15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

Custom CNC Machining Aluminum Brass Copper Stainless Steel Titanium Zinc Metal Mechanical Keycaps

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC Metal Mechanical Keycaps Services Manufacturer

| In the world of mechanical keyboards, custom CNC metal keycaps are very popular. These unique keycaps offer a premium look and feel, taking your typing experience to new heights. Are you looking for a reliable custom CNC metal mechanical keycaps manufacturer? We are a 13-year professional custom-made CNC metal mechanical keycap manufacturer, providing one-stop CNC machining services, from design to CNC machining, with a professional engineer team to provide you with guidance and analysis. |

|

|

|

||

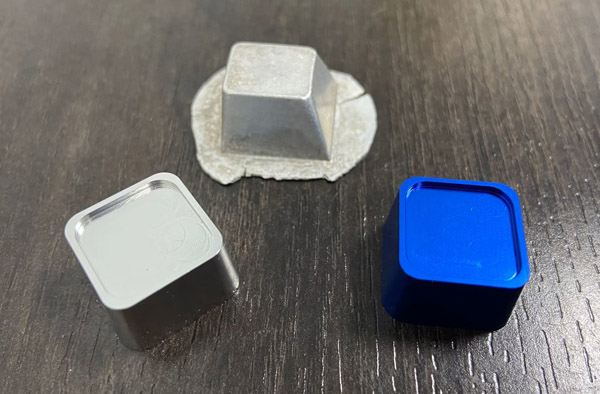

CNC Metal Mechanical Keycaps Prototyping Machining |

Die-casting + Custom CNC Metal Mechanical Keycaps |

||

| CNC prototyping plays an important role in custom CNC metal mechanical keycap fabrication. CNC keycap designs are precisely manufactured using CNC machining machines. A digital 3D model of the keycap is first created, which is then translated into machine instructions. A CNC machine then mills or engraves the keycaps from a solid block of metal, ensuring accuracy and consistency. |

The die-casting process is also commonly used to customize CNC mechanical keycaps, which produce keycaps with excellent precision and durability through die-casting. The cost of CNC machining is higher than that of die-casting. For mass production, the die-casting process is generally used to customize CNC-machined metal mechanical keycaps to ensure the consistency of parts and save costs. |

|

|

|

||

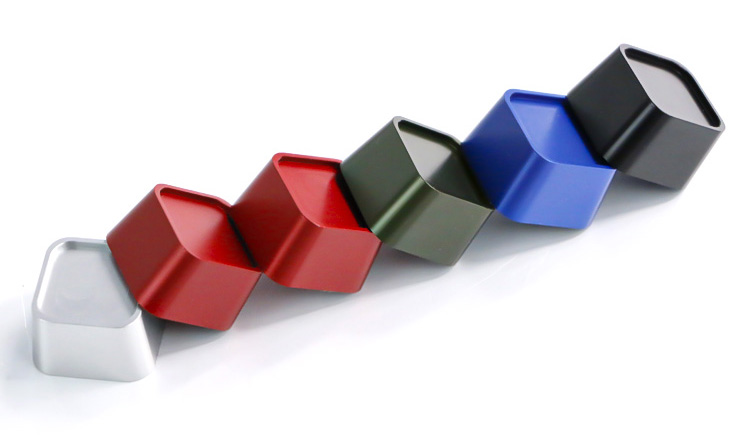

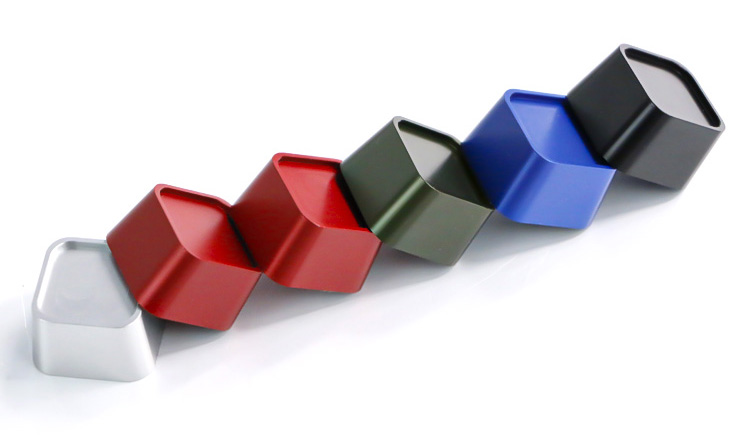

Custom CNC Metal Mechanical Keycaps Surface Treatment |

Custom CNC Metal Mechanical Keycaps Material |

||

|

To further elevate the visual appeal of custom CNC metal mechanical keycaps, surface treatments are applied. These treatments not only enhance the aesthetics but also provide protection against wear and corrosion. Some common surface treatments include anodizing, electroplating, powder coating, and PVD coating. Each treatment option offers different colors and finishes, allowing for customization according to individual preferences. |

Custom CNC metal mechanical keycaps can be manufactured using various materials, each with its unique characteristics and aesthetics. Some popular materials include aluminum, brass, stainless steel, and titanium. These materials offer excellent durability and lend a premium feel to the keycaps, enhancing the overall typing experience. |

Custom CNC Metal Mechanical Keycaps Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Custom CNC metal mechanical keycaps, the choice of materials plays a significant role in determining their durability, aesthetics, and overall performance. In this section, we will delve into the different materials commonly used in manufacturing custom CNC metal keycaps. |

|

|

Aluminum CNC Machining Mechanical Keycaps

Aluminum: Aluminum is a popular choice for CNC metal keycaps due to its lightweight nature and excellent machinability. It offers durability and is known for its resistance to corrosion. Aluminum CNC Mechanical keycaps often have a sleek and modern appearance, making them a favored option among keyboard enthusiasts.

More Details>> |

|

|

|

Brass CNC Machining Mechanical Keycaps

Brass: Brass keycaps exude a sense of elegance and luxury. They have a substantial weight to them, providing a satisfying typing experience. Brass is known for its durability and resistance to tarnishing, which ensures that the keycaps maintain their aesthetic appeal over time.

More Details>> |

|

|

|

Stainless Steel CNC Machining Mechanical Keycaps

Stainless Steel: Stainless steel is a robust and durable material that can withstand heavy usage without showing signs of wear. It offers a unique aesthetic, often characterized by a sleek and industrial look. Stainless steel CNC mechanical keycaps are highly resistant to corrosion and can provide a satisfying tactile feedback.

More Details>> |

|

|

|

Titanium CNC Machining Mechanical Keycaps

Titanium: Titanium keycaps are a premium option known for their exceptional strength-to-weight ratio. They offer a unique combination of lightweight properties and excellent durability. Titanium CNC mechanical keycaps often showcase a refined and high-end appearance, making them a sought-after choice for keyboard enthusiasts.

More Details>> |

|

|

|

Zinc CNC Machining Mechanical Keycaps

Zinc: Zinc keycaps combine the strength and durability of metals like zinc with the ability to achieve intricate designs. They are often plated with different finishes, such as chrome or nickel, to enhance their appearance and protect against corrosion.

More Details>> |

|

|

Every material has its own unique properties and every part has different requirements. When choosing materials for your custom CNC metal mechanical keycaps, we will consider weight, appearance, durability, and your custom processing requirements, and choose cost-effective, cost-effective materials for custom CNC metal mechanical keycaps. |

|

Surface treatments play a vital role in enhancing the aesthetics and durability of custom CNC metal mechanical keycaps. These treatments not only provide a protective layer but also offer opportunities for customization. The following are common finish options: |

|

1. Anodizing

Anodizing: Anodizing is an electrochemical process that creates an oxide layer on the surface of the metal. This treatment offers a range of color options and provides excellent corrosion resistance. Anodized CNC metal mechanical keycaps can have a matte or glossy finish, depending on the desired aesthetic. |

|

|

2. Electroplating

Electroplating: Electroplating involves depositing a thin layer of metal onto the keycap's surface using an electrochemical process. This treatment can provide various metallic finishes such as chrome, gold, or nickel. Electroplating enhances the durability of CNC metal mechanical keycaps and offers a lustrous appearance. |

|

|

|

3. Powder Coating

Powder Coating: Powder coating involves applying a dry powder to the keycap's surface and then curing it through a heating process. This treatment offers a wide range of colors, textures, and finishes. Powder-coated CNC metal mechanical keycaps are known for their durability, scratch resistance, and resistance to fading. |

|

|

|

4. PVD

PVD: PVD coating is a vacuum deposition process where a thin film is deposited onto the keycap's surface. This treatment provides a range of metallic finishes such as gold, rose gold, or black. PVD-coated CNC metal mechanical keycaps offer excellent wear resistance and durability. |

|

|

|

5. Painting

Painting: Painting is a common surface treatment option where a layer of paint is applied to the CNC metal mechanical keycap's surface. This treatment allows for a wide variety of color choices and finishes. Painting can be combined with other treatments for added durability and customization. |

|

|

|

6. Laser Etching

Laser Etching: Laser etching involves using a laser to engrave designs or patterns onto the CNC metal mechanical keycap's surface. This treatment provides precise and detailed customization options. Laser-etched designs can be filled with color to enhance visibility and aesthetics. |

|

|

|

When customizing a CNC metal mechanical keycap finish, we select a finish based on your appearance, durability, and compatibility with the material you choose. Different surface treatments have different surface effects and textures. Finishes such as anodizing, plating, powder coating, PVD coating, painting, laser etching and custom finishes offer a range of options to customize and protect your custom CNC metal mechanical keycaps. |

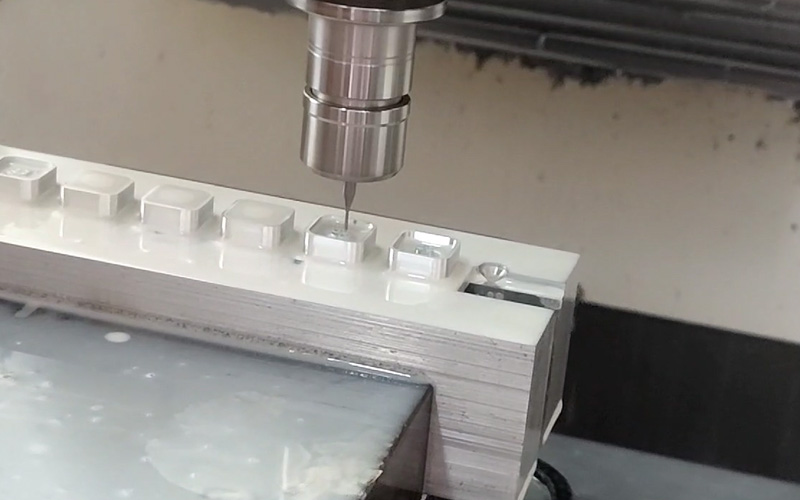

| The manufacturing process of custom CNC metal mechanical keycaps involves several steps to transform raw materials into finished products. A professional engineering team guides you through the creation of these purpose-built CNC keycaps. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with designing the CNC keycaps. Designers use CAD software to create digital models that custom CNC machine the shape, size and detail of the keycaps. The design serves as a blueprint for the manufacturing process. Prototyping can also be done to ensure the design meets the required specifications. |

|

2. Material Selection

Material Selection: Once the design is finalized, the appropriate material for the CNC machining keycap is chosen. Common materials include aluminum, brass, stainless steel, titanium, and copper, each offering unique characteristics in terms of weight, appearance, and durability. |

|

3. CNC Machining

CNC machining: Precision CNC machining machines shape the selected material into CNC mechanical keycaps. The CAD design is translated into instructions that instruct the CNC machine to cut, drill and engrave the CNC keycaps according to the required specifications. This process ensures the accuracy and consistency of CNC metal mechanical keycap production. |

|

4. Surface Treatments

Surface Treatments: After custom CNC machining mechanical keycaps, surface treatment is applied to enhance their appearance and durability. Common surface treatments include anodizing, plating, powder coating, PVD coating, painting, laser etching or custom finishes. These treatments provide protection, customization options, and aesthetics to the CNC keycaps. |

|

5. Quality Control

Quality Control: After the CNC machined mechanical keycaps are completed, they must go through strict quality control inspections. Inspect keycaps for any defects, ensuring correct size, finish and overall function. Ensure that 0 defect high quality CNC keycaps reach customers. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and delivery: Metal mechanical keycaps are packaged after passing quality control, and packaging and shipping methods can be customized according to customer requirements to prevent damage during transportation. |

|

Manufacturing processes may vary depending on the specific manufacturer and its production techniques. The manufacturing process of custom CNC metal mechanical keycaps includes design and prototyping, material selection, CNC machining, surface treatment, quality control, and packaging. By following these steps, manufacturers can ensure the production of high-quality CNC mechanical keycaps that meet the required specifications. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Metal Mechanical Keycaps FAQs

Here are some frequently asked questions about custom CNC RM-6 ribbon wireless microphone bodies:

|

1. Are custom CNC metal mechanical keycaps compatible with all mechanical keyboards?

Yes, custom CNC metal mechanical keycaps can be designed to fit various mechanical keyboard models. However, it is essential to check compatibility specifications before making a purchase.

2. Can I request a specific design for my custom CNC metal mechanical keycaps?

Absolutely! Custom CNC metal mechanical keycaps services specialize in creating personalized designs. You can work closely with the manufacturer to bring your unique keycap vision to life.

3. How durable are CNC metal keycaps compared to plastic keycaps?

CNC metal keycaps are highly durable and long-lasting compared to plastic keycaps. Metal keycaps can withstand heavy usage without showing signs of wear and tear.

4. Is it possible to change the keycap design after the manufacturing process begins?

Once the manufacturing process begins, it becomes challenging to alter the keycap design. It is crucial to finalize the design details beforehand to ensure a smooth production process.

5. Are custom CNC metal mechanical keycaps services cost-effective?

While custom CNC metal mechanical keycaps services may have a higher price point compared to mass-produced keycaps, they offer superior quality, durability, and customization options. The investment is worthwhile for enthusiasts seeking a premium typing experience.

6. Why choose custom CNC metal mechanical keycaps?

7. Can custom CNC metal mechanical keycaps be personalized?

|

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.