15 years one-stop China custom CNC machining parts factory

Home / Product / Industrial Industry /

VMT is a manufacturing facility for various industrial CNC machining parts. With 13 years of experience in CNC processing industrial parts and various types of CNC industrial parts samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of industrial CNC machining product services to meet your customized CNC machining needs.

Product Specification:

Custom CNC Machining Turning M3 M4 M5 M8 Copper Brass Knurled Threaded Insert Nuts Manufacturer

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Our Custom Brass Knurled Threaded Insert Nuts Manufacturer

| As a dedicated custom CNC machining manufacturer, we provide tailor-made solutions to meet your specific requirements. Whether you require a unique dimension, special thread size, or specific design feature, understanding your needs and delivering a custom brass knurled thread insert nut to your specifications ensures that each product is delivered with the highest quality and precision. |

Custom Brass Knurled Threaded Insert Nuts Services

|

In Custom Brass Knurled Thread Insert Nut services, as a leading CNC prototype manufacturer, we specialize in providing high quality Brass Knurled Thread Insert Nuts and solutions that meet your specific needs. From CNC prototyping to working with multiple materials and offering a variety of finishes, delivered on time. Trust us to be your reliable partner in the field of custom CNC machining and experience the outstanding results we can achieve together. |

Custom Brass Knurled Threaded Insert Nuts Prototyping Machining

With our state-of-the-art CNC machines, we can create accurate and precise prototypes of custom brass knurled threaded insert nuts. Whether you require a small batch or a large production run, our CNC prototyping capabilities ensure consistent quality and dimensional accuracy. Our skilled technicians and advanced equipment allow us to deliver prototypes quickly and efficiently, saving you time and cost in the development process. |

|

|

|

|

||

Custom Brass Knurled Threaded Insert Nuts Surface Treatment |

Custom Brass Knurled Threaded Insert Nuts Material |

||

|

We understand that different applications may require specific material properties. That's why we offer a wide selection of materials for custom brass knurled threaded insert nuts. From brass to stainless steel, aluminum to plastic, we have the expertise to work with various materials based on your project requirements. Our team will guide you in selecting the most suitable material for your specific application, ensuring optimal performance and durability. |

To enhance the functionality, appearance, and longevity of your custom brass knurled threaded insert nuts, we provide a range of surface treatments. These treatments not only improve the aesthetic appeal but also offer additional protection against corrosion and wear. |

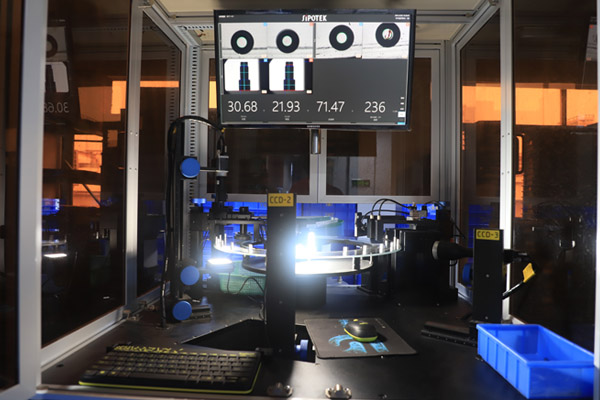

Automatic Chamfer Machine, More precision CCD 100% Inspection Machine, 100% Guarantee Quality

Custom Brass Knurled Threaded Insert Nuts Parts Sample

| Inserts For Plastic | Sheet Metal Fasteners | Direct Screw Fixings |

| Plugs | Knurled Insert |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| When it comes to custom brass knurled threaded insert nuts, the choice of material plays a crucial role in determining their performance, durability, and suitability for specific applications. Here are some common materials used in the manufacturing of custom brass knurled threaded insert nuts: |

|

|

Aluminum Knurled Threaded Insert Nuts

Aluminum: Aluminum insert nuts are lightweight yet strong, making them suitable for applications where weight is a concern. They have good corrosion resistance and are often used in industries such as automotive and aerospace.

More Details>> |

|

|

|

Stainless Steel Knurled Threaded Insert Nuts

Stainless Steel: Stainless steel insert nuts offer high corrosion resistance, making them ideal for applications exposed to harsh environments or chemicals. They are also known for their strength and durability, making them suitable for heavy-duty applications.

More Details>> |

|

|

|

Brass Knurled Threaded Insert Nuts

Brass: Brass is a popular material choice for insert nuts due to its excellent corrosion resistance, durability, and thermal conductivity. It is known for its attractive golden appearance and is suitable for both indoor and outdoor applications.

More Details>> |

|

|

|

Steel CNC Knurled Threaded Insert Nuts

Steel: Steel insert nuts provide high strength and durability, making them suitable for applications that require robust fastening. They are commonly used in heavy machinery, construction, and automotive industries.

More Details>> |

|

|

|

Plastics CNC Knurled Threaded Insert Nuts

Plastics:Plastic insert nuts are chosen for applications where electrical insulation, lightweight construction, or non-magnetic properties are required. They are commonly used in electronics, automotive, and consumer goods industries.

More Details>> |

|

|

|

Other Metals: We can also work with other metals such as brass, copper, and various alloys, depending on your project's needs. These materials offer unique properties and aesthetic options for your custom CNC machining parts. More Details>> |

|

| Custom brass knurled threaded insert nuts are available in various materials, each offering unique properties and advantages. Whether you require the corrosion resistance of brass, the strength of stainless steel, or the lightweight characteristics of aluminum or plastic, there is a material suitable for your specific application. Consider the requirements of your project and consult with experts to choose the right material for your custom brass knurled threaded insert nuts. |

|

Surface treatments play a vital role in enhancing the performance, durability, and aesthetics of custom brass knurled threaded insert nuts. Depending on the application requirements and desired outcomes, different surface treatments can be applied. Here are some common surface treatments for custom brass knurled threaded insert nuts: |

|

1. Anodizing

Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the insert nuts. This treatment is commonly used for aluminum insert nuts but can also be applied to brass. Anodizing enhances corrosion resistance, improves surface hardness, and provides a range of color options. It can also create a smooth, aesthetically pleasing finish. |

|

|

2. Powder Coating

Powder Coating: Powder coating involves applying a dry powder to the surface of the insert nuts and then curing it to form a durable and protective coating. This treatment offers excellent corrosion resistance, impact resistance, and a wide range of color options. Powder coating provides a smooth and attractive finish, making it popular for both functional and decorative applications. |

|

|

|

3. Painting

Painting: Painting is a surface treatment option that allows for customization in terms of color and finish. It provides an additional layer of protection against corrosion and enhances the aesthetics of the insert nuts. Painting is suitable for applications where specific color requirements or branding considerations are essential. |

|

|

|

4.Plating

Plating: Plating involves depositing a thin layer of metal, such as nickel, chrome, or zinc, onto the surface of the brass knurled threaded insert nuts. This treatment provides enhanced corrosion resistance, improved durability, and an attractive finish. Plating can also offer a decorative element by providing a specific color or a reflective surface. |

|

|

|

5.Passivation

Passivation: Passivation is a chemical treatment that removes surface contaminants and forms a passive oxide layer on stainless steel insert nuts. This treatment improves corrosion resistance and enhances the natural protective properties of stainless steel. Passivation is especially beneficial in applications where the insert nuts are exposed to harsh environments or chemicals. |

|

|

|

Custom Finishes: We offer custom finishes to meet your specific design requirements. This can include brushed finishes, textured surfaces, or unique patterns. These custom finishes add a touch of personalization and can help your fascia gun housing stand out. |

|

|

|

Surface treatments for custom brass knurled threaded insert nuts offer a range of benefits, including enhanced corrosion resistance, improved durability, and aesthetic appeal. Plating, anodizing, passivation, powder coating, and painting are among the common surface treatments applied to these insert nuts. By selecting the appropriate surface treatment, you can optimize the performance and appearance of your custom brass knurled threaded insert nuts for their intended applications. The choice of surface treatment depends on factors such as the application environment, desired appearance, level of corrosion resistance required, and specific industry standards. It is recommended to consult with experts or surface treatment specialists to determine the most suitable treatment for your custom brass knurled threaded insert nuts. |

| Our custom CNC massager fascia gun housing manufacturing process involves several key steps to ensure precision, quality, and customization. Here is an overview of the typical process: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The manufacturing process begins with the design phase. Our skilled engineers work closely with you to understand your specifications and create detailed 3D models. Using advanced software, we then develop prototypes of the fascia gun housing to validate the design and make any necessary adjustments. |

|

2. Material Selection

Material Selection: The first step in the manufacturing process is selecting the appropriate material for the insert nuts. Brass, stainless steel, aluminum, or other materials are chosen based on the desired properties, application requirements, and industry standards. Material Preparation: Once the material is selected, it undergoes preparation, which may involve cutting the raw material into suitable lengths or shapes. This step ensures that the material is ready for further processing. |

|

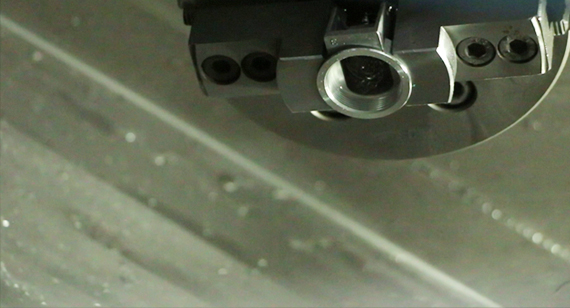

3. CNC Machining

CNC Machining: CNC (Computer Numerical Control) machining is widely used for manufacturing custom brass knurled threaded insert nuts. CNC machines are programmed to accurately and precisely cut, shape, and form the insert nuts according to the specified dimensions and design requirements. CNC machining ensures consistency and high-quality results. |

|

4. Knurling

Knurling: Knurling is a process where a pattern of ridges or grooves is formed on the surface of the insert nuts. This pattern improves grip and allows for secure fastening. Knurling is performed using specialized knurling tools or CNC machines with knurling capabilities. |

|

5. Threading

Threading: Threading involves creating internal or external threads on the insert nuts. This process is crucial for their functionality as they are designed to mate with corresponding threaded components. Threading can be achieved through various methods, including cutting threads using taps or dies or using CNC machines with thread-cutting capabilities. |

|

6. Surface Treatment

Surface Treatment: After the insert nuts are machined and threaded, they may undergo surface treatment for enhanced properties and aesthetics. This can include plating, anodizing, passivation, powder coating, or painting, as discussed in the previous section. |

|

7. Quality Control

Inspection and Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the insert nuts meet the required specifications and standards. Inspection may involve dimensional checks, thread gauging, surface quality assessment, and other quality control procedures. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

8. Packaging and Delivery

Packaging and Delivery: Once the custom brass knurled threaded insert nuts pass the quality control checks, they are carefully packaged to protect them during transportation. Proper packaging helps prevent damage or contamination. The insert nuts are then delivered to the customers or distributors, ready to be used in various applications. |

|

The manufacturing process of custom brass knurled threaded insert nuts involves material selection, CNC machining, knurling, threading, surface treatment, inspection, and packaging. Each step is crucial to ensure the production of high-quality insert nuts that meet the required specifications. By following these manufacturing processes, manufacturers can deliver reliable and durable custom brass knurled threaded insert nuts for a wide range of applications. |

Custom Brass Knurled Threaded Insert Nuts Application

|

Custom brass knurled threaded insert nuts find versatile applications across various industries and sectors. Their unique design and functionality make them an essential component in numerous assemblies. Here are some common applications of custom brass knurled threaded insert nuts: |

|

Furniture Manufacturing:

Custom brass knurled threaded insert nuts are widely used in the furniture industry to provide strong and secure connections. They are used to join different components, such as legs, handles, and brackets, ensuring stability and durability in furniture pieces.

Electronics and Electrical Equipment:

These insert nuts are utilized in the manufacturing of electronics and electrical equipment. They help secure components, such as circuit boards, panels, and connectors, ensuring proper alignment and preventing loosening or damage due to vibrations.

Automotive Industry:

Custom brass knurled threaded insert nuts play a crucial role in the automotive industry. They are used in various applications, including securing interior components, such as dashboard panels and trim, as well as in engine assemblies, suspension systems, and electrical connections.

Plastic Injection Molding:

These insert nuts are often incorporated into plastic injection-molded parts. They provide a reliable and durable threaded connection within the molded component, enabling easy assembly and disassembly.

Machinery and Equipment:

Custom brass knurled threaded insert nuts are used in the manufacturing of machinery and equipment across different sectors. They are employed to fasten components, mount handles and grips, and create adjustable connections in various mechanical assemblies.

Medical Devices:

These insert nuts find applications in the medical industry, where precision and reliability are of utmost importance. They are used in medical devices and equipment, such as surgical instruments, diagnostic tools, and patient care equipment.

Industrial Manufacturing:

Custom brass knurled threaded insert nuts are extensively used in industrial manufacturing processes. They provide secure connections in machinery, fixtures, jigs, and other equipment, ensuring efficient and reliable operations.

Aerospace and Defense:

These insert nuts are utilized in the aerospace and defense industries for their strength and reliability. They are employed in aircraft assembly, defense equipment, and aerospace applications, where high-performance fastening is crucial.

|

| Custom brass knurled threaded insert nuts find wide-ranging applications across industries such as furniture manufacturing, electronics, automotive, plastic injection molding, machinery, medical devices, industrial manufacturing, and aerospace and defense. Their ability to provide secure and reliable connections makes them an essential component in various assemblies and equipment. With their versatility and durability, custom brass knurled threaded insert nuts continue to play a vital role in numerous industries, ensuring the integrity and functionality of various products and systems. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Brass Knurled Threaded Insert Nuts FAQs

|

Q: What are custom brass knurled threaded insert nuts?

Q: What materials are custom brass knurled threaded insert nuts compatible with?

Q: How do custom brass knurled threaded insert nuts provide a secure connection?

Q: What advantages do custom brass knurled threaded insert nuts offer over other fastening methods?

Q: Can custom brass knurled threaded insert nuts be used in high-temperature applications?

Q: Are custom brass knurled threaded insert nuts reusable?

Q: What surface treatments are available for custom brass knurled threaded insert nuts?

Q: Can custom brass knurled threaded insert nuts be customized for specific dimensions and designs?

Q: What industries commonly use custom brass knurled threaded insert nuts?

Q: Where can I find custom brass knurled threaded insert nuts?

|

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.