15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

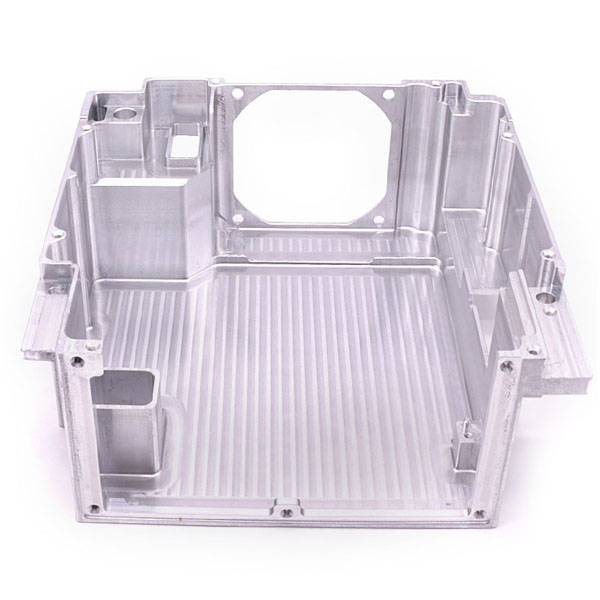

Custom High Quality Metal Aluminum CNC Milling Parts Service

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom Aluminum CNC Milling Parts Services Manufacturer in China

| The success of china custom aluminum CNC machining parts lies in the attention to detail and precision during the CNC prototyping machining, surface treatment, and material selection processes. Manufacturers that prioritize these aspects can deliver high-quality components that meet the exact specifications and performance requirements of their clients. |

Custom Aluminum CNC Milling Parts Prototyping Machining

CNC prototyping is the initial stage of the manufacturing process that turns ideas and designs into tangible prototypes. Engineers and designers are able to validate and refine their concepts before going to full production. CNC prototyping uncovers design flaws, reducing costly mistakes and improving the overall efficiency of the production process. |

|

|

|

|

||

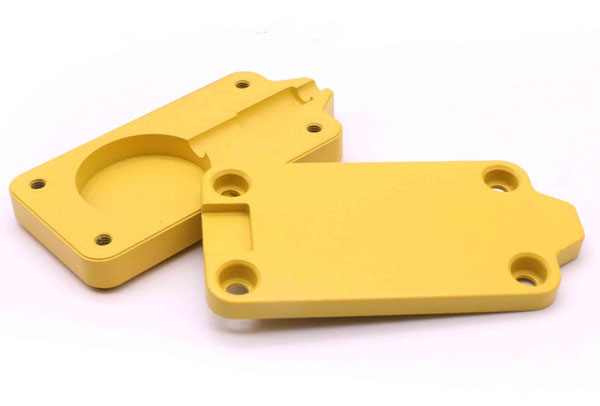

Custom Aluminum CNC Milling Parts Surface Treatment |

Custom Aluminum CNC Milling Parts Material |

||

|

We can customize different surface effects according to the specific requirements of customers, and different surface treatments have unique advantages. The choice of surface treatment depends on the specific functional and aesthetic requirements of custom aluminum CNC machined parts, ensuring they meet the required standards for the intended application. |

There are a variety of aluminum alloys to choose from, each with unique properties for specific applications. Proper selection of aluminum alloys ensures that custom aluminum CNC machined parts will have the desired properties and will meet the demands of their intended application. |

Custom Aluminum CNC Milling Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| In the world of custom aluminum CNC milled parts, material selection plays a vital role in determining the performance, durability and functionality of the component. Aluminum is a versatile metal with a variety of alloy options, making it the first choice for CNC milling due to its exceptional properties. The following are commonly used aluminum alloy materials: |

|

|

6061 Aluminum Alloy

Applications: 6061 aluminum is one of the most widely used alloys in CNC milling. Its excellent machinability and weldability make it suitable for a wide range of applications, including: Aerospace components

|

|

|

|

7075 Aluminum Alloy

Applications: Known for its high strength and toughness, 7075 aluminum is often used in CNC milling for applications that demand superior mechanical properties, such as: Aircraft and aerospace parts

|

|

|

|

5052 Aluminum Alloy

Applications: 5052 aluminum is commonly utilized in CNC milling for components that require excellent corrosion resistance, such as: Marine components

|

|

|

|

6082 Aluminum Alloy

Applications: 6082 aluminum is favored in CNC milling for its versatility and performance in various applications, including: Structural components

|

|

|

|

2024 Aluminum Alloy

Applications: 2024 aluminum is commonly used in CNC milling for aerospace and structural applications, including: Aircraft fittings

|

|

、

|

|

5083 Aluminum Alloy

Applications: 5083 aluminum is widely used in CNC milling for components intended for marine and underwater environments, such as: Boat hulls and structures

|

|

| The choice of the right aluminum alloy is critical in achieving the desired performance and quality for custom CNC milling parts. Each aluminum alloy brings its unique set of properties, enabling manufacturers to cater to a wide range of applications across diverse industries. By carefully considering the specific requirements of each project, manufacturers can deliver custom aluminum CNC milling parts that meet the highest standards of precision and reliability. |

|

In the world of custom aluminum CNC milled parts, surface treatment plays a vital role in enhancing the functionality, durability and aesthetics of the part. These treatments provide additional protection against environmental elements and improve the overall performance of the part. The following are common surface treatments for custom aluminum CNC milled parts: |

|

1. Anodizing

Anodizing: Anodizing improves corrosion resistance, makes aluminum CNC milled parts suitable for challenging environments, increases surface hardness, and increases component durability. Available in a variety of colors, with a non-conductive finish, anodized is ideal for electronic applications. |

|

|

2. Powder Coating

Powder Coating: Powder coating results in a smooth, even and durable finish. Excellent impact, chemical and UV resistance for extended life of aluminum CNC milled parts. Multiple color options and finishes allow for customization and branding. Environmentally friendly process with minimal waste and VOC emissions.

Application: Powder coating is commonly used on custom aluminum CNC milled parts in industries such as automotive, construction and outdoor equipment. |

|

|

|

3. Painting

Painting: Painting involves applying liquid paint to the surface of an aluminum part. It is a versatile finish that provides protection and decorative appeal. Protects against corrosion and environmental elements. A variety of colors and finishes can be customized to meet specific design requirements. Cost-effective compared to other surface treatments.

Application: Painting custom aluminum CNC milled parts for a variety of industries including consumer electronics, appliances and signage. |

|

|

|

4. Brushing

Brushing: Brushing is a mechanical surface treatment that creates a brushed or satin finish on aluminum parts. It involves using abrasive materials to create parallel lines on the surface.Attractive and visually appealing surface finish.Hides fingerprints, scratches, and minor imperfections effectively.Suitable for decorative parts and applications where aesthetics are essential.

Applications: Brushing is commonly used in architectural and decorative applications for custom aluminum CNC milling parts. |

|

|

|

5. Polishing

Polishing: Polishing is a mechanical surface treatment that results in a smooth and reflective finish on aluminum parts. It involves using abrasives to remove material and achieve a lustrous appearance.Provides a mirror-like finish, adding a touch of sophistication to the components.Enhances the appearance and aesthetic value of the parts.Reduces surface roughness, which can be beneficial in certain applications.

Applications: Polishing is utilized in various industries, including automotive, marine, and consumer goods, for custom aluminum CNC milling parts that require a high-end finish. |

|

|

|

|

|

The choice of surface treatment for custom aluminum CNC milling parts depends on the specific requirements of the components, such as their intended application, environmental conditions, and design considerations. Manufacturers work closely with clients to determine the most suitable surface treatment to ensure the parts meet the desired standards of functionality, aesthetics, and durability.

|

| The manufacturing process of custom aluminum CNC milled parts involves multiple steps, each of which contributes to the precision and quality of the final part. Following are the key stages of the CNC milling process for custom aluminum parts: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with the conceptualization and design phase. Clients work closely with engineers and designers to communicate their requirements and specifications. CADsoftware is used to create detailed 3D models of the custom aluminum CNC parts. During this stage, factors such as dimensions, tolerances, and material selection are carefully considered. |

|

2. Material Selection

Material selection: High-quality aluminum stock material is selected based on the design specifications. The aluminum blocks or sheets are carefully inspected for any defects or impurities before being clamped securely onto the CNC milling machine's worktable. |

|

3. CNC Machining

CNC machining: After the material is selected, a CNC milling machine is used to remove excess material from the aluminum billet. During CNC milling, the machine rotates the cutting tool at high speed while moving along multiple axes (X, Y, and Z) simultaneously to achieve the desired shape and size of a custom aluminum CNC machined part until it reaches its final size and surface finish. |

|

4. Quality Control

Quality Control: Throughout the CNC milling process, rigorous quality control measures are implemented to ensure the components meet the required specifications. Skilled operators and quality inspectors perform inspections using precision measurement tools to verify dimensional accuracy and surface finish. |

|

Surface Treatments: After the CNC milling process is complete, the custom aluminum CNC machining parts may undergo surface treatments to enhance their properties and appearance. Common surface treatments include anodizing, powder coating, painting, brushing, or polishing, as mentioned in the previous section. |

|

6. Final Inspection and Finishing

Final Inspection and Finishing: Before the parts are ready for delivery, they undergo a final inspection to ensure they meet all quality standards and specifications. Any necessary finishing touches are applied to the aluminum CNC machining parts to address any minor imperfections and ensure they are visually appealing and ready for use. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: Once the custom aluminum CNC milling parts pass the final inspection, they are carefully packaged to prevent damage during transportation. They are then delivered to the client, ready to be integrated into their respective applications. |

| The manufacturing process for custom aluminum CNC milling parts relies on advanced technology, skilled craftsmanship, and strict quality control to produce components that meet the highest standards of precision, functionality, and durability. By following this comprehensive process, manufacturers can deliver custom aluminum CNC machining parts that fulfill the unique requirements of their clients across various industries. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Aluminum CNC Milling Parts FAQs

|

Q: What are custom aluminum CNC milling parts?

Q: Which industries commonly use custom aluminum CNC milling parts?

Q: What are the advantages of using aluminum for CNC milling parts?

Q: How precise are custom aluminum CNC milling parts?

Q: What is the typical lead time for manufacturing custom aluminum CNC milling parts?

Q: Can custom aluminum CNC milling parts be produced in large quantities?

Q: What surface treatments are available for custom aluminum CNC milling parts?

Q: Can custom aluminum CNC milling parts be used in harsh environments?

Q: How are design changes accommodated for custom aluminum CNC milling parts?

Q: What is the typical lifespan of custom aluminum CNC milling parts?

Q: Can custom aluminum CNC milling parts be recycled?

|

| These frequently asked questions provide valuable insights into the world of custom aluminum CNC milling parts, highlighting their benefits, applications, and production process. Manufacturers and clients can use this knowledge to make informed decisions when creating high-quality and tailor-made aluminum CNC machining components for diverse industries.If you have any other questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.