15 years one-stop China custom CNC machining parts factory

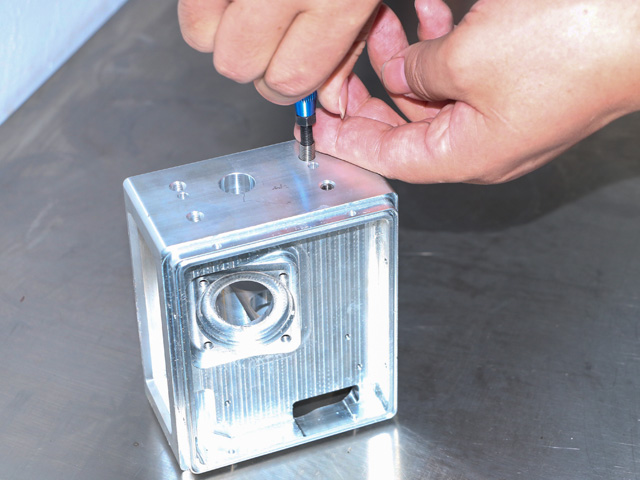

Threaded inserts are very common in the CNC machining of mechanical parts. Why do you need a threaded insert? What are the benefits of product braces? In the CNC machining of mechanical parts, the braces are thread braces. After the threads are processed, the thread braces are installed on the threads. With so many CNC machining factories, how should we choose?

Why do you want to thread insert for CNC machining aluminum alloy parts? What are its benefits?

Threaded braces can increase the connection strength + wear resistance + anti-rust knot + anti-loosening + anti-vibration = prolong the service life of the thread. Because the thread belongs to the assembly position, it must be tightened and loosened frequently. If the thread is operated for a long time, the thread will be damaged, which will lead to slippage and insufficiency of the thread.

The threaded inserts are made of high-quality stainless steel wire. The diameter of the threaded sleeve is larger than the diameter of the screw hole, so the threaded insert has a large contact surface and is stronger than the original thread. Many designers take this into consideration when designing products, and mark the position where the thread needs to be embedded in the drawing. The purpose is to extend the service life of the thread, thereby extending the service life of the entire product.

Common problems and solutions of the aluminum alloy shell of the communication cavity shell

1. After most communication shells are processed by CNC, the surface is specially sprayed. The surface of some parts needs to be sprayed repeatedly. If the braces are inserted after spraying, they will melt, deform and block when passing through a high-temperature oven. The best solution is to first consider the surface treatment method, block the hole during spraying, and then thread insert after the surface treatment is completed.

2. In the process of processing, the braces are not smooth, and the threads of the braces are deformed, causing the locking screws to be not smooth when assembling the finished product, and the shell parts are scrapped in serious cases. In the process of processing, we must determine the large and small diameters of the front thread of the brace, purchase the thread of the tooth gauge control material, and ensure that it meets the thread size of the material and the outer diameter of the

brace. Purchase professional braces tools to reduce scrap due to poor assembly!

VMT produces small batch machining of 300+ communication cavity shells, all products are sprayed first and then braces are set. From the product design stage to small batch CNC machining and production services, and then to mass die-casting production services, we have accumulated a wealth of CNC machining experience for such products, which can meet

customer needs!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!