15 years one-stop China custom CNC machining parts factory

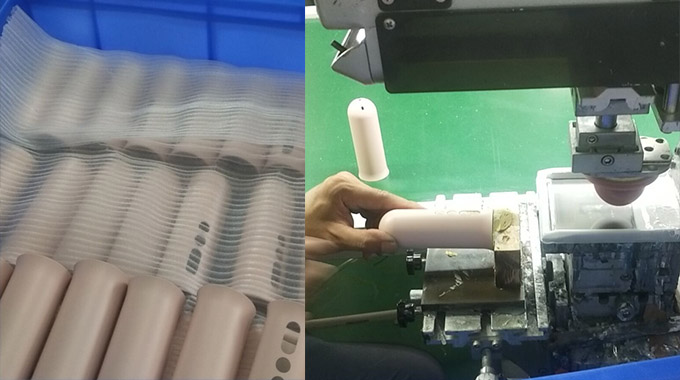

Step 1: use a 200T stretching machine and cutting

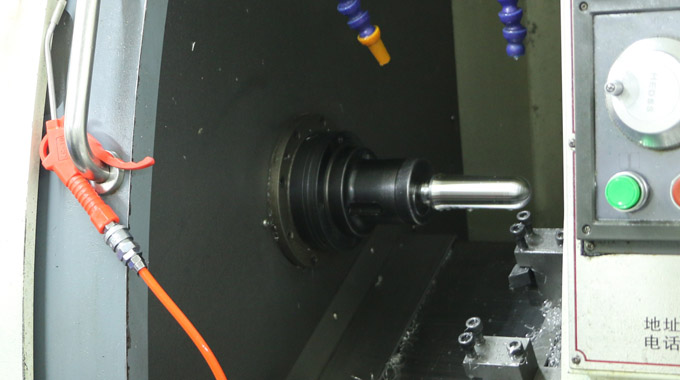

Step 2: Machining the outer surface and inner wall by lathe

Step 4:painting

Step 5: Silk screen

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!