15 years one-stop China custom CNC machining parts factory

Home / Product / Industrial Industry /

VMT is a manufacturing facility for various industrial CNC machining parts. With 13 years of experience in CNC processing industrial parts and various types of CNC industrial parts samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of industrial CNC machining product services to meet your customized CNC machining needs.

Product Specification:

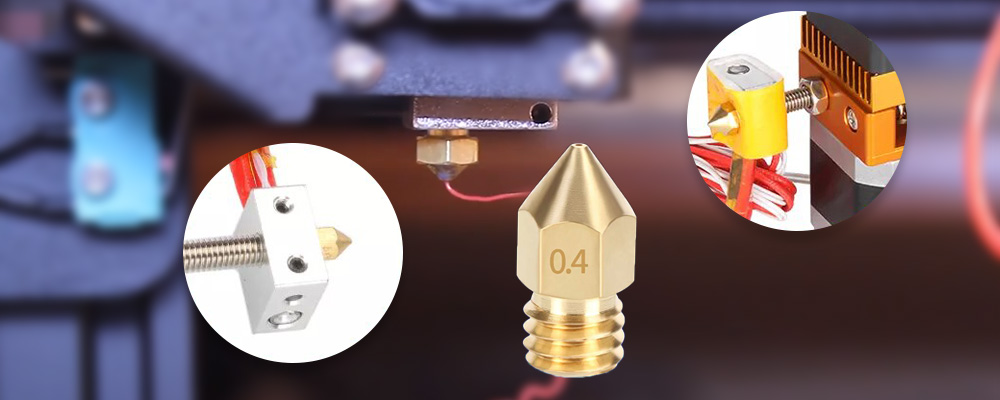

Custom MK8 MK10 Extruder Nozzle Parts 0.2mm to 1.0mm CNC Aluminum Stainless Steel Brass 3d Printer Nozzle

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC 3d Printer Brass Nozzle Services Manufacturer

| We are a professional custom CNC machining 3d printer brass nozzle manufacturer, we have provided personalized brass nozzle design and manufacture for more than 30 customers. We offer a wide range of capabilities including CNC prototyping, working with a variety of materials and providing surface treatments. Our services meet the needs of customers requiring high-quality, custom CNC fabrication. |

Custom CNC 3d Printer Brass Nozzle Prototyping Machining

Our CNC prototyping services allow us to create precise and accurate prototypes for brass nozzles. Using advanced CNC machines, we can quickly transform your design concepts into functional prototypes. This enables you to test and evaluate the performance of the nozzle before proceeding to full-scale production. Our skilled team ensures that the prototyping process is efficient and delivers superior results. |

|

|

|

|

||

Custom CNC 3d Printer Brass Nozzle Surface Treatment |

Custom CNC 3d Printer Brass Nozzle Material |

||

|

In addition to brass, we work with a variety of materials to meet the diverse needs of our clients. Our extensive material selection includes stainless steel, aluminum, titanium, and more. Whether you require a specific material for its properties or need to match existing components, we have the expertise to deliver outstanding results. We source high-quality materials to ensure durability, performance, and precision in every brass nozzle we manufacture. |

To enhance the functionality and aesthetics of brass nozzles, we offer a variety of finishes. Apply different finishes and coatings to meet your specific requirements. We make sure that the custom CNC 3D printer brass nozzles we manufacture not only perform optimally, but also match your aesthetic preferences. |

Custom CNC 3d Printer Brass Nozzle Parts Sample

|

|

|

|||

|

|

||||

|

|

|

|||

|

|

||||

|

|

|

| When it comes to custom CNC 3D printer brass nozzles, we understand the importance of selecting the right materials. The choice of materials directly affects the performance, durability, and overall quality of the nozzle. At VMT, we offer a range of high-quality materials for manufacturing custom CNC brass nozzles. Here are some of the materials we work with: |

|

|

Copper/Brass CNC 3d Printer Nozzle

Copper/Brass: Brass is the primary material used for manufacturing brass nozzles. It offers excellent thermal conductivity, corrosion resistance, and durability. Brass nozzles are known for their ability to handle high temperatures and maintain dimensional accuracy during the 3D printing process.

More Details>> |

|

|

|

Stainless Steel CNC 3d Printer Nozzle

Stainless Steel: Stainless steel is another popular material option for custom CNC 3D printer nozzles. It provides high strength, good thermal conductivity, and resistance to wear and corrosion. Stainless steel nozzles are suitable for applications that require enhanced durability and compatibility with a wide range of filament materials.

More Details>> |

|

|

|

Aluminum CNC 3d Printer Nozzle

Aluminum: Aluminum is a lightweight material with good thermal conductivity. It is commonly used in applications where weight reduction is a priority. Aluminum nozzles can offer efficient heat transfer while reducing the overall weight of the 3D printing setup.

More Details>> |

|

|

|

Steel CNC 3d Printer Nozzle

Steel: Steel insert nuts provide high strength and durability, making them suitable for applications that require robust fastening. They are commonly used in heavy machinery, construction, and automotive industries.

More Details>> |

|

|

|

Titanium CNC 3d Printer Nozzle

Titanium: Titanium is a premium material known for its exceptional strength-to-weight ratio and excellent corrosion resistance. Titanium nozzles are highly durable and can withstand high temperatures. They are often preferred for demanding applications that require superior performance and reliability. More Details>> |

|

| At VMT, we carefully select and source high-quality materials to ensure that our custom CNC 3D printer brass nozzles meet the highest standards of performance and reliability. Depending on your specific requirements, our team can recommend the most suitable material for your custom nozzle project. |

|

In addition to selecting the right materials, surface treatments play a crucial role in enhancing the performance, appearance, and durability of custom CNC 3D printer brass nozzles. At [Our Company Name], we offer a range of surface treatments to meet the specific needs and preferences of our clients. Here are some of the surface treatments we provide: |

|

1. Polishing

Polishing: Polishing is a process that involves smoothing the surface of the brass nozzle to create a visually appealing finish. This treatment not only enhances the aesthetics but also improves the nozzle's resistance to corrosion and wear. |

|

|

2. Anodizing

Anodizing: Anodizing is an electrochemical process that forms a protective layer on the brass nozzle's surface. This treatment offers excellent corrosion resistance, increases wear resistance, and provides options for coloring the nozzle. Anodized brass nozzles can be customized with different colors to suit individual preferences. |

|

|

|

3. Powder Coating

Powder Coating: Powder coating is a popular surface treatment that involves applying a dry powder to the brass nozzle's surface and then curing it. This creates a durable and protective coating that offers enhanced resistance to chemicals, impacts, and abrasions. Powder coating allows for a wide range of color options and provides a smooth and even finish. |

|

|

|

4. Plating

Plating: Plating is a process where a layer of metal, such as nickel or chrome, is deposited onto the brass nozzle's surface. This treatment not only enhances the aesthetics but also provides additional protection against wear and corrosion. Plated brass nozzles are known for their durability and resistance to harsh environments. |

|

|

|

5. Laser Engraving

Laser Engraving: Laser engraving is a precise and permanent marking method that can be used to add logos, serial numbers, or other designs to the surface of the brass nozzle. This customization option allows for easy identification and branding. |

|

|

|

At VMT, we are committed to providing custom CNC 3D printer brass nozzles with exceptional surface treatments. Whether you require a polished finish, anodized colors, powder coating, plated surfaces, or laser engraving, we have the expertise and capabilities to meet your specific requirements. |

| At VMT, we follow a meticulous manufacturing process to ensure the highest quality custom CNC 3D printer brass nozzles. Our streamlined approach combines advanced technology, skilled craftsmanship, and strict quality control measures. Here's an overview of our brass nozzle manufacturing process: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with design and engineering. Our team works closely with clients to understand their specific requirements and develop detailed designs for the custom brass nozzles. We utilize CAD software and other design tools to create precise digital models. |

|

2. Material Selection

Material Selection: Based on the design specifications and application requirements, we carefully select the appropriate brass material for the nozzles. We source high-quality brass that meets the necessary standards for durability, thermal conductivity, and corrosion resistance. |

|

3. CNC Machining

CNC Machining: Once the design and material selection are finalized, we proceed with CNC machining. Our state-of-the-art CNC machines are programmed to accurately shape the brass material into the desired nozzle design. CNC machining ensures high precision and consistency in every brass nozzle we manufacture. |

|

4. Surface Treatment

Surface Treatment: After the CNC machining process, we apply the chosen surface treatment to the brass nozzles. This could involve polishing, anodizing, powder coating, plating, or other surface treatments, depending on the client's requirements. Our skilled technicians carefully execute the surface treatment process to achieve the desired finish and functionality. |

|

5. Quality Control

Quality Control: Quality control is an integral part of our manufacturing process. We conduct rigorous inspections and tests to ensure that each brass nozzle meets the highest standards of performance and quality. This includes dimensional checks, surface finish evaluations, and functional tests to verify proper fit and functionality. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: Once the brass nozzles pass our quality control checks, they are carefully packaged to protect them during transportation. We pay attention to proper packaging techniques to prevent any damage during shipping. We then arrange for prompt delivery to our clients, ensuring that their custom CNC 3D printer brass nozzles reach them in optimal condition. |

|

Throughout the manufacturing process, we prioritize precision, durability, and customer satisfaction. Our team of skilled professionals is dedicated to delivering custom CNC 3D printer brass nozzles that meet the unique requirements of our clients. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC 3d Printer Brass Nozzle FAQs

|

Q: What is a custom CNC 3D printer brass nozzle?

Q: Why choose a brass nozzle for 3D printing?

Q: Can I use a brass nozzle with different filament materials?

Q: How do I clean a brass nozzle?

Q: What are the advantages of custom CNC 3D printer brass nozzles?

Q: Are custom CNC brass nozzles expensive?

Q: Can I replace the nozzle on my 3D printer with a custom brass nozzle?

Q: How can I order custom CNC 3D printer brass nozzles?

Q: Can I get assistance in choosing the right brass nozzle for my 3D printing needs?

Q: What is the expected lifespan of a custom CNC brass nozzle?

|

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.