15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

371 |

Published by VMT at May 06 2021 | Reading Time:About 1 minutes

371 |

Published by VMT at May 06 2021 | Reading Time:About 1 minutes

What are the advantages of using aluminum alloy machining flashlight housing?

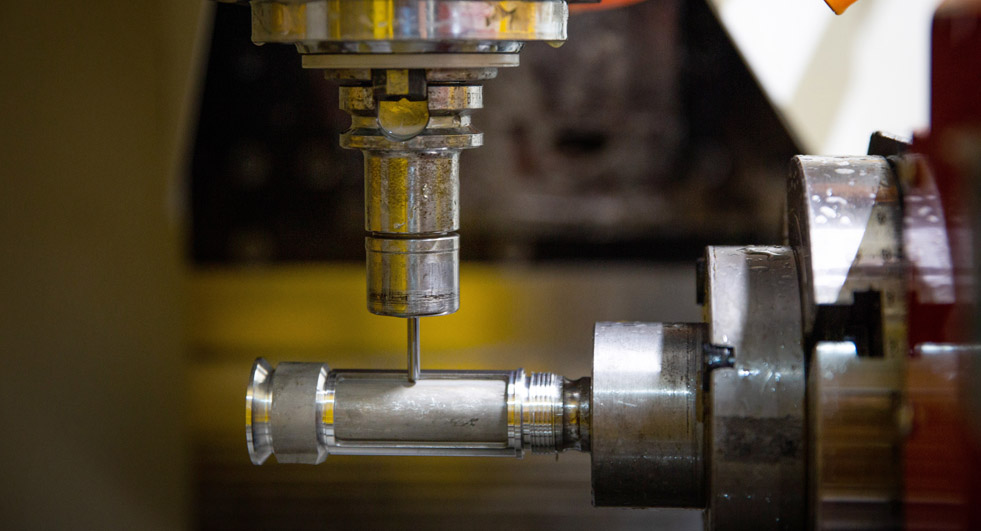

In the flashlight industry, facing the pressure of market competition, the shell of the flashlight has gradually changed from plastic to an aluminum alloy shell. The more high-end flashlight shell will be made of aviation-grade aluminum alloy T6061. The flashlight is made of aluminum alloy for better visual sense and texture.

CNC machining flashlight shell material: the more common aluminum alloy for the flashlight body, in addition to stainless steel and titanium alloy. Stainless steel is heavier, titanium alloy is expensive, and aluminum alloy is relatively moderate and generally used.

The shells of explosion-proof flashlights are mostly made of aluminum alloy or high-strength aluminum alloy. What is the reason?

First of all, the heat dissipation performance of aluminum alloy is the better among all materials. This has also been confirmed in the aviation field. Explosion-proof flashlight with strong brightness and high heat generation. If there is no metal that conducts heat quickly, it is likely to burn out the lamp because the heat cannot be dissipated. The aluminum alloy material happens to have this characteristic, so it is logical to become the material of the explosion-proof flashlight housing.

Explosion-proof flashlights currently mostly refer to strong light flashlights that use led light sources as their luminous body. Explosion-proof flashlights have the characteristics of high brightness, energy saving and environmental protection, long service life, sturdiness and durability. Explosion-proof flashlights usually require an explosion-proof certificate to meet the requirements of explosion-proof flashlights for safe use in various flammable and explosive places such as coal mines, electric power, petrochemicals, earthquake relief, and fire protection.

On the premise of energy saving, LED flashlights use nano colloidal lead-acid batteries in order to achieve high-brightness lighting effects. This type of battery uses nanotechnology heat to treat and modify the surface of the powder, and monitor the disturbing elements of the sol-gel production process through the sol-gel method to add the total amount of colloidal electrolyte to increase the capacity of the battery. It prevents the battery from leaking liquid and the electrolytic liquid from showing a layered appearance, reducing the corrosion rate. It is light in weight and can be manufactured by molds, with low manufacturing cost, easy surface treatment or no surface treatment, and the torch shell has excellent corrosion resistance, which is very suitable for diving and other applications.

The performance of different aluminum materials is different, which will also cause a big price gap. The shells of brand flashlights mostly use the highest level of aviation-grade aluminum alloy T7075 and T6061. This material is super corrosion-resistant, impact-resistant, and easy to precision processing. The flashlight made of materials has a very delicate appearance, deep and clear thread, very good sealing performance, and a very good hand feeling. It is the best aluminum material at present, but the price is a bit expensive! The barrel processing technology and the military-regulated oxidation of the aluminum alloy surface directly affect the processing price of the flashlight housing.

The product made of aluminum alloy flashlight housing. LED flashlight is a new type of lighting with light-emitting diodes as the light source. It has the advantages of energy saving, economic use, and strong brightness. The photodiode will not work normally, and the power will be greatly reduced. Aluminum alloy flashlight shell The product shell is made of high-quality aluminum, and the surface of the product is processed by oxidation and coloring technology to make the surface of the product more advanced and durable, and it is not easy to touch flowers or fade.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!