14 years one-stop China custom CNC machining parts factory

The poor surface effect of CNC aluminum case is not just a problem of surface treatment. The CNC machining process involves many steps, and it also cannot solve the problem if change surface treatment factory. It is necessary to determine the specific reasons for the poor surface effect, such as materials, processing parameters, the tools, equipment accuracy and other issues.

During the anodizing process of CNC machined aluminum case, there will always exist problems such as inconsistent appearance, gloss, color, and surface dents between the previous and current batches.As a CNC machining aluminum case factory, how can we avoid this problem?China VMT believes that as long as the 3 points in the video are achieved, the problems of color difference can be solved, so that the yield rate of your parts can reach 98%.

There are many reasons for the unstable delivery of CNC machining parts factory. What are the reasons that affect the delay in delivery of CNC machining parts?The production plan is not thorough, the output is saturated, the material supply chain and the quality is unstable, also no quality standards.

Does The Surface of The Herb Grinder You Bought Have Texture? Do You Hate It? When the texture processed by CNC is messy, it affects people's feelings. We posted a video a few days ago, then we got a feedback that the biggest problem with CNC machined grinders is the texture on the surface. But the beauty of CNC processing lies in its texture.

Will you encounter bumps or scratches on CNC parts when receiving them? As long as the packaging is improved, these problems can be easily solved. Do you know what the standard packaging process is?The following video is about the packaging and shipping process of the VMT CNC machining factory. 6 points can ensure that CNC parts are safely delivered to customers without defects.

What will VMT do when defects occurred on CNC machining parts during production? And ensure that CNC parts can be delivered on time?When defects occurred on CNC machining parts,first we will check whether other parts have the same problem to determine whether it is caused for all batches or just single piece.

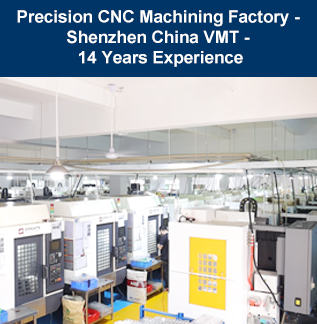

Meet China VMT, our Sales Manager Carol Yue, providing you with the best quality and CNC machining services. From small to high-volume orders, more than 100 CNC machining machines create unparalleled quality parts in a variety of sizes, materials and finishes.

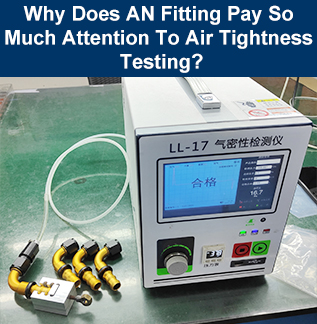

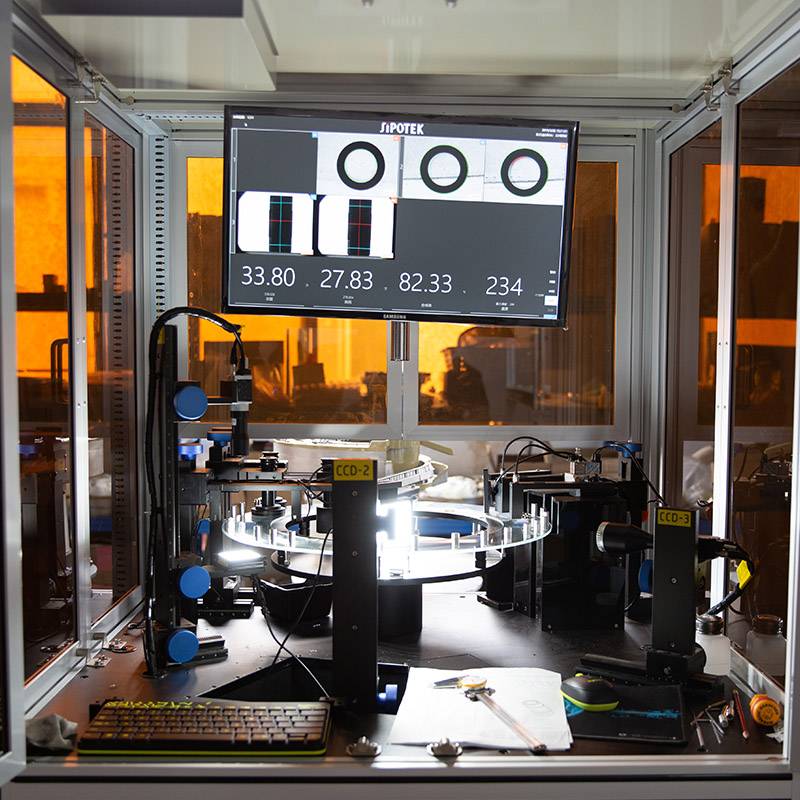

Today we will introduce to you about air tightness test for AN fittings.Because if the air leak occurs, it will become unusable.In order to ensure the quality, generally we will conduct the test.Then, let us take a look at the air tightness testing process.

Does the CNC weed grinder you purchased have problems with the teeth not being sharp and the surface easily scratched?The truth is you chose the wrong weed grinder.I purchased 2 weed grinders from the market to compare with our custom CNC machined weed grinder.3 different craft weed grinders, 3 different prices.

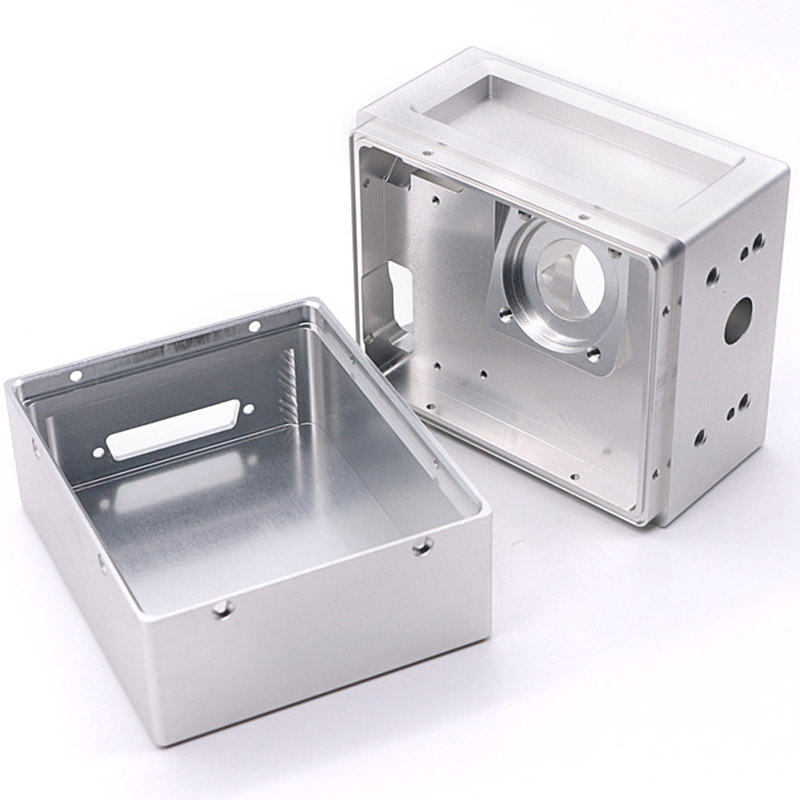

VMT is a 14-year factory specializing in precision CNC machining parts, located in Shenzhen, China. It has passed ISO9001 and 16949 certification and obtained 11 patents. VMT also has imported 5-axis CNC machines, CNC turning machines, automatic lathes, a total of 100 CNC machines. The precision can reach 0.005mm, and has built its own reliability laboratory, with 3D projector, 2D projector, CCD inspection, height, hardness tester and other testing equipment.

The prices of CNC herb grinders on the market vary. Do you know how to choose the CNC right herb grinder suppliers? Let’s take a look at how we choose?

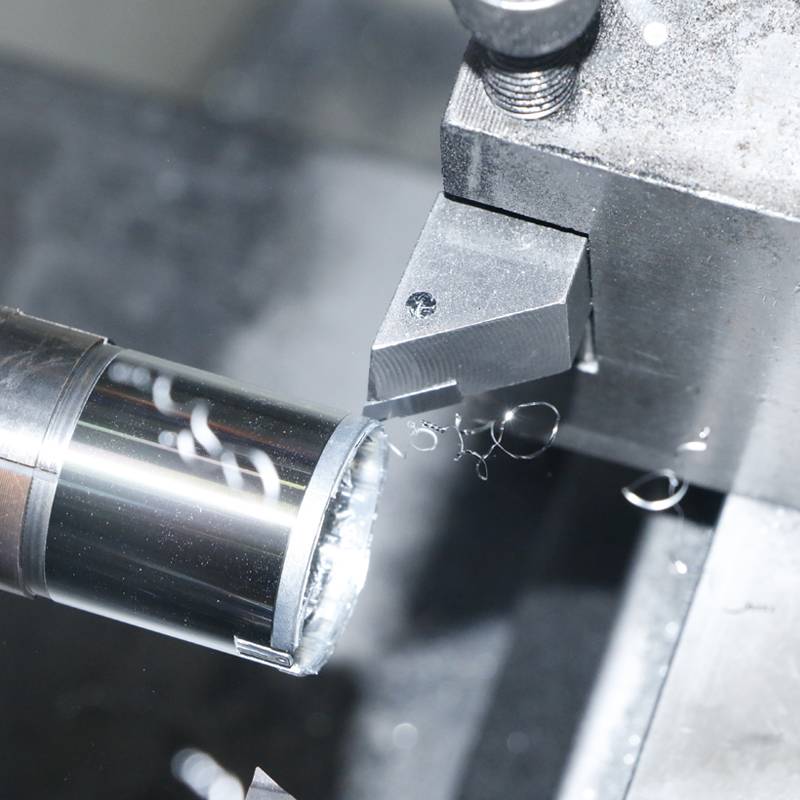

Let me take you 1 minute to take you through our CNC machining production line. How do we produce CNC machined parts? 1. CNC machine adjustment 2. Use calipers to measure raw materials 3. Raw material clamping 4. Start CNC machining 5. Secondary CNC machining 6. CNC machining completed If you have any CNC machining questions, please contact us: vmt@vimetal.com.cn

Let me tell you what a high-quality aluminum grinder looks like. Why are the teeth of other aluminum grinder not sharp and the color coating falling off? Let me give you specific instructions using the video below.On-stock Sharp teeth, no chip-off coating, CNC machining 4 layers 60mm round aluminum herb grinder China VMT.

The principle of VMT CNC machining parts quotation is to provide the lowest price possible to reduce the customer's cost on the premise of meeting the customer's quality requirements. For this,we need customers to provide us with the 5 pieces of information as below.

Today I will introduce to you our CNC machining factory and let you know about us in 1 minute. Welcome to visit us.

Available in USD2, USD8, USD15 and USD20.Today we will take a look at what the USD15 herb grinder looks like.This grinder is we made before, today we will make an experiment.Many people always say that the anodized film is easy to fall off when they are using grinder, the teeth are not sharp, so let's see what will happen on our grinder.Now, we have stock, we can provide the free sample for you.

It has its own quality inspection room, equipped with spectrum analyzer, 3-dimensional detection, height meter and other equipment. From raw materials to finished CNC parts, after 12 quality inspection processes, the yield rate of your CNC machining parts can reach 98%. How are your CNC parts inspected for quality?

For high-quality CNC machining parts, if you want to make sure that the dimensions and appearance of each CNC part match the requirements of drawing. Quality control during the CNC machining production process is very important, otherwise the defective CNC machining parts rate will be high and delivery will be slow. Let me tell you how we control quality during the CNC machining production process?

In VMT, How to Control the Quality of Finished CNC Machining Parts? How to Ensure that the CNC Machining Parts Shipped to Customers are 100% in Line with Customer Requirements? All our produced and purchased finished products will first enter our IQC for inspection. During the inspection, we will check the production order, the incoming parts list, and the drawing. Then sampling inspections are carried out according to AQL, but for important appearance and size need to be fully inspected. In addition, products with special surface treatments must undergo relevant reliability testing and issue an inspection report. When defects are found, we will issue the defect report, the quality supervisor will be notified as soon as possible to check again and determine whether to accept or reject. When the quality supervisor cannot make a decision, review the decision with other departments. Qualified products need to be stamped with a seal of approval and then packaged for shipment.

Many customers ask what surface treatments can be applied to Aluminum CNC machined parts? What are the functions of these surface treatments? let me tell you!

According to many years of personal CNC Machining experience. Aluminum alloy the side wall height of ten millimeters can be at least zero point two. The height of twenty millimeters can be zero point three. The bottom thickness should be determined according to the bottom area. Sixty millimeters can be zero point three. One thousand can be zero point four. The thinner the thickness of the CNC machining time. The longer, the higher the cost. The project must consider this factor in the design to facilitate the product cost more competitive advantage!

Gold-Plated Stainless Steel CNC Machining Parts, Quality and Quantity, Sophisticated Technology, Sufficient Supply and Sufficient Supply.

We are a professional CNC machining service manufacturer with 13 years of experience. While providing you with quality services, we can also provide you with rigorous processing solutions.

VMT is mainly focused on the production of custom aluminum herb weed grinder. According to the customer's drawings and designs, make custom aluminum herb weed grinder with competitive styles and prices.

We are a professional CNC machining service manufacturer with 11 years of experience. We have accumulated 6582 models for customers and cumulative production models: 9628 models.We also provide you with a one-stop processing solution from design to production.

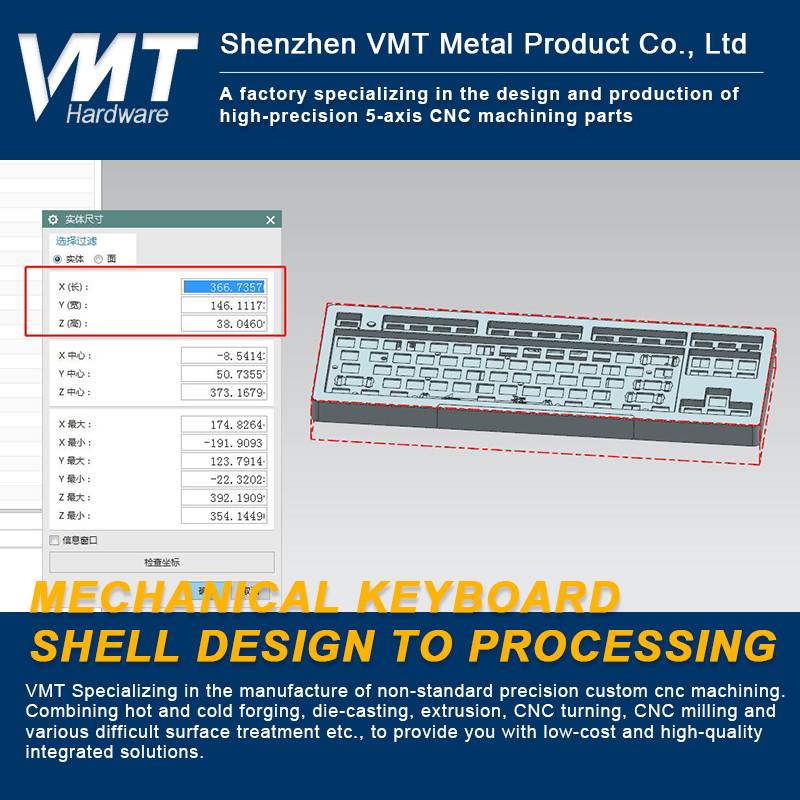

This is to let you know how to custom the mechanical keyboard case. We can CNC machining your aluminum keyboard with various colors of anodizing. You can also make all copper, stainless steel, aluminum alloy, brass and other materials according to your requirements, and choose your favorite color and size for CNC customization.

We always consider the mechanical keyboard shell tolerance, anodic oxidation and other issues when processing mechanical keyboard. This video explains your doubts. 1.How to feel after oxidation. 2.Whether oxidation will have dead angle, etc.

Galvanometer of laser machine parts are machined with square solid materials, and CNC machining takes 35 minutes, which wastes materials and the mahining cost is beyond the customer's acceptable range.In order to reduce costs, our engineers use cold forging, the machining time is reduced to 12 minutes, and the cost is reduced by 60%.

Here is a video that allows you to clearly understand the 5 axis CNC machining process. VMT is a professional CNC precision metal machining manufacturer. Can provide you with professional opinions and suggestions. We are honored when you subscribe, and hope to bring you some useful help.

Today, I will tell you how to choose the supplier of this products, herb grinder.Let me give you specific instructions using the video below.

How to Choose the Process of CNC Machining or Die Casting for Aluminum Cases ? Let me give you specific instructions using the video below.

What Services can be Offered by A Professional CNC Aluminum Knob Machining Factory?We have our own CNC machining workshop, so we can also make CNC aluminum knobs of any size, type, and color you need.

Hello everyone, I'm Carol from VMT. Chinese new year is the biggest festival in China. All people have to go back to their homes and parents' homes, eat and chat together, and send the best wishes to their family, relatives, and friends. It's the happiest time for everyone. Here, on behalf of all VMT employees, I would like to extend my most sincere New Year blessings to all our customers and partners. May you and your family be happy every day! May happiness and smile always be with you in the new year. I wish you good luck and all the best in the Year of the Dragon! I wish VMT employees a happier life and partners more prosperity. At VMT, we always focus on technological innovation and teamwork. It is this spirit that has allowed us to achieve certain gains in the past year. In the new year, VMT will continue to pursue excellence and forge ahead.

How to reduce the CNC machining cost of the wireless microphone main body shell? Let me give you specific instructions using the video below.

How to Control the Yield Rate of Customized CNC Aluminum Keyboard Case Machining? Let me give you specific instructions using the video below.

What Kind of Knob We Can Produce ? We can make any design and any size. we can make different knurled. we can make many different color. What kind of knob do you need? Let me give you specific instructions using the video below.

How to reduce the cost of CNC laser galvanometer shell? Let me give you specific instructions using the video below.

How to reduce the cost of 5 axis CNC machining connectors by 20%? Let me give you specific instructions using the video below.

Today we will talk about DIY aluminum keycap by forging & CNC machining.What process will you choose to reduce the cost?

What should we do when customers receive aluminum knobs with scratches on the surface? Recently, our customer feedback that the surface of aluminum knob was scratched, and want us to find a solution to avoid this issue. As an aluminum knob CNC turning factory, how can we avoid it?

Recently, a customer said that the cost of CNC machining is too high. In fact, this can be solved by changing the CNC machining process. Do you have any better suggestions for choosing different CNC machining processes for the CNC machining parts with different structure?

How is quality control carried out in Shenzhen CNC machining factory? Different regions or types of products have different quality control standards.Because we are making CNC machined parts with good appearance, the surface requirements are relatively high generally. Therefore, we have set up 12 quality control processes, and there is a quality control standard from raw material to shipment.

In fact, the surface effect of high-end CNC machined aluminum case cannot be solved by changing to another surface treatment factory.Because if the surface treatment factory does not know the quality standards of your product, it will not be able to do it well, and it will only increase the cost.This is just like a customer who needs you to make CNC aluminum case, both parties need to communicate and make clear about product standards, what needs to be paid attention to and how to control it. There needs a standard for the parts.

Threaded braces can increase the connection strength + wear resistance + anti-rust knot + anti-loosening + anti-vibration = prolong the service life of the thread. Because the thread belongs to the assembly position, it must be tightened and loosened frequently. If the thread is operated for a long time, the thread will be damaged, which will lead to slippage and insufficiency of the thread.

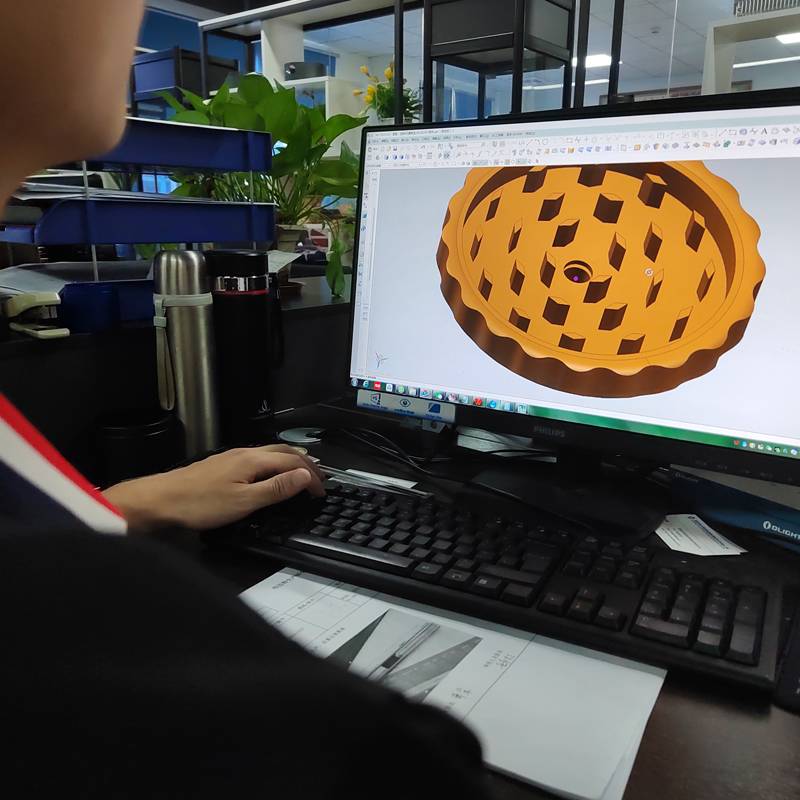

There are many grinding methods, but it is best to use the appropriate herb grinder. This is a video about the CNC processing of herbal grinders, which can be made of metal, plastic or wood. Some lack removable parts, and some can be assembled into up to five pieces. This video will show you how it is made. 1. Design and manufacture of herb grinder drawings 2. Computer simulation 3. Use of raw materials 4.Generation of computer processing program 5. Start CNC machining 6. Tool change 7. Product display

You can support our channel to provide more tutorials. We provide CNC machining process, CNC surface treatment and CNC knowledge. We will see the following features in the video. 1. Drawing analysis 3.Product simulation program 4. Actual Operation of CNC Walking Tool 5. product forming

VMT is the metal housing supplier of the world's TOP 5 tactical flashlight company.Learn more about VMT and our products, please contact us.

VMT customized machining of various metal parts, 5-axis CNC machine to meet your processing requirements.

5-axis machined aluminum products, we have imported machining machines, which can produce metal parts with high efficiency and high quality.

VMT specializes in producing and processing aluminum products, we have a variety of cnc machines to meet your processing needs.

VMT CNC machining factory has achieved ISO9001 quality management system certification in 2015, customized machining of various metal parts, 5-axis CNC machine to meet your processing requirements.

VMT has automatic lathes, CNC lathes, CNC machining centers and other machines. Customizing various High-precision knurling and threads.

We have professional testing machines to ensure that our products are 100% qualified.