15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

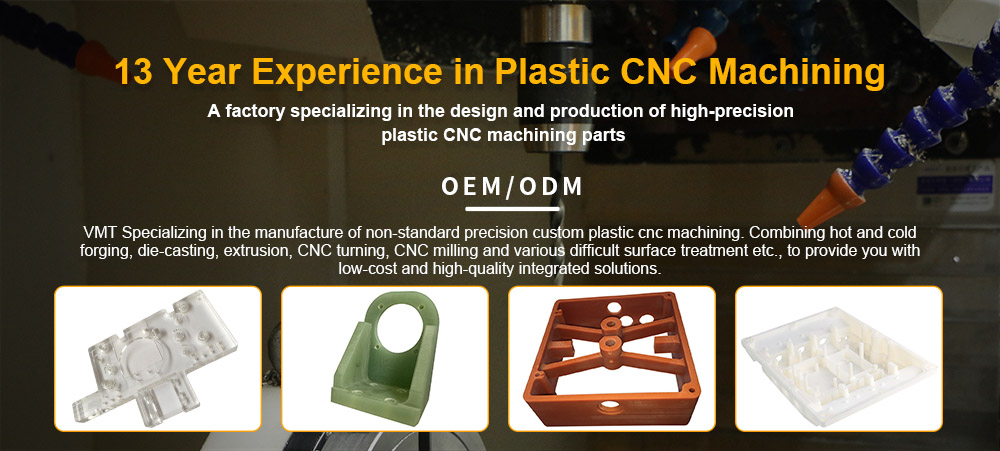

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

China Custom CNC Machining POM Nylon Plastic Parts Factory

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

| In CNC machining design, plastics are often used to customize CNC plastic parts to verify your creativity. If your idea includes metal material and plastic material, you also need to assign to two different suppliers and finally assemble it yourself? In VMT precision CNC machining factory, there is no need to assemble and separate processing by yourself. VMT precision CNC machining factory can process plastic and metal materials, and provide customers with one-stop service from CNC machining to surface treatment to assembly for a long time, so that your design can be guaranteed. At the same time of performance, it is more attractive to customers in appearance. |

| In the process of developing new parts, will you use plastic prototypes as prototypes for verification? If you need, VMT is a plastic CNC machining manufacturer with 13 years of experience. It provides one-stop service from drawing DFM analysis, CNC prototype machining and manufacturing to surface treatment. There is no MOQ standard. From single parts to small batches and mass production, we will There are professional project engineers to follow up for you, and each production run has detailed records and is transparently shared with customers. |

|

|

|

|

||||

|

|

||||||

CNC Plastic Prototyping |

CNC Plastic Machining Materials |

Batch CNC Plastic Machining Parts |

||||

| VMT is one of the best plastic material CNC machining manufacturers with professional plastic machining capabilities. We can process a variety of different plastic manufacturing projects according to customers' ideas and product performance. Our accumulation in plastic machining enables us to quickly customize CNC plastic machining parts according to your application requirements, allowing you to get them within 3 days. |

Capable of manufacturing quality CNC plastic machined parts from over 30 different plastic materials, we have the capability to manufacture high performance plastics in a variety of materials including sheet stock, round rod and more. Common plastic materials used include: ABS, PC, PMMA (acrylic), PA (nylon), glass fiber, POM, PP, PVC, HDPE, PPS, PBT, PEEK, PEI (Ultem), Teflon, Bakelite, Nylon . |

VMT has an advanced plastic CNC machining workshop that can provide machining technologies including CNC milling, CNC turning, drilling, tapping, etc. With rich experience in CNC plastic machining parts, we provide high-quality CNC plastic parts at very competitive prices, and we have completed more than 1200 POM Nylon CNC plastic machining projects for our customers. |

||||

|

|

|

|

||||

|

VMT precision CNC machining manufacturers can not only do surface treatment for metal parts, plastic parts can also be customized surface treatment: spray painting, silk screen printing, baking varnish, powder spraying, electroplating, laser engraving, polishing transparent, fumigation transparent, dyeing, etc., if you If you need to customize CNC machining in small batches, we can also provide customized packaging services according to your needs, saving you purchasing time and costs. |

|

|

|

|

||||

|

|

||||||

Transparent |

Spray Painting |

Anodizing |

||||

|

|

|

|

ABS - CNC Plastic Machining Parts |

|

|

Color: natural color, black, transparent |

||

| Density: 1.04 | ||

|

Features: High mechanical strength, high stiffness, high surface hardness, high dimensional stability, easy to spray, and electroplating. |

||

|

Application: Prototype models, plastic cnc machining parts electronic appliances and other shells and components. |

||

| More Details>> |

|

|

PMMA - CNC Plastic Machining Parts |

|

|

Color: transparent. |

||

| Density: 1.18 | ||

| Features: High mechanical strength, the surface can be polished and transparent, good insulation performance. | ||

| Application: CNC plastic machining parts machine covers and accessories, avionics, aircraft and ships, various lampshades, signage, etc. | ||

| More Details>> |

|

|

POM - CNC Plastic Machining Parts |

|

|

Color: White, Black. |

||

| Density: 1.4 | ||

|

Features: High mechanical strength, hardness and compressive strength, good sliding, wear-resistant, good machinability. |

||

|

Application: Suitable for sliding parts, precision mechanical plastic CNC machining parts and water-resistant parts, such as: bearings, gears, impellers, cams, bushes, washers, handles, fixtures, etc. |

||

| More Details>> |

|

|

PTFE - CNC Plastic Machining Parts |

|

|

Color: White. |

||

| Density: 2.16 | ||

|

Features: Wide temperature range (-200℃~+260C), CNC plastic machining parts strong corrosion resistance,excellent mechanical properties and flame retardancy, and very good wear resistance. |

||

|

Application: mechanical parts, corrosion resistance industries, oil and gas, instruments and equipment, etc. |

||

| More Details>> |

|

|

PEEK - CNC Plastic Machining Parts |

|

|

Color: Taupe, Black, Beige. |

||

| Density: 1.32 | ||

|

Features: PEEK CNC plastic machining parts has excellent comprehensive properties, mechanical properties, high rigidity and hardness, high temperature resistance of about 260 ° C, excellent chemical resistance and hydrolysis resistance, wear resistance, UV resistance, radiation resistance, and low flammability. |

||

| Application: PEEK CNC plastic machining is widely used in aerospace, medical, pharmaceutical and other industries. | ||

| More Details>> |

CNC Precision Plastic Parts Machining anufacturers

|

|

|

||||

DFM Analysis |

Programming |

||||

|

Custom CNC plastic machining technology: Our precision CNC machining engineer team formulates the most economical and reasonable machining technology according to customer needs. For major projects, we will discuss with customers, provide constructive suggestions to customers from the perspectives of structure, material selection, surface treatment, etc., solve customer problems, and reduce customer machiningcosts. |

More than 15 years of experience in engineering master programming, programming software: MASTERCAM, UG, POWERMILL, other engineering software: CAD, PROE, SOLIDWORKS. VMT precision CNC machining adopts milling technology, which improves the efficiency of rough machining by 50% compared with traditional CNC. It is specially aimed at: fast clamping of complex products, precision products and batch products. |

|

|

|

Raw Material Testing

Every batch of raw materials arriving at the factory must undergo a series of material inspections and have a material inspection report before they can be used. Make sure to use real raw materials for customers. |

|

Tool Detection

After the programming master writes the CNC machining program, the first thing the operator has to do is to prepare the required tools in advance. The concentricity behind the head controls the risk brought by the tool before processing, and saves the step of testing the concentricity on the CNC machine, which improves the machining efficiency. |

|

|

|

|

|

Inspection

During the plastic CNC machining parts process, quality control personnelconduct routine inspections on all parts being producedevery two hours to avoid problems and save costs andtime. |

|

Inspection Process

According to the shape and tolerance requirements of CNC plastic machining parts, colleagues in the quality department choose three-dimensional, two-dimensional, altimeter, micrometer and other precision instruments to measure all dimensions of plastic parts to ensure that the dimensions of CNC plastic machining parts meet the requirements of customer drawings. |

|

|

|

|

|

CNC Plastic Machining Parts Surface Treatment

After the CNC plastic machining parts are tested and qualified by the colleagues of the quality department, the corresponding surface treatment of the plastic CNC machining parts is done according to the customer's needs, such as: In-Mold Decoration Technology (IMD), painting, and Out-Mold Decoration-IMD , Painting, Non-Condictive vacuum Metalize, plastic electroplating, silk screen, Laser, bite pattern, water transfer printing and other surface treatments, and various colors can be customized according to customer needs. |

|

Full Inspection

After the surface treatment of CNC plastic machining parts, there will be certain dimensional tolerances. In order to ensure that the dimensions of CNC plastic machining parts after surface treatment are within the precise range required by customers. Full inspection report before shipment: number of parts, critical dimensions, threads and tolerances, thickness and depth, appearance of parts, etc. |

|

|

|

|

|

Packing

Four layers of protection: 1.Wrapping paper CNC plastic machining parts. |

|

Shipping

Transportation :We use express couriersuch as UPS, DHL,EMS, TNT,FEDEX for sample shipping. We canarrange air orocean shipping for bulk delivery as yourrequirement. |

|

|

A variety of machining techniques, only for better product details

PO CNC Machining Parts

Bakelite CNC Machining Parts

Nylon CNC Machining Parts

Fiberglass Cloth CNC Machining Parts

|

Plastic CNC Machining: Your Comprehensive Guide to Plastic Machining |

||||||||||

|

If you are looking for in-depth knowledge about plastic CNC machining then it’s a must-read piece of writing for you. And it is highly recommended that you read till the end.… |

|

In the field of CNC machining parts industry, plastics are often used as raw materials for further processing. Now there are many types of plastics on the market, so what kind of plastic... |

From metal materials to plastics, CNC precision machining products can be used in many kinds of materials. Each material has its own different characteristics, suitable for different kinds of CNC parts machining products. … |

|||||||

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.