15 years one-stop China custom CNC machining parts factory

626 |

Published by VMT at Sep 01 2023 | Reading Time:About 3 minutes

626 |

Published by VMT at Sep 01 2023 | Reading Time:About 3 minutes

Aluminum alloys are identified by a combination of numbers and letters that make up their alloy designation or grade. This system helps to categorize and describe the specific alloy composition and properties. Here's a breakdown of the typical aluminum alloy designation format:

Series Number: The first digit(s) indicate the alloy series. For example:

Subseries Number (if applicable): Some alloys within a series have additional digits to further specify the alloy composition.

Alloying Elements: Letters or symbols following the series and subseries (if present) indicate specific alloying elements. For example, "T6" indicates that the alloy has undergone heat treatment for increased strength.

Here are a few examples of aluminum alloy designations:

These designations help engineers and manufacturers select the right aluminum alloy for specific applications based on factors like strength, corrosion resistance, formability, and other properties.

| Material |

Formability |

Machinability |

Weldability |

CNC Machining Performance |

Corrosion Resistance |

Heat Treatment |

Strength |

Hardness |

Density (g/cm³) |

Common Forms |

Typical Applications |

| Aluminum Alloy 1100 |

Excellent |

Poor–Fair |

Excellent |

Good for simple parts |

Excellent |

Non-heat-treatable |

Low |

Very soft |

2.71 |

Sheet, plate, foil |

Chemical equipment, reflectors, HVAC parts |

| Aluminum Alloy 2011 |

Fair |

Excellent (best for machining) |

Poor |

Ideal for high-speed machining |

Fair |

Heat-treatable |

Medium |

High |

2.80 |

Rod, bar |

Precision screw machine parts, fasteners |

| Aluminum Alloy 2024 |

Poor |

Good |

Poor |

Very good for aerospace parts |

Fair |

Heat-treatable |

High |

High |

2.78 |

Plate, bar, sheet |

Aircraft components, structural parts |

| Aluminum Alloy 3003 |

Excellent |

Fair |

Good |

Good for general parts |

Very good |

Non-heat-treatable |

Medium-Low |

Soft |

2.73 |

Sheet, plate |

Cooking utensils, heat exchangers |

| Aluminum Alloy 5052 |

Very good |

Fair |

Excellent |

Good for sheet-metal machining |

Excellent |

Non-heat-treatable |

Medium |

Medium |

2.68 |

Sheet, plate |

Marine parts, enclosures, tanks |

| Aluminum Alloy 6061 |

Good |

Good–Excellent |

Good |

Most widely used for CNC machining |

Very good |

Heat-treatable |

Medium-High |

Medium |

2.70 |

Plate, bar, extrusion |

Automotive, aerospace, machinery components |

| Aluminum Alloy 6063 |

Excellent |

Good |

Excellent |

Good for extruded CNC parts |

Very good |

Heat-treatable |

Medium-Low |

Medium-Low |

2.69 |

Extrusions |

Architectural profiles, frames |

| Aluminum Alloy 7075 |

Poor |

Good |

Poor |

Excellent for high-strength CNC parts |

Moderate |

Heat-treatable |

Very high |

High |

2.81 |

Plate, bar |

Aerospace, performance components |

| Aluminum Alloy 5083 |

Good |

Fair |

Excellent |

Good for precision welded parts |

Superior marine resistance |

Non-heat-treatable |

High |

Medium |

2.66 |

Plate, sheet |

Marine structures, pressure vessels |

| Aluminum Alloy 6082 |

Good |

Good |

Good |

Stronger alternative to 6061 |

Good |

Heat-treatable |

High |

Medium-High |

2.70 |

Plate, bar |

Bridges, cranes, high-load parts |

| Aluminum Alloy 7050 |

Poor |

Fair |

Poor |

Premium aerospace machining |

Moderate |

Heat-treatable |

Very high |

High |

2.83 |

Plate, forging |

Aerospace structural fittings |

| Aluminum Alloy 2219 |

Poor |

Fair |

Excellent (for high-temp welding) |

Good for aerospace |

Good |

Heat-treatable |

High |

High |

2.84 |

Plate, bar |

Fuel tanks, structural aerospace components |

| Aluminum Alloy 3004 |

Good |

Fair |

Good |

General-purpose CNC |

Good |

Non-heat-treatable |

Medium |

Low–Medium |

2.73 |

Sheet |

Packaging, heat-exchange components |

| Aluminum Alloy 2020/2030 |

Fair |

Excellent |

Poor |

High-speed automatic machining |

Poor–Fair |

Heat-treatable |

High |

High |

2.80 | Rod, bar |

Screws, high-precision turned parts |

Aluminum alloys come in various series, each with its own unique properties and applications. Here are some common aluminum alloy series:

Each series encompasses a range of specific alloy compositions with varying characteristics to suit different industrial and commercial needs. The choice of alloy depends on the requirements of the specific application, such as strength, corrosion resistance, and formability.

Notes: “Yield” = 0.2% offset yield (MPa). “Tensile” = ultimate tensile strength (MPa). “Elongation” = % in 50 mm or 2 in gauge (depends on spec). Price Level = relative material cost vs 6061 (Low / Medium / High). Anodizing quality = how well the alloy accepts decorative/functional anodize.

| Material |

Yield (MPa) |

Tensile (MPa) |

Elongation (%) |

Electrical Conductivity (% IACS) |

Thermal Conductivity (W/m·K) |

Hardness (HB) |

Density (g/cm³) |

Price Level |

Anodizing Quality |

Typical Forms |

Typical Applications |

Recommended CNC tooling & notes |

| 1100 (pure Al) |

30–40 |

90–120 |

30–40 |

~60–62 |

~220–230 |

15–25 |

2.71 |

Low |

Excellent |

Sheet, foil, plate |

Chemical tanks, reflectors, heat shields |

Use high-feed finishing; carbide endmills okay; low DOC, high RPM for fine finish; easy to anodize. |

| 2011 (free-machining) |

150–220 |

300–380 |

6–12 |

~25–35 |

~130–150 |

50–90 |

2.80 |

Medium |

Fair |

Rod, bar |

Precision turned parts, fasteners, screws |

Excellent machinability — turn at higher feeds; use sharp carbide tools, rigid setup, moderate coolant; avoid heavy welding. |

| 2024 (Al-Cu) |

300–350 |

470–520 |

10–20 |

~30–35 |

~120–140 |

120–160 |

2.78 |

Medium–High |

Fair |

Plate, bar, sheet |

Aerospace structures, fittings |

Good for milling; use carbide tooling, lower feeds than 2011, peck drilling for deep holes; limited weldability. |

| 3003 (Al-Mn) |

55–95 |

130–200 |

20–35 |

~35–45 |

~160–170 |

30–50 |

2.73 |

Low |

Good |

Sheet, plate |

Cookware, heat exchangers, general sheet parts |

Good formability; use HSS or carbide; moderate cutting speeds; suits bending and forming operations. |

| 5052 (Al-Mg) |

110–165 |

200–260 |

6–15 |

~35–37 |

~140–150 |

40–70 |

2.68 |

Low–Medium |

Excellent |

Sheet, plate |

Marine parts, enclosures, fuel tanks |

Good weldability; moderate machinability — climb milling, light DOC; anodizes reasonably well. |

| 6061 (Al-Mg-Si) |

240–260 |

270–310 |

8–17 |

~40–45 |

~150–170 |

70–110 |

2.70 |

Medium |

Good |

Plate, bar, extrusion |

Structural parts, frames, fittings |

Shop favorite for CNC — good balance. Carbide tooling, moderate to high cutting speeds, good surface finish after anodize. |

| 6063 (Al-Mg-Si, extrusion) |

150–170 |

190–230 |

8–12 |

~40–45 |

~160–180 |

60–90 |

2.69 |

Low–Medium |

Excellent |

Extrusions, profiles |

Architectural frames, extruded profiles |

Excellent surface finish; optimized for extrusion shapes; CNC as-milled finish is very good; use light finishing passes. |

| 7075 (Al-Zn) |

480–520 |

560–620 |

5–11 |

~30–35 |

~130–140 |

150–190 |

2.81 |

High |

Fair |

Plate, bar |

Aerospace fittings, high-strength parts |

High strength but lower ductility; use rigid tooling, carbide with stiff holders; stress-relief recommended after heavy machining. |

| 5083 (Al-Mg) |

120–170 |

300–370 |

10–20 |

~35–38 |

~135–155 |

60–90 |

2.66 |

Medium |

Excellent (marine) |

Plate, sheet |

Shipbuilding, pressure vessels, marine structures |

Excellent weldability; machining needs robust fixturing; best with moderate cutting speeds. |

| 6082 (Al-Mg-Si) |

260–300 |

310–350 |

8–12 |

~35–42 |

~150–170 |

90–120 |

2.70 |

Medium |

Good |

Bar, plate |

Structural, high-load components |

Stronger alternative to 6061; carbide tooling, lower feed for heavy cuts. |

| 7050 (Al-Zn-Mg) |

400–480 |

500–580 |

6–10 |

~28–33 |

~120–140 |

140–180 |

2.83 |

High |

Fair |

Plate, forging |

Premium aerospace structures |

High strength; requires precise heat-treatment control; use tough tooling, pre-stress relief advisable. |

| 2219 (Al-Cu) |

250–320 |

390–470 |

8–15 |

~30–35 |

~120–140 |

100–140 |

2.84 |

High |

Good (specialized) | Plate, bar |

Rocket/fuel tanks, aerospace high-temp parts |

Good weldability for high-temp service; machine with care; aerospace spec handling. |

| 3004 (Al-Mn) |

70–110 |

180–220 |

10–25 |

~36–42 |

~150–160 |

35–60 |

2.73 |

Low |

Good |

Sheet | Packaging (cans), general sheet metal |

Similar to 3003 — formable and widely used in sheet metal forming. |

| 2020 / 2030 (free-machining variants) |

140–220 |

300–380 |

6–12 |

~25–35 |

~130–150 |

60–100 |

~2.80 |

Medium |

Fair |

Rod, bar |

High-speed turned parts, precision screw machine parts |

Very good for automatic turning and threading; use sharp carbide, high feed, low chip thickness. |

Engineering Recommendations:

The combination of aluminum alloy forms and metal forming processes allows for the creation of a wide range of aluminum components with various shapes and characteristics. Here's an overview of some common aluminum alloy forms and the metal forming processes used with them:

Aluminum Alloy Forms:

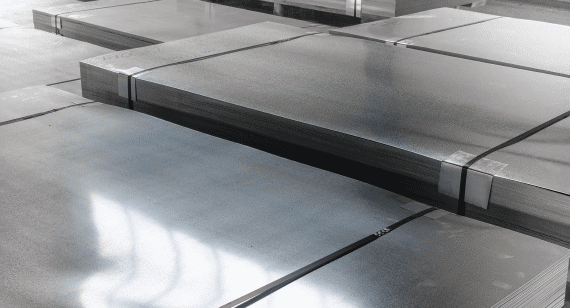

Sheet: Thin, flat pieces of aluminum. Commonly used for panels, covers, and lightweight structures.

Plate: Thicker than sheets, plates are used for heavier-duty applications that require strength and stability.

Bar: Solid bars of aluminum with various cross-sectional shapes, like round, square, or hexagonal. Used for machining, fasteners, and structural components.

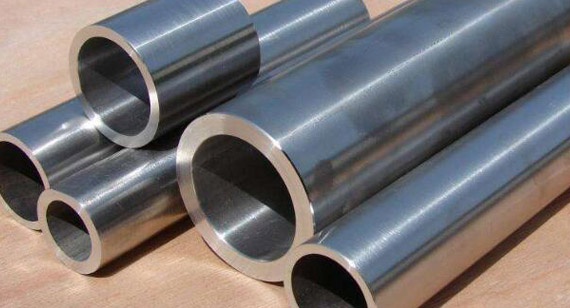

Rod: Cylindrical bars, often used for applications where corrosion resistance is important.

Tube: Hollow cylindrical shapes, available in various diameters and wall thicknesses. Used in tubing systems, structural components, and heat exchangers.

Extrusion: Aluminum is pushed through a die to create complex cross-sectional shapes. Extrusions are commonly used for frames, profiles, and architectural components.

Aluminum Alloy Metal Forming process

Aluminum alloy metal forming processes are often chosen based on the specific characteristics of the alloy series and the desired final product. Here's a general overview of which aluminum alloy series is commonly used for different metal forming processes:

1. Extrusion:

Extrusion: As mentioned earlier, extrusion is used to create aluminum profiles and structural shapes with uniform cross-sections.

Alloy Series: 6000 Series (Aluminum-Magnesium-Silicon Alloys) is frequently used for extrusion due to its excellent formability, machinability, and weldability. These alloys can be easily extruded into complex shapes, making them ideal for applications like frames and structural components.

Alloy Series: For sheet metal forming processes like bending, stretching, and stamping, the 1000 Series (Pure Aluminum) and 5000 Series (Aluminum-Magnesium Alloys) are commonly used. They offer good formability and corrosion resistance, making them suitable for automotive body panels, kitchen utensils, and other formed sheet metal products.

3. Casting:

Casting: Molten aluminum is poured into molds to create parts with intricate shapes. Common casting methods include die casting and sand casting.

Alloy Series: Casting processes, such as sand casting and die casting, often use various aluminum alloy series depending on the desired properties. The 3000 Series (Aluminum-Manganese Alloys) and 4000 Series (Aluminum-Silicon Alloys) are common choices for casting applications due to their good castability and corrosion resistance.

4. Forging:

Forging: Aluminum is heated and shaped by applying compressive force. Forging is used to create strong and durable components like automotive parts and aircraft components.

Alloy Series: Forging requires alloys with good mechanical properties and heat-treatability. The 2000 Series (Aluminum-Copper Alloys) and 7000 Series (Aluminum-Zinc Alloys) are suitable for forging applications, as they offer high strength and are heat-treatable for further improvement.

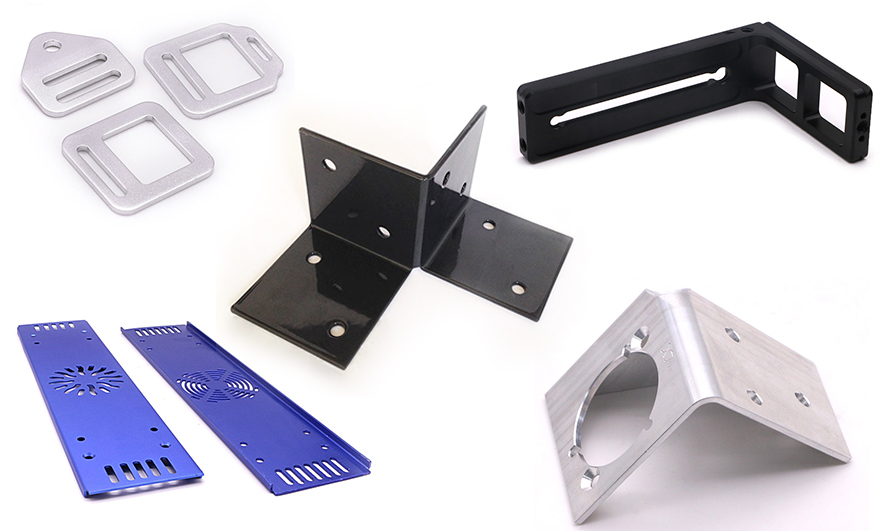

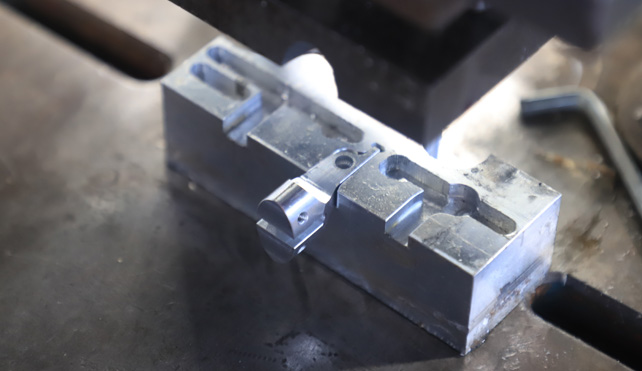

5. CNC Machining:

CNC Machining: Precision machining processes like milling, turning, and drilling are used to shape aluminum components with high accuracy. Suitable for complex geometries.

Alloy Series: When machining aluminum, the 6000 Series and 7000 Series alloys are often preferred. They provide good machinability and can be easily shaped into various components using milling, turning, and drilling processes.

6. Welding:

Welding: Joining aluminum components by melting the material and fusing it together. Various welding techniques like TIG, MIG, and spot welding are used.

Alloy Series: The choice of aluminum alloy for welding depends on the welding method. Generally, the 6000 Series and 7000 Series are suitable for welding processes like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) due to their good weldability.

7. Stamping: Metal sheets are cut and shaped using dies and punches. Often used for mass-producing parts with consistent shapes.

8. Drawing: Thin-walled aluminum tubes or rods are pulled through a die to reduce their diameter and increase their length.

9. Rolling: Aluminum sheets and plates can be reduced in thickness through rolling processes. This is often used for creating foil or thinner sheets.

The choice of alloy form and metal forming process depends on the specific requirements of the component, including its intended use, desired properties, and manufacturing volume. Each combination offers distinct advantages and limitations in terms of cost, efficiency, and performance.

It's important to note that the specific alloy within each series can also affect its suitability for different metal forming processes. The selection should consider factors such as the required strength, corrosion resistance, and the intended application of the final product. Additionally, each alloy series can be further customized with specific alloying elements to meet precise performance requirements.

Certainly, here's a comparison of some common aluminum alloy series based on their characteristics:

1. 1000 Series (Pure Aluminum):

2. 2000 Series (Aluminum-Copper Alloys):

3. 3000 Series (Aluminum-Manganese Alloys):

4. 5000 Series (Aluminum-Magnesium Alloys):

5. 6000 Series (Aluminum-Magnesium-Silicon Alloys):

6. 7000 Series (Aluminum-Zinc Alloys):

The choice of aluminum alloy series depends on the specific requirements of the application, including strength, corrosion resistance, formability, and weight considerations. Each series offers unique properties suited to different industrial and commercial needs.

|

Aluminum Series |

Main Alloying Elements |

Key Characteristics & Performance |

Common Application Industries |

Typical CNC Machined or Formed Parts |

| 1000 Series (Pure Aluminum) |

None (99%+ Al) |

|

Electrical, chemical processing, lighting, food equipment |

Reflectors, heat shields, chemical tanks, busbars, thin housings |

| 2000 Series (Al-Cu) |

Copper (primary), Mg, Mn |

|

Aerospace, defense, high-strength machinery |

Aircraft fittings, structural frames, precision screws, fasteners, high-load brackets |

| 3000 Series (Al-Mn) |

Manganese |

|

HVAC, packaging, consumer goods, automotive |

Heat exchanger fins, cookware, panels, stamped housings, enclosures |

| 4000 Series (Al-Si) |

Silicon |

|

Automotive, welding, engine components |

Pistons, cylinder heads, welding filler wires, cast housings |

| 5000 Series (Al-Mg) |

Magnesium |

|

Marine, energy, transportation, outdoor equipment |

Boat hulls, marine plates, fuel tanks, electronic enclosures, pressure vessels |

| 6000 Series (Al-Mg-Si) |

Magnesium + Silicon |

|

CNC machining, automotive, aerospace, electronics |

Structural parts, brackets, frames, housings, extrusions, fixtures |

| 7000 Series (Al-Zn-Mg) |

Zinc, Magnesium, Copper |

|

Aerospace, military, robotics, performance sports |

High-strength brackets, arms, tooling plates, aerospace joints, performance components |

| 8000 Series (Special Alloys) |

Li, Fe, Si (varies by grade) |

|

Aerospace, packaging, industrial engineering |

Battery casings, foil, advanced lightweight structures |

Aluminum alloy series materials find diverse applications across various industries due to their unique properties. Here's an overview of the applications of different aluminum alloy series:

1. 1000 Series (Pure Aluminum):

2. 2000 Series (Aluminum-Copper Alloys):

3. 3000 Series (Aluminum-Manganese Alloys):

4. 4000 Series (Aluminum-Silicon Alloys):

5. 5000 Series (Aluminum-Magnesium Alloys):

6. 6000 Series (Aluminum-Magnesium-Silicon Alloys):

7. 7000 Series (Aluminum-Zinc Alloys):

8. 8000 Series (Other Aluminum Alloys):

9. Cast Aluminum Alloys:

10. Wrought Aluminum Alloys:

The choice of aluminum alloy series depends on the specific requirements of the application, including factors like strength, corrosion resistance, formability, and weight. Engineers and manufacturers select the most suitable alloy series and alloy within that series to meet the desired performance criteria for their products.

The “Aluminum Series Materials” guide shows that there is no one “perfect” aluminum alloy — rather, different series have unique advantages depending on the application. The 1000-series offers excellent corrosion resistance and formability (useful for chemical equipment, food-grade, or corrosive environments). 2000-series (Al-Cu) and 7000-series (Al-Zn/Mg) alloys deliver high strength and heat-treatability, ideal for aerospace or highly stressed parts. 5000-series (Al-Mg) stands out for corrosion resistance and weldability, making it suitable for marine, automotive, or outdoor components. The 6000-series (Al-Mg-Si), such as 6061 or 6063, balances machinability, strength, weldability, and corrosion resistance — making it the most versatile and commonly chosen for structural, extrusion, or general industrial applications.

In short: choose the alloy based on the part’s requirements — workload, environment, machining or welding needs — rather than seeking a “best aluminum.”

At VMT, we specialize in custom CNC machining of aluminum parts — and our material-series expertise ensures you get the right alloy for your needs. Whether you need lightweight, corrosion-resistant parts for marine or automotive use (5000-series); high-strength structural components for aerospace or high-stress applications (7000/2000 series); or versatile, general-purpose parts with excellent machinability and weldability (6000-series) — VMT has you covered. We work with a broad range of aluminum alloys and provide one-stop CNC services including milling, turning, precision tolerances, surface finishing and heat treatment (as required). Our goal: deliver high-quality, application-optimized aluminum components tailored to your design and performance needs.

Let VMT turn your design into precisely machined, performance-fit aluminum parts — with the right material from the start.

Is 5052 or 6061 aluminum stronger?

6061 aluminum is stronger than 5052 due to its heat-treatable composition. 6061 offers higher tensile strength and better structural performance, making it suitable for CNC-machined parts requiring rigidity. 5052 is softer but provides excellent corrosion resistance and formability.

What is the difference between 5000 series and 6000 series aluminum?

What is the grade of pure aluminum?

Pure aluminum is classified as 1000-series aluminum, typically containing 99% or higher aluminum content (e.g., 1050, 1100).

Which is better, 6061 or 6063 aluminum?

What is 3000 series aluminum used for?

3000-series (Al-Mn) aluminum is used for cooking utensils, heat exchangers, chemical equipment, building materials, and applications requiring good corrosion resistance and moderate strength.

What are the three grades of aluminum?

Commonly referenced “grades” include:

(These cover most industrial and CNC-machining needs.)

What is 7000 series aluminum?

7000-series aluminum (Al-Zn/Mg) is a high-strength, heat-treatable alloy group widely used in aerospace, defense, sports equipment, and high-performance CNC-machined parts.

What series is pure aluminum?

Pure aluminum belongs to the 1000 series, containing 99.0%+ aluminum.

What is 6000 series aluminum?

6000-series aluminum (Al-Mg-Si) offers excellent machinability, corrosion resistance, weldability, and medium-to-high strength. Alloys like 6061 and 6063 are widely used for CNC machining and industrial structures.

Is 6061 or 7075 aluminum stronger?

7075 aluminum is significantly stronger than 6061 thanks to its higher zinc content and heat-treatable structure. It is used in aerospace and high-stress components, while 6061 provides a better balance of strength, machinability, and cost.

What's 1 lb of aluminum worth?

The price fluctuates based on global markets, but aluminum scrap typically ranges from USD $0.40–$1.00 per pound, while raw industrial aluminum material is higher depending on grade and form.

Can you weld 5000 series aluminum?

Yes. 5000-series aluminum is one of the best aluminum groups for welding due to its magnesium content, which enhances weldability and corrosion resistance.

Is 7000 series aluminum good?

Yes. The 7000 series offers exceptional strength-to-weight performance. It’s ideal for aerospace parts, performance components, and CNC-machined parts requiring maximum mechanical strength.