15 years one-stop China custom CNC machining parts factory

420 |

Published by VMT at Jun 20 2025 | Reading Time:About 7 minutes

420 |

Published by VMT at Jun 20 2025 | Reading Time:About 7 minutes

Tungsten is one of the most unique and valuable metals in the world—but few people outside of specialized industries truly understand its power. Whether you're in aerospace, automotive, or medical manufacturing, you've likely encountered challenges that demand a material strong enough to withstand heat, pressure, and corrosion. That’s where tungsten steps in. Its exceptional physical and chemical properties make it indispensable in high-performance environments, especially in precision industries like CNC machining. If you’ve ever wondered why tungsten is so prized—or how it fits into the world of CNC machining parts and services—this article will give you the answers.

Tungsten metal is a dense, high-strength material known for its exceptional heat resistance, durability, and conductivity. It is widely used in CNC machining parts, aerospace components, medical tools, and electronics. Its high melting point and hardness make it ideal for precision applications, and it’s commonly processed by advanced CNC machining services in modern factories.

Now that we've defined tungsten metal and its general significance, let's explore its origin, physical and chemical characteristics, the different forms and types it can take, and why it plays such a vital role in the CNC machining industry. Whether you're sourcing materials or designing parts, understanding tungsten's full potential is essential to making informed engineering decisions.

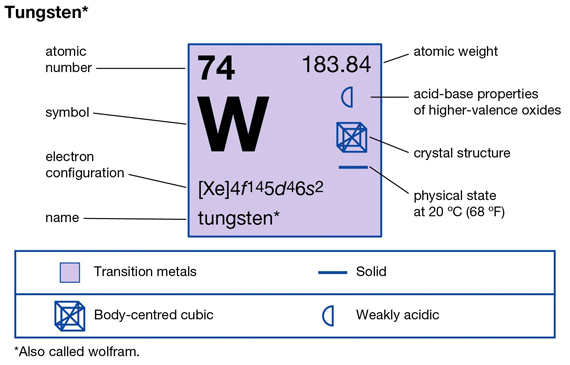

Tungsten is a rare and incredibly durable metallic element with the chemical symbol W (derived from its German name, Wolfram) and the atomic number 74. As a refractory metal, tungsten is renowned for its extremely high melting point—the highest of any metal in pure form—reaching 3,422°C (6,192°F). Its outstanding resistance to heat, wear, and corrosion makes it an ideal choice for demanding industrial environments, including aerospace, defense, electronics, and especially CNC machining.

In the context of CNC machining services, tungsten metal is often used when producing parts that require not only dimensional accuracy but also the ability to endure high thermal and mechanical stress. Because of its high density (19.25 g/cm³), nearly equivalent to gold, and excellent conductivity, tungsten is favored in the fabrication of CNC machining parts used in high-performance tools, molds, and precision devices.

Though it’s challenging to machine due to its hardness and brittleness at room temperature, tungsten metal CNC machining parts can be successfully produced using advanced CNC machining factories equipped with high-rigidity machines, coated tools, and proper cooling systems. In these facilities, careful selection of feed rates, speeds, and cutting paths ensures efficient shaping of tungsten into functional and complex components.

Tungsten is not typically found in its pure form in nature; instead, it occurs in minerals such as scheelite and wolframite. It must undergo extensive processing to be refined into usable metal. Its strategic importance and industrial applications have made tungsten a critical material on global markets—one that continues to drive innovation in CNC machining and other high-precision fields.

Tungsten metal, known by its chemical symbol W, has the atomic number 74 and belongs to Group 6 of the periodic table. Its most recognized chemical name is tungsten, but it also goes by wolfram in many European contexts—hence the symbol “W.” In its pure form, tungsten is composed of a single element with no stable naturally occurring isotopes apart from W-182, W-183, W-184, and W-186, which collectively make up nearly all of the element’s naturally found mass. The atomic weight of tungsten is approximately 183.84 u (unified atomic mass units).

Chemically, tungsten metal is highly stable and inert at room temperature. It forms compounds primarily in the +4 and +6 oxidation states, with tungsten trioxide (WO₃) and tungsten carbide (WC) being among the most widely used tungsten-based materials. These compounds are essential in the production of hard coatings, cutting tools, and high-performance CNC machining parts.

In CNC machining factories, the elemental purity and consistent composition of tungsten are crucial. Any trace elements like carbon, oxygen, or molybdenum must be tightly controlled, especially in aerospace or medical applications. The quality of tungsten metal CNC machining parts depends heavily on the purity and uniformity of the material being used.

Tungsten also bonds with carbon to form tungsten carbide (WC), a compound that is nearly twice as hard as steel and widely used in CNC machining services for making cutting tools, wear-resistant components, and mining equipment. In high-stress environments, the chemical stability of tungsten ensures that it resists oxidation, corrosion, and degradation far better than most engineering metals.

In summary, the precise chemical composition of tungsten underpins its unique physical and mechanical characteristics, making it one of the most valuable materials in advanced manufacturing—including CNC machining of precision parts.

Chemical Properties of Tungsten

Tungsten metal is highly valued in engineering and CNC machining not just for its strength, but also for its remarkable chemical stability. Its ability to maintain structural and chemical integrity under extreme conditions makes it indispensable in the production of tungsten metal CNC machining parts, especially those used in high-performance industries like aerospace, defense, and medical technology.

Resistance to Acid

Pure tungsten exhibits excellent resistance to most mineral acids under normal conditions. It is largely unaffected by hydrochloric acid, hydrofluoric acid, and even nitric acid at room temperature. This property is particularly useful in CNC machining services for producing parts intended for chemically aggressive environments. The resistance to acid extends the life of tungsten components in chemical reactors, pipelines, and laboratory equipment.

Dissolution in Mixed Acids

While tungsten is resistant to many single acids, it can dissolve in oxidizing acid mixtures, such as a combination of nitric and hydrofluoric acid. This reactivity must be considered in the post-machining cleaning or etching stages in CNC machining factories, where care is taken to avoid corrosive agents that could compromise the integrity of the material.

Reaction with Oxidants

Tungsten reacts with strong oxidizing agents at elevated temperatures. For example, it can form tungsten oxides (WO₂, WO₃) when exposed to oxidants or oxygen at high heat. This oxidation process must be tightly controlled in manufacturing and finishing environments to prevent the degradation of CNC machining parts made from tungsten.

Resistance to Alkalis

Tungsten also displays notable resistance to alkalis like sodium hydroxide and potassium hydroxide under normal conditions. However, at elevated temperatures, alkalis may slowly attack the metal. For CNC machining factories, this stability allows the use of tungsten in components exposed to both acidic and alkaline conditions without risk of rapid deterioration.

Reaction with Carbon

Tungsten readily combines with carbon at high temperatures to form tungsten carbide (WC)—a compound that significantly enhances hardness. This reaction is harnessed in CNC machining services to fabricate ultra-hard cutting tools and wear-resistant inserts that outperform conventional steel-based tools.

Combinations with Elements

Tungsten can also alloy with elements such as nickel, iron, cobalt, and copper, creating various tungsten alloys tailored for specific applications like radiation shielding or high-speed machining. These chemical combinations contribute to the versatility and demand for tungsten metal CNC machining parts across industries.

Oxidation in Air

In its pure form, tungsten is relatively stable in air at room temperature. However, it begins to oxidize slowly at around 400–500°C, forming tungsten trioxide (WO₃), which appears as a yellowish layer. For high-temperature CNC machining applications, protective coatings or inert atmospheres are often used to prevent unwanted oxidation during processing or operation.

Below is a table summarizing the chemical properties of tungsten, designed for clarity and easy reference in your CNC machining article. This table also includes references to how each property affects its use in CNC machining parts and CNC machining services.

Table: Chemical Properties of Tungsten Metal

| Property |

Description |

Relevance to CNC Machining Parts |

| Acid Resistance |

Resists most mineral acids at room temperature (e.g., HCl, HF, HNO₃). | Ideal for parts used in corrosive chemical environments. |

| Mixed Acid Dissolution |

Dissolves in oxidizing acid mixtures (e.g., HNO₃ + HF) at elevated temperatures. | Cleaning processes in CNC machining factories must avoid aggressive acids to preserve part quality. |

| Reaction with Oxidants |

Reacts with oxidizing agents (e.g., oxygen) at high temperatures, forming tungsten oxides. | Surface oxidation control is essential during high-temp applications or post-machining treatment. |

| Alkali Resistance |

Stable in alkalis under ambient conditions. | Suitable for components in mixed chemical environments. |

| Reaction with Carbon |

Forms tungsten carbide (WC) at high temps, enhancing hardness. | Used to manufacture wear-resistant CNC cutting tools and inserts. |

| Element Combinations |

Forms strong alloys with Ni, Fe, Cu, Co. | Enhances mechanical performance of tungsten-based CNC parts. |

| Oxidation in Air |

Begins oxidizing above 400–500°C, forming WO₃. | Requires protective atmosphere or coatings in high-temp machining processes. |

Here is a comprehensive table of the physical properties of tungsten metal, tailored for readers in the CNC machining industry. This table explains each property in plain language while also highlighting its significance for CNC machining parts and CNC machining services.

Table: Physical Properties of Tungsten Metal

| Property |

Description |

Relevance to CNC Machining Parts |

| Appearance |

Steel-gray to silver-white, lustrous metal | Offers a professional, high-tech look for precision-engineered components |

| Group |

Group 6 (Transition Metal) | Shares mechanical strength and heat resistance typical of transition metals |

| Melting Point |

3,422 °C (6,192 °F) — Highest of all metals | Allows CNC machining parts to withstand extreme heat without deforming or melting |

| Boiling Point |

5,930 °C (10,706 °F) | Useful for aerospace and high-temperature furnace applications |

| Atomic Number |

74 | Defines its position in the periodic table |

| Atomic Weight |

183.84 u | Important for chemical and alloying calculations |

| Density |

19.25 g/cm³ — comparable to gold and uranium | Ideal for vibration-dampening parts, counterweights, and compact designs |

| Conductivity |

Good electrical and thermal conductor | Makes it suitable for electrical contacts, heating elements, and welding electrodes |

| Modulus of Elasticity |

~400 GPa | Indicates extreme rigidity; essential for parts requiring dimensional stability under stress |

| Oxidation State |

Common states: +6, +4, +2 | Influences alloy behavior and chemical reactivity |

| Electronic Configuration |

[Xe] 4f14 5d4 6s2 | Determines bonding, conductivity, and chemical interactions |

Tungsten metal is renowned for its remarkable physical properties that make it invaluable in advanced engineering and CNC machining applications. Whether used for aerospace parts, electrical components, or specialized cutting tools, tungsten’s physical characteristics give it a clear advantage in high-performance environments. Understanding these properties helps CNC machining factories and engineers design more reliable, precise, and efficient components.

Appearance

Tungsten is a steel-gray to silver-white metal with a naturally lustrous surface. It maintains its metallic sheen under normal atmospheric conditions, making it suitable for applications where aesthetics and durability are essential. This visual characteristic is often favored in both industrial and consumer-grade CNC machining parts.

Periodic Table Group

Tungsten belongs to Group 6 of the periodic table, classifying it as a transition metal. Like others in this group, it exhibits excellent toughness, strength, and resistance to wear—key factors in the success of CNC machining services that work with demanding materials.

Melting and Boiling Points

One of tungsten’s most defining traits is its extremely high melting point—3,422°C (6,192°F), the highest of all pure metals. Its boiling point is equally impressive at 5,930°C (10,706°F). These qualities allow tungsten CNC machining parts to operate reliably in high-temperature environments like jet engines, furnaces, and power generation systems without deforming.

Atomic Number and Weight

Tungsten’s atomic number is 74, and its atomic weight is 183.84 u. These fundamental properties define its place in material science and influence how it bonds with other elements in alloy development.

Density

Tungsten has a density of 19.25 grams per cubic centimeter, which is comparable to that of gold and uranium. Its high mass makes it ideal for applications requiring compact, weight-intensive components—such as counterweights in aerospace or vibration-dampening elements in automotive CNC machining parts.

Electrical and Thermal Conductivity

Although not as conductive as copper or silver, tungsten still has good electrical and thermal conductivity. This makes it suitable for heating elements, electrical contacts, and specialized welding electrodes used in CNC machining services.

Elastic Modulus (Modulus of Elasticity)

Tungsten’s modulus of elasticity is approximately 400 GPa, indicating extremely high rigidity and resistance to deformation. This means CNC machining parts made from tungsten maintain their shape and accuracy under heavy mechanical stress—ideal for precision engineering.

Oxidation States

Tungsten exhibits several oxidation states, with +6 being the most common. This chemical versatility allows it to form a wide range of compounds and alloys, enhancing its usability in various industrial and CNC processing applications.

Electronic Configuration

Tungsten’s electronic configuration is [Xe] 4f14 5d4 6s2. This configuration is essential for understanding how the element behaves chemically and electrically, and it plays a crucial role in its high-temperature stability and conductivity.

Tungsten metal, known for its exceptional hardness and highest melting point among all pure metals, has a rich and intriguing history that reflects centuries of scientific exploration. Its discovery marked a significant turning point in metallurgy, especially in applications that would later become essential to industries relying on CNC machining parts.

The Early Clues in Wolframite and Scheelite

Long before tungsten was isolated, its mineral forms—wolframite and scheelite—were already known to miners in Europe. These heavy minerals were difficult to process and interfered with tin smelting, leading to their initial reputation as "troublesome" materials. In fact, the name "wolfram" (still used in German and on the periodic table with the symbol W) derives from the German words "wolf rahm", meaning "wolf’s foam," due to its aggressive nature in consuming tin ores.

The Isolation of Tungsten Metal

The breakthrough came in 1781 when Carl Wilhelm Scheele, a Swedish chemist, successfully identified a new acid—tungstic acid—from scheelite. Shortly after, in 1783, Juan José and Fausto Elhuyar, two Spanish brothers, isolated the element tungsten for the first time. By reducing tungsten acid with charcoal, they obtained the metal in its pure form. This remarkable discovery laid the foundation for the future development of tungsten-based alloys and industrial applications.

Naming and Adoption in Industry

The name “tungsten” is of Swedish origin and means “heavy stone,” an appropriate descriptor for its dense nature. Despite its early discovery, the metal wasn't widely used until the late 19th and early 20th centuries, when advances in metallurgy and the advent of electrical technologies revealed its full potential.

Industrial Adoption and Role in CNC Machining

Tungsten’s commercial significance grew rapidly with the invention of the tungsten filament light bulb by William Coolidge in 1909. Its durability, high melting point, and conductivity made it ideal for filaments and electrical contacts. In modern times, tungsten metal CNC machining parts are critical in aerospace, defense, electronics, and high-performance tooling industries due to these very same properties.

Today, CNC machining factories rely on tungsten for producing parts that must withstand extreme conditions, including high temperatures, abrasion, and pressure. Its discovery and subsequent industrial adoption revolutionized precision manufacturing and paved the way for innovations in CNC machining services.

The production of tungsten metal is a complex, multi-stage process that transforms naturally occurring ores into pure metal suitable for demanding industrial uses—including high-performance CNC machining parts. The process requires careful extraction, chemical refinement, and thermal treatment to achieve the exceptional hardness, density, and melting point that make tungsten indispensable in CNC machining services and other advanced manufacturing sectors.

1. Mining the Ores

Tungsten is not found as a free element in nature. It occurs mainly in the minerals wolframite (Fe,Mn)WO4 and scheelite (CaWO4)(CaWO₄)(CaWO4). These ores are extracted from both open-pit and underground mines. Major tungsten-producing countries include China (which leads global production), Russia, Vietnam, and Portugal.

After mining, the ore is crushed and concentrated using gravity separation, magnetic separation, or froth flotation, depending on the specific mineral composition. This step yields a concentrate that contains around 60–75% tungsten trioxide (WO₃).

2. Chemical Processing to Tungsten Trioxide (WO₃)

The concentrated ore undergoes chemical conversion in a multi-step hydrometallurgical process:

3. Reduction to Pure Tungsten Metal

The yellow tungsten trioxide (WO₃) is reduced to metallic tungsten powder through hydrogen reduction in high-temperature furnaces:

4. Powder Metallurgy: Sintering and Forming

Pure tungsten cannot be melted easily due to its extremely high melting point (3,422°C), so it is processed using powder metallurgy:

For applications requiring CNC machining factories to fabricate precision components, these sintered blanks are machined using specialized cutting tools due to tungsten’s extreme hardness.

5. Alloying and Final Processing

Tungsten can also be alloyed with elements like copper, nickel, or cobalt to form heavy metal tungsten alloys or with carbon to produce tungsten carbide. These materials are used to create cutting tools, electrodes, X-ray shielding, and aerospace parts—all of which are common outputs from CNC machining services.

In summary, producing tungsten metal involves a sophisticated sequence of mining, chemical conversion, reduction, and powder metallurgy techniques. The resulting material is ideal for applications that demand extreme heat resistance, wear durability, and strength—making it a preferred material in precision CNC machining and advanced industrial manufacturing.

Tungsten metal is highly versatile and is manufactured into a variety of forms to meet the needs of different industrial applications—including those in CNC machining factories. Depending on its final use, tungsten can be processed into bars, rods, plates, foils, and sheets. Each form offers unique advantages in terms of strength, shapeability, and compatibility with CNC machining services.

Here is a table summarizing the different forms of tungsten, their description, and common applications—especially relevant to CNC machining services and manufacturing industries:

| Form |

Description |

Common Applications |

| Bars |

Solid rectangular blocks; high density; used in bulk applications. | Counterweights, radiation shielding, aerospace components, CNC machined tooling. |

| Foil |

Extremely thin and flexible; retains strength and thermal stability. | Heat shielding in aerospace, semiconductors, X-ray targets, precision electronics. |

| Plate |

Flat and thick sections; excellent dimensional stability under heat/pressure. | Vacuum furnace parts, ballistic protection, molds, CNC machined dies. |

| Rod |

Cylindrical shape; uniform density; ideal for electrical and welding purposes. | TIG welding electrodes, heating elements, electric contacts, CNC turning applications. |

| Sheet |

Intermediate thickness; good strength-to-flexibility ratio. | X-ray shielding, electronics packaging, CNC-machined components in medical/defense. |

This table helps engineers, designers, and procurement specialists quickly identify the most suitable form of tungsten based on their needs—especially when sourcing tungsten metal CNC machining parts through professional CNC machining services.

Bars

Tungsten bars are solid rectangular blocks typically used in heavy-duty applications such as counterweights, radiation shielding, and aerospace components. They are manufactured via powder metallurgy, sintered to achieve high density, and can be further refined using precision CNC machining. Due to tungsten's extreme hardness and high melting point, it’s often used in bar form when mechanical stability under heat or force is essential.

Applications:

Foil

Tungsten foil is extremely thin (often microns thick) and flexible, yet retains the metal’s hallmark strength and heat resistance. It's produced by rolling tungsten sheets under high pressure and is commonly used in high-temperature furnaces, electronics, and aerospace insulation. The foil form is also ideal for applications requiring light weight and precision thickness control.

Applications:

Plate

Tungsten plates are flat, thick sections of metal that combine high density with dimensional stability. These are especially useful for high-temperature molds, vacuum furnace parts, and ballistic protection. Plates are often ground to precise tolerances and customized using CNC machining services, particularly in industries requiring superior flatness and thermal stability.

Applications:

Rod

Tungsten rods are cylindrical and come in various diameters and lengths, often used in welding electrodes, electric contacts, and heating elements. They can be either sintered or swaged (hot-worked) for enhanced strength and grain structure. Due to their shape and uniform density, tungsten rods are also a favored raw material in tungsten metal CNC machining parts production.

Applications:

Sheet

Tungsten sheets are intermediate between foil and plate in thickness, offering a good balance of flexibility and strength. They’re produced by rolling sintered billets and are used in applications where heat resistance and minimal deformation are critical. Tungsten sheets can be precisely cut and shaped using CNC machining, making them suitable for precision components in medical, defense, and electronics sectors.

Applications:

Each of these tungsten forms serves specific roles across a wide range of industries—from medical imaging and aerospace insulation to precision CNC machining parts. Their adaptability, combined with tungsten’s innate thermal and mechanical strength, makes them invaluable to modern manufacturing.

Tungsten is rarely used in its pure form for industrial purposes. Instead, it is commonly alloyed with other elements to enhance its machinability, hardness, toughness, and heat resistance. These tungsten-based alloys are vital in industries such as aerospace, defense, medical, and heavy machinery—especially for CNC machining parts that require high durability and performance under extreme conditions.

Here is a clear and organized table summarizing the different types of tungsten alloys, their properties, uses, and related CNC machining aspects:

| Type of Tungsten Alloy | Introduction |

Key Properties |

Major Uses |

CNC Machining Notes |

| Tungsten Carbide |

Compound of tungsten and carbon; extremely hard material | Very high hardness, wear-resistant, high melting point, brittle | Cutting tools, drills, mining machinery, CNC inserts | Requires specialized CNC machining due to brittleness |

| Cemented Carbide |

Composite of tungsten carbide particles with cobalt binder | Tougher than pure carbide, impact resistant, heat and corrosion resistant | Milling inserts, dies, aerospace tooling, oil/gas parts | Machined with precision CNC tools for durability |

| Tungsten Alloys |

Tungsten combined with metals like nickel, iron, copper | High density, corrosion resistant, good machinability | Aerospace parts, radiation shielding, balancing weights | Suitable for complex CNC parts needing high density |

| Heavy Metal Tungsten Alloys |

High-density tungsten alloys with nickel, iron, or copper | Non-toxic lead alternatives, dense, strong | Counterweights, vibration dampeners, military applications | Machinable with CNC for precision and strength |

| Pure Tungsten |

Nearly pure tungsten, very brittle | Very high melting point, brittle, difficult to machine | Filaments, heating elements, electron emitters | Requires expert CNC machining for fine tolerances |

| Tungsten-Based Chemicals |

Tungsten compounds used in chemical industries | Various chemical forms like oxides and chlorides | Catalysts, pigments, semiconductor manufacturing | Not directly related to CNC machining parts |

This table captures the essential aspects of tungsten alloys relevant for tungsten metal CNC machining parts and their applications in industry.

Tungsten Carbide

Tungsten carbide is one of the most well-known tungsten alloys. It is a compound formed by combining tungsten with carbon atoms, resulting in an extremely hard and wear-resistant material.

Manufacturing of Tungsten Carbide

Tungsten powder is mixed with carbon powder and heated in a hydrogen atmosphere at high temperatures to produce tungsten carbide (WC). The resulting powder is then pressed into shapes and sintered to create dense, solid parts.

Properties of Tungsten Carbide

Major Uses of Tungsten Carbide

Health Problems Related to Tungsten

Prolonged exposure to tungsten carbide dust may cause respiratory problems such as hard-metal lung disease. Adequate industrial hygiene and protective equipment are essential.

Cemented Carbide

Cemented carbide is a composite material made by mixing tungsten carbide particles with a metallic binder, commonly cobalt. It’s a subset of tungsten carbide but designed for greater toughness and versatility.

Composition of Cemented Carbide

Properties of Cemented Carbide

Major Uses of Cemented Carbide

Tungsten Alloys

Tungsten alloys are created by combining tungsten with metals like nickel, iron, or copper to improve ductility and machinability while retaining high density and thermal resistance.

Properties of Tungsten Alloys

Uses of Tungsten Alloys

Heavy Metal Tungsten Alloys

These are specialized high-density alloys, typically composed of 90–98% tungsten with small amounts of nickel, iron, or copper. They are non-toxic alternatives to lead in applications like counterweights, vibration dampeners, and radiation shielding. Their machinability and strength make them ideal for precision CNC machining services.

Pure Tungsten

While difficult to machine due to its brittleness, pure tungsten is used in environments requiring extremely high temperatures, such as filaments, heating elements, and electron emitters. Advanced CNC machining factories can process pure tungsten into fine-tolerance parts, especially for electronics and aerospace applications.

Tungsten-Based Chemicals

Tungsten also forms compounds used in catalysts, pigments, and corrosion inhibitors. Common examples include:

These chemicals are crucial in semiconductor manufacturing, industrial coatings, and chemical processing.

Together, these tungsten alloys form the backbone of many modern technologies, especially when precision and endurance are critical. Their integration into CNC machining parts through expert CNC machining services supports everything from cutting tools to aerospace shielding.

Applications of Tungsten Metal

Tungsten metal is highly valued across multiple industries due to its unique combination of physical and chemical properties. Its high density, exceptional hardness, corrosion resistance, and extremely high melting point make it an ideal material for a wide variety of applications, especially in demanding environments. In CNC machining services, tungsten metal CNC machining parts are crafted precisely to meet these application requirements.

Here is a table summarizing the Applications of Tungsten with clear categories and descriptions:

| Application Area |

Description |

| Electronics |

Used for electrical contacts, filaments, and X-ray tubes due to excellent conductivity and heat resistance. |

| Alloys |

Tungsten alloys with nickel, iron, cobalt used in aerospace and defense for strength and wear resistance. |

| Fusion Energy |

Plasma-facing materials in fusion reactors for heat and radiation resistance. |

| Medical Applications |

X-ray shielding, radiation therapy devices, surgical tools, and implants requiring biocompatibility. |

| Nanowires |

Used in nanotechnology for electronic devices and sensors with superior electrical and mechanical properties. |

| Aerospace and Defense |

Armor-piercing ammunition, radiation shielding, counterweights, and vibration damping parts. |

| Chemical Applications |

Catalysts and chemical manufacturing components resistant to corrosion and high temperatures. |

| Jewelry |

Rings, watches, and accessories valued for hardness and scratch resistance. |

| Welding |

Tungsten electrodes in TIG welding for stable arcs and durable welds. |

| Cutting Tools and Drills |

Tungsten carbide tools used in machining for precision and long tool life. |

| Lighting Industry |

Filaments for incandescent and halogen bulbs operating at high temperatures. |

| Electrical and Electronic Equipment |

Heating elements, electrical contacts, and X-ray tubes needing heat stability and conductivity. |

| Automotive |

Engine parts, lighting components, counterweights improving vehicle performance and balance. |

| Sports Equipment |

High-performance snowboarding gear, fitness accessories using tungsten for strength and weight distribution. |

Electronics

Tungsten plays a critical role in the electronics industry, where it is used to manufacture electrical contacts, filaments, and X-ray tubes. Its excellent electrical conductivity combined with resistance to high temperatures makes tungsten indispensable in components that must withstand electrical arcing and heat without degrading.

Alloys

Tungsten is often alloyed with other metals such as nickel, iron, and cobalt to create tungsten alloys with enhanced properties. These alloys are commonly used in aerospace and defense applications where high strength, wear resistance, and density are crucial. Tungsten alloys contribute to the performance and durability of parts that endure extreme mechanical and thermal stress.

Fusion Energy

In the emerging field of fusion energy, tungsten is prized for its ability to withstand intense heat and neutron radiation inside fusion reactors. Tungsten components serve as plasma-facing materials, protecting reactor walls and improving operational safety.

Medical Applications

Tungsten’s high density makes it ideal for medical uses, particularly in X-ray shielding and radiation therapy devices. Additionally, tungsten components are machined into surgical devices and implants that require biocompatibility and wear resistance, enhancing patient safety and treatment effectiveness.

Nanowires

Advanced research and nanotechnology utilize tungsten nanowires for electronic devices and sensors. Their superior mechanical and electrical properties allow for miniaturization and improved device performance.

Aerospace and Defense

Tungsten’s extreme hardness and density make it a prime material for armor-piercing projectiles and radiation shielding in military applications. Its weight and strength also make it valuable in aerospace engineering, especially for counterweights and vibration damping components.

Chemical Applications

Tungsten compounds are used in catalysts and chemical manufacturing processes. Their resistance to corrosion and high temperatures ensures longevity and efficiency in harsh chemical environments.

Jewelry

Tungsten’s unique properties have made it popular in the jewelry industry for rings, watches, and other accessories. Its hardness resists scratches, maintaining the appearance and durability of fine jewelry.

Welding

In welding technology, tungsten electrodes are standard for TIG welding due to their high melting point and excellent conductivity, ensuring stable arcs and quality welds.

Cutting Tools and Drills

Tungsten carbide is widely used in cutting tools and drills, especially in CNC machining factories where precision and tool longevity are critical. Its hardness allows for machining of tough materials with minimal tool wear.

Lighting Industry

Tungsten filaments are used in incandescent and halogen light bulbs, benefiting from their ability to operate at high temperatures without melting.

Electrical and Electronic Equipment

Beyond contacts and tubes, tungsten components serve as heating elements in various industrial and consumer devices, leveraging their stability and heat resistance.

Automotive

In automotive manufacturing, tungsten parts such as engine components, lighting elements, and counterweights contribute to vehicle performance, balance, and durability.

Sports Equipment

Tungsten’s density and strength are used in manufacturing high-performance sports equipment including snowboarding gear and fitness accessories, improving balance, durability, and overall effectiveness.

In summary, tungsten’s versatility and superior properties enable its widespread use in fields ranging from electronics to aerospace. CNC machining services rely on tungsten metal CNC machining parts to meet the precise demands of these applications, ensuring optimal performance and reliability.

Tungsten is renowned for its exceptional physical and chemical properties, making it a highly valuable metal in many industrial and technological fields. However, like any material, tungsten has both advantages and disadvantages that influence its selection for specific applications, including CNC machining parts. Understanding these characteristics helps engineers and manufacturers make informed decisions when working with tungsten metal CNC machining parts and related CNC machining services.

Here’s a table summarizing the advantages and disadvantages of tungsten:

| Aspect |

Advantages |

Disadvantages |

| High Temperature Stability |

Highest melting point (~3422°C), maintains strength under extreme heat | — |

| Density and Weight |

Very dense, useful for counterweights, radiation shielding, and ballast | High density leads to heavy weight |

| Conductivity & Inertness |

Good electrical conductivity combined with chemical inertness | — |

| Corrosion Resistance |

Resistant to acids, alkalis, and oxidation | — |

| Mechanical Properties |

Hard material suitable for cutting tools and wear-resistant parts | Hard and brittle; difficult to machine and prone to fracture under impact |

| Applications |

Ideal for aerospace, electronics, medical devices, and heavy-duty tools | Weight can be a drawback in lightweight applications |

Advantages of Tungsten

One of tungsten’s most significant advantages is its high temperature stability. Tungsten has the highest melting point of all metals, at approximately 3422°C (6192°F), allowing it to maintain strength and integrity even under extreme heat. This makes it ideal for applications such as aerospace components, lighting filaments, and cutting tools where high heat resistance is crucial.

Tungsten also boasts a high density and weight, which can be advantageous for applications requiring heavy, compact materials, such as counterweights, ballast, and radiation shielding. This density contributes to tungsten’s ability to provide effective protection and stability in these uses.

Another key benefit is its excellent combination of electrical conductivity and chemical inertness. Tungsten conducts electricity well while resisting corrosion, oxidation, and chemical reactions in many environments, making it valuable in electronics and electrical contacts.

Additionally, tungsten offers high corrosion resistance, especially against acids and alkalis, which prolongs the lifespan of tungsten metal CNC machining parts in harsh chemical environments. This property is crucial for tools and components exposed to corrosive substances.

Disadvantages of Tungsten

Despite its many strengths, tungsten is known to be hard and brittle. Its hardness makes machining and forming more challenging, often requiring specialized CNC machining services and equipment in CNC machining factories. This brittleness also means tungsten components can fracture under sudden impacts or stress, limiting their use in dynamic or shock-loaded applications.

Furthermore, tungsten’s high density means it is very heavy, which can be a disadvantage in applications where weight savings are critical, such as in certain automotive or aerospace parts. The extra weight can add to the overall mass and affect performance or fuel efficiency.

Table: Tungsten vs. Tungsten Carbide: Key Differences

Here's a comparison table highlighting the key differences between tungsten and tungsten carbide:

| Feature |

Tungsten (Pure Metal) |

Tungsten Carbide (Compound) |

| Composition |

Pure tungsten metal (chemical element W) | Compound of tungsten and carbon (WC) |

| Hardness |

Very hard but less than tungsten carbide | Extremely hard and wear-resistant |

| Brittleness |

Tougher, less brittle | More brittle, prone to chipping |

| Melting Point |

Very high (~3422°C) | Lower than pure tungsten (~2870°C) due to compound |

| Density |

High (~19.25 g/cm³) | Slightly less dense due to compound structure |

| Machinability |

Difficult to machine due to hardness | Very difficult to machine, requires specialized tools |

| Applications |

High-temperature uses, radiation shielding, heavy metal parts | Cutting tools, drills, wear-resistant CNC machining parts |

| Corrosion Resistance |

Excellent | Good, but depends on binder materials like cobalt |

| Electrical Conductivity |

Good | Lower than pure tungsten |

| Typical Use in CNC Machining |

Tungsten metal CNC machining parts used for strength and heat resistance | Tungsten carbide CNC machining parts used for cutting and tooling due to hardness |

Tungsten is a pure chemical element, known for its exceptional hardness, high melting point, and density. It is a heavy metal with excellent thermal and electrical conductivity. In CNC machining, tungsten metal parts are valued for their strength and durability, especially in applications requiring high temperature resistance and corrosion resistance.

Tungsten carbide, on the other hand, is a composite material made by combining tungsten with carbon atoms to form tungsten carbide (WC). This compound is synthesized through a sintering process, where tungsten powder is mixed with carbon and other binders such as cobalt, then heated to produce an extremely hard and wear-resistant material. Tungsten carbide is much harder and more brittle than pure tungsten and is widely used in cutting tools, drills, and wear-resistant parts.

Key distinctions include:

In summary, tungsten carbide combines tungsten’s strength with enhanced hardness from carbon, resulting in a material optimized for demanding machining and tooling applications, whereas tungsten metal serves broader industrial uses where toughness and temperature resistance are critical.

Conclusion: Tungsten's Versatility

Tungsten stands out as a remarkable metal with exceptional physical and chemical properties that make it indispensable in modern industries. Its high melting point, outstanding hardness, excellent corrosion resistance, and unique conductivity enable it to perform in extreme environments where many other materials fail. Whether in pure metal form or as tungsten carbide alloys, tungsten’s applications span a vast range—from aerospace components and medical devices to cutting tools and electronics.

In the realm of CNC machining, tungsten metal and tungsten carbide parts are highly valued for their precision, durability, and ability to withstand demanding operational conditions. CNC machining services and factories that specialize in tungsten parts ensure that manufacturers across industries can leverage its benefits to create high-quality, reliable products.

Despite its advantages, tungsten’s hardness and density pose machining challenges, requiring specialized equipment and expertise. However, these factors only highlight the metal’s superior strength and suitability for advanced applications.

Overall, tungsten’s versatility, combined with its adaptability in various forms and alloys, secures its place as a critical material in cutting-edge manufacturing and technology. Understanding tungsten’s properties and uses helps businesses and engineers make informed decisions when selecting materials for CNC machining parts, ensuring optimal performance and longevity in their projects.

Does tungsten rust?

Tungsten does not rust like iron or steel because it is highly resistant to corrosion. It forms a thin protective oxide layer on its surface that prevents further oxidation, making it very durable in most environments.

What is the difference between titanium and tungsten?

Titanium is lighter and more flexible than tungsten, which is much denser and harder. Tungsten has a higher melting point and is more brittle, while titanium is prized for its strength-to-weight ratio and corrosion resistance.

What are the uses of tungsten metal?

Tungsten is widely used in electronics, aerospace, medical devices, cutting tools, lighting filaments, and heavy metal alloys. Its high melting point and durability make it ideal for applications requiring extreme heat and wear resistance.

Is tungsten an expensive metal?

Tungsten is moderately expensive due to its rarity and complex extraction process, but it is generally less costly than precious metals like gold or platinum. Its value comes from its unique properties and industrial demand.

Is tungsten stronger than titanium?

In terms of hardness and density, tungsten is stronger and harder than titanium. However, titanium is more flexible and has better resistance to fatigue and corrosion.

Is tungsten stronger than steel?

Tungsten is much harder and denser than most steels, offering superior wear resistance. However, steel can be tougher and more ductile, depending on the alloy.

Is tungsten a good metal to wear?

Yes, tungsten is popular in jewelry, especially in rings and watches, due to its scratch resistance and weight. However, it is brittle and can crack if dropped hard.

What makes tungsten so special?

Tungsten’s extremely high melting point, density, hardness, and resistance to corrosion and heat make it unique among metals, suitable for demanding industrial and technological uses.

What is tungsten useful for?

Tungsten is useful for manufacturing cutting tools, electrical contacts, heating elements, armor-piercing ammunition, radiation shielding, and components in aerospace and medical equipment.

Which country produces the most tungsten in the world?

China is the largest producer of tungsten globally, supplying over 80% of the world’s tungsten production.

Does China have tungsten?

Yes, China has vast tungsten reserves and is the leading producer and exporter of tungsten metal and alloys.

Is tungsten stronger than diamond?

While tungsten is extremely hard and dense, diamond is harder in terms of scratch resistance. However, tungsten is tougher and less brittle compared to diamond.

What is the life span of tungsten?

Tungsten products, especially when machined for industrial use, can last decades due to their exceptional durability and resistance to wear and corrosion.