After receiving the task, the VMT engineer carefully studied and discussed, and finally made the following changes to the customer's structure:

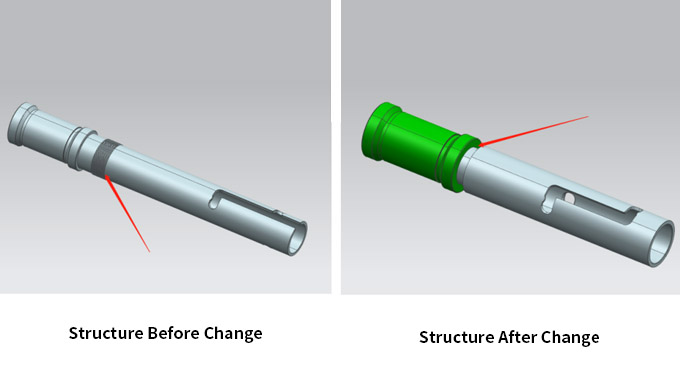

One: The integrated fixed cylinder on the mandrel is changed to a split spring cylinder. The reason for this change is to make the cylinder elastic and smoothly embedded in the shell.

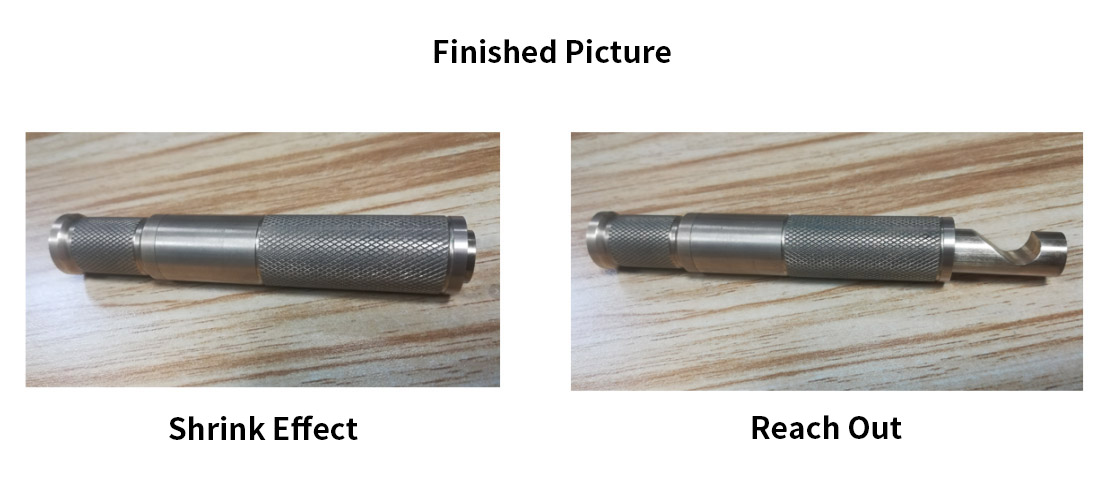

Two: Cancel the thread on the inner shell. The reason for this change is the interference between the thread and the spiral groove inside the housing.

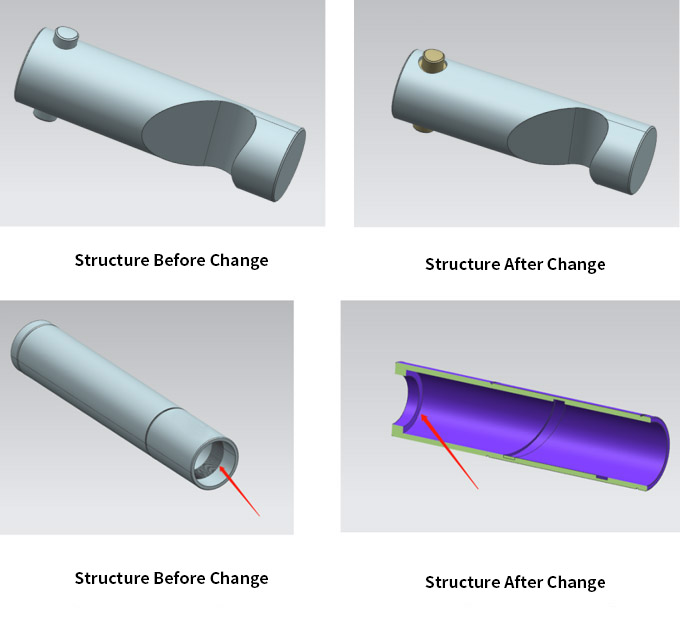

1. The inner shell is divided into two parts and fixed with M4 screws.

2. Under the condition that the function and appearance are not affected, the total length is shortened by 20MM, thereby reducing the manufacturing cost.

3. Add a floating platform inside the shell, leaving a gap of 0.15mm between the inner shells, so that the inner shell can rotate 360 degrees without shaking.

4. Under the condition that the function and appearance are not affected, the total length is shortened by 20mm, thereby reducing the manufacturing cost.