15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

190 |

Published by VMT at Aug 11 2022

190 |

Published by VMT at Aug 11 2022

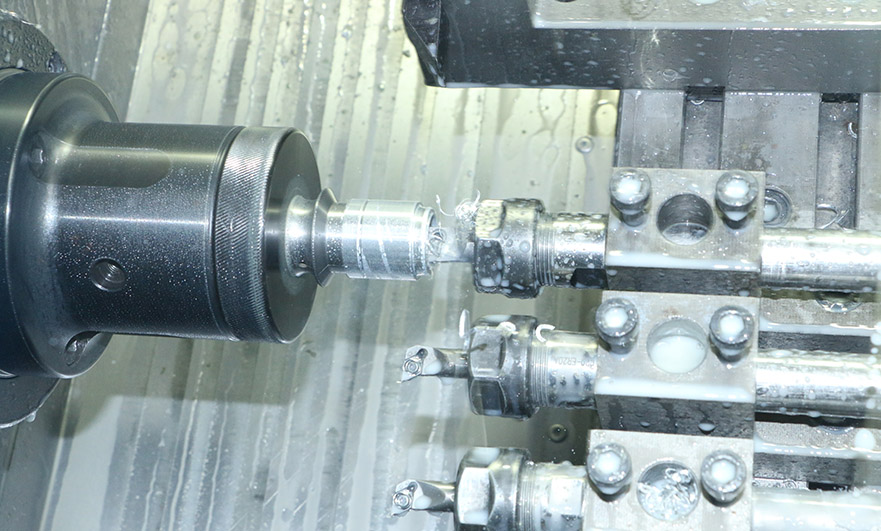

CNC turning and CNC milling machines

CNC turning and CNC milling are two typical types of machining, which is a method of using tools (cutting tools) to cut and machine various materials such as metal, plastic, and wood into desired shapes. It is a processing method for removing chips from a substrate, which belongs to "removal processing". When cutting, the tool scrapes the material through the relative movement of the tool and the material.

Rotating the tool or material enables high-speed and efficient CNC machining when moving the tool and material relative to each other. CNC turning uses a device called a lathe, a method of rotating material to convey and contact a tool for machining. Milling is the method of feeding and applying a fixed material by rotating a tool with a device called a milling machine.

CNC turning is good at machining round objects

The elements that make up a lathe are the spindle that grips (grabs) the material and makes it rotate, and the tool holder that moves the cutting tool. There is an auxiliary push rod to dampen material jumping. Since CNC turning is performed by rotating the material, the parts being machined are machined into cylindrical, conical or spherical shapes. Geometrically, the shape of the cross section perpendicular to the axis of rotation is a circle. Not only round, but also outer diameter and tapping inner diameter can be machined.

Compared with other cutting processes, circular machining has a higher roundness, such as when cnc machining of outer and inner diameters, can produce products with less runout. In addition, since the diameter can be adjusted simply by changing the position of the tool, it is a cnc machining method that can easily improve dimensional accuracy. In summary, lathe machining can be said to be a CNC machining method suitable for rotating parts such as shafts.

Conversely, I'm not good at dealing with planes. For example, it is difficult to flatten the sides of a cylinder with a lathe, and machining with a milling machine is common. With a lathe, only surfaces perpendicular to the axis of rotation can be leveled.

There are several types of lathes, which are selected according to the diameter, length, weight of the material, the required cnc machining accuracy, etc. The image of the lathe is that the material is installed horizontally for processing, but there are also types of lathes that are installed vertically. It is a type of lathe suitable for heavy workpieces, called a vertical lathe, which is not easily affected by gravity.

In order to improve the cnc machining accuracy of the lathe, the material must be centered when it is clamped to the spindle. In the case of cylindrical materials, a three-chuck chuck is often used. The material does not necessarily have to be round, it can be clamped with a four-chuck collet, but it will take time to center. CNC machining for mass production requires an initial cost, but by preparing a dedicated chuck, the CNC machining time per piece can be shortened.

Use different tools depending on the part you want to cnc machine. Outer diameter and face machining use outer diameter tools, inner diameter machining uses center tools, thread cutting uses thread cutting tools, and cutting uses parting tools. There are two types of knives, one that is made by sharpening tool steel into the shape of a cutting edge, and the other that is used by screwing the tip (blade) to a special handle. Since the accuracy of the type used for sharpening depends on the skill of the person handling it, the type that uses a tip has become mainstream in recent years.

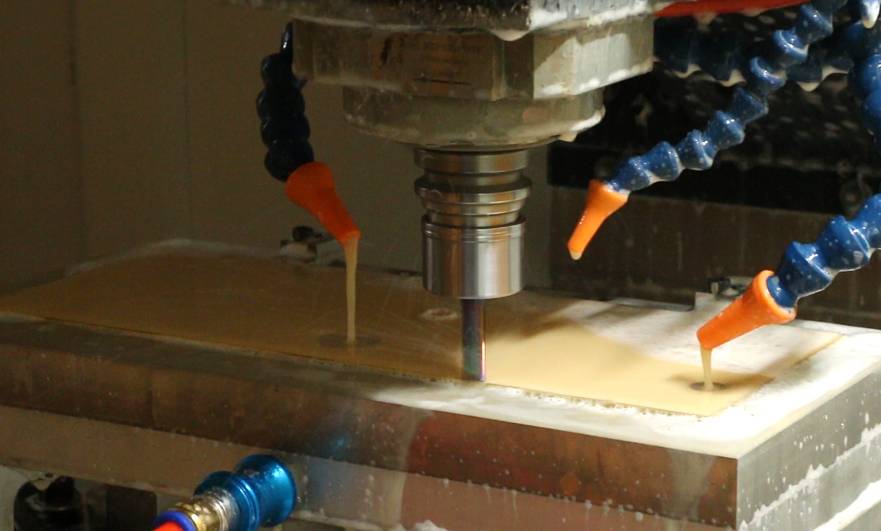

CNC milling is good at plane machining and bevel machining

The elements that make up a milling machine include the spindle, which mounts and rotates the tool, and the table, which clamps (fixes) the material. Milling excels at flat and grooving because it cuts through material by moving the table linearly while hitting a rotating tool.

By changing the tool attached to the rotating spindle, CNC machining into various shapes is possible. If you install a tool called a front mill, you can level wide surfaces at once. If the width of one processing is wider, the corresponding spindle power is required, so a tool with a suitable diameter should be selected.

If you install a tool called an end mill, you can perform flat machining, step machining and grooving using the side of the tool. It can be machined finer than a face mill, but the width that can be cut at one time is narrower.

Drilling can also be done with a drill or drilling tool. The impression of using a drilling machine is that the drilling is strong, but the milling machine is stronger and can drill with higher positional accuracy.

In addition, by using a specially shaped tool, it is possible to cnc machine a groove in a shape called a T-slot or groove. T-slots and dovetail grooves are a type of groove commonly used in machine bed and slide rails.

As for the method of clamping the material on the workbench, in addition to fixing it directly on the workbench, you can also choose a method according to the shape, such as a vise for clamping square wood/plank and a vise for clamping cylindrical material chuck. The positioning accuracy during clamping is important to improve the parallelism and perpendicularity of the machined surface.

By combining these two processes, various parts can be processed by cnc.

The machines used in the world are often manufactured by combining the above two methods of CNC machining, not just one of the above CNC machining methods. By taking full advantage of the characteristics of each CNC machining method and using them correctly, a variety of CNC machined parts can be manufactured.

Consider CNC machining sequence and clamping method when designing

When designing a CNC machined part, what sequence should be used for both CNC turning and CNC milling to achieve the desired accuracy, what tool should be used to machine the shape, and where should the material be clamped during machining. It is also important to consider whether to deal with it.

Due to the high forces acting on both the tool and the material during cutting, the material must be held securely. If the clamping allowance of the clamping is small, the material will move during the CNC machining process, which may cause problems such as the need to reduce the amount of cutting or the inability to process.

The CNC machining method is not left to the CNC machining company, but is considered in the design, so that the machining process can be carried out smoothly, the cost is reduced, and the delivery time is shortened.

Generally speaking, there are very few machining companies that both CNC turning and CNC milling can handle all small to large parts, and depending on the equipment they have, they are not suitable. It needs to be used correctly according to whether the CNC machined part is small, high precision, fine or large and heavy.

There is also a model called a multitasker, which combines the features of CNC turning and CNC milling. The milling cutter can be mounted on a tool holder with a shaft that rotates the material like a lathe, and planes, grooves and many holes can be machined by CNC milling after rounding. Since various CNC machining can be performed while clamping the material, it has the advantage that the CNC machining core can be CNC machining without moving. However, this is often expensive equipment that may not be owned by every CNC machining company.

If you want to know more about CNC turning and CNC milling, you can click this link to view: https://www.machining-custom.com/ or contact us: inquiry@vimetal.com.cn.

VMT is mainly engaged in custom precision CNC machining parts, metal and plastic prototype processing, and its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options with free service design, project reviews and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!