15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

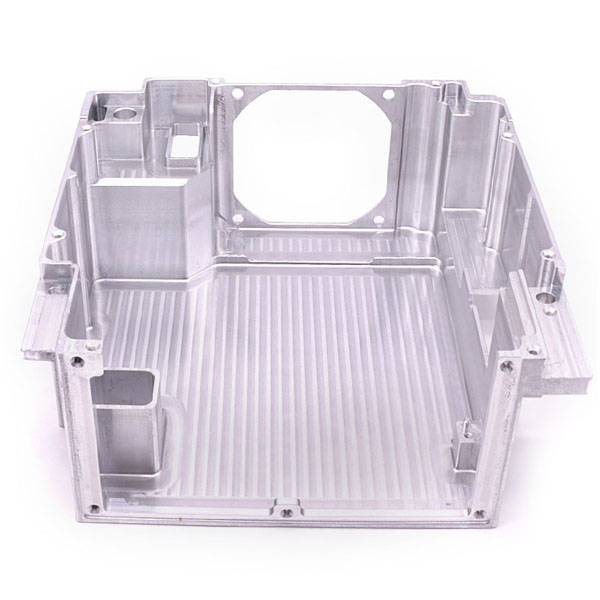

Custom 7075 6063 5052 Oxidized CNC Aluminum Machining Parts

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Our Custom Oxidized CNC Aluminum Machining Parts Services Manufacturer

|

Do you need high-quality, custom CNC machined aluminum parts? Our company offers professional CNC prototyping services for a wide variety of materials and finishes. As a leading manufacturer in this field, we provide comprehensive CNC machining services to meet the needs of different industries. To provide you with valuable insights and excellent service. let's start! |

Custom Oxidized CNC Aluminum Machining Parts Prototyping Machining

CNC prototyping involves the use of numerically controlled machining machines to create precise and detailed prototypes or parts, allowing for rapid iteration and design refinement, enabling you to test and validate your concepts before going into full-scale production. This method of fabrication has many advantages, including faster production times, cost-effectiveness, and the ability to create complex geometries. CNC machining enables manufacturers to achieve tight tolerances and high repeatability, ensuring the production of oxidized CNC aluminum machined parts with exceptional precision. |

|

|

|

|

||

Custom Oxidized CNC Aluminum Machining Parts Surface Treatment |

Custom Oxidized CNC Aluminum Machining Parts Material |

||

|

To enhance the performance, durability and visual appeal of custom oxidized CNC machined aluminum parts, we offer a wide range of surface treatments. These treatments provide additional protection and customization options. Common surface treatments include: anodizing, powder coating, polishing, brushed, chemical etching. By utilizing these finishes, we can tailor the appearance and function of a custom oxidized CNC aluminum machined part to your exact specifications. |

The Importance of Material Selection for Custom Oxidized CNC Aluminum Machining Parts. We provide various aluminum alloys to meet your specific requirements. Commonly used aluminum alloys include: 6061, 7075, 5052. Our professional team can guide you in selecting the most suitable aluminum alloy based on the functional and aesthetic needs of your project. |

|

Our custom oxidized CNC aluminum machining services encompass CNC prototyping, a wide range of aluminum materials, and diverse surface treatments.While providing high-quality, precise, and visually appealing parts that meet the demands of various industries. Partner with us to bring your design ideas to life and benefit from our expertise and commitment to excellence.

To learn more about our services and how we can assist you in manufacturing custom oxidized CNC aluminum machining parts, feel free to reach out to us. Our dedicated team is ready to provide personalized solutions tailored to your specific needs. |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

|

In the realm of custom aluminum CNC machining, surface treatments play a vital role in enhancing the appearance, durability, and performance of the finished parts. Let's explore some commonly used surface treatments for custom aluminum CNC machining parts. |

|

1. Anodizing

Anodizing is a popular surface treatment for CNC aluminum parts. It involves creating a controlled oxide layer on the surface of the part, which improves corrosion resistance, hardness, and aesthetic appeal. Anodizing offers various color options and can be categorized into different types, including:

Type II: Provides a decorative finish with a range of colors and enhanced corrosion resistance.

|

|

|

2. Powder Coating

Powder coating is another commonly employed surface treatment for aluminum CNC parts. It involves applying a dry powder onto the surface of the part and then curing it to form a protective and decorative coating. Powder coating provides benefits such as: Durability: It offers excellent resistance to impact, abrasion, and chemicals.

|

|

|

|

3. Polishing

Polishing is employed to achieve a smooth, reflective surface finish on CNC machining aluminum parts. It involves using abrasives to remove imperfections, scratches, and blemishes from the surface. Polishing can enhance the aesthetic appeal of the parts and prepare them for additional surface treatments like anodizing or coating. |

|

|

|

4.Brushing

Brushing, also known as satin finishing, creates a textured or brushed appearance on the surface of CNC aluminum machining parts. It involves using abrasive materials or brushes to create fine parallel lines or circular patterns. Brushing is often used to achieve a decorative effect while masking surface imperfections. |

|

|

|

4. Chemical Etching

Chemical etching is a process that selectively removes material from the surface of CNC aluminum machining parts to create intricate designs, logos, or text. It is commonly used for branding and identification purposes. Chemical etching offers precise and permanent marking without affecting the structural integrity of the parts. |

|

|

|

These are just a few examples of surface treatments for custom aluminum CNC machining parts. Other options, such as chromating, painting, and passivation, are also available based on specific requirements.

By utilizing the appropriate surface treatment, businesses can enhance the appearance, durability, and functionality of their custom aluminum CNC machining parts, catering to the needs of various industries and applications.

Surface treatments like anodizing, powder coating, polishing, brushing, and chemical etching offer numerous benefits for custom aluminum CNC machining parts. These treatments improve corrosion resistance, enhance aesthetics, and provide options for branding and identification. Collaborate with a reliable CNC machining partner to determine the most suitable surface treatment for your specific requirements, ensuring the production of high-quality and visually appealing custom aluminum parts. |

| Custom aluminum CNC machining parts offer versatility, durability, and excellent performance across various industries. When it comes to aluminum materials for CNC machining, several options are available. Commonly used aluminum alloys and their applications. |

|

|

6061 CNC Aluminum Machining Parts

6061 Aluminum Alloy

Aerospace components: 6061 aluminum is often used in the aerospace industry for structural parts, aircraft fittings, and hardware.

Automotive parts: It finds application in automotive components like brackets, connectors, and housings due to its lightweight properties and strength.

Electronic enclosures: The corrosion resistance and electrical conductivity of 6061 aluminum make it ideal for electronic enclosures and heat sinks.

|

|

|

|

7075 CNC Aluminum Machining Parts

7075 Aluminum Alloy

Aerospace industry: 7075 aluminum is commonly used for aircraft structures, wings, and fuselage components that require exceptional strength.

Sporting equipment: It finds application in the production of high-performance sporting goods like bicycle frames, rock climbing equipment, and firearm components.

Marine industry: 7075 aluminum is used for marine applications such as boat fittings and components that require corrosion resistance and durability.

|

|

|

|

5052 CNC Aluminum Machining Parts

5052 Aluminum Alloy

Marine industry: 5052 aluminum is widely used for boat hulls, decks, and other marine components due to its excellent corrosion resistance.

Architectural applications: It finds application in architectural structures, signage, and decorative elements due to its aesthetic appeal and durability.

Electrical industry: 5052 aluminum is used in electrical enclosures, panels, and conductive components due to its electrical conductivity and corrosion resistance.

These are just a few examples of the aluminum materials commonly used in CNC machining. Other aluminum alloys, such as 5083, 6063, and 2024, also offer unique properties suitable for specific applications.

|

|

| Custom aluminum CNC machined parts offer a wide range of material options including 6061, 7075 and 5052 aluminum alloys. These materials can be used in aerospace, automotive, marine, electronics and other industries. By partnering with a reliable CNC machining manufacturer, it is possible to obtain precision-manufactured CNC aluminum parts that meet their unique needs and contribute to the success of their projects. |

Custom Oxidized CNC Aluminum Machining Parts Application

|

Custom aluminum CNC machining parts find applications in various industries, including: |

|

Aerospace and aviation

By leveraging the benefits of custom aluminum CNC machining, industries can achieve lightweight, durable, and high-performance parts tailored to their specific requirements.

|

| The manufacturing process for custom aluminum CNC machining parts involves several steps to transform raw materials into finished components with precision and accuracy. Let's explore the typical process involved in manufacturing custom aluminum CNC machining parts. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with the design and engineering phase. This involves creating a detailed CAD model of the part, specifying dimensions, tolerances, and other requirements. Design considerations include the intended application, functionality, and manufacturability of the part. |

|

2. Material Selection

Material Selection: Once the design is finalized, the appropriate aluminum material is selected based on the specific requirements of the part. Commonly used aluminum alloys, such as 6061, 7075, or 5052, are chosen considering factors such as strength, corrosion resistance, and machinability. |

|

3. CNC Machining

CNC Machining: The actual CNC machining process begins with the setup of the CNC machine. This involves mounting the aluminum material securely on the machine bed and installing the necessary cutting tools. The CNC machine then executes the programmed instructions to shape the aluminum material into the desired form, guided by the cutting tool's movements. During CNC machining, the cutting tools remove excess material from the aluminum workpiece, following the programmed toolpaths. This includes operations such as milling, drilling, turning, and threading to create the required features, holes, and surface finishes. |

|

4. Quality Control and Inspection

Quality Control and Inspection: Throughout the CNC machining process, quality control and inspection procedures are implemented to ensure the dimensional accuracy and adherence to specifications. This may involve in-process inspections using measuring instruments, such as calipers or micrometers, to verify critical dimensions at various stages of machining. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

5. Surface Treatment

Surface Treatment: After the CNC machining process is complete, the custom aluminum parts may undergo surface treatments, such as anodizing, powder coating, polishing, or brushing. These treatments enhance the appearance, corrosion resistance, and functionality of the parts, based on specific requirements. |

|

6. Final Inspection and Finishing

Final Inspection and Finishing: Once the surface treatments are applied, a final inspection is conducted to verify the quality and integrity of the custom aluminum parts. This inspection includes dimensional checks, surface finish evaluation, and functional testing, if applicable. Any necessary finishing touches, such as deburring or chamfering sharp edges, are also performed during this stage. |

|

7. Packaging and Delivery

Packaging and Delivery: The final step in the manufacturing process involves carefully packaging the custom aluminum CNC machining parts to ensure their protection during transportation. The parts are labeled, documented, and prepared for delivery to the designated destination, ready for their intended use. |

|

By following these steps, manufacturers can efficiently produce custom aluminum CNC machining parts that meet the desired specifications and quality standards.

In conclusion, the manufacturing process for custom aluminum CNC machining parts involves design and engineering, material selection, CNC machining programming and operations, quality control and inspection, surface treatments, final inspection and finishing, as well as packaging and delivery. This comprehensive process ensures the production of high-quality, precise, and functional aluminum parts tailored to specific requirements. Collaborating with a reliable CNC machining provider is crucial to ensure the successful execution of each step and the delivery of top-notch custom aluminum parts. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Oxidized CNC Aluminum Machining Parts FAQs

|

Here are some frequently asked questions about custom aluminum CNC machining parts:

Q: What are the advantages of custom aluminum CNC machining parts?

Q: What industries commonly use custom aluminum CNC machining parts?

Q: How long does it take to manufacture custom aluminum CNC machining parts?

Q: What tolerances can be achieved with custom aluminum CNC machining?

Q: Can custom aluminum CNC machining parts be used for prototyping?

Q: Can custom aluminum CNC machining parts be produced in large quantities?

Q: Can custom aluminum CNC machining parts be made with specific surface finishes?

Q: How do I ensure the quality of custom aluminum CNC machining parts?

Q: Can I provide my own design files for custom aluminum CNC machining?

Q: How can I request a quote for custom aluminum CNC machining parts?

|

| These FAQs address common inquiries regarding custom aluminum CNC machining parts. If you have specific questions or require further information, it is recommended to reach out to a reputable CNC machining provider who can offer personalized assistance and guidance for your project. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.