15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

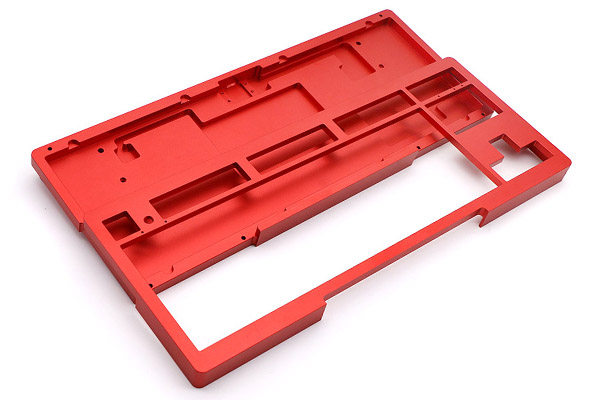

Custom CNC Machining GH60 45% 50% 60% 75% 80% Keyboard Case DIY Anodized Aluminum Mechanical Keyboard Shell Plate

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC GH60 60% 80% Keyboard Shell Services Manufacturer in China

|

Welcome to our exceptional service offering custom CNC anodized aluminum keyboard shell manufacturing. We specialize in catering to the unique requirements of GH60 60% and 80% layouts. With a focus on prototyping, surface treatment, and material excellence, here's how we bring your keyboard customization dreams to life: |

Custom CNC Aluminum Keyboard Shell Prototyping Machining

Our journey begins with meticulous prototyping. We understand the importance of precision, so we create prototype keyboard shells that match your desired layout down to the last detail. Our prototyping process ensures that you have a tangible representation of your vision before moving into full-scale production. |

|

|

|

|

||

Custom CNC Anodized Aluminum Keyboard Shell Surface Treatment |

Custom CNC Keyboard Shell Material |

||

|

Elevate your keyboard shell aesthetics with our exceptional surface treatment options. Our anodizing process enhances the aluminum's durability while offering a stunning array of colors. Whether you seek the elegance of brushed silver, the sleekness of matte black, or a burst of vibrant color, our surface treatments transform your keyboard into a work of art. |

We pride ourselves on sourcing only the highest quality aluminum for our keyboard shells. Aluminum combines lightweight versatility with remarkable durability, making it an ideal material for keyboard enclosures. Its anodizability ensures a protective layer that resists wear, scratches, and corrosion, maintaining the shell's appearance over time. |

Custom CNC GH60 60% 80% Keyboard Shell

|

|

|

||

|

Gh60 60% CNC Aluminium Keyboard Shell |

87 80% Key Aluminum Keyboard Shell | ||

|

|

|

||

|

ABM648 64 Key Aluminum Keyboard Shell |

Acrylic CNC Keyboard Shell | ||

| When it comes to custom CNC GH60 60% and 80% anodized aluminum keyboard shells, material selection plays a crucial role in both aesthetics and functionality. Here's a rundown of commonly used materials and a material price comparison to help you make an informed decision: |

|

|

Custom CNC Aluminum Keyboard Shell

Aluminum is a popular choice for keyboard cases because of its light weight and versatility. Durability and light weight make it suitable for GH60 60% and 80% layouts. Its anodizing capabilities provide custom color options and enhanced wear and corrosion resistance. Aluminum is generally more cost-effective than brass and stainless steel.

More Details>> |

|

|

|

Custom CNC Brass Keyboard Shell

Brass exudes a premium and substantial feel, adding weight to the keyboard. While less commonly used due to its weight, brass offers a unique aesthetic with its warm and classic appearance.Brass is often more expensive due to its higher material cost and the challenges associated with machining.

More Details>> |

|

|

|

Custom CNC Stainless Steel Keyboard Shell

Stainless steel provides a sleek and polished look with added durability. It's heavier than aluminum but offers a modern aesthetic and exceptional resistance to corrosion.Stainless steel falls on the higher end of the price spectrum due to its material cost and the precision required during machining.

More Details>> |

|

| The material you choose depends on your preferences, budget, and desired keyboard experience. Each material has its own unique characteristics, and the price difference reflects factors like availability, machining complexity, and aesthetics. Consider your priorities and consult with a manufacturer to find the best material that aligns with your vision. |

|

Welcome to the realm of custom CNC GH60 60% and 80% anodized aluminum keyboard shell surface finishing. Our selection of surface treatments enhances not only the visual allure of your keyboard shell but also its overall durability. Here's a closer look at our exquisite finishing options: |

|

1. Anodizing CNC Keyboard Shell Anodizing is a versatile surface treatment that offers a protective layer while introducing an array of vibrant colors. From classic blacks to bold reds and sleek silvers, anodizing enriches your keyboard shell's aesthetics while bolstering its resistance against scratches and corrosion. |

|

|

2. Brushed CNC Keyboard Shell

The brushed finish introduces a touch of sophistication with its finely textured linear patterns. This treatment exudes refinement and is a perfect fit for those seeking a subdued yet stylish appearance for their keyboard shell. |

|

|

|

3. Electrophresis CNC Keyboard Shell

For a modern, understated look, an electrophoretic matte finish is ideal for CNC keypad enclosures. It offers a non-reflective finish that exudes elegance, making it a favorite in minimalist settings. |

|

|

|

4. Polishing CNC Keyboard Shell

The high gloss finish delivers a polished and reflective surface that demands attention. This option imparts a sleek and premium appearance, elevating the overall visual impact of your keyboard shell. |

|

|

|

5. Patterned Engravings CNC Keyboard Shell

Add a personal touch to your keyboard case with pattern engraving. Intricate designs, logos or patterns can be etched into the surface of the CNC keypad case, allowing you to showcase your unique style and personality. |

|

|

|

6. Natural Oxidation CNC Keyboard Shell

If you prefer the inherent look of aluminum, clear anodizing enhances the metal's innate characteristics while adding a protective layer. This treatment preserves the original color while safeguarding against wear and corrosion. |

|

|

|

With our diverse range of surface finishing options, your custom CNC GH60 60% and 80% anodized aluminum keyboard shell will captivate the eye and stand the test of time. Whether you gravitate toward vibrant hues or refined subtlety, our surface finishing ensures a keyboard shell that mirrors your individuality.

To view the surface finishing effect, click here: https://www.machining-custom.com/aluminum-surface-finishing/ |

| Welcome to the world of custom CNC GH60 60% and 80% anodized aluminum keyboard shell manufacturing. Our meticulous process combines precision engineering and innovative techniques to create keyboard shells that embody both aesthetics and functionality. Here's an overview of our manufacturing journey: |

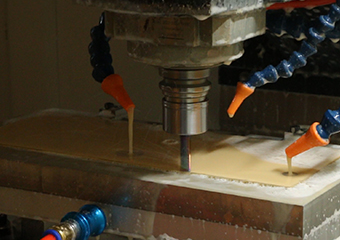

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping:The process begins with design conceptualization. Our team collaborates with you to understand your layout preferences and design elements. We create prototypes that bring your vision to life, allowing you to visualize the final product before full-scale production. |

|

2. Material Selection

Material selection: Choosing the right material is crucial. We carefully select high-quality anodized aluminum known for its durability and lightweight properties. The selected aluminum serves as the foundation for crafting your keyboard shell. |

|

3. CNC Machining

CNC machining: Precision CNC machining is at the heart of our manufacturing process. Using advanced machinery, we transform the selected aluminum into the intricate design specified in the prototype. Every cut, curve, and angle is meticulously executed to ensure a perfect fit and flawless appearance. |

|

Surface Treatment: The chosen surface treatment is applied to enhance both aesthetics and durability. Anodizing, brushing, matte or gloss finishes, and other treatments are meticulously applied to achieve the desired appearance. This step adds a protective layer that resists wear, scratches, and corrosion. |

|

Quality Inspection: Each keyboard shell undergoes rigorous quality control. Our experts inspect the shell for precision, finish quality, and adherence to design specifications. Any imperfections are addressed to ensure that every shell meets our high standards. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

6. Assembly Compatibility

Assembly Compatibility: To guarantee seamless assembly, we ensure that the keyboard shell is designed with precise cutouts for switches, keycaps, connectors, and other components. Compatibility with both GH60 60% and 80% layouts is meticulously ensured. |

|

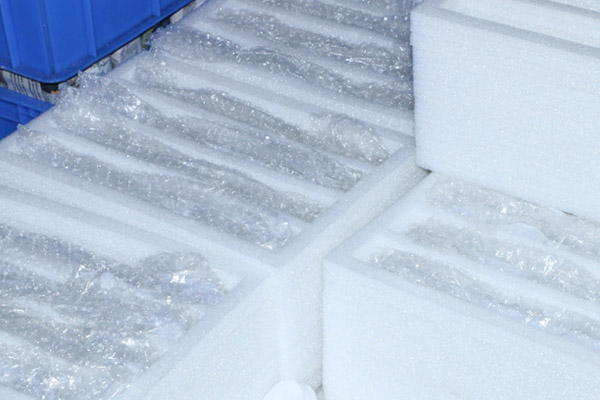

7. Packaging and Delivery

Packaging and Delivery: Each completed keyboard shell is carefully packaged to protect it during transit. Our efficient logistics ensure timely and safe delivery of your customized keyboard shell to your doorstep. |

|

At every stage of our custom CNC GH60 60% and 80% anodized aluminum keyboard shell manufacturing process, we prioritize precision, craftsmanship, and attention to detail. The result is a keyboard shell that not only looks stunning but also performs exceptionally, elevating your keyboard experience to new heights. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC machining work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC GH60 60% 80% Anodized Aluminum Keyboard Shell FAQs

|

What is a GH60 keyboard layout?

The GH60 layout refers to a compact 60% keyboard design that eliminates the number pad, function row, and navigation cluster, resulting in a smaller and more minimalist layout.

What are 60% and 80% keyboard layouts?

Why choose anodized aluminum for keyboard shells?

What surface treatments are available for keyboard shells?

Can I customize the color and design of my keyboard shell?

Are these keyboard shells compatible with different layouts?

What is the manufacturing process for these keyboard shells?

Are these keyboard shells easy to assemble?

How can I order a custom keyboard shell?

What is the turnaround time for orders?

|

|

If you have more questions or specific inquiries about our custom CNC GH60 60% 80% anodized aluminum keyboard shells, feel free to reach out to our dedicated customer support team. We're here to help you create the perfect keyboard shell that suits your preferences and needs. Contact us now to discuss your custom precision CNC keyboard shells requirements and get a quote. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.