15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

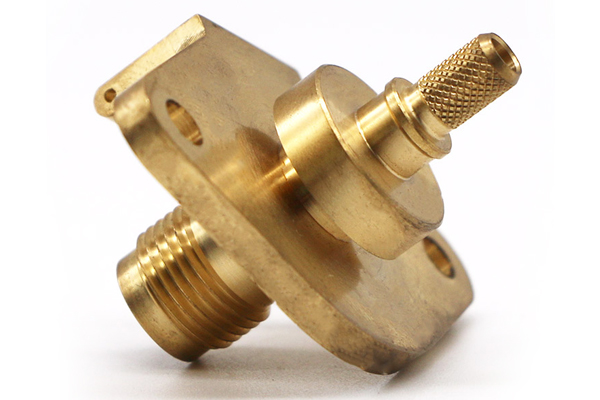

OEM Custom Electronic CNC Brass Precision Turned Components Parts Services Manufacturer

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC Brass Precision Turned Components Services Manufacturer in China

|

Brass is known for its excellent electrical and thermal properties, making it ideal for a variety of applications. We are a 13-year professional custom CNC brass precision turning parts service manufacturer, we can customize brass CNC parts according to your specific design requirements. |

Custom CNC Brass Precision Turned Components Prototyping Machining

CNC prototyping is a critical step in the manufacturing process. We can rapidly produce multiple prototypes within 24 hours for testing and design improvement. Eliminate design flaws, shorten development time, and save costs. Prototyping with CNC technology ensures accuracy and consistency in the final product. |

|

|

|

|

||

Custom CNC Brass Precision Turned Components Surface Treatment |

Custom CNC Brass Precision Turned Components Material |

||

|

Enhance component durability with surface treatments that can improve the durability, appearance and function of copper precision parts. We have a surface treatment factory with 10 years of cooperation, 13 years of surface treatment experience and a surface quality management system to ensure the yield of parts. |

With your own material library, choosing the right material is critical to achieving the desired properties and performance of your brass CNC turned parts. 5000+ CNC brass turning parts have been customized for customers in various industries, and a professional engineering team will provide you with solutions. |

Custom CNC Brass Precision Turned Components Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Custom CNC precision turned brass parts are integral components used in various industries due to their unique properties. The CNC machining process ensures high precision and consistency, making them ideal for critical applications.Custom CNC precision turned brass parts are manufactured using CNC machining machines, allowing for precise and intricate designs. The following are commonly used brass materials: |

|

|

Custom C36000 Copper Brass Turned Parts

C36000, also known as Free-Cutting Brass, is an alloy of copper and zinc, offering excellent machinability. It is ideal for intricate designs and high-speed machining processes.

More Details>> |

|

|

|

Custom C37700 Copper Brass Turned Parts

C37700, also known as Forging Brass, contains small amounts of lead, enhancing its hot working properties. It is commonly used in applications requiring forging or bending.

More Details>> |

|

|

|

Custom C26800 Copper Brass Turned Parts

C26800, also known as Yellow Brass, is composed of copper, zinc, and small amounts of other elements. It offers good corrosion resistance and is suitable for decorative applications.

More Details>> |

|

|

|

Custom C22000 Copper Brass Turned Parts

C22000, also known as Commercial Bronze, is a copper-zinc alloy with excellent cold working properties. It is widely used in electrical connectors and terminals.

More Details>> |

|

、

| Custom CNC precision turned brass parts, with their excellent properties and machinability, are essential components in numerous industries. The various copper alloys, such as C36000, C37700, C26800, and C22000, offer unique advantages, including superior conductivity, machinability, corrosion resistance, and thermal efficiency. Their applications in electronics, plumbing, automotive, and industrial machinery highlight their significance and versatility in modern manufacturing. |

|

Custom CNC Brass Precision Turned Parts are widely used in various industries due to their excellent performance. To further enhance its performance and appearance, more than 15 surface treatments are available to provide you with additional functional and protective coatings.The following are commonly used surface treatments: |

|

1. Electroplating

Electroplating is a widely used surface treatment method for custom CNC brass copper precision turned parts. In this process, a thin layer of metal is deposited onto the copper surface through an electrochemical reaction. Common metals used for electroplating brass copper parts include nickel, chrome, and gold. Electroplating enhances the component's corrosion resistance and provides decorative finishes. |

|

|

2. Sandblasting

Sandblasting, also known as abrasive blasting, is a surface treatment process in which a stream of abrasive material is propelled at high speed to remove paint, rust, or other surface contaminants and to create a textured finish on the material.brass parts cannot undergo anodizing. |

|

|

|

3. Passivation

Passivation is a chemical process used to remove surface impurities and create a protective oxide layer on the brass copper precision turned parts. It enhances the part's corrosion resistance and improves its biocompatibility for medical applications. |

|

|

|

4. Chemical Etching

Chemical etching is a precise surface treatment method used to create intricate designs, patterns, or text on custom CNC brass copper precision turned parts. The process involves using chemicals to selectively remove material, leaving the desired design on the surface. |

|

|

|

5. Polishing

Polishing is mechanical surface treatment processes that improve the surface smoothness and shine of custom CNC brass copper precision turned parts. They create a mirror-like finish and remove imperfections, enhancing the part's appearance. |

|

|

|

Surface treatment plays a crucial role in enhancing the performance and appearance of custom CNC brass copper precision turned parts. Processes like electroplating, anodizing, passivation, chemical etching, and polishing offer various benefits, such as improved corrosion resistance, protective coatings, and decorative finishes. Selecting the appropriate surface treatment depends on the specific requirements and intended applications of the precision turned parts.

To view the surface finishing effect, click here: https://www.machining-custom.com/aluminum-surface-finishing/ |

| Custom CNC brass precision turned components undergo a carefully planned manufacturing process to achieve the desired precision, accuracy, and quality. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The first step in manufacturing a custom CNC brass precision turned part is creating a detailed design. CAD software is used to design assemblies, specifying dimensions, tolerances, and other critical details. Once the design is complete, the CAD file is converted into a CNC-readable format (called G-code) by CAM software. |

|

2. Material Selection

Material selection: Selecting the appropriate brass material is crucial for the performance and properties of the final component. Factors such as the required strength, conductivity, and corrosion resistance influence the choice of brass alloy. |

|

3. CNC Turning

CNC Turning: The brass material is then precisely cut and formed using CNC turning and drilling, CNC milling and other processes. After CNC machining is complete, it is followed by deburring to remove sharp edges and any excess material. |

|

4. Surface Treatments (Optional)

Surface Treatments: Depending on the application and requirements, custom CNC brass precision turned components may undergo surface treatment processes such as electroplating, anodizing, or polishing to enhance their properties and appearance. |

|

5. Quality Inspection

Quality Inspection: Custom CNC brass precision turned components undergo rigorous inspection to ensure they meet the specified tolerances and dimensions. Precision measuring tools, such as calipers and micrometers, are used to verify the component's accuracy. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: After passing the quality inspection, we have many ways of packing. We will choose the appropriate or customized packaging method for aluminum CNC parts according to the customer's needs and transportation methods to ensure safe transportation. |

|

The manufacturing process of custom CNC brass precision turned components involves careful design, programming, material selection, and CNC machining operations such as turning, drilling, milling, and threading. Rigorous inspection and optional surface treatment contribute to the overall quality and performance of the components. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Brass Precision Turned Components FAQs

|

What are custom CNC brass precision turned components?

What is the advantage of using brass for precision turned components?

What industries commonly use custom CNC brass precision turned components?

How precise are custom CNC brass precision turned components?

What surface finishes can be applied to custom CNC brass precision turned components?

Are custom CNC brass precision turned components cost-effective?

Can custom CNC brass precision turned components be used for high-temperature applications?

How are the dimensions and tolerances of custom CNC brass precision turned components controlled?

Can custom CNC brass precision turned components be used in corrosive environments?

Are custom CNC brass precision turned components suitable for high-frequency applications?

What are the typical lead times for manufacturing custom CNC brass precision turned components?

Can custom CNC brass precision turned components be used in marine environments?

Are custom CNC brass precision turned components environmentally friendly?

|

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.