15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

999 |

Published by VMT at Oct 06 2021

999 |

Published by VMT at Oct 06 2021

There are many small batches of CNC prototype machining methods, such as CNC machining, simple molds made of silicone, and 3D printing. Look at the needs of customers. For CNC small batch prototype machining, we must first choose a suitable CNC prototype machining factory. There are many professional CNC machining factories in China, but they are not the same in scale. So in the face of many CNC prototyping machining factories, how do we choose?

The existence of CNC prototype machining is to verify whether the structure, function and appearance of the developed product can meet the design input. This is a fast DVT verification method that is both fast and low-cost.

Therefore, the Prerequisites for a Qualified Small Batch CNC Prototype Machining factory are:

Before we delve into the details of selecting the right factory, let's take a moment to appreciate the significance of CNC prototype machining manufacturing. CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by enabling the production of highly precise and intricate prototypes. These prototypes serve as functional and visual representations of your design, allowing you to test and refine your concepts before moving on to mass production.

One of the crucial factors to consider when choosing a small batch CNC prototype machining manufacturing factory is their expertise and experience in the industry. Look for a factory that has a proven track record of delivering high-quality prototypes to clients across various industries. Check their portfolio to evaluate the complexity and precision of the prototypes they have produced in the past.

Furthermore, consider the factory's experience in working with different materials, such as metals, plastics, or composites. This will ensure that they can accommodate your specific requirements and provide you with the best possible solutions for your project.

The technological capabilities and equipment available at the factory play a pivotal role in determining the quality and efficiency of the CNC prototype machining manufacturing process. Ensure that the factory utilizes state-of-the-art CNC machines and software, as these factors greatly influence the accuracy and intricacy of the prototypes.

Additionally, inquire about the factory's quality control measures to ensure that they have stringent processes in place to maintain consistent and superior quality throughout the production cycle. A factory with advanced equipment and robust quality control systems is more likely to deliver exceptional results.

A reputable CNC prototype machining manufacturing factory should offer customization options and comprehensive design support to cater to your unique requirements. The ability to adapt to your specific design needs and provide expert guidance can significantly enhance the outcome of your project.

Look for a factory that has a skilled team of engineers and designers who can collaborate with you from the initial concept phase to the final prototype. Their expertise can help optimize your design for manufacturing, ensuring efficient production and minimizing potential issues or delays.

While quality should always be a top priority, it is essential to find a CNC prototype machining manufacturing factory that offers competitive pricing without compromising on the quality of the prototypes. Request quotes from multiple factories and compare their pricing structures to make an informed decision.

Moreover, consider the factory's production capacity and turnaround time. Efficient and timely production is crucial, especially when you are working on tight deadlines. A factory that can meet your production requirements within the specified time frame will contribute to a seamless and hassle-free manufacturing process.

Intellectual property protection is a critical aspect to consider when outsourcing your CNC prototype machining manufacturing to a factory in China. Ensure that the factory has strict confidentiality agreements in place and takes the necessary measures to protect your design files and project information. This will give you peace of mind, knowing that your intellectual property is secure throughout the collaboration.

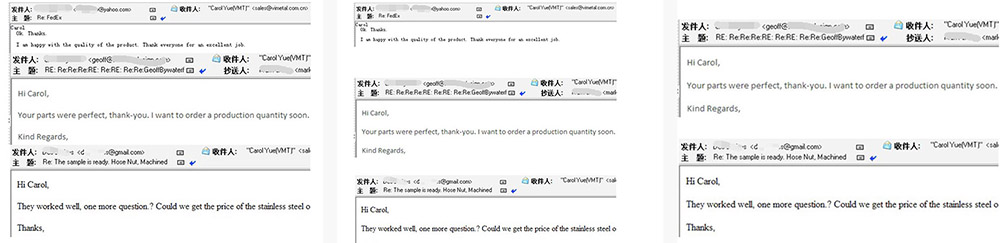

Effective communication is vital to the success of any project. When selecting a CNC prototype machining manufacturing factory in China, pay attention to their communication channels and language proficiency. Look for factories that have dedicated English-speaking representatives who can understand and address your queries and concerns promptly. Clear and efficient communication will help you navigate the production process smoothly and avoid any misunderstandings or delays.

Customer service is another crucial factor to consider when choosing a CNC prototype machining manufacturing factory. A factory that values its customers and provides excellent support throughout the production journey will make your experience more pleasant and hassle-free.

Evaluate the responsiveness and helpfulness of the factory's customer service team. Do they promptly address your inquiries? Are they willing to provide guidance and clarification when needed? Opting for a factory that prioritizes customer satisfaction ensures that you receive the necessary support and assistance whenever required.

Before finalizing your decision, take the time to research and read reviews from past clients of the CNC prototype machining manufacturing factories you are considering. This will give you valuable insights into the experiences of others and help you gauge the reputation and reliability of each factory.

Platforms such as industry forums, social media, and business directories can be excellent sources of honest feedback. Consider both positive and negative reviews to gain a comprehensive understanding of each factory's strengths and weaknesses.

If possible, consider arranging an on-site visit to the shortlisted CNC prototype machining manufacturing factories. This will allow you to personally assess their facilities, equipment, and overall working environment. Meeting the team face-to-face can also help establish a stronger rapport and build trust in their capabilities.

During the visit, inquire about the factory's quality assurance processes. A factory that places a strong emphasis on quality control will have well-defined procedures in place to ensure that each prototype meets your specifications and expectations.

Choosing the right small batch CNC prototype machining manufacturing factory in China requires careful consideration of various factors. From expertise and technological capabilities to customization options and customer service, each aspect plays a crucial role in determining the success of your project.

By evaluating the factory's experience, equipment, communication channels, and reputation, you can make an informed decision that aligns with your specific requirements. Remember to prioritize quality, cost-effectiveness, and intellectual property protection throughout the selection process.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!