15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

157 |

Published by VMT at Aug 10 2022

157 |

Published by VMT at Aug 10 2022

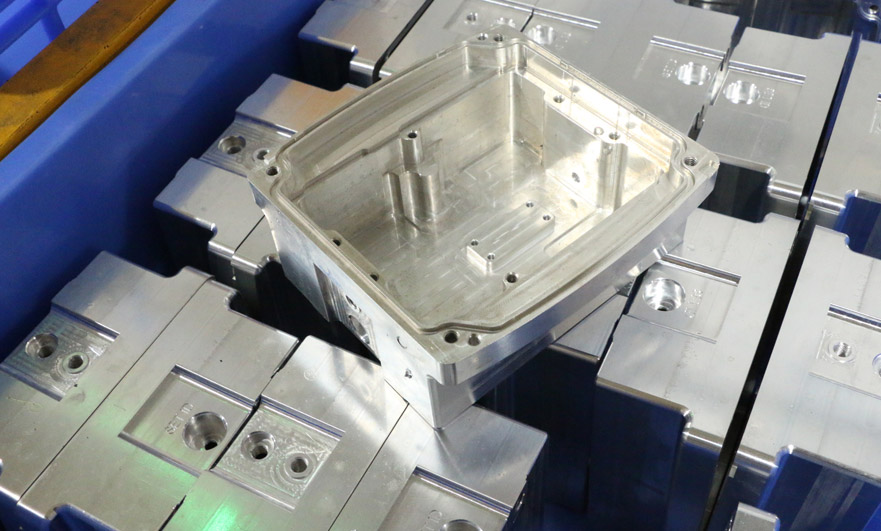

CNC aluminum machining parts have good mechanical properties, small proportion of material, good corrosion resistance and excellent craftsmanship. They are often used in universal structural parts and frame parts, which can not only meet the requirements of mechanical strength and accuracy, but also Effectively reduce the weight of the equipment, so it is widely used in complex parts.

However, complex CNC aluminum machining parts have complex shapes and high dimensional accuracy requirements. VMT introduces the problems and solutions faced by complex CNC aluminum machining parts here, hoping to help you.

1. Machining problems faced by complex CNC aluminum machining parts

In the process of machining complex CNC aluminum parts, it is first necessary to solve the problem of part deformation caused by large material removal allowance, because the blank is a bar, pipe or thick plate, in order to make the size close to the CNC machined part itself, it needs to be processed by CNC after Remove most of the remainder. Due to the large amount of material removed, the original fiber structure is completely destroyed, the CNC machining stress is large, and the residual stress is rebalanced after CNC machining, which causes the deformation of CNC machining parts and increases the machining difficulty.

Another problem to be overcome in the machining process of complex CNC aluminum parts is the problem of stress deformation. There are two kinds of residual stress, one is initial residual stress and the other is machining residual stress. The initial residual stress is the relatively balanced internal stress existing in the aluminum alloy blank. When the excess material is removed, the original stress balance is destroyed, and the stress is rebalanced, which will lead to the deformation of CNC machining parts. The residual stress of CNC machining is the plastic deformation of the area where the tool interacts with the workpiece under the interaction of cutting force, cutting heat or both, and the deformation is affected by other factors to generate residual stress.

Insufficient process conditions is another problem that must be solved in the process of complex CNC aluminum machining parts. The machining of complex CNC aluminum machining parts requires a machine tool with more than four axes, and the machine tool must have high geometric accuracy and good stability.

In the process of complex CNC aluminum machining parts, the problem of insufficient matrix strength needs to be solved. Due to the lack of rigidity in some parts of complex CNC aluminum machining parts, elastic deformation occurs under the action of cutting force during the machining process, forming a let-down knife, which rebounds after unloading, resulting in excessive size. Due to the instability of the cutting process due to the letting of the knife, it is often accompanied by vibration of the knife, resulting in large vibration lines on the machined surface, which seriously affects the surface quality of CNC machined parts.

2.The solution to the problem of complex CNC aluminum machining parts

In order to ensure the quality of CNC aluminum machining parts, the problem of machining deformation must be overcome in the process of complex CNC aluminum machining parts. Therefore, when designing the process route, the general principle of "deformation first, machining later" should be grasped, and based on this, the process division, process size design, tool and parameter selection, fixture and clamping method selection, auxiliary clamping, etc. should be carried out.

Most of the machining allowance should be removed in the roughing stage. Slots, holes, tables and other parts that cause the overall or important local deformation of the part should be pre-processed. In particular, the sidewall opening groove, the through plane on the circumference, the asymmetric slot structure, etc., these parts will break the original stress balance after machining, causing large deformation of CNC aluminum parts, so CNC machining should be carried out in the roughing stage. The general outline can be directly CNC machined to the final size for functional holes and grooves such as weight reduction that do not require high precision.

Selection of CNC machining tools. In the roughing stage, aiming at high efficiency and low cost, the requirements for tools are low. However, due to the large cutting allowance, a large amount of cutting heat is generated, and the residual stress is increased, so the tool should be kept sharp and fully cooled during machining. In the finishing stage, the selected tool should have sufficient rigidity and good wear resistance to ensure the accuracy of dimensional and geometric tolerances. The tool should be kept sharp and the cutting edge smoothness is good to reduce cutting force, reduce cutting heat, and make the cutting process. Smooth and reduce system chatter. Use hard alloy milling cutters and coating cutters as much as possible, and polycrystalline diamond cutters can be used when conditions permit.

The tooling should be reasonably designed and positioned reliably. The clamping and pressure can not only meet the clamping requirements, but also minimize the impact on the deformation of CNC aluminum machining parts.

A reasonable process route must be formulated. Due to the complex structure and high precision, complex CNC aluminum machining parts must be divided into rough machining, semi-finishing, and finishing, and heat treatment processes are interspersed in the middle to reduce the influence of residual stress. The allocation of allowances between processes should be reasonably allocated according to the structural characteristics of each CNC machined part, and the finishing allowance should be minimized on the premise that the allowance after deformation is sufficient. For dimensional elements with large tolerances, they should be guaranteed during semi-finishing to reduce the finishing removal allowance and reduce the probability of deformation.

The purpose of rough machining is to remove the allowance, and it can be clamped with a vise or three-jaw, and the clamping force should ensure reliable clamping. During finishing, in order to ensure the accuracy of dimensional and geometric tolerances, the positioning reference surface must have a good flatness, so that the positioning surface and the working platform have a good fit. Therefore, before finishing, a special process is generally arranged to finish the positioning surface to eliminate the deformation of the positioning surface caused by semi-finishing and stress relief. The open plane generally chooses fitter grinding, and the closed plane chooses high-precision machine tools. Milling. When the positioning surface is refined, a vise is generally used for clamping, and the clamping force is required to be small. The parts are clamped in a natural state and must not be knocked flat.

In the finishing stage of complex CNC aluminum machining parts, multi-faceted machining is generally required, so the clamping method of tooling positioning and pressing is adopted. In order to prevent the deformation caused by excessive pressing, the pressing force of the pressing plate is required to be perpendicular to the force-bearing surface, and the lateral component force should be avoided as much as possible. When selecting the pressing position, the workpiece should be solid in the force-bearing position, and in close contact with the positioning tooling, without large windows, suspension, etc., in order to reduce the influence of the pressing force factor.

When CNC aluminum parts are processed, due to insufficient rigidity in some areas, it is easy to cause the knife to be accompanied by vibration lines, which seriously affects the size and surface quality of CNC aluminum parts. In order to reduce or even eliminate the phenomenon of letting the knife, in addition to optimizing the cutting parameters, the method of adding auxiliary support can also be used, which can greatly reduce the phenomenon of knife letting and knife vibration, and ensure the dimensional accuracy and surface quality of CNC aluminum machining parts.

The dimensional change caused by local deformation can be adjusted by the numerical control program. Through the analysis of the detection data, the advance and retraction compensation program is added to the program. Through the knife lift compensation, the thickness and dimensional changes caused by deformation are partially compensated, so as to meet the requirements of batch production stability.

Due to its complex structure and high precision requirements for CNC aluminum machining parts, the principle of "deformation first, machining later" should be followed for the difficulties in CNC machining of complex parts. Based on this principle, a reasonable machining process route is formulated, equipped with suitable process equipment, and measures such as selecting appropriate process parameters, positioning and clamping methods, correct machining of finishing positioning surfaces, adding auxiliary supports, and introducing CNC program compensation, etc. So as to effectively solve the problem of high-precision CNC aluminum machining parts.

VMT is mainly engaged in custom precision CNC aluminum machining parts, metal and plastic prototype machining, and its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options with free service design, project reviews and DFM analysis. To ensure the quality of CNC aluminum machining parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!