15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

121 |

Published by VMT at Mar 02 2024

121 |

Published by VMT at Mar 02 2024

Evaluating CNC Machining Suppliers' Delivery Capability

In the realm of CNC machined parts manufacturing, assessing the delivery capability of CNC machining suppliers is a critically important task. This not only concerns the smooth execution of production plans but also directly impacts operational efficiency and customer satisfaction. Therefore, for CNC machining factories and custom CNC machining requesters, mastering a scientific and effective evaluation method is particularly crucial.

I. Understand the Basic Information of CNC Machining Suppliers

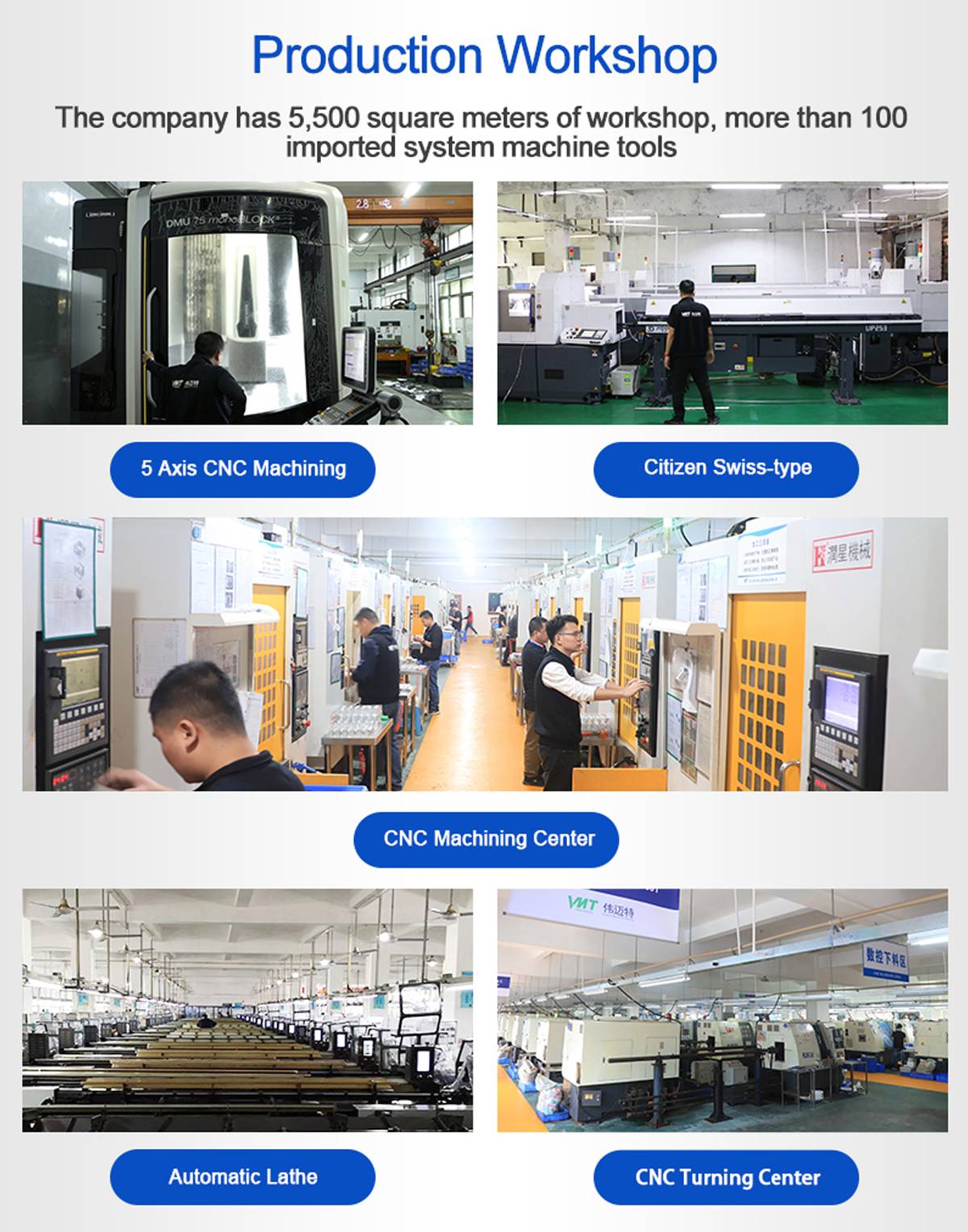

To evaluate the delivery capability of CNC machining suppliers, it's essential to first understand the basic information about the supplier. This includes the supplier's scale, equipment condition, technical expertise of personnel, and production experience. Obtaining this information provides an initial understanding of the supplier's delivery assurance capability.

II. Analyze Supplier's Production Capacity and Workload

Production capacity and workload are crucial factors in assessing the delivery capability of CNC machining suppliers. It's necessary to understand the supplier's production capacity, equipment utilization rate, and current production workload. If the supplier's workload is already high, their delivery capability may be limited. Therefore, when selecting suppliers, it's crucial to consider both their production capacity and workload to ensure they can meet production demands.

III. Examine Supplier's Production Management and Quality Control Levels

Production management and quality control levels directly influence the delivery capability of CNC machining suppliers. By inspecting the supplier's production site, process flow, quality testing, etc., one can gauge the standardization of their production management and the effectiveness of quality control. A supplier with a high level of production management and quality control is usually better positioned to ensure accurate delivery timelines.

IV. Understand the Stability of Supplier's Supply Chain

The stability of the supply chain is also a vital factor in evaluating the delivery capability of CNC machining suppliers. It's necessary to understand the supplier's raw material procurement, inventory management, and logistics distribution. If the supplier's supply chain is unstable, factors such as insufficient raw material supply or logistics delays may affect their delivery capability. Therefore, attention should be given to the stability of the supplier's supply chain to ensure on-time product delivery.

V. Reference Supplier's Historical Delivery Performance

Understanding the historical delivery performance of a supplier is a crucial basis for evaluating their delivery capability. This information can be obtained through communication with the supplier and reviewing relevant records. If a supplier has consistently delivered products on time in the past, demonstrating stable delivery performance, their delivery capability is generally reliable.

VI. Establish Reasonable Evaluation Indicators and System

To comprehensively assess the delivery capability of CNC machining suppliers, it's important to establish reasonable evaluation indicators and a systematic approach. This may include indicators such as production capacity utilization rate, on-time delivery rate, production management level, quality control level, supply chain stability, and more. By comprehensively evaluating these indicators, one can gain a more accurate understanding of the supplier's delivery capability.

VII. Case Analysis and Practical Application

Taking a CNC machining factory as an example, when evaluating the delivery capability of CNC machining suppliers, the factory employed the aforementioned methods. They first understood the supplier's basic information and production capacity, then examined the supplier's production management and quality control levels, and considered the supplier's historical delivery performance. Ultimately, the factory chose a supplier with a strong delivery capability as a partner, achieving positive collaborative results.

VIII. Conclusion and Outlook

Evaluating the delivery capability of CNC machining suppliers is a crucial aspect of ensuring smooth production. By understanding the supplier's basic information, analyzing production capacity and workload, examining production management and quality control levels, considering supply chain stability, referencing historical delivery performance, and establishing reasonable evaluation indicators, CNC machining factories and custom CNC machining requesters can accurately assess the delivery capability of suppliers. In the future, as CNC machining technology continues to advance and market competition intensifies, the evaluation of CNC machining suppliers' delivery capability will become even more critical. Therefore, continual refinement of evaluation methods, improvement of accuracy, and the establishment of long-term stable partnerships with high-quality suppliers are essential for success.

In summary, evaluating the delivery capability of CNC machining suppliers is a complex yet crucial task. By mastering scientific and effective evaluation methods, coupled with practical application through real-world cases, CNC machining factories and custom CNC machining requesters can make better choices in selecting partners, ensuring the smooth execution of production plans, and enhancing customer satisfaction.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!