15 years one-stop China custom CNC machining parts factory

Easier and faster production of high-quality parts from prototype design to on demand production with 1-on-1 guidance from professional engineers extensive capabilities a complete quality management system and free DFM analysis to turn your ideas into reality.

![]() Delivery time is 1 working day

Delivery time is 1 working day

![]() No MOQ requirement

No MOQ requirement

![]() 12 quality inspection processes

12 quality inspection processes

![]() 40+ surface treatments and materials

40+ surface treatments and materials

![]() Value-added services

Value-added services

ISO 9001 IATF 16949 Rohs Certification

10 Senior Engineers

Production Yield Rate Reaches 99.8%

Hand Metrology Laser & CMM Inspections

Hardware Installation & Mechanical Assembly

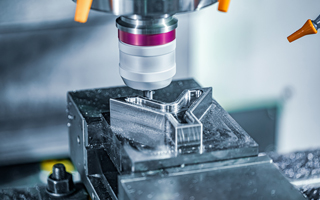

China custom CNC machining parts factory with small batch rapid prototyping

VMT is located in Shenzhen, China, with 15 years of experience in manufacturing China customized CNC machining metal parts and assembly. We are certificated by ISO9001 and 16949, also get 11 patents.

Our business has grown to now cover 62 countries worldwide. We strictly control the quality from the initial engineering review DFM, pre-production, IQC, first article, in-process to final inspection to ensure the quality.

To achieve zero defects, we utilize automatic inspection machines, 2D and 3D projectors to check dimensions and surfaces. Our machines include high-speed CNC lathes, Automatic Lathes, CNC milling, Drilling, tapping, grinding, Welding machines, Tube bending machines. And working with a wide range of materials including steel, aluminum, and stainless steel, copper, bronze, brass and aircraft alloys.

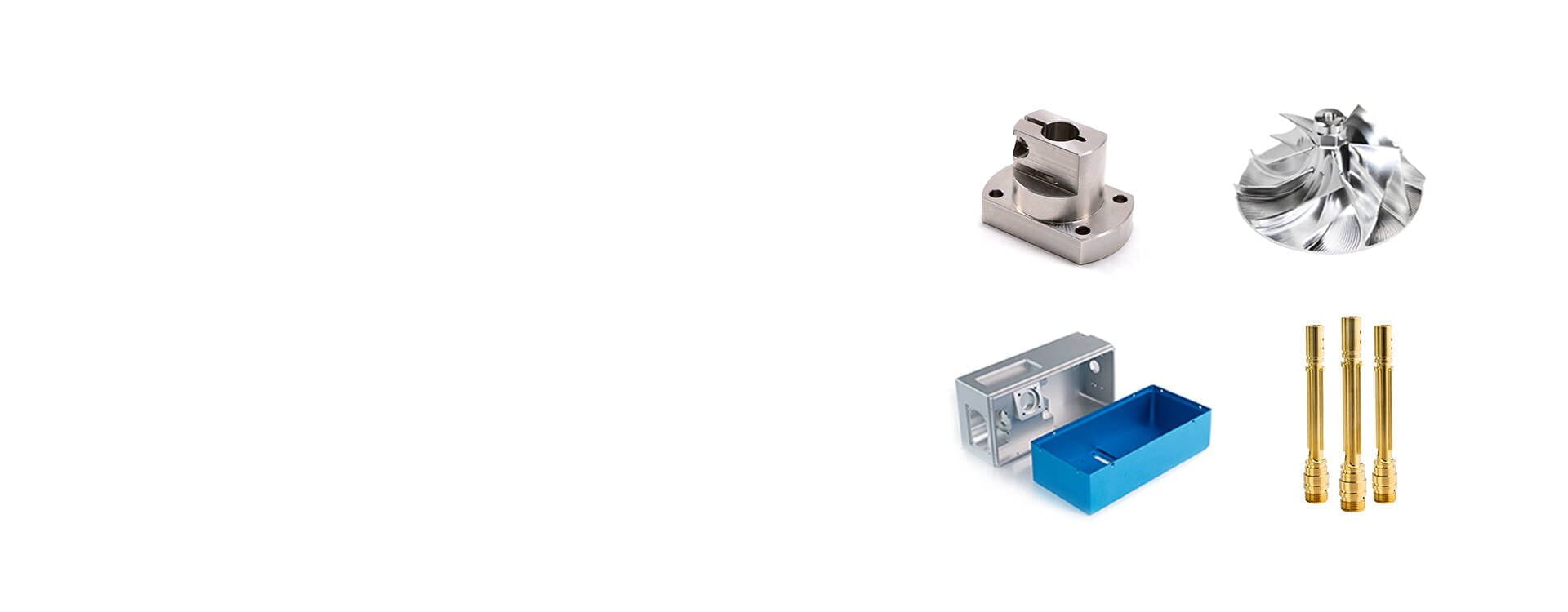

To offer competitive prices, VMT combines diverse processes for various designs, such as CNC Machining, stamping, forged, extrusion, castings, bending, welding, etc. Our commitment is to produce quality products on time with friendly customer service to increase our business with your company. The products include different fields such as Medical, Automotive Plumbing and Performance Parts, Agriculture, Electronics, Electron, Hardware, Audio and Video, Control Systems, Oil & gas industrial, Energy, Lighting, Pressure & Filtration Systems, and Heating and Cooling systems.

Our product library currently totals 7692 non-standard parts. We welcome your visit and look forward to your manufacturing opportunities.

300 Units CNC Machining

45 Units CNC Turning

50 Units Automatic lathe

120 People Team

Quality Inspection Team,12 Quality inspection process yield rate reaches 98%

3D CMM Measuring Instrument

Foreign trade office,24 hours online quotation

China custom CNC machining parts factory with small batch rapid prototyping

300 CNC machining machines with a monthly output of 1 million pieces of more than 40 kinds of metal materials and 15 kinds of surface treatment appearances are carried out according to Apple appearance standards. Various processes combined with CNC machining free evaluation DFM analysis quality control.

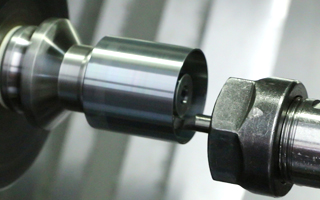

read moreSwiss CNC machining services with a monthly output of 300000 pieces free drawing review optimization quotation and DFM within 4 hours. Automatic lathes: 50 sets CNC lathes: 45 sets Turning and milling combination: 15 Citizen Swiss-style automatic lathes: 10 Various types of lathes provide you with CNC turning parts manufacturers in China.

read moreThe five-axis CNC machining center can complete all the China custom CNC machining parts procedures of the workpiece in one clamping and meet all the processing requirements from rough machining to precision CNC machining. It is not only suitable for small batch CNC machining but also suitable for mass production reducing processing time and production cost increasing CNC turning Milling service manufacturer production capacity and machining cost.

read moreGood surface treatment increases the value of the customer's brand. In order to provide lower costs many parts combine extrusion and China custom CNC machining parts forging and CNC machining low-pressure casting and CNC machining. It saves cost and time also fast delivery.

read more300 CNC machining machines with a monthly output of 1 million pieces of more than 40 kinds of metal materials and 15 kinds of surface treatment appearances are carried out according to Apple appearance standards. Various processes combined with CNC machining free evaluation DFM analysis quality control.

read moreSwiss CNC machining services with a monthly output of 300000 pieces free drawing review optimization quotation and DFM within 4 hours. Automatic lathes: 50 sets CNC lathes: 45 sets Turning and milling combination: 15 Citizen Swiss-style automatic lathes: 10 Various types of lathes provide you with CNC turning parts manufacturers in China.

read moreThe five-axis CNC machining center can complete all the China custom CNC machining parts procedures of the workpiece in one clamping and meet all the processing requirements from rough machining to precision CNC machining. It is not only suitable for small batch CNC machining but also suitable for mass production reducing processing time and production cost increasing CNC turning Milling service manufacturer production capacity and machining cost.

read moreGood surface treatment increases the value of the customer's brand. In order to provide lower costs many parts combine extrusion and China custom CNC machining parts forging and CNC machining low-pressure casting and CNC machining. It saves cost and time also fast delivery.

read moreDo you know how we process different products?

Because the batch is only 300 sets, the customer wants to use CNC machining to produce it like a prototype. We found that many curved surfaces on the arrow should be completed in 3D during the review stage. After our Engineer was reviewed with DMF, we recommended that the customer analyze the cost of this project.

Our engineers conduct a process review according to the customer's drawings. During the review, it is found that it is an irregular eccentric shaped part. According to the traditional processing method, it can only be produced by a 5-axis machine, and the material that needs to be purchased must be twice the outer diameter of the parts. The processing area is large, the time is long, and materials are wasted.

The customer of Industrial Controller found 5 CNC milling suppliers for quotations. Because the quantity is only 1,000 pieces, the quotations of other suppliers are higher than the customer's cost budget.In the end, customers find us, and our company insists that there is no difference between big and small customers. After the engineer analyzed the product structure, it was determined that the extrusion + CNC machining met the customer's requirements, and the cost was reduced, and the quality was also recognized by the customer.

This kind of mechanical keyboard is not standard design, like GH60 GK61 , DIY TKL , 65, it is mainly sold to niche fans. Because it is taking the mid-to-high-end route, customers have strict requirements on the appearance and cannot have any defects on aluminum mechanical keyboard case. According to customer requirements by custom cnc machining, our engineers formulate corresponding special tools, fixtures and reasonable tool paths, and finally meet the customer's quality requirements.

When making the main shell of this microphone at the beginning, the process was bar material + CNC machining, which was a waste of material and long milling time.After mass production, in order to meet customer needs, our engineers changed the process to extrusion + CNC milling. The cost was directly reduced by 50%, and the quality reached the customer's requirements.

Galvanometer of laser machine parts are machined with square solid materials, and CNC machining takes 35 minutes, which wastes materials and the mahining cost is beyond the customer's acceptable range.In order to reduce costs, our engineers use cold forging, the machining time is reduced to 12 minutes, and the cost is reduced by 60%.

I received a thank-you letter from the customer today, an unexpected surprise. I am very happy to share this case with more designers, so that everyone can avoid detours in similar designs.

Braces are very common in the machining of mechanical parts. Why do you need braces? What are the benefits of product braces? In the cnc machining of mechanical parts, the braces are threaded insert. After the threads are processed, the threaded insert are installed on the threads. With so many CNC machining factories, how should we choose?

CNC machining manufacturers process brass thread insert to improve the reduction of thread inner diameter after nut pressure riveting

The Camera lens ring enclosure is a world-renowned brand camera, taking the mid-to-high-end route, and has very strict product quality requirements.

15 years one-stop custom China CNC machining parts manufacturer factory

High Precision 3、4、 5 Axis Machining Turning Aluminum Stainless Steel Custom CNC Machine Milling Parts

OEM China Custom Cheapest Electronic Precision CNC Machining Stainless Steel Radiator Manufacturers

Hot Selling Customized Anodzing Parts CNC Lathe Turning Milling Aluminium CNC Machining Service

Factory Custom CNC Machining Manufacturing Consumer Electronics Aluminum Case

DIY Metal Anodized Keyboard Board Aluminum Stainless Steel Titanium Custom CNC Machining Mechanical Keyboard Case

China Custom CNC Machining POM Nylon Plastic Parts Factory

OEM Custom CNC Aluminum Profile Metal Aluminum Mechanical Machinery Precision Milled Parts

Factory Customized Cnc Milling High Quality Metal Aluminum Brackets

Custom 7075 6063 5052 Oxidized CNC Aluminum Machining Parts

China Custom Polished 304 Stainless Steel Machining Parts

China Manufacturer Custom Brass Precision Turned Components

Custom CNC Milling Machining Precision Machining Parts Aluminum Flashlight Housing

Custom Design CNC machined aluminum Herb Weed Grinder

OEM cheap precision machinery CNC parts customized aluminum CNC machining service Machining process Contens Description Standard Materia Aluminum AL 6061-T6, 6063, 7075-T 2014

15 years one-stop custom China CNC machining parts manufacturer factory

We have professional equipment and a team. We have accumulated 6582 models for customers and cumulative production models: 9628 models. Our business has spread to 62 countries. such as medical automotive plumbing and performance parts agriculture electronics electron hardware video and audio control systems oil & gas industrial energy lighting pressure & filtration systems cooling and heating system.

We will complete different processing designs based on customers' processing needs and combine different processing techniques to give customers the best solutions such as CNC machining turning milling stamping forging extrusion casting bending welding etc.

As long as we can do it you only need to provide your project drawings and samples and we can customize and manufacture for you.

Customized processing can be obtained within 1 day to obtain prototypes and small batch production parts to provide customers with high-quality and low-cost CNC machined products.

Experience in precision parts manufacturing

CEO with 25years experience in presicion parts

Different design made

Repeated order

Countries customers

15 Years One-Stop China Custom CNC Machining Parts Manufacturer Factory

Every customer's evaluation is our goal of continuous improvement

We are very happy with the CNC machined parts we received. In the early days the structure of our CNC machining parts was too complicated and many CNC machining factories could not process it so we were very dissatisfied. Try to cooperate with VMT entrust the demand provide us with DFM analysis understand the function of CNC machining parts disassemble the process optimize the structure save us 50% of the cost and ensure product quality.

I am very happy to cooperate with VMT's. high-quality products competitive prices and excellent professional services. This CNC machining part of mine was in the previous CNC machining factory and the delivery time has not met our needs. After cooperating with VMT if there is something wrong with some parts VMT can fix it at any time so that the products can be delivered on time.

Share our China custom CNC machining process

There are many small batches of prototype machining methods, such as CNC machining, simple molds made of silicone, and 3D printing. Look at the needs of customers. For CNC small batch prototype machining, we must first choose a suitable CNC prototype machining factory. There are many professional CNC machining factories in China, but they are not the same in scale. So in the face of many CNC prototyping factories, how do we choose?

read moreAs a global China CNC machining parts manufacturer industry, China occupies an important position in this industry. In China, from rapid prototyping, to small batch manufacturing of CNC parts, to the production and surface treatment of batch processed parts, a scale has been formed. China's CNC machining parts have the core advantages of fast delivery, high quality and low price in terms of materials, technology, machinery, processing, etc., so they have attracted buyers from all over the world. This article summarizes how to choose a supplier suitable for domestic CNC machining parts.

read moreAfter sandblasting and oxidation of aluminum machining processing parts, trachoma and holes will appear on the surface, which will seriously affect the surface texture of the product. This is a frequent problem in the industry, which has a great impact on customers, and also seriously affects customers' brands and delivery dates!

read moreReady To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!