15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

226 |

Published by VMT at Dec 15 2023

226 |

Published by VMT at Dec 15 2023

Introduction:

As a lightweight, high-strength material, aluminum alloy is widely used in various fields such as construction, transportation, and electronic equipment. In order to increase the surface beauty and durability of aluminum alloy products, aluminum alloy anodizing technology came into being. In addition to adding a protective layer, anodizing can also give aluminum alloys rich and colorful colors to meet personalization and decoration needs.

Anodizing of aluminum CNC machined parts is a process that combines electrolyte and anodizing technology to form an oxide film with high corrosion resistance and high decorativeness on the surface of the aluminum material. This treatment method can not only improve the corrosion resistance and wear resistance of aluminum materials, but also give aluminum materials various colors and textures to meet the needs of different fields.

1. Basic principles of anodizing

Anodizing is an electrochemical process that uses aluminum as an anode and energizes the electrolyte to form an oxide film on the surface of the aluminum. This process consists of three stages:

Formation of oxide film: When current passes through the electrolyte and aluminum material, an oxide film will form on the surface of the aluminum material. This oxide film is mainly composed of alpha aluminum oxide, and its structure is very dense, which can effectively protect the aluminum material from corrosion and wear.

Selection of electrolyte: The composition and concentration of the electrolyte have a great impact on the color and texture of the oxide film. For example, using an electrolyte containing sulfuric acid can produce a thin, highly transparent oxide film, while using an electrolyte containing chromate can produce an oxide film with iridescent colors.

Treatment conditions: The treatment conditions of anodizing will also affect the color and texture of the oxide film. For example, processing time, current density, temperature, etc. will all affect the formation of oxide film.

2. Advantages of anodizing

Anodizing technology has the following advantages:

Improve corrosion resistance: The oxide film formed by anodization has high density and corrosion resistance, which can effectively protect aluminum materials from corrosion and wear.

Improve wear resistance: The oxide film formed by anodization has high hardness and wear resistance, which can improve the service life and performance of aluminum materials.

Increase the aesthetics: Anodizing can give aluminum materials various colors and textures, increasing the aesthetics and decoration of aluminum materials.

Improve insulation: The oxide film formed by anodization has good insulation and can be used to manufacture electronic components and circuit boards.

Environmentally friendly and sustainable: Anodizing is an environmentally friendly and sustainable technology that does not produce harmful substances and waste and meets the requirements of modern industrial development.

3. Colors that can be achieved with aluminum alloy anodization:

1. Natural silver:

Natural silver is the basic color of anodizing. It is the color of the oxide layer obtained when no colorant is added, showing silver or gray. This is the most common color effect and is suitable for a variety of applications, especially where economical and practical requirements are required.

2. Black:

By adding an appropriate amount of dye (such as sodium nickelate) during the oxidation process, the oxide layer can be rendered uniformly black. The black oxide layer not only has a beautiful appearance, but also has excellent wear resistance and corrosion resistance, and is widely used in automotive parts, interior decoration and other fields.

3. Gold or Bronze:

By using stains containing metal salts (such as magnesium salts), the anodized layer can be given a gold or bronze effect. These colors can give aluminum alloy products a noble and simple appearance, and are often used in architectural decoration, home furnishings and other fields.

4. Color:

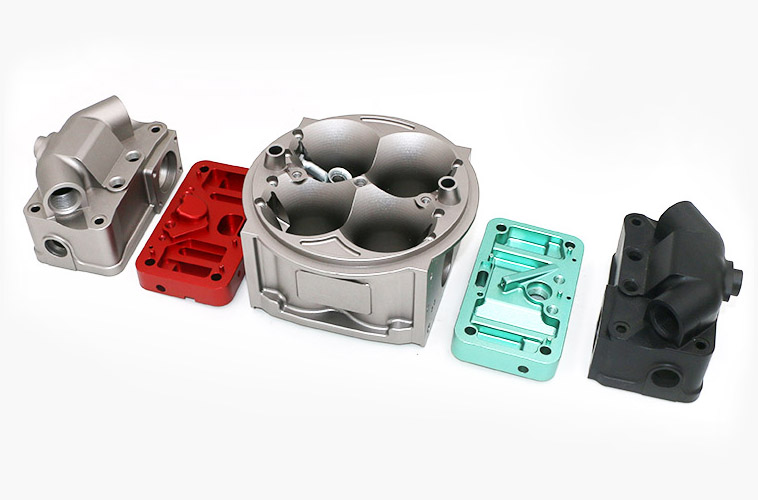

In addition to the common colors mentioned above, anodizing can also achieve a variety of color effects. By using special dyes such as organic dyes, a variety of bright and bright colors such as red, blue, and green can be achieved. This colorful anodized layer is widely used in art production, electronic equipment and other fields, adding decoration and personalization.

4. Application fields of aluminum alloy anodizing:

Aluminum alloy anodizing technology is widely used in various fields to meet the needs of different industries:

Architectural decoration: Color anodizing can give various rich colors to building facades, windows, doors and other aluminum alloy products, improving the aesthetics and visual effects of the building.

Automotive industry: Black anodizing is widely used in automotive parts, such as frames, bodies, etc., to provide a durable protective layer and a personalized appearance.

Electronic devices: Color anodizing can add personalization and style to the casings of electronic products, such as smartphones, laptops, etc.

Aerospace: Aluminum alloy anodizing technology can increase the corrosion resistance and surface hardness of aircraft, provide better protection, and achieve marking and decorative effects through dyeing.

Art production: Color anodizing provides more creative possibilities for art production. It can give bright colors to sculptures, art installations, etc., enhancing the appreciation and uniqueness of artworks.

Summarize:

Aluminum alloy anodizing can not only provide surface protection for aluminum alloy products, but can also achieve a variety of colorful colors through dyeing. From natural silver to black, gold, color and other options, aluminum alloy anodizing technology can meet the personalized needs of different fields and applications. Whether it is architectural decoration, automobile industry, electronic equipment or art production, anodizing provides more design possibilities and decorative effects. With the continuous development and innovation of technology, aluminum alloy anodization will continue to create a more colorful world for us and meet the changing needs.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!