15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

China Custom 3 Axis CNC Machining 304 Stainless Steel Parts Services Factory

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC Machining 304 Stainless Steel Parts Factory in China

| We are a custom CNC machined 304 stainless steel parts manufacturer in China, providing comprehensive CNC machining services. Various processing techniques can be used to manufacture stainless steel parts, and the CNC machining 304 stainless steel parts project has been completed for thousands of customers. With 13 years of experience in CNC machining and manufacturing, we can provide you with stainless steel parts of different complex shapes. |

Our Custom CNC Machining 304 Stainless Steel Parts Services Manufacturer

| Custom CNC machining of 304 stainless steel parts provides unmatched precision, versatility and build quality. Through careful material selection, prototyping, surface treatment and quality control, manufacturers can produce components that meet the requirements of various industries. |

Custom CNC 304 Stainless Steel Parts Prototyping Machining

Prototyping is a critical step in the process of custom CNC machining stainless steel parts. By creating prototypes, manufacturers can evaluate the design, functionality, and performance of intended parts before going into mass production. This step helps to identify and correct any potential problems or improvements needed in the design. |

|

|

|

|

||

Custom CNC 304 Stainless Steel Parts Surface Treatment |

Custom CNC 304 Stainless Steel Parts Material |

||

|

Surface treatment enhances the properties and aesthetics of 304 stainless steel parts. Options such as passivation, electropolishing, and coating can improve corrosion resistance, enhance appearance, and provide additional protection against wear and tear. |

When it comes to machining 304 stainless steel parts, material selection is vital. 304 stainless steel is renowned for its excellent corrosion resistance, strength, and durability. It is widely used in industries such as automotive, aerospace, and medical due to its exceptional mechanical properties. |

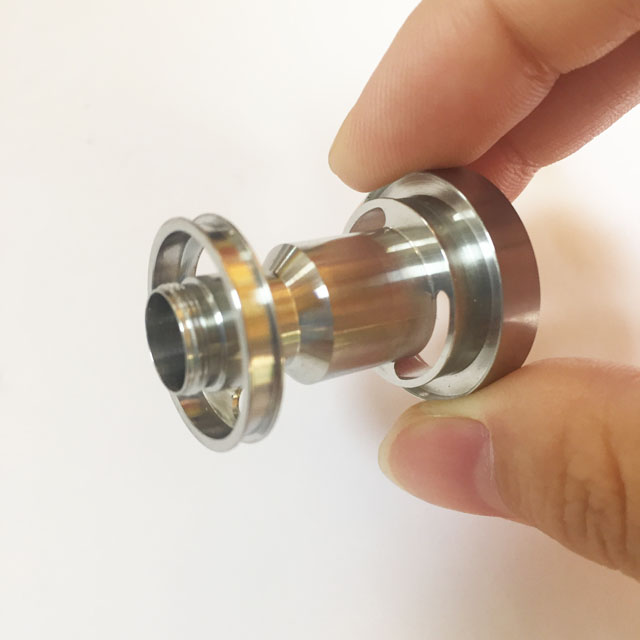

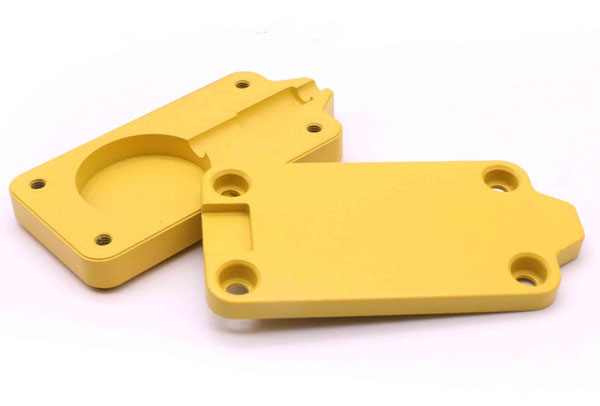

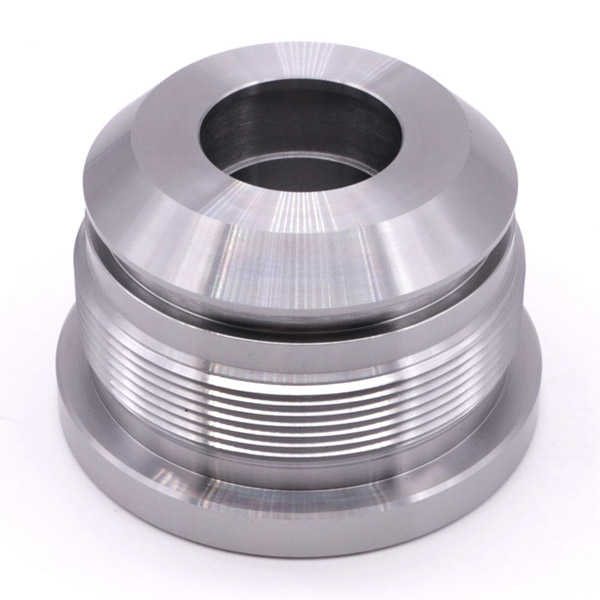

Custom CNC Machining 304 Stainless Steel Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Custom CNC machining of 304 stainless steel parts offers numerous advantages in terms of corrosion resistance, strength, durability, and versatility. By carefully considering material selection factors, machinability, surface finish requirements, and cost considerations, manufacturers can ensure the successful production of high-quality components. |

|

|

Advantages of Using 304 Stainless Steel for CNC Machining

There are several advantages to using 304 stainless steel for custom CNC machining: Corrosion Resistance: 304 stainless steel is highly resistant to corrosion, making it suitable for applications where the parts may be exposed to moisture, chemicals, or harsh environments.

More Details>> |

|

|

Surface treatments play an important role in enhancing the performance, aesthetics and durability of custom CNC machined 304 stainless steel parts. Below are various surface treatment options for achieving desired properties and finishes on machined components. |

|

1. Passivation

Passivation: Passivation is a widely used surface treatment for stainless steel parts. It involves immersing the parts in an acidic solution to remove iron particles and contaminants from the surface. Passivation improves the corrosion resistance of 304 stainless steel by forming a protective oxide layer on the surface. |

|

|

2. Electropolishing

Electropolishing: Electropolishing is an electrochemical process that removes a thin layer of material from the surface of the stainless steel part. It provides a smooth, bright, and mirror-like finish, enhancing the aesthetics and improving the corrosion resistance of the part. Electropolishing can also eliminate surface defects and micro-roughness, improving cleanability. |

|

|

|

3. Powder Coating

Powder Coating: Powder coating involves applying a dry powder onto the surface of the 304 stainless steel part. The powder is then cured, forming a durable and protective coating. Powder coating offers a wide range of color options, excellent corrosion resistance, and resistance to chemicals, abrasion, and UV exposure. |

|

|

|

4. Brushing and Polishing

Brushing and Polishing: Brushing and polishing are mechanical surface treatments that create a smooth and visually appealing finish on 304 stainless steel parts. Brushing involves using abrasive materials to create fine parallel lines or a textured pattern on the surface. Polishing uses abrasives and buffing to achieve a glossy and reflective surface. |

|

|

| Surface treatment options for custom CNC machined 304 stainless steel parts offer a range of benefits, including improved corrosion resistance, enhanced aesthetics, and additional functional properties. Passivation, electropolishing, powder coating, anodizing, brushing, and polishing are among the popular treatments available. The choice of surface treatment depends on the desired characteristics, application requirements, and aesthetics of the finished part. To view the surface finishing effect click here: https://www.machining-custom.com/aluminum-surface-finishing/ |

| The manufacturing process for custom CNC machining of 304 stainless steel parts involves several stages to ensure the precision and high quality of the parts. Critical steps from design to final inspection and packaging. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with the design and engineering phase, where the requirements and specifications for the 304 stainless steel parts are determined. Designers create detailed CAD models and drawings, considering factors such as functionality, dimensions, tolerances, and material properties. |

|

Material selection: Based on the design requirements, 304 stainless steel is selected as the material for the parts. Material selection takes into account the desired properties, such as corrosion resistance, strength, and machinability, to ensure optimal performance in the intended application. |

|

3. CNC Machining

CNC machining: We use milling, turning, drilling and other machining processes based on design requirements. The CNC machine precisely follows the programmed toolpath to remove material and shape the CNC machined 304 stainless steel part. |

|

Surface Treatments: After CNC machining is complete, 304 stainless steel parts can be surface treated and finished. This can include passivation, electropolishing, powder coating, anodizing, brushing or polishing, depending on the desired level of performance and aesthetics of the finished part. |

|

5. Quality Control

Quality Control: Throughout the CNC machining process, frequent inspections and quality control checks are conducted to ensure dimensional accuracy and adherence to specifications. Advanced measuring equipment, such as coordinate measuring machines (CMM), gauges, and micrometers, are used to verify critical dimensions, tolerances, and surface finishes. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: After surface preparation and finishing, a final inspection is performed to ensure the quality and consistency of the 304 stainless steel parts. This inspection involves verifying critical dimensions, surface finish, and any specific requirements outlined in the design. Then pack according to customer requirements to prevent scratches during transportation and storage. |

| The manufacturing process for custom CNC machining of 304 stainless steel parts follows a systematic flow from design to final inspection and packaging. With meticulous attention to detail at each stage, manufacturers can ensure the production of precise, high-quality components that meet the design specifications and functional requirements. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Machining 304 Stainless Steel Parts FAQs

|

Q1: What are the advantages of custom CNC machining for 304 stainless steel parts?

Q2: How long does it take to produce custom CNC machined 304 stainless steel parts?

Q3: Are custom CNC machined 304 stainless steel parts cost-effective?

Q4: What surface treatment options are available for custom CNC machined 304 stainless steel parts?

Q5: Can custom CNC machined 304 stainless steel parts be produced in large quantities?

Q6: What are the material considerations for CNC machining 304 stainless steel parts?

Q7: How can I ensure the quality of custom CNC machined 304 stainless steel parts?

Q8: Can custom CNC machined 304 stainless steel parts be used in different industries?

Q9: Can 304 stainless steel parts be customized for specific dimensions and tolerances?

Q10: Can I provide my own design files for custom CNC machining of 304 stainless steel parts?

|

| Custom CNC machining of 304 stainless steel parts offers advantages such as precision, versatility, cost-effectiveness, and the ability to meet specific design requirements. Surface treatment options, quality control, material considerations, and customization possibilities are important factors to consider when opting for custom CNC machining of 304 stainless steel parts. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.