15 years one-stop China custom CNC machining parts factory

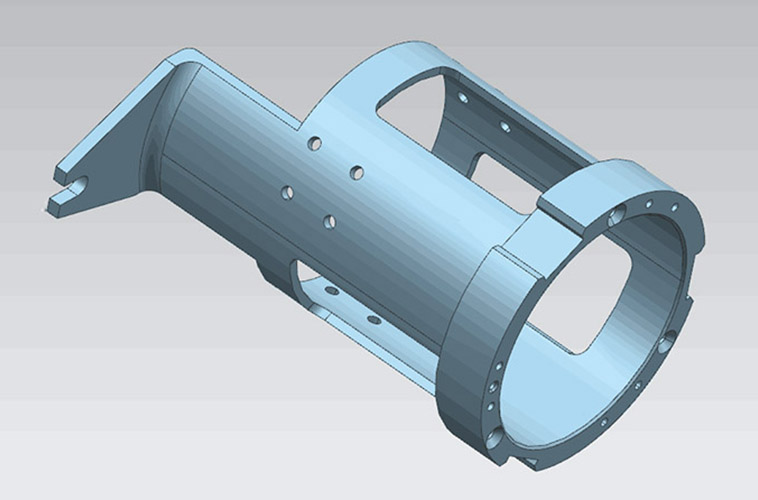

Our CNC Coffee Machine Parts Manufacturing Capabilities

With a focus on CNC machining for 14 years, VMT has successfully completed over 9,628 projects for our clients, encompassing various CNC coffee machine parts. We offer a one-stop service that includes material selection, CNC machining, surface treatment, and custom logo engraving, all aimed at delivering high-quality parts with zero defects as our standard. If you are in need of customized CNC coffee machine parts, feel free to reach out to VMT. We will provide you with a satisfactory response.

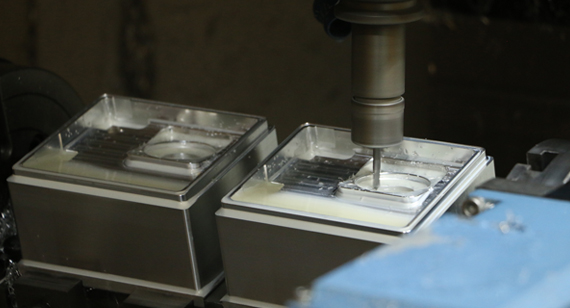

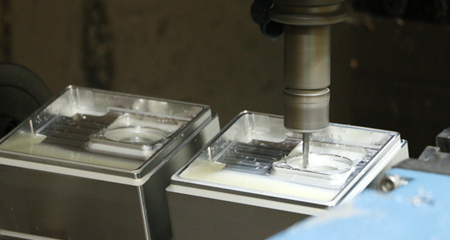

Custom 3 & 5-axis CNC Milling Services

5-axis CNC machining enables the production of coffee machine parts with complex and irregular surfaces, as well as multi-directional machining requirements. The minimum precision can reach 0.01 millimeters, and it is applicable to various metal materials. We have the capability to customize and manufacture various types of CNC coffee machine parts.

Tolerances as tight as +/- 0.01 mm.

Custom milled parts for prototyping and production.

Quick turn milling services.

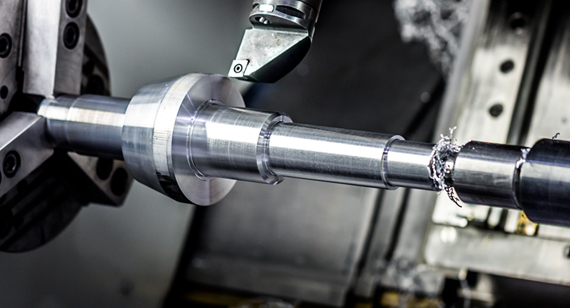

Custom CNC Turning Services

CNC turning service with a monthly output of up to 300,000 pieces, free review of drawings, optimization of quotes and DFM within 4 hours. CNC coffee machine prototype machining parts manufacturing and delivery within 24 hours.

Achieves +/- 0.0002 in. precision.

Custom turned parts for prototyping and production

Quick turn turning services.

Custom CNC Coffee Machine Parts Manufacturer

VMT is a professional CNC coffee machine parts manufacturing service provider with 13 years of experience in CNC machining. We offer tailored solutions, carefully refining designs to meet your specifications and optimize functionality. With our own material library and a variety of surface treatment options to choose from, we provide competitive pricing. Our strict quality control system ensures precision and excellence in manufacturing, whether it's CNC Coffee Portable Hand Grinder Housing, Stainless Steel Coffee Tamper and Dispensers, Stainless Steel Conical Burr Grinder, Steam Lever, or any other intricate components. Simply send us your customized drawings and requirements, and we will turn your ideas into reality.

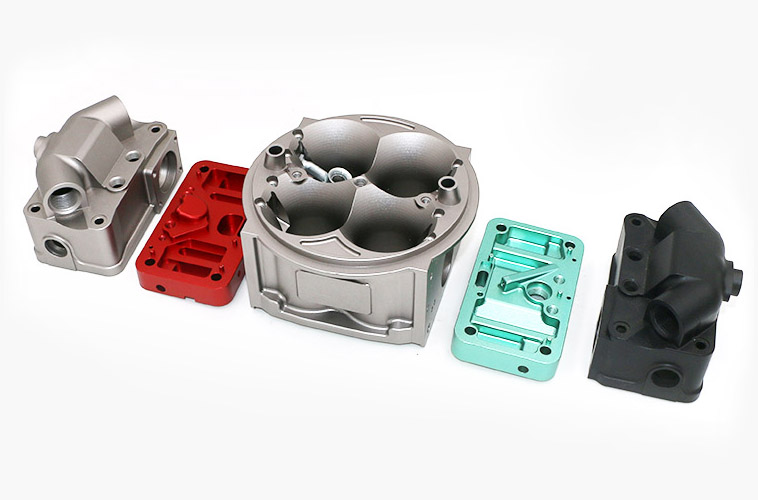

Custom CNC Coffee Machine Parts

VMT offers a range of excellent OEM and ODM CNC machining services for custom coffee machine parts. We have the capability to manufacture CNC coffee machine accessories of various types and utilizing different technologies. Whether it's custom-made or standard components, we can accommodate your specific CNC machining needs. Here is one of our projects for custom CNC coffee machine parts, and we hope you can find your desired CNC machining requirements within it.

CNC Coffee Portable Hand Grinder Housing

For the CNC Coffee Portable Hand Grinder Housing in our CNC machining process, we use aluminum as the material with a surface treatment of black oxidation. The customer's requirement is to maintain consistent assembly patterns while allowing for variations in width dimensions. Therefore, during inspection, we employ a two-dimensional measurement to accurately assess the depth and precision of the teeth, maintaining detailed inspection records. To ensure the accuracy of the pattern, we strictly control the reference position of the inner hole, keeping it within 2μm. As a result, we achieve a final yield rate of 98% and ensure on-time delivery.

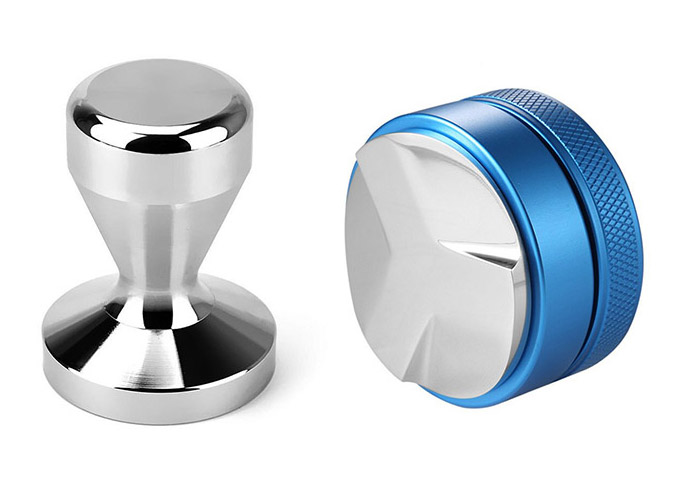

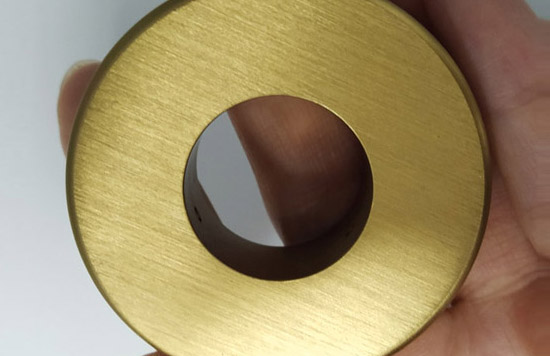

CNC Stainless Steel Coffee Tamper Base and Dispensers

VMT can customize different shapes, materials, logos, and surface treatments for CNC Coffee Tamper Base and Dispensers according to the specific requirements of our customers. We offer customization options for models such as Flat, Three Angled Slopes, Ripple (Concentric), and more. Stainless steel is commonly used as the material for CNC machining and manufacturing of these components.

Custom CNC Aluminum Coffee Geared Spinning WDT Tool Machining

Custom CNC Aluminum Coffee Geared Spinning WDT Tool Machining applications require durable, corrosion-resistant, visually smooth aluminum materials for CNC machining. VMT can also provide different models of aluminum materials according to your needs. In the field of aluminum CNC machining parts, VMT is confident that it has advantages in quality and cost, providing you with high-quality CNC Aluminum Coffee Geared Spinning WDT Tool.

Custom CNC Aluminum Espresso Coffee Extraction Chiller Machining

We offer comprehensive custom CNC machining services for aluminum espresso extraction coolers, including design, programming, precision machining, surface treatment, assembly, and functional testing. We ensure the products meet customer requirements, featuring excellent heat dissipation performance and durability, providing a one-stop solution for your personalized customization needs.

Why Choose Us

High-Quality Parts with Tight Tolerances

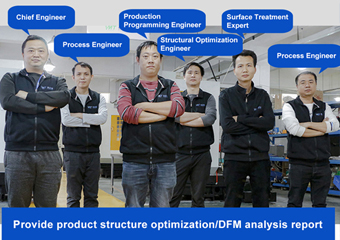

With our extensive experience in CNC machining, we have a professional engineering team dedicated to designing and manufacturing CNC coffee machine parts. We offer a wide range of customization options, including dimensions, materials, surface treatments, and special functionalities. This enables us to precisely tailor the parts to your coffee machine specifications, ensuring a perfect fit and optimal functionality. We specialize in providing CNC machining parts that meet your specific requirements.

Fast Quoting and Delivery

We understand the importance of timely delivery. For simple projects, we can complete the sampling within 1 day. For more complex projects, we aim to finish the sampling within 3 days. Whether you require small-scale or large-scale production, we have the capability to meet your deadlines and ensure smooth delivery of your CNC coffee machine parts.

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

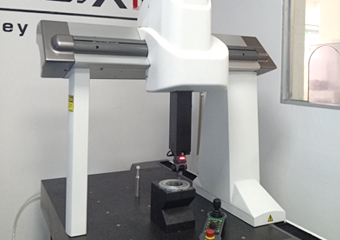

Quality Inspection

Quality is our top priority. We employ advanced CNC machining technology and implement strict quality control measures throughout the entire manufacturing process. From material selection to final inspection, we adhere to rigorous standards to ensure that each CNC coffee machine part meets or exceeds your expectations. Our commitment to quality guarantees reliability, durability, and consistent performance.

Surface Finishing

We have surface treatment experts with 20 years of experience who strictly control the process and maintain comprehensive inspection records. This ensures that you receive CNC coffee machine parts with a flawless appearance. We offer 15 different surface treatment options, and you can view the surface treatment effects on our surface treatment page or contact us to select the appropriate surface treatment for your needs.

Customer Satisfaction

We are committed to ensuring your satisfaction throughout the entire process. Our team provides personalized customer support to address your inquiries, guide you through customization options, and keep you informed about the progress of your order through images or videos. If your order does not meet your machining requirements, we are prepared to rework or refund as necessary.

Custom CNC Machining Solutions Services

Rapid Prototyping Machining

Our rapid machining services support product development, providing rapid prototyping and mold tooling to ensure design verification. CNC machining accurately creates plastic and metal parts to simulate the appearance and function of the final product.

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Small and Large Batch Machining Production

We provide flexible CNC machining services to meet your needs, whether it is small batch or large-scale production. With precise tolerance control and comprehensive production capabilities, we ensure consistency in batch production while maintaining high quality.

CNC machining is particularly suitable for the rapid production of custom parts. Its high precision, repeatability and material diversity help products to be put on the market quickly. Our CNC machine shop is dedicated to providing a one-stop solution for custom machined parts or products, effectively shortening production cycle. Whether it is 10 or 10,000 custom parts, we provide efficient and accurate CNC machining services at an affordable price.

CNC Machined Parts Gallery

Below is a small selection of CNC machined prototypes and end-use parts we produce for our customers. Used with permission.

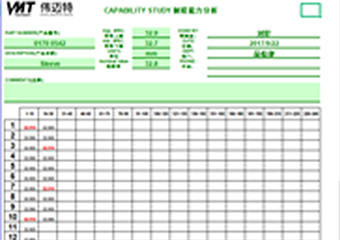

12 Quality Inspection Process

Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way.

DFM Analysis

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Dimensional Tolerance Determination

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

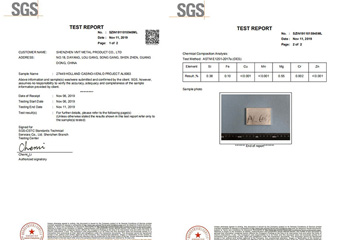

Material Testing

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

CNC Machining Production

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

FQC Detection

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

SPC / CKP

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Problem Found

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Problem Solving

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

OQC Detection

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Surface Finishing

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Full Inspection

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

Package

Our professional CNC services ensure quality and accuracy, and promise fast delivery to help you quickly verify the feasibility of your design.

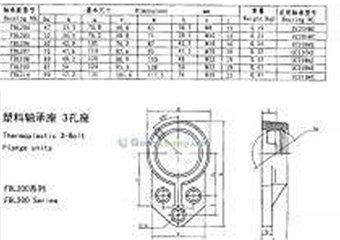

Customized CNC Machining Materials

We work with long-term material suppliers to provide SGS certified materials, and cooperate with surface finishingmanufacturers with more than 10 years of experience to provide more than 40 finishingoptions. Our full-time SQE monitors the entire process at the finishingplant to ensure 100% inspection of product appearance and quality assurance.

Metal Materials

We also provide a variety of CNC machining metal materials to manufacture different customized precision CNC machining parts.

Plastics Materials

We also offer a variety of different CNC machined plastic materials to manufacture different custom precision CNC machined parts.

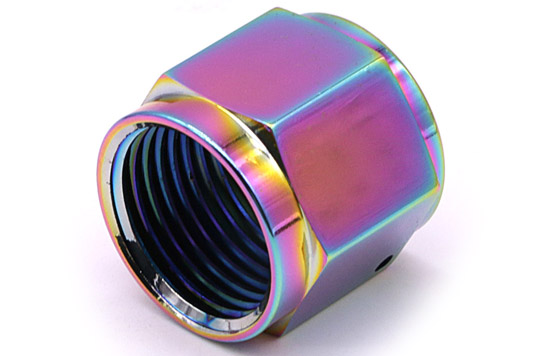

Custom CNC Machining Surface Finishing

We offer a comprehensive range of surface finishingservices to help you achieve the perfect finish for your parts. Whether you require anodizing, electroplating or painting, we can meet the visual and functional needs of your various designs. No need to wait, we can quickly provide you with a quote for various types of surface finish after processing to ensure that the surface finish after processing meets your expectations.

As-Machined Finish

Anodizing

Multi-Color Anodized

Hard Anodizing

Chrome Plating

Blue Zinc Plated

PVD

Electrophoresis

Nickel Plating

Laser Carving

Brushed

Polishing

Custom CNC Machining Ordering Process

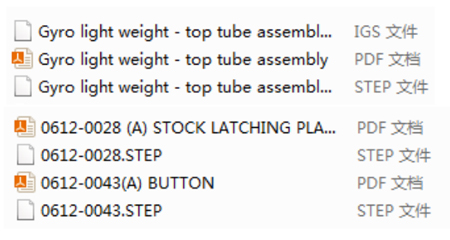

Upload Your CAD File

Upload your file directly or send your project information through the quote page. All files support NDA.

Quotation and DFM Analysis

We will send back the design for manufacturability analysis and real-time quotation within 12 hours.

Start Production

Once the order is confirmed, we will start the manufacturing process using your CAD design.

Receive Your Machining Parts

The prototype or part will be produced within a few days and sent directly to you by international courier.

CNC Machining Parts Tolerance

During the production process, we will implement the stricter standards than ISO Tolerances DIN ISO 2768-1 for the unrequired parts, and the CNC machining components standard tolerances of our machines.

| Nominal linear range tolerance (mm) |

Linear dimensions DIN ISO 2768-F |

Our CNC machining parts |

Our plastic parts |

| 0.5 up to 3 |

±.0.05 |

±.0.02 |

±0.05 |

| over 3 up to 6 |

±.0.05 |

±.0.03 |

±0.05 |

| over 6 up to 30 |

±0.1 |

±0.05 |

±0.1 |

| over 30 up to 120 |

±0.15 |

±0.05 |

±0.15 |

| over 120 up to 400 |

±0.2 |

±0.1 |

±0.2 |

| Nominal angle range tolerance (mm) |

Linear dimensions DIN ISO 2768-F |

Our metal parts |

Our plastic parts |

| ≦10 |

±1° |

±1° | ±1° |

| 10~50 |

±0°30′ |

±0°30′ |

±0°30′ |

| 50~120 |

±0°20 |

±0°20 |

±0°20 |

| 120~400 |

±0°10 |

±0°10 |

±0°10 |

| Text and color |

VMT can use CNC engraving or laser carving to create standard text based on customers' requirements. VMT can customize any color according to customers' requirements. |

||

| Lead Time |

Simple CNC machining components parts: 1-day prototype machining delivery. Complex CNC machining components parts: 3-days prototype machining delivery. |

||

CNC Machining Workshop

Established in 2010 and is located in Guangming District, Shenzhen, Guangdong Province, China,has own factory cover an area of 5000 m2. We are customized machining parts manufacturer with 100 employees,can provide items within 24 hours.

100 sets machines including 4 & 5 axis imported CNC centers,turning & milling machines for fast delivery, 6 engineers who have been working for more than 20 years to provide you with free design service to ensure that parts can reach the appearance of iPhone, the accuracy of Atomic Clock, tolerance per 0.01 mm, the key procedure controlled by CPK1.68 or more. At the same time,2 engineers specialized in surface finishingcontrol the finish procedures. Passed ISO 9001:2005 & IATF 16949 & SGS in 2015.

Devoted to helping 10,000 enterprises to break through the difficulty of processing, and strive for becoming a leader in high-efficiency, high-yield, and precise parts. In the past 15 years, our business has spread to 62 countries around the world,covered military, medical, semiconductor, Telecommunication, automotive and other fields.No matter how complicated part is, or any technical problems faced with,we can find the solution and offer you with professional service.

100+

Sets of Machine

120+

Countries Shipped

100,000+

Parts Manufactured

Other Industry Applications

Our business has grown to now cover 62 countries worldwide. We have done products in the electronics industry, industrial industry, automotive industry, and medical industry. If you need custom CNC Machining Components parts service, we have rich manufacturing experience and can turn your ideas into products.

VMT x Armstrong Holland Casino Venlo: Stainless Steel CNC Turned Advertising Nail Parts Project

The perfect combination of stamping, spinning, welding, extrusion, polishing, cold forging and other processes with CNC machining can reduce costs for customers by 10%. From sample production to approval and optimization, from the coordination of various processes to controlling the cost of parts within the most reasonable range, we provide customers with solutions and deliver on time.

CNC Machining Coffee Machine Parts FAQs

What types of coffee machine parts can be made using CNC machining?

CNC machining can produce various components for coffee machines, including:

What materials are commonly used for CNC machining coffee machine parts?

The materials chosen depend on the specific application and required properties. Common materials include:

What is the lead time for CNC machining coffee machine parts?

Lead time for CNC machining depends on the complexity of the part, the material, and the number of components being produced. For prototypes, it typically takes a few days to a couple of weeks. For larger production runs, lead times can range from a few weeks to several months, depending on the size and scope of the project.

Can CNC machining help with prototyping new coffee machine designs?

Yes, CNC machining is ideal for rapid prototyping. Designers can create and test new components for coffee machines quickly and accurately, refining designs before committing to larger-scale production. This is particularly important in industries like coffee equipment manufacturing, where innovation and customization are key to standing out in the market.

Can CNC machining handle customizations and unique designs for coffee machines?

Absolutely. CNC machines can create one-off custom parts or small batch runs of unique designs, allowing manufacturers to experiment with new shapes, features, or materials. This is especially useful for high-end or boutique coffee machines, where bespoke parts are often needed.

How do I ensure my CNC-machined coffee machine parts are food-safe?

To ensure that CNC-machined coffee machine parts are safe for food contact, the following measures should be considered:

What post-machining services are available for CNC coffee machine parts?

After the machining process, several post-processing services may be needed, such as:

Explore Related Resources

Custom Machined Enclosures: A Basic Guide

This article explores the true meaning of custom machined enclosures, discusses their practical applications, examines various manufacturing methods, and ...

Custom Shaft Machining: Types, Manufacturing Processes, and Techniques

In this article, we will introduce the types of custom shafts, the machining manufacturing techniques used, and the methods to ensure your parts meet stringent specifications. ...

CNC Machining Stainless Steel: Challenges, Tips, Types, Advantages, and Disadvantages

Read this article to learn about the challenges, tips, types, advantages, and disadvantages of CNC machining stainless steel. It will help you make informed decisions ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red