15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

Professional 7050 Aluminum CNC Machined Parts Factory

24-hour CNC machining, samples can be provided within 7-10 days

As a professional manufacturer specializing in custom 7050 aluminu, we delifull-process support—from material selection and engineering optimization to precision machinin.

Our expertise in machining 7050 aluminum allows us to solve your toughest challenges, including tight-tolerance requirements, complex geometries, structural strength demands, lightweight design needs, and fast turnaround expectations. Whether you need prototypes, small batches, or large-volume production, we ensure exceptional dimensional accuracy, outstanding mechanical performance, and consistent quality.

By choosing us, you gain a reliable partner committed to helping you accelerate product development, reduce production risks, and achieve superior performance in every 7050 aluminum CNC machined component.

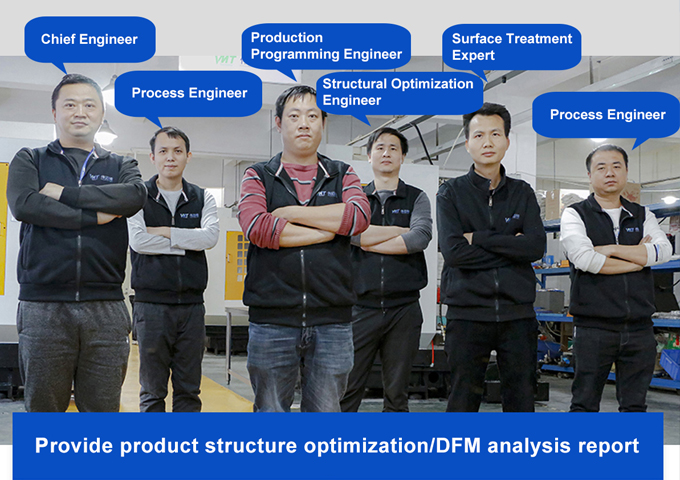

6 Project Engineers With 20 Years Of Experience

Custom Prototypes and High-Volume CNC-Machined 7050 Aluminum parts

As a professional factory specializing in custom prototype and mass-production 7050 aluminum CNC machining parts, we combine advanced equipment, engineering expertise, and strict quality management to deliver reliable, high-performance solutions. Equipped with 120+ CNC machining centers, ±0.005 mm tolerance capability, and a 98.7% on-time delivery rate, we help customers turn complex 7050 aluminum designs into precision-built components with speed and consistency.

We understand the common pain points customers face—material deformation, tight-tolerance failures, slow lead times, inconsistent quality, and difficulty machining high-strength aluminum alloys. Our engineering team tackles these issues through DFM optimization, high-rigidity fixturing, real-time process monitoring, and aerospace-grade inspection standards, ensuring every part meets its functional requirements.

Whether you need 1–10 prototype samples within 3–5 days or 5,000+ mass-production parts with stable repeatability, we provide end-to-end support covering machining, surface finishing, assembly, and testing. By choosing us, you gain a manufacturing partner capable of delivering strong, lightweight, and dimensionally accurate 7050 aluminum parts—faster, more reliably, and at scale.

Customized 7050 Aluminum CNC Machining Process

7050 aluminum alloy boasts high strength, good machinability, and excellent mechanical properties. VMT can provide various CNC machining and metalworking techniques to manufacture parts. Common processing methods include:

3 Axis CNC Milling

Extrusion Machining

CNC Laser Cutting

CNC Turn-Mill Combination Machining

Forging Machining

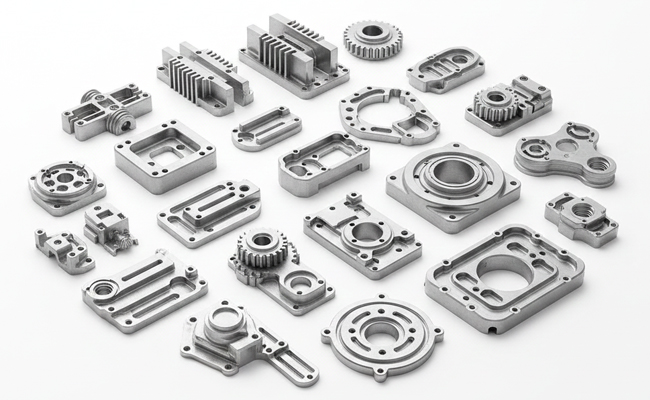

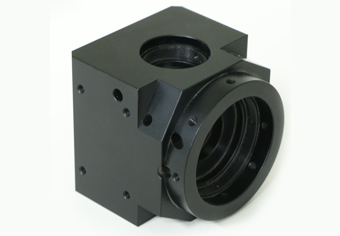

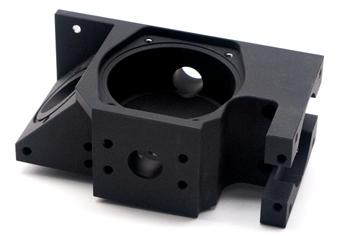

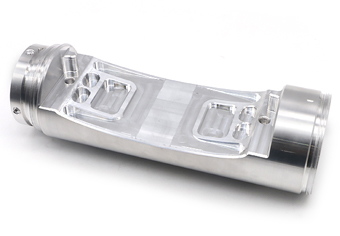

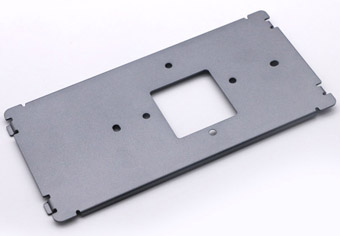

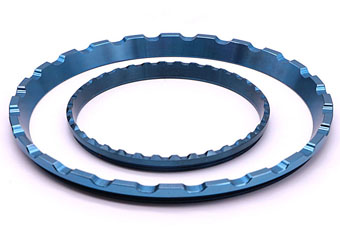

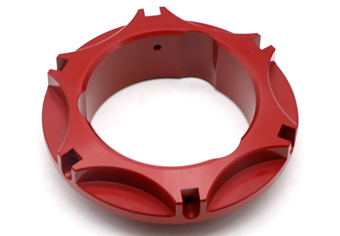

7050 Aluminum CNC Machining Parts Display

Explore our collection of high-precision 7050 aluminum CNC machining parts, showcasing the strength, accuracy, and craftsmanship behind every component we produce. From aerospace-grade structural brackets to complex housings, fixtures, and precision mechanisms, each part reflects our capability to machine 7050 aluminum with ±0.005 mm tolerance, superior surface finish, and reliable dimensional stability.

The parts images have been authorized for use by the customer.

Custom CNC Machined Aluminum Parts – Surface Finishing

Enhance your 7050 aluminum CNC parts with our surface treatments, including anodizing, polishing, and coating, improving corrosion resistance, wear protection, and appearance for durable, high-performance components.

Laser Carving

Silk Screen

Etching

Brushed

Anodizing

Sandblasting

Electroplating

Powder Coating

Polishing

Brushed

Electrophoresis

Nickel Plating/Zinc Plating

Silkscreen Printing

PVD

Oil Spraying

Etching

Custom CNC Machining Parts: 12 Quality Inspection Processes

Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way.

DFM Analysis

Before CNC machining, engineers conduct a DFM analysis to identify and resolve potential issues in advance. This ensures optimized designs for efficient manufacturing, minimizes defects, and reduces machining costs.

Dimensional Tolerance Determination

Check whether the parts meet the specified dimensional tolerances, ensure the technical feasibility of the tolerance design, and optimize the production process to meet your quality requirements and cost-effectiveness.

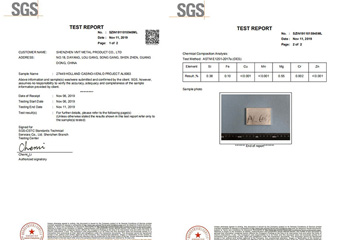

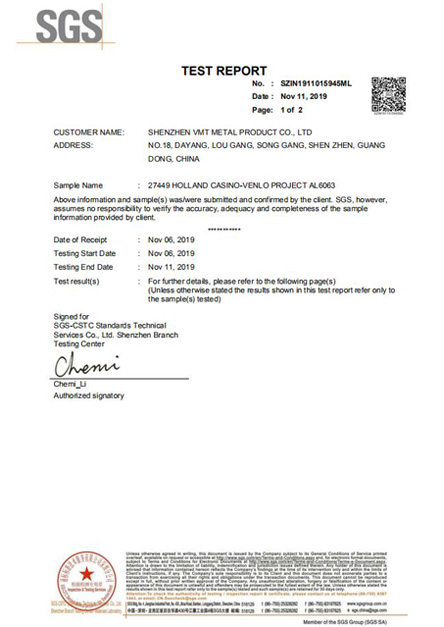

Material Testing

We have long-term stable partnerships with material suppliers for decades and can provide third-party inspection reports from organizations such as SGS, CTI, and TUV.

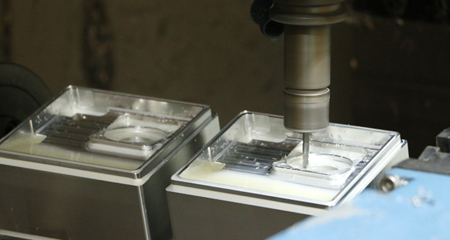

CNC Machining Production

We have a dedicated team to track order progress, maintaining detailed records for each production run. Photos and videos are transparently shared with customers, keeping you informed about the machining process.

FQC Detection

During the machining production process, dimensional tolerance inspections are conducted every two hours, and the first article is inspected to ensure it meets design and quality standards. This guarantees process stability, product consistency, and improved production efficiency.

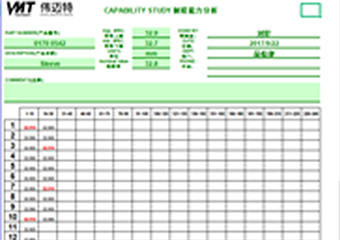

SPC / CKP

Implement statistical analysis to monitor and control the manufacturing process and provide inspection reports.

Problem Found

If any deviations, defects, or non-compliance issues are discovered during the machining process, an immediate meeting is held to address the problem.

Problem Solving

Respond within 30 minutes, provide solutions within 2 hours, and resolve within 1 day.

OQC Detection

Before CNC parts leave the factory, 100% dimensional inspection is conducted according to customer drawings. Inspection reports are provided before proceeding to the next processing step.

Surface Finishing

In addition to conventional surface treatments, there are a variety of special surface treatments. We have a full-time SQE to follow up and control each process in the surface treatment factory. After returning to our workshop, the product appearance will be 100% inspected.

Full Inspection

QC specilists will check the parts at every step with testing equipments accordingly,like 3D / 2D project, height/thread /roughness gauge. Offering inspection report with full dimensions for each part.

Package

Many different ways to pack the goods,avoid the damage, easy to carry and enviornmentally,Accept customer customization, commonly used pearl cotton, bubble bag.

Flexible Turnaround Time

We customize production schedules for various projects to ensure we meet your aluminum CNC machining parts needs.

Project Type

Urgent high-Precision Samples

CNC Aluminum Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Customized 7050 Aluminum CNC Machined Parts Ordering Process

Upload Your CAD Drawing File

Quotation and DFM Analysis

We will send the design back within 12 hours for manufacturability analysis and real-time quotation.

Start Production

Once the order is confirmed, we will begin the production process based on your CAD design.

Received Your Machined Parts

The aluminum prototype parts will be produced within a few days and shipped directly to you via your specified logistics method.

CNC Machining Workshop

Established in 2010 and is located in Guangming District, Shenzhen, Guangdong Province, China,has own factory cover an area of 5000 m2. We are customized machining parts manufacturer with 100 employees,can provide items within 24 hours.

100 sets machines including 4 & 5 axis imported CNC centers,turning & milling machines for fast delivery, 6 engineers who have been working for more than 20 years to provide you with free design service to ensure that parts can reach the appearance of iPhone, the accuracy of Atomic Clock, tolerance per 0.01 mm, the key procedure controlled by CPK1.68 or more. At the same time,2 engineers specialized in surface finishingcontrol the finish procedures. Passed ISO 9001:2005 & IATF 16949 & SGS in 2015.

Devoted to helping 10,000 enterprises to break through the difficulty of processing, and strive for becoming a leader in high-efficiency, high-yield, and precise parts. In the past 15 years, our business has spread to 62 countries around the world,covered military, medical, semiconductor, Telecommunication, automotive and other fields.No matter how complicated part is, or any technical problems faced with,we can find the solution and offer you with professional service.

100+

Sets of Machine

120+

Countries Shipped

100,000+

Parts Manufactured

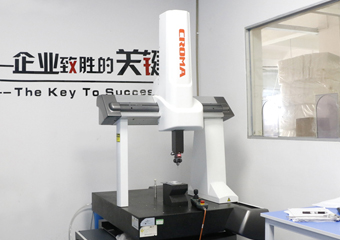

Roundness Meter

3D Detection

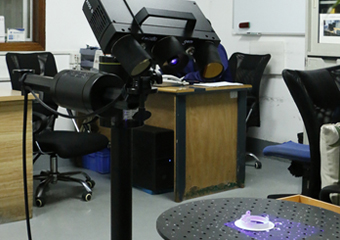

Blu-Ray 3D Scanning

Salt Spray Tester

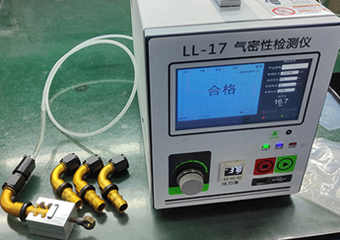

Air Tightness Test

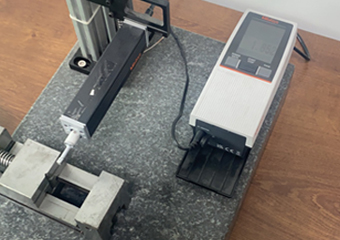

Surface Finish Inspection

IPQC Inspection

Hardness Testing

Electronic Height Gauge

2D Detection

7050 Aluminum CNC Machining Applications

7050 aluminum CNC machining is ideal for aerospace, defense, automotive, robotics, UAVs, medical devices, sporting equipment, and high-performance engineering parts due to its exceptional strength-to-weight ratio, fatigue resistance, dimensional stability, and suitability for precision machining and critical structural components.

Aerospace Industry

Structural brackets, aircraft ribs, frames, landing gear components, actuator housings – Ultra-high strength, excellent fatigue resistance, superior toughness, stable under high loads.

Automotive & Motorsport Industry

Suspension components, performance brackets, transmission housings, chassis reinforcements – Lightweight yet strong, improves speed and fuel efficiency, ideal for high-stress applications.

Robotics & Automation Industry

Robot arms, joint housings, precision mounts, motor brackets – Dimensional stability, machinability, and strength for high-precision movement.

UAVs & Drones Industry

Airframe sections, gimbal housings, structural connectors – Lightweight, high stiffness, perfect for load-sensitive airborne systems.

Bicycle Industry

High-end Bicycle components, strength-focused sporting frames, precision mounts – Combines low weight with exceptional strength.

Electronics & Precision Instruments Industry

Heat-resistant housings, rigid mounts, structural plates– Maintains dimensional accuracy and performs well in thermal environments.

Aluminum CNC Machined Parts Assembly and Packaging Services

WWe provide professional assembly and secure packaging for 7050 aluminum CNC parts, ensuring precise fit, functionality, and safe delivery to maintain part integrity and meet customer requirements.

Assembly

The following is the assembly service process for 7050 aluminum alloy parts at the VMT CNC machining factory:

This structured process ensures the precision, functionality, and safe delivery of 7050 aluminum CNC components.

Package

For CNC machined parts made from 7050 aluminum alloy, we offer a variety of packaging solutions. Each part is carefully packaged and cushioned to prevent damage during transportation, ensuring all components arrive safely and intact to the customer.

The following are our packaging methods for CNC aluminum parts:

These methods are typically combined depending on the size, material, and fragility of the parts to ensure safe transportation.

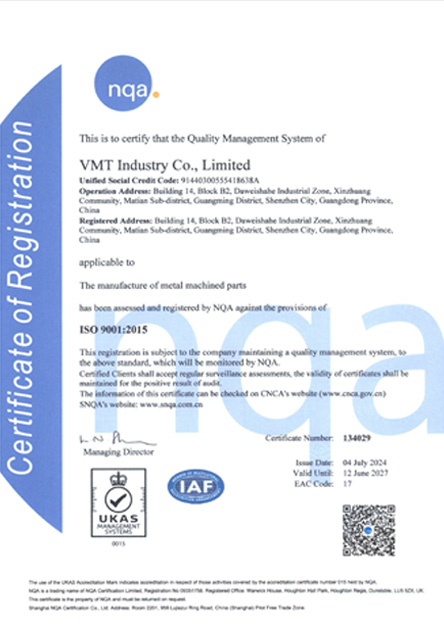

ISO 9001:2015 Certified Factory

VMT has obtained ISO 9001:2015 quality management system, IATF 16949, and RoHS certifications, ensuring that our 7050 aluminum alloy parts are consistently high-quality, traceable, and reliable. These certifications demonstrate our commitment to precision, safety, and industry standards, giving our customers confidence in every custom part we deliver.

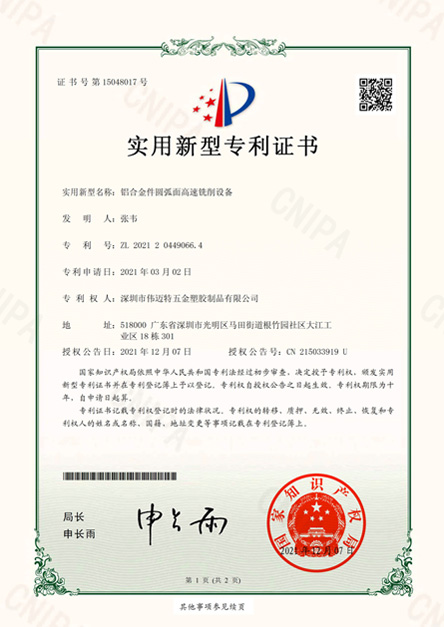

Patent Certified

ISO 9001:2015

IATF 16949

SGS Materials Test Report

FAQs About 7050 Aluminum CNC Machining

What are the Differences Between 7050 Aluminum and 7075 Aluminum?

In summary, 6060 = better extrudability and finish, while 6061 = higher strength and better load-bearing performance.

What are the Differences Between 6061 Aluminum Alloy and 7050 Aluminum Alloy?

What is 7050 Aluminum Equivalent to?

Common equivalents:

Similar high-strength aerospace aluminum grades include 7475 and 7040, depending on the application.

Is 6061 Aluminum Alloy Stronger Than 7075 Aluminum Alloy?

No, 6061 aluminum is weaker than 7075.

Can 7050 Aluminum be Welded?

7050 is not recommended for conventional welding due to high susceptibility to hot cracking and reduced strength in the heat-affected zone.

For critical applications, mechanical fastening, adhesives, or friction stir welding (FSW) are preferred.

What are the Differences Between 7050 Aluminum and 7040 Aluminum?

What is the Price of 7050 Aluminum?

Price depends on form (plate, bar, sheet), size, and market conditions.

Typically higher than 6061 and 7075 due to superior strength, toughness, and aerospace-grade quality.

What are the Advantages and Disadvantages of 7050 Aluminum Alloy Material?

Advantages:

Disadvantages:

What are the Characteristics of 7050-T7451 Aluminum?

T7451: Solution heat-treated, stress-relieved by stretching, and artificially aged

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.