15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

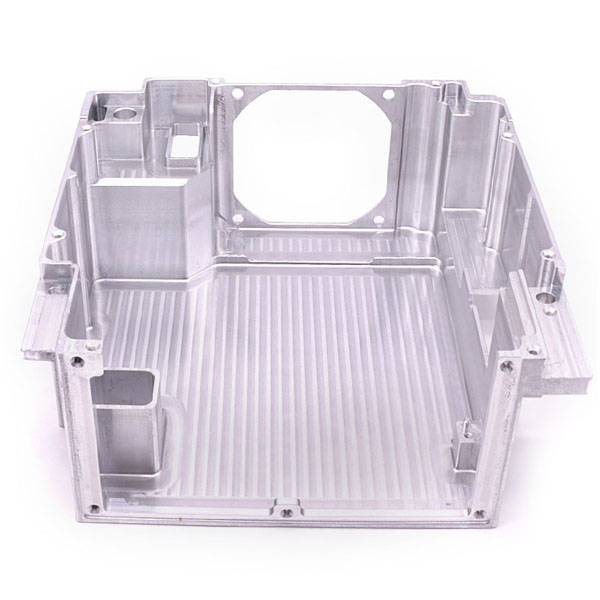

Precision Custom Electronic Aluminum CNC Parts Fabrication Services

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom Aluminum CNC Parts Fabrication Services in China

|

Custom aluminum CNC part fabrication is possible with CNC Prototyping, manufacturers can quickly develop accurate prototypes for testing and validation. A variety of surface treatment options ensures that CNC parts not only perform well, but also look good. Choosing the right aluminum alloy ensures that the final product meets the required performance and functionality criteria. For businesses looking for a reliable partner in custom aluminum CNC part fabrication, it is critical to work with an experienced and reputable fabricator who understands the intricacies of CNC prototyping, surface finishing and material selection. Can ensure the successful realization of its projects and gain a competitive advantage. |

Custom Aluminum CNC Parts Fabrication Prototyping Machining

CNC prototyping involves the use of CNC machining to create accurate and fully functional prototypes of aluminum parts. The process begins at the design stage, where the aluminum material is cut, shaped and prototyped by CNC machining machine commands. The strengths of CNC prototyping lie in its high precision, repeatability, and ability to produce complex geometries, test, and validate beyond traditional methods. |

|

|

|

|

||

Custom Aluminum CNC Parts Fabrication Surface Treatment |

Custom Aluminum CNC Parts Fabrication Material |

||

|

We have a cooperative factory of surface treatment for 10 years, and surface treatment plays a vital role in improving the aesthetics, functionality and service life of custom aluminum CNC parts. We have a variety of surface treatment options to choose from, each with unique benefits. |

Choosing the right aluminum alloy is essential to the success of any CNC machining project. Different aluminum alloys have different properties to meet specific application needs. Common aluminum materials are 6061-T6 aluminum, 7075 aluminum, 5052 aluminum, 6063 aluminum and so on. Choosing the right aluminum alloy requires consideration of factors such as mechanical properties, corrosion resistance, cost, and project-specific requirements. |

Custom Aluminum CNC Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Aluminum is a widely used material in CNC manufacturing due to its exceptional properties. Different aluminum alloys have different properties that make them suitable for different applications. The following are commonly used aluminum materials: |

|

|

Custom 6061 Electronic Aluminum CNC Parts Fabrication

This alloy is one of the most versatile and widely used in CNC fabrication.It offers excellent strength, good weldability, and high corrosion resistance.6061 aluminum is well-suited for structural components, marine hardware, and automotive parts.、

More Details>> |

|

|

|

Custom 7075 Electronic Aluminum CNC Parts Fabrication

Known for its high strength-to-weight ratio, 7075 is ideal for applications requiring exceptional strength.It exhibits excellent fatigue resistance and is often used in aerospace components and high-stress parts.

More Details>> |

|

|

|

Custom 5052 Electronic Aluminum CNC Parts Fabrication

5052 aluminum is known for its formability and corrosion resistance.It is commonly used in marine and architectural applications, as well as small boat hulls and fuel tanks.

More Details>> |

|

|

|

Custom 6063 Electronic Aluminum CNC Parts Fabrication

This alloy is well-regarded for its extrudability, making it suitable for producing intricate shapes and profiles.6063 is often used in architectural applications, window frames, and heat sinks.

More Details>> |

|

|

|

Custom 6082 Electronic Aluminum CNC Parts Fabrication

6082 exhibits good weldability and is commonly used in structural applications, transportation equipment, and machine parts.

More Details>> |

|

、

| We offer a wide variety of aluminum material options, and the success of any CNC machining project depends largely on the correct choice of material. By considering the specific requirements of the application and carefully evaluating the properties of commonly used aluminum alloys such as 6061, 7075, 5052 and 6063, manufacturers can ensure optimal performance, functionality and durability of the end product and obtain high quality, precision engineered aluminum CNC machined components. |

|

In the world of custom aluminum CNC part manufacturing, surface treatments play a key role in enhancing the functionality, aesthetics and durability of the final product. Surface treatment of aluminum parts to enhance their corrosion resistance, appearance and overall performance. Below are various surface finish options commonly used for custom aluminum CNC parts. |

|

1. Anodizing: Enhancing Corrosion Resistance and Aesthetics

Anodizing: Anodizing is a widely used surface treatment method for custom aluminum CNC parts, offering remarkable advantages. This process allows for a variety of color options, enhances the corrosion resistance of the parts, making it a common surface treatment choice. Anodized custom aluminum CNC parts find extensive applications in industries such as aerospace, automotive, and electronics. |

|

|

2. Powder Coating: Durable and Versatile Finishes

Powder Coating: Powder coating provides excellent protection against wear, chemicals, and weather, making it suitable for both indoor and outdoor applications. It is available in a wide range of colors and finishes, allowing for versatile customization. Custom aluminum CNC parts with powder coatings are commonly used in automotive components, architectural structures, and consumer electronics. |

|

|

|

3. Polishing: Achieving Reflective and Smooth Surfaces

Polishing: Polishing is a surface treatment option that creates a smooth and reflective effect for custom aluminum CNC parts. It is commonly used for decorative applications, such as luxury consumer goods, architectural elements, and high-end automotive components. The reflective properties of polished aluminum add an elegant touch to various designs, making it the preferred choice for visually appealing projects. |

|

|

|

4. Painting: Versatility and Customization

Painting: Painting is a versatile surface treatment option for custom aluminum CNC parts. It allows for a wide range of color choices, enabling complete customization to meet branding or specific design requirements. Applied across various industries, including consumer goods, signage, and industrial equipment, painting's ability to offer customized colors and finishes makes it a practical choice for projects emphasizing aesthetics and brand identity. |

|

|

|

To view the surface finishing effect, click here: https://www.machining-custom.com/aluminum-surface-finishing/ |

| Custom aluminum CNC part fabrication is a precise, efficient manufacturing process that involves cutting, forming, and forming aluminum material into complex, functional components. The key stages from design to final product are described below. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The custom aluminum CNC parts fabrication process begins with design and CAD modeling. Engineers work closely with clients to understand their specific requirements and create detailed digital models of the desired parts using CAD software. The CAD models define the dimensions, features, and tolerances of the custom aluminum parts. |

|

2. Material Selection

Material selection: Once the design is complete, the appropriate aluminum alloy is selected based on the application, desired mechanical properties, and cost considerations. Common aluminum alloys used in CNC machining manufacturing include 6061, 7075, 5052, and 6082, each with unique properties suitable for different applications. |

|

3. CNC Machining

CNC machining: At the heart of the custom aluminum CNC part manufacturing process is CNC machining. Precision cutting and forming of aluminum materials using CNC machining and milling, turning, drilling and other operations enables complex geometries and tight tolerances to ensure consistent quality across multiple parts. |

|

Surface Treatments: Once the CNC machining is complete, custom aluminum parts may undergo surface treatments to enhance their properties. Surface treatments such as anodizing, powder coating, polishing, and painting are applied to improve corrosion resistance, aesthetics, and overall performance. |

|

5. Quality Inspection

Quality Inspection: Quality inspection is a critical stage in the custom aluminum CNC parts fabrication process. Each part is meticulously inspected to verify that it meets the specified dimensions and tolerances. Advanced measurement tools, such as coordinate measuring machines (CMMs), are used to ensure the accuracy and precision of the final product. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Assembly (if required)

Assembly (if required): In some cases, custom aluminum CNC parts may require assembly as part of the fabrication process. This could involve joining multiple CNC-machined components or integrating the aluminum parts with other materials or electronic components. |

|

7. Packaging and Delivery

Packaging and Delivery: After passing the quality inspection and assembly, we will choose the appropriate or custom packaging method for aluminum CNC parts according to the customer's needs, transportation method, to ensure safe transportation. They are then shipped to the customer's location or specified destination. |

|

Custom aluminum CNC part fabrication is an integrated process that combines design, material selection, CNC machining, surface treatment, quality inspection, and (if required) assembly. With its precision and versatility, CNC machining can produce complex and high-quality aluminum parts for various industries such as aerospace, automotive, electronics, and more. By working with an experienced and reputable manufacturer who specializes in custom aluminum CNC parts fabrication, you can obtain a high quality and rigorous finish to your machining project that meets their specific requirements. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Aluminum CNC Parts Fabrication FAQs

|

Q1: What are the advantages of custom aluminum CNC parts fabrication?

Q2: Can custom aluminum CNC parts be used for both prototypes and production runs?

Q3: What are the typical lead times for custom aluminum CNC parts fabrication?

Q4: Is surface treatment necessary for custom aluminum CNC parts?

Q5: Can custom aluminum CNC parts be made with different aluminum alloys in the same project?

Q6: How do I choose the right manufacturer for custom aluminum CNC parts fabrication?

Q7: Are custom aluminum CNC parts cost-effective compared to other manufacturing methods?

Q8: Can I customize the finish and color of custom aluminum CNC parts?

Q9: Are custom aluminum CNC parts suitable for high-temperature applications?

Q10: Can custom aluminum CNC parts be fabricated with tight tolerances?

|

| If you have any other custom aluminum CNC parts fabrication questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.