15 years one-stop China custom CNC machining parts factory

Home / Industry / Electronics /

Developing consumer electronics and computer components requires advanced manufacturing processes to accelerate production and reduce costs. With extensive experience, technical expertise, and cutting-edge technology, VMT takes electronics manufacturing to the next level, delivering high-quality, user-friendly prototypes and products. VMT offers rapid prototyping solutions across various industries, supporting everything from early-stage prototypes to final components, backed by professional facilities and knowledge to realize complex designs.

High-Quality Parts with Tight Tolerances

VMT specializes in custom manufacturing high-quality electronic device components, covering both industrial and consumer electronics, regardless of design complexity. With robust manufacturing capabilities and precision tolerances as tight as ±0.001 inches (±0.01 mm), we ensure product accuracy to fully meet your diverse needs.

Fast Quoting and Delivery

VMT helps you quickly obtain quotes and parts. With our professional engineers, advanced skills, and extensive CNC manufacturing experience, we can shorten the project timeline for consumer electronic device components by 50%. We provide quotes within 2 hours and delivery within 3 days, accelerating your project progress.

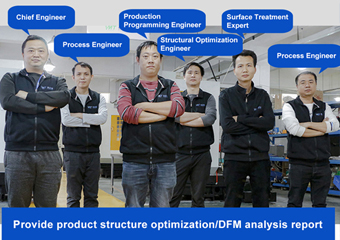

Engineering Support

VMT helps you quickly obtain quotes and parts. With our professional engineers, advanced skills, and extensive CNC manufacturing experience, we can shorten the project timeline for consumer electronic device components by 50%. We provide quotes within 2 hours and delivery within 3 days, accelerating your project progress.

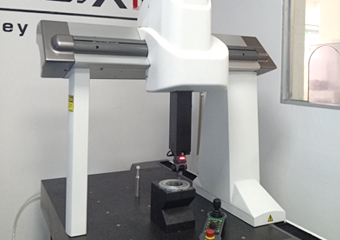

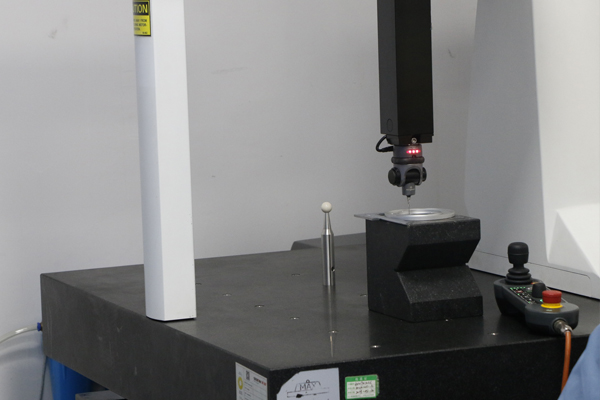

Quality Inspection

We have a comprehensive quality control system, including IQC, IPQC, and FQC, to monitor the entire process from raw material intake to shipment, and we retain inspection reports for two years. Equipped with advanced 3D and 2D measuring instruments and laboratories, we ensure precise dimensional accuracy and material compliance. We offer CMM inspections, material testing, and conformity certificates to guarantee exceptional product quality.

Surface Finishing

With a decade-long partnership with our surface treatment factory, we offer over 40 surface treatment processes. Our two senior engineers work closely with you to customize cost-effective solutions based on your specific requirements. We strictly control the entire process, ensuring a high yield rate of 98% and exceptional surface treatment results.

Certifications and Patents

VMT is an ISO 9001:2015 and IATF 16949 certified manufacturer, holding 12 patents. We utilize advanced technologies such as CNC machining, sheet metal manufacturing, and die casting to ensure the precise and efficient production of consumer electronics components. We are committed to meeting your highest standards for quality, dimensions, and performance, while providing exceptional service.

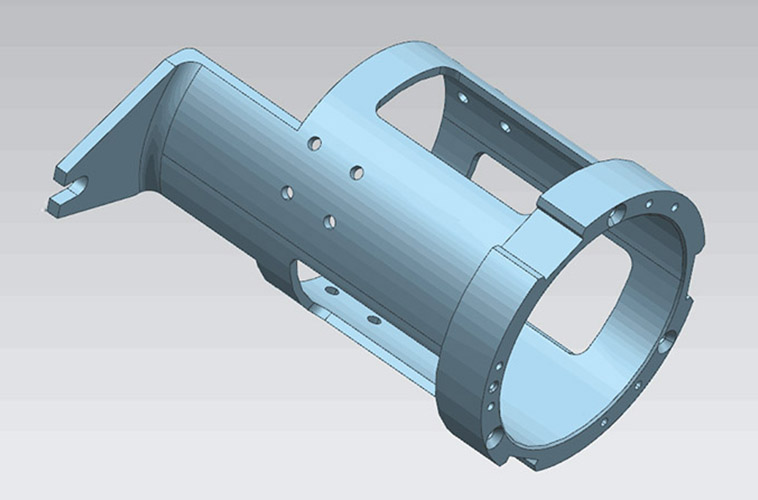

Prototyping and CAD Digital Model

We use production-grade materials to create prototypes for consumer electronic products, bringing designs to life with fully functional features ready for testing. Our 20-person technical team provides comprehensive support, from material selection to final production, ensuring prototypes precisely meet your specifications and helping you evaluate and optimize designs, taking a crucial step in electronic product development.

Engineering Validation and Testing

Through rigorous engineering testing and performance validation, we quickly refine and improve consumer electronic product prototypes, mimicking the final product and providing clear visual representation to identify potential issues. VMT accelerates iteration with precise machining processes, ensuring the prototype meets standards and speeding up the product's time to market.

Structural and Appearance Verification Testing

Collaborate with VMT's professional design team to assess and enhance the performance, functionality, and aesthetics of consumer electronic products. During the prototype stage, we use CNC machining to validate designs, offering a variety of materials and surface treatment options. By evaluating multiple dimensions comprehensively, we identify and resolve issues early, saving time and resources.

Production Validation and Testing

Leverage our production-grade manufacturing capabilities and expert quality control to simplify large-scale production design. Our technical team provides in-depth feedback, evaluating the manufacturability and applicability of product parts. Through small-batch trials and transparent quality control, we optimize design and supply chains during the PVT phase, addressing potential issues and laying a solid foundation for mass production.

Mass Production

After product testing, VMT delivers final-use components quickly, seamlessly integrating your quality standards into the manufacturing process for easy transition to mass production. Our experienced engineering team and advanced processes ensure efficient output, closely aligned with quality requirements, accelerating time-to-market and meeting the dual demands of quality and efficiency.

With top-tier manufacturing capabilities, VMT specializes in rapid prototyping and custom production. We have our own factory and an extensive manufacturing network, ensuring the efficient and precise delivery of complex, high-quality parts, combining speed and quality to perfectly meet a wide range of manufacturing needs.

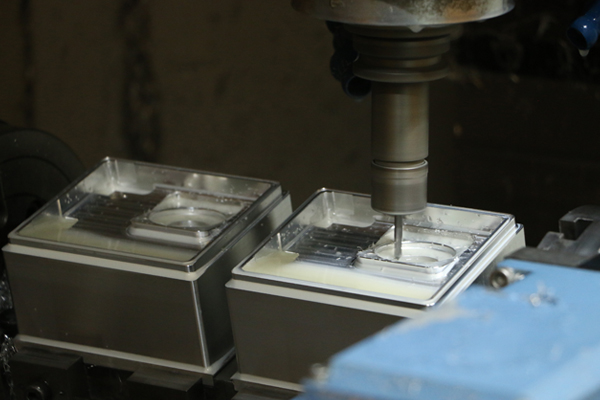

CNC Machining

Using CNC milling, turning, and post-processing techniques, we precisely create complex designs, especially suitable for high-precision prototypes and functional metal parts, ensuring every detail is perfected.

Sheet Metal Fabrication

Flexibly shaping precision metal parts, widely adaptable to various applications, with both accuracy and versatility.

Extrusion machining

Efficient and cost-effective technology, compatible with a wide range of materials, capable of producing complex-shaped parts, improving production efficiency and material utilization.

Die Casting

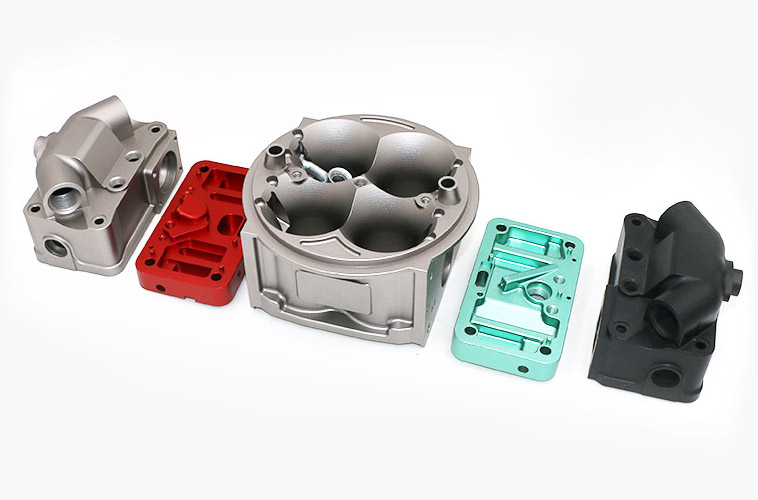

This process is ideal for large-scale CNC metal parts manufacturing, reducing costs while shortening turnaround times, and ensuring consistent quality across all parts.

We have our own material library and stable partnerships with material suppliers for decades, offering SGS material reports. We also collaborate with a surface treatment factory with over 10 years of experience, providing 40+ surface treatment options. Our dedicated SQE team follows up and controls each process at the surface treatment facility, and performs 100% visual inspection of the products upon return to the factory.

Materials

We also offer a variety of metal and plastic materials to meet different precision CNC machining and manufacturing requirements.

Surface Finishing

With over 40 surface finishing processes, two surface treatment engineers oversee process control to enhance the appearance and functionality of your precision CNC machined parts.

VMT, with advanced manufacturing processes and extensive production capabilities, creates functional consumer electronics prototypes and products through customized manufacturing solutions, covering circuit boards, microcontrollers, and 3C electronic product enclosures. We enhance the productivity of consumer electronics components, widely applied across various industries, helping you stay ahead in market competition.

Our business has grown to now cover 62 countries worldwide. We have done products in the electronics industry, industrial industry, automotive industry, and medical industry. If you need custom CNC Machining Components parts service, we have rich manufacturing experience and can turn your ideas into products.

Electronic Industry

Industrial Industry

Automotive Industry

Medical Industry

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red