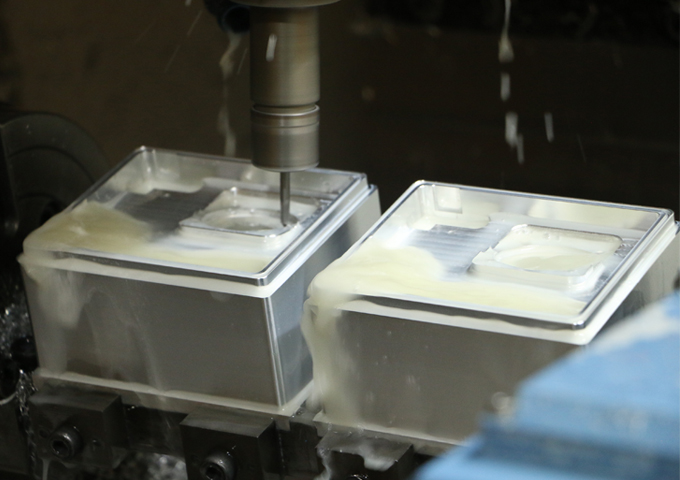

Our Rapid CNC Prototyping Machining Services

We can provide professional rapid CNC prototyping machining and manufacturing solutions for various industries. No matter how complex your project is, we have an experienced and professional project team to provide follow-up services. Choose our rapid CNC prototyping machining manufacturing services to bring your ideas to life and market. Choose us now!

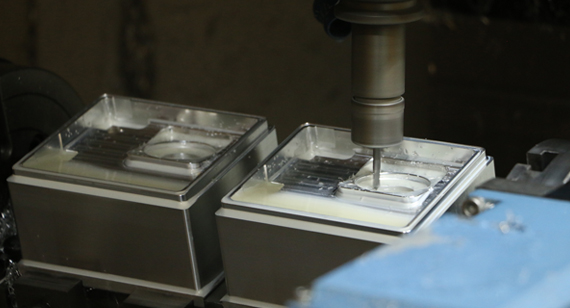

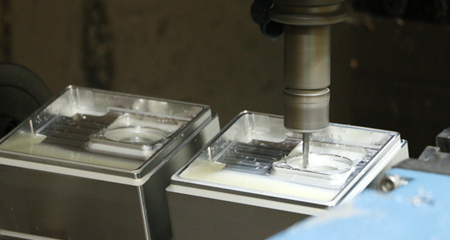

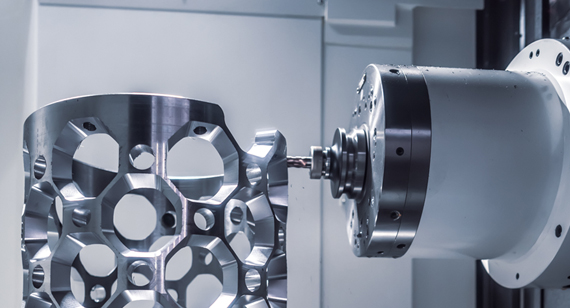

Custom 3+2 Axis CNC Machining Services

With 300 sets of 3+2-axis CNC machining equipment and 3-dimensional testing equipment, we provide high-quality solutions, save time, and obtain CNC machining parts at the lowest price. Some CNC parts do not need to be machined with 5-axis CNC, but can be completed with 3+2-axis CNC. 3+2 axis CNC machining has low cost, higher precision, faster machining speed and easier operation.

Tolerances as tight as +/- 0.0003 in.

Custom milled parts for prototyping and production.

Quick turn milling services.

Custom CNC Turning Services

VMT has advanced equipment and can provide high-precision CNC turning and milling compound machining services. Offer quick turnaround times of 3 to 7 days for low-volume production prototypes of plastic and metal parts. Tight tolerance of 0.002mm. We provide a complete test report and you can entrust your project to us.

Achieves +/- 0.0002 in. precision.

Custom turned parts for prototyping and production

Quick turn turning services.

Why Choose Us

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC prototyping machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC prototyping machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

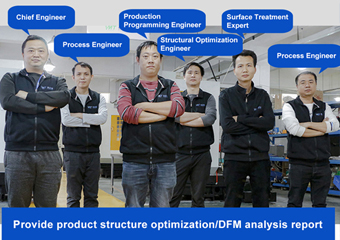

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC prototyping machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

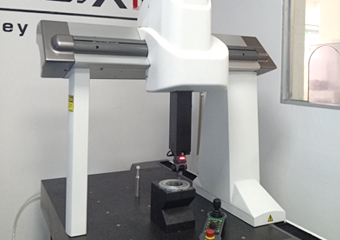

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

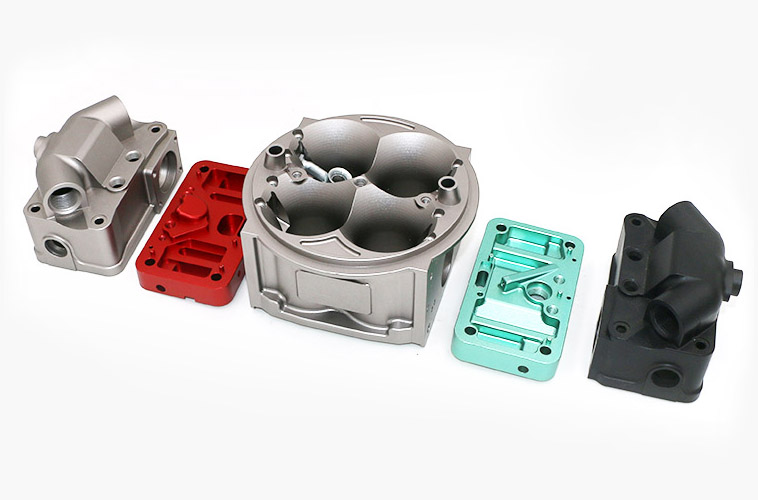

Surface Finishing

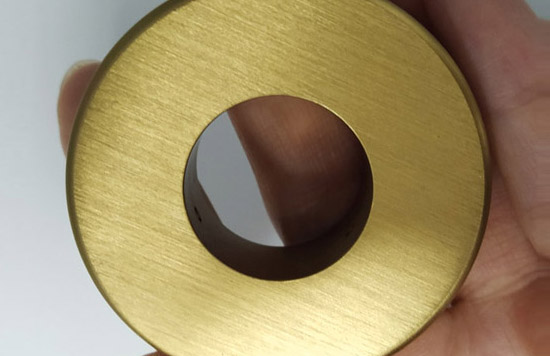

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishingquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC prototyping machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

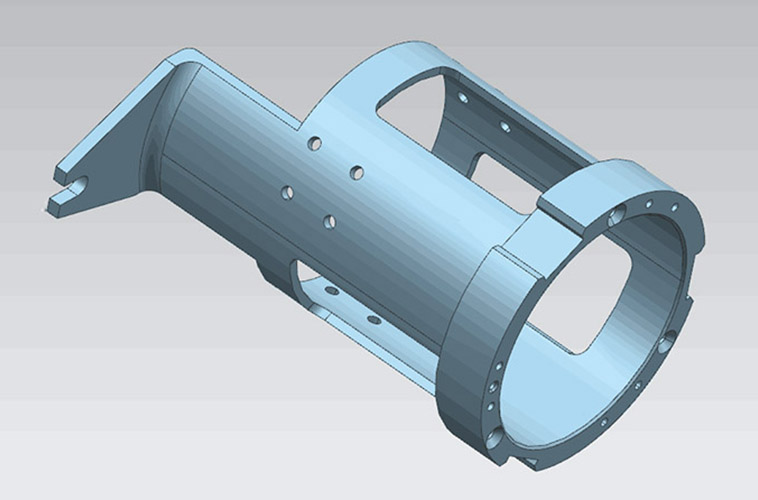

Custom Rapid CNC Prototyping Machining Solutions Services

Rapid Prototyping Machining

Our rapid machining services support product development, providing rapid prototyping and mold tooling to ensure design verification. CNC machining accurately creates plastic and metal parts to simulate the appearance and function of the final product.

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

The fastest parts can be obtained within 3 days for simple parts, and the fastest parts can be obtained within 7 days for complex parts. The specific time needs to be judged according to your rapid CNC prototype machining parts drawings.

Small and Large Batch Machining Production

We provide flexible CNC prototyping machining services to meet your needs, whether it is small batch or large-scale production. With precise tolerance control and comprehensive production capabilities, we ensure consistency in batch production while maintaining high quality.

CNC prototyping machining is particularly suitable for the rapid production of custom parts. Its high precision, repeatability and material diversity help products to be put on the market quickly. Our CNC machine shop is dedicated to providing a one-stop solution for custom machined parts or products, effectively shortening production cycle. Whether it is 10 or 10,000 custom parts, we provide efficient and accurate CNC prototyping machining services at an affordable price.

Every CNC prototyping machining production run is documented in detail, and photos and videos are transparently shared with customers. Video communication can also be used to check the production process. Provide the information required by customers.

Rapid CNC Prototyping Machining Parts Gallery

Below is a small selection of CNC prototyping machining prototypes and end-use parts we produce for our customers. Used with permission.

12 Quality Inspection Process

Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way.

DFM Analysis

Before CNC machining, engineers conduct a DFM analysis to identify and resolve potential issues in advance. This ensures optimized designs for efficient manufacturing, minimizes defects, and reduces machining costs.

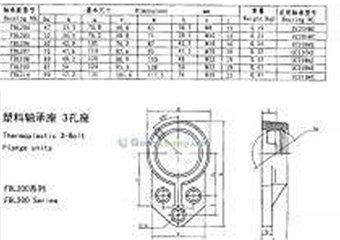

Dimensional Tolerance Determination

Check whether the parts meet the specified dimensional tolerances, ensure the technical feasibility of the tolerance design, and optimize the production process to meet your quality requirements and cost-effectiveness.

Material Testing

We have long-term stable partnerships with material suppliers for decades and can provide third-party inspection reports from organizations such as SGS, CTI, and TUV.

Rapid CNC Prototyping Machining Production

We have a dedicated team to track order progress, maintaining detailed records for each production run. Photos and videos are transparently shared with customers, keeping you informed about the machining process.

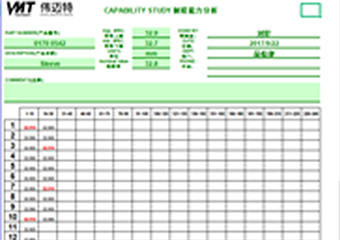

FQC Detection

During the machining production process, dimensional tolerance inspections are conducted every two hours, and the first article is inspected to ensure it meets design and quality standards. This guarantees process stability, product consistency, and improved production efficiency.

SPC / CKP

Implement statistical analysis to monitor and control the manufacturing process and provide inspection reports.

Problem Found

If any deviations, defects, or non-compliance issues are discovered during the machining process, an immediate meeting is held to address the problem.

Problem Solving

Respond within 30 minutes, provide solutions within 2 hours, and resolve within 1 day.

OQC Detection

Before CNC parts leave the factory, 100% dimensional inspection is conducted according to customer drawings. Inspection reports are provided before proceeding to the next processing step.

Surface Finishing

In addition to conventional surface treatments, there are a variety of special surface treatments. We have a full-time SQE to follow up and control each process in the surface treatment factory. After returning to our workshop, the product appearance will be 100% inspected.

Full Inspection

QC specilists will check the parts at every step with testing equipments accordingly,like 3D / 2D project, height/thread /roughness gauge.Offering inspection report with full dimensions for each part.

Package

Many different ways to pack the goods,avoid the damage, easy to carry and enviornmentally,Accept customer customization, commonly used pearl cotton, bubble bag.

Custom Rapid CNC Prototyping Machining Materials

VMT offers a wide range of material options to meet all your CNC prototyping machining needs. From high-precision metals to engineering plastics, our expert team ensures each material is machined to perfection.

Metal Materials

We also provide a variety of CNC prototyping machining metal materials to manufacture different customized precision CNC prototyping machining parts.

Plastics Materials

We also offer a variety of different CNC machined plastic materials to manufacture different custom precision CNC machined parts.

Custom Rapid CNC Prototyping Machining Surface Finishing

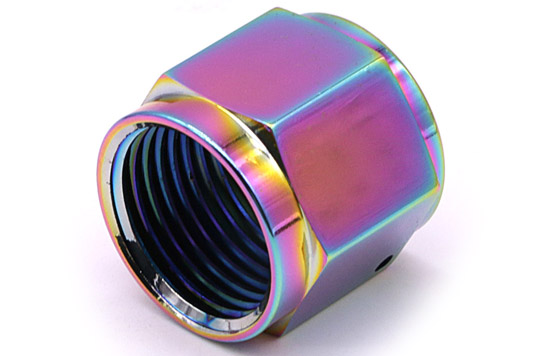

VMT offers a variety of surface finishing options to enhance the texture, hardness, smoothness, chemical resistance, and corrosion resistance of CNC prototyping machining parts. These finishes effectively cover tool marks left by machining, ensuring a refined and flawless product appearance. Here are some of the most common finishing options:

As-Machined Finish

Anodizing

Multi-Color Anodized

Hard Anodizing

Chrome Plating

Blue Zinc Plated

PVD

Electrophoresis

Nickel Plating

Laser Carving

Brushed

Polishing

Custom Rapid CNC Prototyping Machining Ordering Process

Upload Your CAD File

Upload your file directly or send your project information through the quote page. All files support NDA.

Quotation and DFM Analysis

An engineering team of 20 technicians is always ready to get professional suggestions from early-stage material selection, custom prototyping design advice, to money-saving tips and technical reminders before CNC prototyping machining parts manufacturing, all the way to end-use production.

Start Production

Before rapid CNC prototyping machining components, we will give you a detailed quotation, CNC prototyping machining, testing, etc., and deliver in the shortest time. This way you can confirm the next steps and bring them to market.

Receive Your Machining Parts

The fastest parts can be obtained within 3 days for simple parts, and the fastest parts can be obtained within 7 days for complex parts. The specific time needs to be judged according to your rapid CNC prototyping machining parts drawings.

Rapid CNC Prototyping Machining Parts Tolerance

As an ISO 9001-certified factory, we are dedicated to meeting stringent tolerance standards with precision CNC lathe machining. Based on your design specifications, our CNC lathe processes can achieve accuracy down to ±0.005 inches. For metal milling, we adhere to ISO 2768-m tolerance standards, while plastic machining follows ISO 2768-f standards—ensuring each product aligns with your exact requirements.

| 3+2 Axis CNC Milling | 5 Axis CNC Machining | CNC Turning | |

| Max. Part size | 1800 x 1000 x 500 mm 70.9 x 39.4 x 19.7 in |

±.0.02 |

±0.05 |

| Min. Part size | 12.7 x 12.7 x 12.7 mm 0.5 x 0.5 x 0.5 in |

±.0.03 | ±0.05 |

| Min. Feature size | Ø 1 mm Ø 0.039 in |

Ø 1 mm Ø 0.039 in |

Ø 1 mm Ø 0.039 in |

| Metals |

Metals |

Metals |

|

| Metals Standard tolerance | ±0.13 mm ±0.005 in |

±0.13 mm ±0.005 in |

±0.13 mm ±0.005 in |

| Plastics |

Plastics |

Plastics |

|

| Plastics Standard tolerance | ±0.20 mm ±0.008 in |

±0.20 mm ±0.008 in |

±0.20 mm ±0.008 in |

| General Tolerances |

Within ±0.002 mm |

||

| Text and color |

VMT can use CNC engraving or laser carving to create standard text based on customers' requirements. VMT can customize any color according to customers' requirements. |

||

| Lead Time |

Simple CNC prototyping machining components parts: 1-day prototype machining delivery. Complex CNC prototyping machining components parts: 3-days prototype machining delivery. |

||

Rapid CNC Prototyping Machining Workshop

Established in 2010 and is located in Guangming District, Shenzhen, Guangdong Province, China,has own factory cover an area of 5000 ㎡. We are customized machining parts manufacturer with 100 employees,can provide items within 24 hours.

100 sets machines including 4 & 5 axis imported CNC centers,turning & milling machines for fast delivery, 6 engineers who have been working for more than 20 years to provide you with free design service to ensure that parts can reach the appearance of iPhone, the accuracy of Atomic Clock, tolerance per 0.01 mm, the key procedure controlled by CPK1.68 or more. At the same time,2 engineers specialized in surface finishingcontrol the finish procedures. Passed ISO 9001:2005 & IATF 16949 & SGS in 2015.

Devoted to helping 10,000 enterprises to break through the difficulty of processing, and strive for becoming a leader in high-efficiency, high-yield, and precise parts. In the past 15 years, our business has spread to 62 countries around the world,covered military, medical, semiconductor, Telecommunication, automotive and other fields.No matter how complicated part is, or any technical problems faced with,we can find the solution and offer you with professional service.

100+

Sets of Machine

120+

Countries Shipped

100,000+

Parts Manufactured

Other Industry Applications

Our business has grown to now cover 62 countries worldwide. We have done products in the electronics industry, industrial industry, automotive industry, and medical industry. If you need custom Rapid CNC Prototyping Machining Components parts service, we have rich manufacturing experience and can turn your ideas into products.

Case Study: How to Combine Cold Oil Pressure with CNC Turning + CNC Lathe Live Tooling + 5-Axis CNC Machining to Complete this Wireless Microphone Body Shell Part?

When making the main shell of this microphone at the beginning, the process was bar material + CNC machining, which was a waste of material and long milling time. After mass production, in order to meet customer needs, our engineers changed the process to extrusion + CNC milling. The cost was directly reduced by 50%, and the quality reached the customer's requirements.

Custom Rapid CNC Prototyping Machining Applications and Advantages

Applications of Rapid CNC Prototyping Machining

Rapid CNC prototyping machining is a valuable process that allows for quick production of prototype parts and components. Here are some key applications of rapid CNC prototyping:

1. Product Development

Initial Concept Testing: Rapid prototyping enables designers to quickly create and test physical models of new products, facilitating early feedback and design iterations.

Functional Testing: Prototypes can be used to assess the functionality and usability of a product before mass production, reducing the risk of costly design flaws.

2. Engineering Validation

Fit and Assembly Testing: Prototypes allow engineers to verify the fit and assembly of components, ensuring that parts work together as intended in the final product.

Material and Performance Evaluation: Rapid CNC machining helps assess how different materials perform under real-world conditions, aiding in material selection for production.

3. Tooling and Fixture Creation

Custom Tooling: Prototyping can be used to produce custom jigs and fixtures, streamlining manufacturing processes and improving assembly efficiency.

Short-Run Tooling: It allows manufacturers to create tooling for small production runs, making it easier to test new designs without large investments.

Advantages of Rapid CNC Prototyping Machining

Rapid CNC prototyping offers several key advantages that significantly enhance the product development process. Here are the main benefits:

Rapid CNC Prototyping Machining FAQs

Are your materials standard?

We all use new and standard materials, not secondary recycled materials. Our material composition is standard and we can provide third-party test reports from SGS, CTI, TUV, etc. Please see the attachment.

What is your MOQ? Can you do small batch proofing/ small quantity?

Order quantity can start from 1pc. Any big order starts from a small order, just like a baby, it needs to grow step by step. Another more important reason is that in the current economic situation, orders from all indutries tend to be in small batches. If we give up small batch orders, we will give up the entire market. Accepting small batch orders is one of the necessary conditions for a company's future survival.

How long is the sample delivery time?

We accept the sample order if need to test before mass production. 1 pcs or 2 pcs or 10 pcs.... is okay. VMT sets two sampling teams at the sample stage, finish samples 24 hours a day, make complete sample records and keep them for one year. The sample fee will be refunded after mass production.

Is your quality stable?

We use an advanced quality control system, equipped with manual and automated inspection equipment. All reports are archived and kept for two years, such as first article inspection, process inspection, and shipment inspection. From raw materials, CNC processing to shipment, We have dedicated personnel to follow up and share progress in real time. We have a testing laboratory equipped 2D projector, 3D projector and other high-precision testing instruments.

What inspection equipment do you have?

We have a testing laboratory equipped with three-dimensional, two-dimensional, projectors and other high-precision testing instruments.

Can you sign NDA?

Yes, we can sign NDA, do not disclose drawing and design, because we know that every design is important for each company. All customer drawings are kept in the business department and NDA is signed. Only disassembly drawings are used inside the factory, and there are regulations not to forward any videos and pictures of customers on public platforms. Do you have any other comments to add?

Explore Related Resources

Metal Prototyping: A Quick Guide to Creating Metal Prototypes

This quick guide will explore the essentials of metal prototyping, the benefits, methods for producing metal prototypes, and tips on selecting the best method for your project...

CNC Prototyping Machining: A Complete Guide

This comprehensive guide will take you through the fundamentals of CNC prototyping, its advantages, limitations, and applications. We will also explore how CNC machining compares to other...

Plastic Prototype Manufacturing: Key Prototyping Techniques

Plastic CNC prototypes play a crucial role in various stages of product design, development, and production. They are essential tools for designers and engineers to validate design...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red