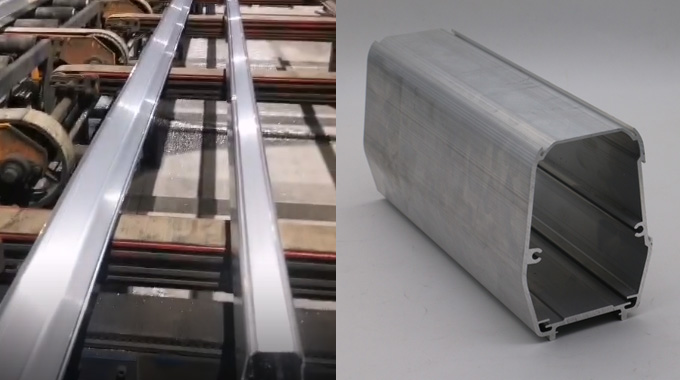

Step 1: Extruding and cutting with a 2500T extruder

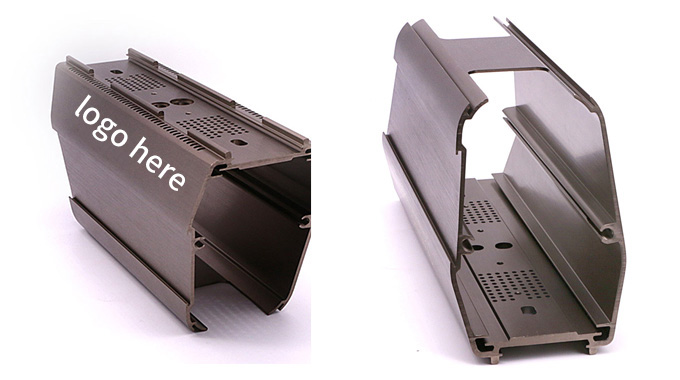

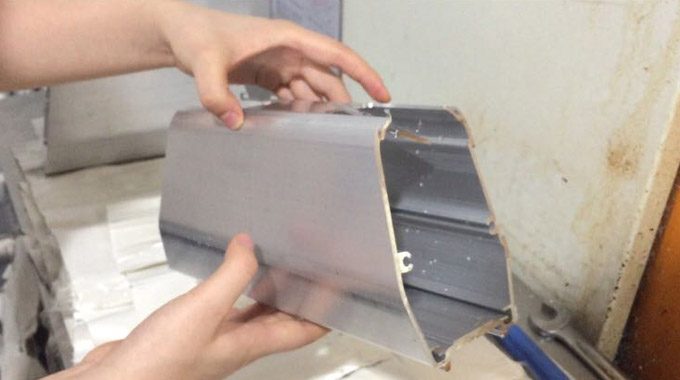

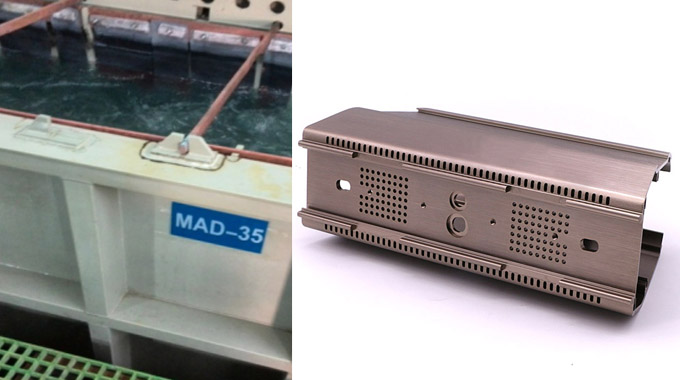

For parts above 120MM*90MM, when some factories are reviewing, they will first think of 2000T for extrusion machines. This can save about 5% in cost, but they can't think of 2000T machines with insufficient pressure. , After CNC milling, the parts with this appearance will cause problems when they are anodized: 1. Extrusion bonding lines will appear on the surface, which makes the surface very ugly; 2. Because the parts need to be equipped with PCB boards, Unstable internal dimensions will cause the assembly to not go in; 3. Sand holes and bubble holes will appear on the surface, which is mainly because the temperature of the raw materials is not controlled and stable. Based on the above problems, our first step is using a 2500T machine to produce. This is a good CNC milling method and the most critical step to obtaining CNC milling prototypes and production parts.