15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

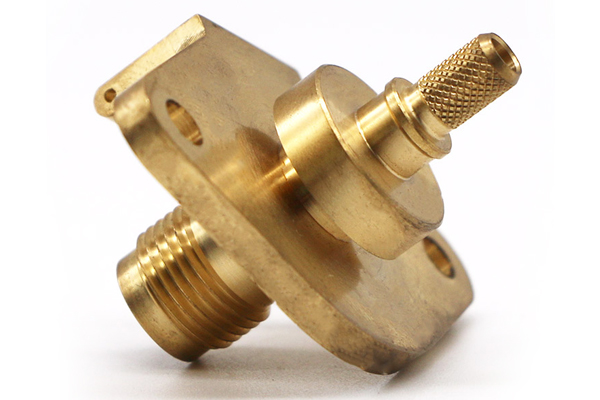

Custom Precision Brass CNC Machining Milling Parts Manufacturing

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom Precision Brass CNC Machining Parts Manufacturing Services in China

|

We provide one-stop custom copper precision CNC machining parts manufacturing services. Professional copper CNC machining project engineers provide you with solutions and analysis. CNC prototyping, surface treatment and material selection, detailed records and transparent sharing of each production, processing and manufacturing, welcome to view the factory online, and now there is a discount for consultation. |

Custom Precision Brass CNC Machining Parts Manufacturing Prototyping Machining

Our CNC prototyping services are all about bringing your ideas to life. Turn your designs into precise prototypes using advanced CNC machining techniques. With CNC prototyping, you can visualize and verify the design of a part before mass production, and quickly modify it to ensure the final product meets your exact specifications. |

|

|

|

|

||

Custom Precision Brass CNC Machining Parts Manufacturing Surface Treatment |

Custom Precision Brass CNC Machining Parts Manufacturing Material |

||

|

Our team of experts offers a range of finishes for your copper CNC machined parts to meet functional and aesthetic needs. There are surface treatment factories that have cooperated for 11 years, providing more than 15 kinds of surface treatments, you can view the surface treatment effect in video, and you can also view the surface effect here: https://www.machining-custom.com/aluminum-surface-finishing/. |

Material Selection: Guaranteed Optimum Performance |

Custom Precision Brass CNC Machining Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Brass is an alloy of copper and zinc that comes in a variety of components, each with its own unique properties. The following are common brass alloy materials: |

|

|

Custom C26000 Copper Brass Machining Parts

C26000 (brass cartridge)

More Details>> |

|

|

|

Custom C36000 Copper Brass Machining Parts

C36000 (free-cutting brass)

More Details>> |

|

|

|

Custom C46400 Copper Brass Machining Parts

C46400 (Navy Brass)

More Details>> |

|

|

|

Custom C48500 Copper Brass Machining Parts

C48500 (leaded navy brass)

More Details>> |

|

|

|

Custom C68700 Copper Brass Machining Parts

C68700 (aluminum brass)

More Details>> |

|

、

、

| Brass alloys offer a wide range of properties and applications, making them valuable materials in various industries. The choice of brass type depends on specific project requirements, such as machinability, corrosion resistance, and strength. It's essential to work with reputable suppliers who can provide suitable brass alloys at competitive prices for your precision brass CNC machining projects. |

|

Copper brass CNC machined parts can be given a variety of surface treatments to enhance their performance and aesthetics. The following are common surface treatments: |

|

1. Oxidation Treatment

|

|

|

2. Polishing

Polishing achieves a reflective and smooth surface that enhances the aesthetics of copper parts for high-end and decorative applications. Polishing is divided into manual and machine, because the manual polishing process requires a lot of labor, polishing will increase the cost. |

|

|

|

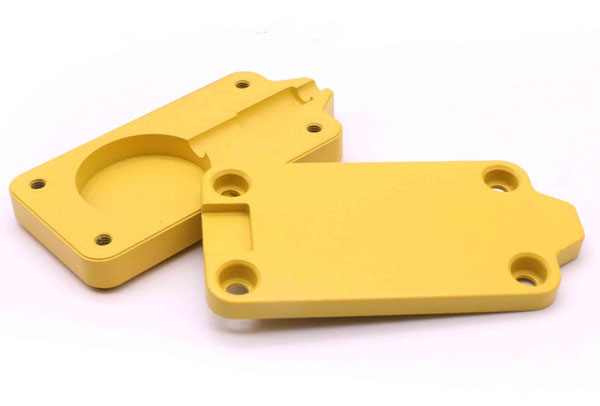

3. Painting

Painting can be customized in a variety of colors for the customer to choose, providing an extra layer of protection. Surface effects present vibrant colors and smooth surfaces. Painting copper parts can have some impact on cost, depending on the complexity and number of colors used. |

|

|

|

4. Powder coating

Available in a variety of colors and textures, the powder-coat finish is durable and scratch-resistant with a matte finish, not metallic. |

|

|

|

5. Electroplating

Electroplating improves the corrosion resistance of copper parts and enables various surface finishes such as chrome, nickel or gold. The surface is mirror-like, shiny and reflective. Applied to high-end products and decorations. Electroplating is generally a medium to moderately expensive finish option compared to other finishes such as anodizing or painting. |

|

|

|

The surface finish of copper CNC machined parts has many advantages. The decision to apply a surface treatment should be based on specific project requirements and budgetary considerations. We have professional surface treatment engineers to determine the best surface treatment options for your custom precision copper CNC machined parts, ensuring they meet your functional, aesthetic and budgetary needs.

To view the surface finishing effect, click here: https://www.machining-custom.com/aluminum-surface-finishing/ |

| The manufacturing process of custom precision brass CNC machined parts involves several critical steps to ensure the highest quality and precision. The following is the process of CNC machining to manufacture precision numerically controlled brass parts: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping:The process begins with the customer's requirements and design specifications. The engineering team collaborates with the customer to understand their needs and create detailed Computer-Aided Design (CAD) models of the brass parts. The CAD models serve as the blueprint for the CNC machining process. |

|

2. Material Selection

Material selection: After finalizing the design, the appropriate brass alloy is chosen based on the specific application and performance requirements of the parts. Brass alloys such as C26000, C36000, and C46400 are commonly used for various applications due to their excellent properties. |

|

3. CNC Turning

CNC machining: The actual CNC machining process begins, where the brass stock material is loaded into the CNC machine. The machine follows the programmed toolpaths and uses various cutting tools to remove material, creating the intricate shapes and features as per the design. |

|

4. Quality Inspection

Quality Inspection: Throughout the machining process, strict quality control measures are implemented. Post-machining, the brass parts undergo comprehensive inspections using precision measuring instruments to verify dimensional accuracy and adherence to design specifications. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

5. Surface Treatments (Optional)

Surface Treatments: Depending on the customer's requirements, the precision brass parts may undergo surface treatments, such as anodizing, polishing, painting, or powder coating, to enhance their properties and appearance. |

|

6. Finishing and Assembly (If Required)

Finishing and Assembly (If Required): Once the surface treatments, if any, are completed, the precision brass parts may undergo additional finishing processes to remove any sharp edges or burrs. If required, the parts may also be assembled into larger components or sub-assemblies. |

|

7. Packaging and Delivery

Packaging and Delivery: We will choose a suitable or customized packaging method for aluminum CNC parts according to the customer's needs and transportation methods to ensure safe transportation and deliver them to customers on time according to the delivery date. |

|

The custom precision brass CNC machining parts manufacturing process combines advanced technology, skilled craftsmanship, and rigorous quality control to produce high-quality brass components. From design and material selection to CNC machining, surface treatments, and finishing, each step is meticulously executed to meet the customer's exact specifications and deliver reliable and precise brass CNC parts for various applications. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Precision Brass CNC Machining Parts Manufacturing FAQs

|

What is CNC machining, and why is it suitable for brass parts manufacturing?

CNC machining stands for Computer Numerical Control machining, a manufacturing process that uses computer-controlled machines to remove material from a workpiece and create precise shapes and features. It is ideal for brass parts manufacturing due to its ability to achieve high accuracy, tight tolerances, and complex geometries, ensuring superior quality and consistency.

What are the advantages of using brass for CNC machining parts?

Brass offers several advantages, including excellent machinability, high corrosion resistance, good electrical conductivity, and an attractive golden appearance. These properties make brass suitable for various industries, including electronics, automotive, plumbing, and architectural applications.

Can you accommodate custom designs and specific requirements for precision brass parts?

Yes, we specialize in custom precision brass CNC machining parts manufacturing. Our engineering team can work closely with you to understand your unique requirements and design specifications, ensuring that the final brass parts meet your exact needs.

What types of brass alloys do you use for CNC machining?

We work with various brass alloys, including C26000 (Cartridge Brass), C36000 (Free-Cutting Brass), C46400 (Naval Brass), and more. The choice of brass alloy depends on your specific application and performance requirements.

Do you offer surface treatments for precision brass parts?

Yes, we provide a range of surface treatments for precision brass parts, including anodizing, polishing, painting, powder coating, and more. These surface treatments enhance the parts' properties and aesthetics, allowing you to tailor the brass components to your desired specifications.

How do you ensure the quality of custom precision brass CNC machining parts?

Quality is our top priority. Throughout the manufacturing process, we implement strict quality control measures and conduct thorough inspections using precision measuring instruments. Our commitment to quality ensures that the precision brass parts meet the highest standards and exceed your expectations.

What is the typical lead time for custom precision brass parts manufacturing?

The lead time for custom precision brass parts manufacturing varies depending on the complexity of the design, quantity, and surface treatments required. Our team will provide you with an estimated lead time based on your specific project details.

Can you handle both small and large production runs for precision brass parts?

Yes, we have the capability to handle both small and large production runs for precision brass parts. Our flexible manufacturing processes and skilled team allow us to accommodate various production volumes.

Do you offer assembly services for precision brass parts?

Yes, if your project requires assembly of precision brass parts into larger components or sub-assemblies, we can provide assembly services to meet your needs.

How can I get a quote for custom precision brass CNC machining parts?

You can easily get a quote by contacting our team through the provided contact link. Please provide us with your design specifications, quantity requirements, and any specific surface treatments or finishing options you desire, and we will promptly provide you with a competitive quote. |

|

If you have any other custom precision brass CNC machining parts fabrication questions or need more information, our professional engineering team is always ready to serve you, 24 hours online.

Contact us now to discuss your custom precision brass CNC machining parts requirements and get a quote. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.