15 years one-stop China custom CNC machining parts factory

Welcome to visit the our factory. Then you will get to know us more truly and also know our processing procedures and prices better, which will also be more helpful for you to find suppliers.

Get an Instant QuoteHome / About / CNC Machining factory /

VMT is located in Building 18, Dajiang Industrial Zone, Genzhuyuan Community, Matian Street, Guangming District, Shenzhen. It was established in 2010. VMT covers an area of 12,500 square meters. The main business is customized precision metal parts. There are currently more than 90 employees. The company’s organizational structure is established according to the nature of the function. The top ones are the general manager and vice-general managers. The general manager coordinates the administration and HR department, finance department, foreign trade department and engineering department, and the vice-general manager coordinates the quality department, materials department and production. The heads of these seven departments are responsible for the staff and affairs of the following functions. The administrative personnel department is mainly responsible for recruitment and staff committees. The Finance Department is mainly responsible for cashier and accounting. The Foreign Trade Department is mainly responsible for international trade, domestic business and customer service. The engineering department is mainly responsible for the research and development and project process engineering. The quality department is mainly responsible for the document control center, the SQE and IQC team, and the IPQC full inspection team. The materials department is mainly responsible for the project, warehouse management team, and PMC documentary. The production department is mainly responsible for the CNC machining department, CNC lathe department, automatic lathe department, and packaging department. These departments are in charge of the operators and secondary processors in each department. We combine hot and cold forging, die-casting, extrusion, CNC turning and milling, and various difficult surface treatment processes to meet customer's requirements.

Updated: Mar 12 2021

Updated: Mar 12 2021

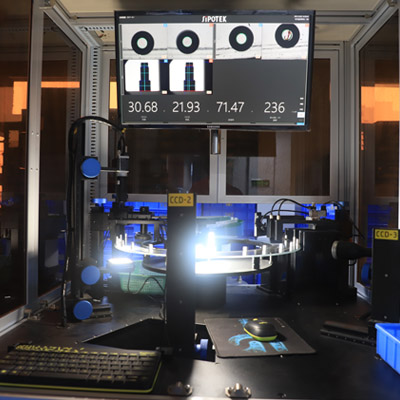

Our existing machinery and equipment: automatic lathes, drilling machines, tapping machines, desktop lathes, CNC lathes, CNC high-speed drilling and tapping machines, 4/5-axis CNC machining centers, grinders, milling machines, sub-column welding machines, pipe benders, etc. Nearly hundreds of machines and equipment. The brother companies that we have been cooperating with for a long time have our indispensable stamping, die-casting and other machinery and equipment. We can combine hot-cold forging, die-casting, extrusion, CNC turning and milling to produce a variety of difficult surface treatment products. The surface treatment and tolerances are strictly implemented in accordance with the international standard ISO Tolerances DIN ISO 2768-1.

Updated: Mar 12 2021

Updated: Mar 12 2021

We have strict quality control procedures. We divide quality control into four steps- IQC, IPQC, FQC, and OQC. The sampling rate and frequency are determined by the acceptance criteria signed by our customers. Each product has different quality control standards to ensure that the product meets strict requirements.

Updated: Mar 12 2021

Updated: Mar 12 2021

Our company's CNC machining turning milling parts cover 62 countries and regions around the world. 24 hours online, come visit us, language communication is not a problem for us. Before confirming the order, we need you to submit 2D and 3D, CAD drawings or samples to our company. We will quote you within a few minutes according to your drawings or samples and confirm your materials, tolerances and surface treatment. After placing the order, we immediately purchase and prepare materials. All incoming materials are inspected and verified through a set of testing equipment and then delivered to the workshop for CNC machining. During the production, we will set up every step of the part. The timely status of processing and inspection will be sent to customers in photos, videos and emails, so that customers can rest assured. After the product has finished the surface treatment and inspection, we will send the parts to the customer for review by express. After confirming that it is correct, perform a manual inspection again, and then package and transport according to the customer's packaging and transportation requirements. After the customer receives the product, if there are quality, tolerance and surface treatment problems, we will reply as soon as possible to solve them. If we are responsible, we can redo or repair the product.

Updated: Mar 12 2021

Updated: Mar 12 2021

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!