Iron sand

Advantages: Iron sand is the cheapest and most durable.

Disadvantages: If it is used for a long time, it will be easy to rust. Because it will not be replaced frequently, it will cause the product to be sprayed and dirty. It is suitable for products that are generally not very strict on quality and appearance.

Glass Sand

Advantages: medium price.

Disadvantages: The effect will be uneven in thickness. Because the glass sand is easily broken, it will cause the sand to be used for a period of time, the size will be different, and the sand will be uneven, which will lead to long-term irregular use for a period of time.Then it is needed to be replace to ensure this quality.

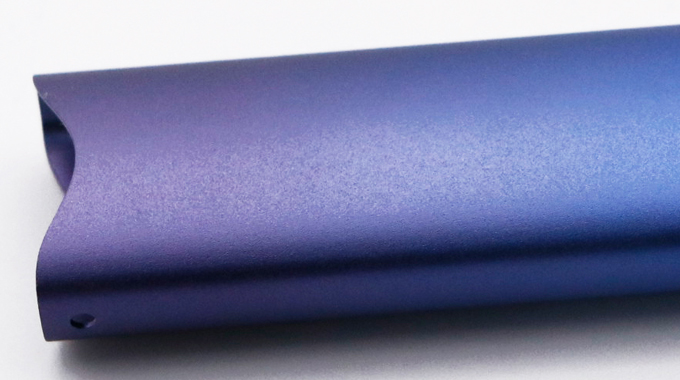

Zirconium sand: The best effect of these three common sands. It is the most delicate and has the best texture, but its cost is also very high. Usually, most products will not use this kind of zirconium sand. Unless for a special electronic product, such as a case like an iPhone, this zircon sand will be chosen to be made to reach good looking.

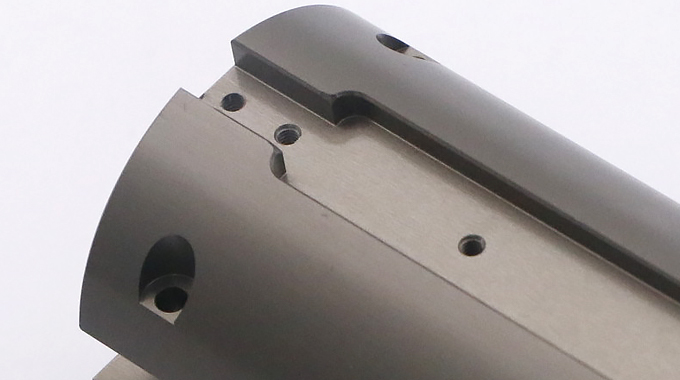

Uncommon sands include quartz sand, plastic sand, etc. These are not commonly used, but they are for special products, such as some titanium alloy products which cannot be sprayed with iron sand, because they will spark when sprayed, which will result in injury to the operator.

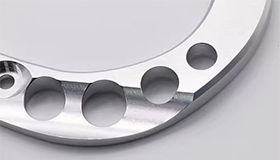

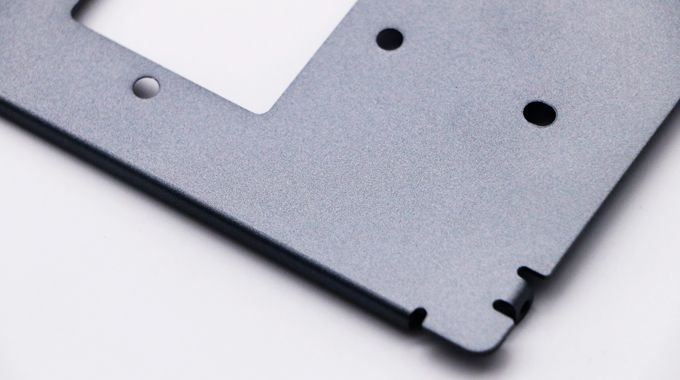

Sandblasting is a process to make this product achieve better consistency, make roughness on the surface of the product, and increase roughness. It's like we choose different roughness for different products, then we need to make them according to customer's requirements. We are more commonly used in this kind of mechanical parts,and equipment parts. Then we will choose 50, 80, or 100 mesh, etc. These types are a bit rough, basically, they do not have very strict requirements on the surface of the product, so quality is the main thing, and the overall consistency of the product will be better after making them.

Ordinary products: For some commonly used electronic products, most of them are in 120 mesh and 150 mesh. For example, 150 mesh belongs to a medium-to-high-end product, and the overall look will be more better. Generally, the customer has appearance requirements for this product, and needs to cover the machining marks on the surface, then 150 mesh will be chosen.

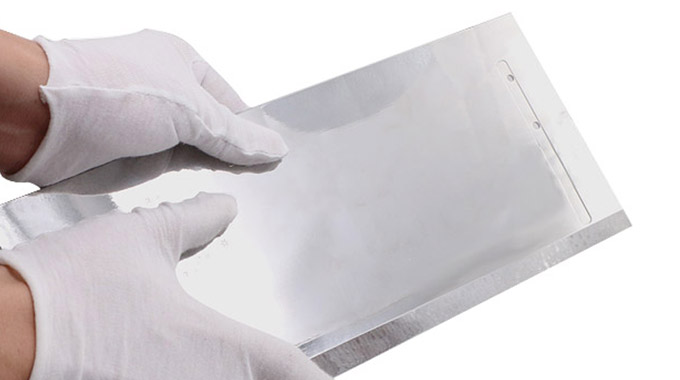

High-precision products: For some high-precision products, they have very delicate requirements on the appearance. In addition to the requirements for the surface of this product during our usual processing, we also choose finer ones when sandblasting and roughening. Such as the 180 mesh sand we usually use, has high requirements on the surface of the product, and the sand will be fine. It looks very high-end, for example, compared to the shell of this kind of iPhone that we usually use, which is 220 mesh sand, which basically has no roughness and is very small. But the cost will be higher than the 120 and 150 we said before, because the production control requirements are very strict compared to those common products.