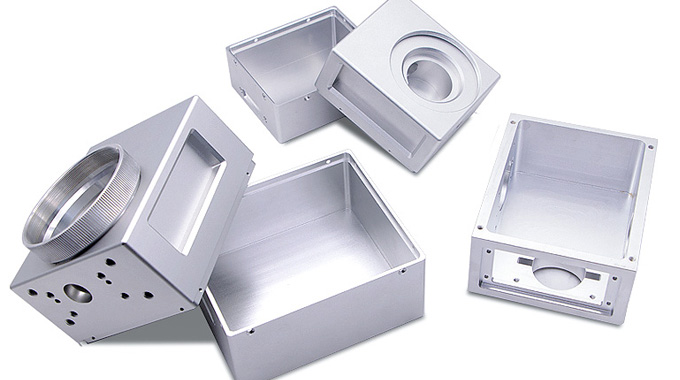

15 years one-stop China custom CNC machining parts factory

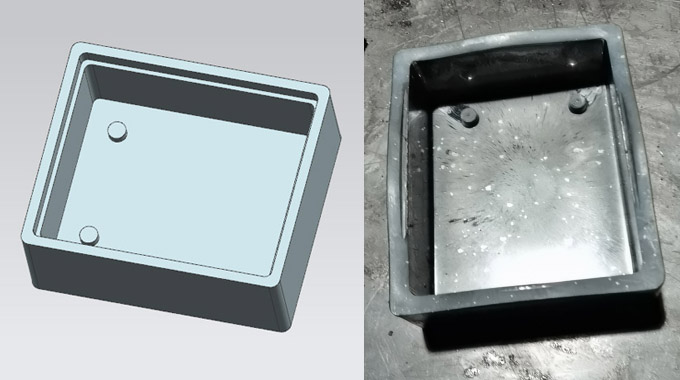

Cold forging+cnc machining

T6 heat treatment

Quality Inspection

Pack and ship

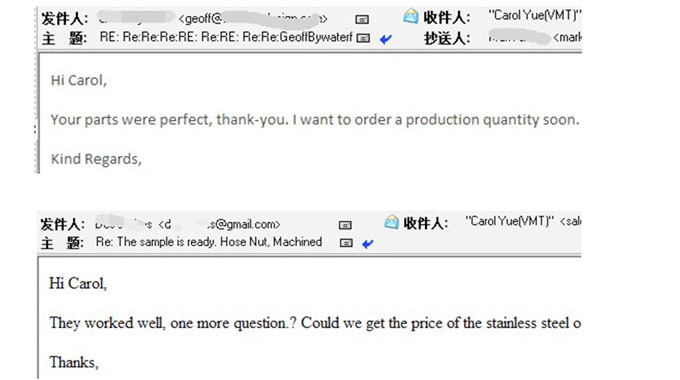

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!