15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

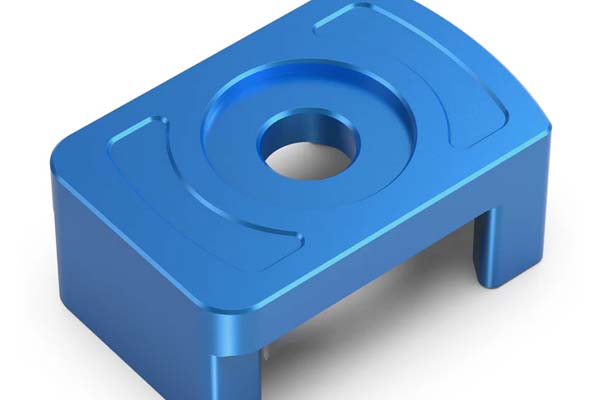

| Custom Precision CNC Aluminum Alloy Engine Motor Mount Insert Bracket Machining Parts - OEM ODM CNC Milling Services Manufacturer - China VMT |

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Machining Services

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete CNC machining and delivery of CNC aluminum alloy engine motor mount insert bracket prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Surface Treatment |

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Material |

||

|

Our own material library can provide you with special materials such as stainless steel, brass, copper, aluminum, etc., with material testing reports attached. There are professional CNC aluminum alloy engine motor mount insert bracket machining project engineers to choose the right materials for you. |

We can provide a variety of surface treatment services based on your Custom CNC aluminum alloy engine motor mount insert bracket machining project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

| Still selecting materials for your custom CNC machined metal CNC aluminum alloy engine motor mount insert bracket? Different materials have different properties, and you can customize the CNC aluminum alloy engine motor mount insert bracket to your liking. Here are some common materials used in manufacturing metal CNC aluminum alloy engine motor mount insert bracket: |

|

|

|

||

|

|

|

12 Quality Inspection Processes

| Refined production standards, providing you with precision parts with a pass rate of up to 98% |

|

|

|

|

||

| DFM Analysis | Dimensional Tolerance | Material Testing | ||

|

|

|

|

||

| CNC Machining | FQC detection | SPC / CKP | ||

|

|

|

|

||

| Problem Found | Problem Solving | OQC Detection | ||

|

|

|

|

||

| Surface Treatment | Full Inspection | Package |

| The following is the manufacturing process of customized CNC machined metal CNC aluminum alloy engine motor mount insert bracket. Due to the need to protect the rights and interests of customers, the following picture is not the manufacturing process of this part and is for reference only: |

|

|

|

||

| DFM Analysis | Material | CNC Machining | ||

|

|

|

|

||

| Surface Treatment | Quality Inspection | Package |

|

Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Machining Quality Assurance

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC machining work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Aluminum Alloy Engine Motor Mount Insert Bracket Machining FAQs

|

What materials are used for the CNC aluminum alloy engine motor mount insert brackets?

Our engine motor mount insert brackets are machined from high-quality aluminum alloys, typically 6061 or 7075. These alloys offer a combination of strength, durability, and lightweight properties, making them ideal for engine mount applications.

What is the primary function of the engine motor mount insert bracket?

The engine motor mount insert bracket is designed to provide additional support and stability to the engine mount system. It helps reduce vibration, improves the alignment of the engine, and enhances overall performance, particularly in high-performance and racing applications.

How do I know if this CNC aluminum engine motor mount insert bracket is compatible with my vehicle?

Compatibility depends on the make, model, and engine specifications of your vehicle. We offer both universal and custom-engineered options. If you need a custom solution, we can machine a bracket that meets your exact specifications. Please provide your vehicle’s details when placing an order.

Can I install the CNC aluminum engine motor mount insert bracket myself?

Yes, installation is generally straightforward for individuals with basic mechanical skills. However, it may require specific tools, such as a torque wrench, to ensure proper fitment and tightening. For optimal results, we recommend professional installation, especially if you’re unfamiliar with engine mounting systems.

What are the benefits of using a CNC machined aluminum alloy engine motor mount insert bracket?

CNC machining ensures precise manufacturing, leading to better fitment and improved reliability. The aluminum alloy provides superior strength while remaining lightweight, which can help reduce overall vehicle weight. Additionally, CNC machining allows for more intricate designs, leading to better performance in harsh driving conditions.

What are the advantages of using aluminum alloy over other materials for engine motor mount brackets?

Aluminum alloys are favored for their excellent combination of strength, weight, and corrosion resistance. Compared to steel, aluminum is much lighter, which can help improve vehicle performance by reducing overall weight. Additionally, aluminum alloys are more resistant to rust and environmental wear, making them more durable in various climates.

How can I maintain the CNC aluminum engine motor mount insert bracket?

To ensure longevity and optimal performance, it’s essential to regularly inspect the bracket for any signs of wear, cracks, or damage. Cleaning with a mild detergent and water will help prevent dirt and grime buildup. Avoid using harsh chemicals or abrasive cleaning agents, as they may damage the surface. If necessary, reapply any protective coatings (e.g., anodizing) to maintain corrosion resistance.

Can I get a custom-designed CNC aluminum motor mount insert bracket for my specific needs?

Yes, we offer custom CNC machining services. If you have specific requirements, such as unique mounting configurations or design considerations, we can work with you to create a bracket that fits your exact needs. Simply provide us with the specifications or a CAD file of the design, and we will tailor the solution to meet your demands.

What finishes are available for the CNC aluminum engine motor mount insert bracket?

Our CNC aluminum motor mount insert brackets can be finished in a variety of ways to enhance durability and aesthetics. Common finishes include anodizing (which adds corrosion resistance and can be colored), bead blasting (for a matte surface), and polishing (for a shiny, smooth finish). If you have a preference, please let us know when placing your order.

What is the lead time for CNC aluminum engine motor mount insert bracket machining?

The lead time can vary depending on factors such as the complexity of the design, current workload, and customization requirements. Generally, the process takes between 5 to 15 business days. For custom orders or larger quantities, lead times may be longer. We recommend discussing your project in advance to confirm delivery expectations.

Can CNC aluminum engine motor mount insert brackets be used in high-performance applications like racing or off-road vehicles?

Yes, CNC aluminum engine motor mount insert brackets are ideal for high-performance applications due to their lightweight yet durable properties. They help improve engine alignment, reduce vibrations, and contribute to the overall stability of the vehicle. This makes them a great choice for motorsports, off-road, and other high-stress driving environments.

Are the CNC aluminum engine motor mount insert brackets heat resistant?

Yes, aluminum alloys used for CNC machining can withstand high temperatures typically found in engine environments. However, for extreme temperature conditions (e.g., motorsport engines), we can recommend specific alloys or treatments that further enhance heat resistance and performance under high thermal stress.

How do I ensure that my CNC aluminum motor mount insert bracket is properly fitted to my vehicle?

For the best fit, we encourage customers to provide as much detail as possible, including the vehicle make, model, year, and any other pertinent measurements. If you’re unsure about fitment, our team can help verify compatibility, or we can offer a custom design that meets your specific requirements.

Is there a warranty for the CNC aluminum engine motor mount insert bracket?

Yes, we offer a warranty on all CNC machined parts. The warranty typically covers defects in materials and workmanship. It does not cover damage resulting from improper installation or misuse. Please refer to our warranty policy for complete details or contact us directly for more information.

Are CNC aluminum motor mount insert brackets available in different sizes?

Yes, we offer CNC aluminum motor mount insert brackets in various sizes to fit a wide range of vehicles. If you require a specific size or configuration, we can work with you to ensure the bracket meets your exact needs. Custom machining is available for non-standard sizes and applications. |

| We hope these CNC metal CNC aluminum alloy engine motor mount insert bracket faqs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you build the perfect custom CNC aluminum alloy engine motor mount insert bracket just for you. |

Contact Us

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.