15 years one-stop China custom CNC machining parts factory

Home / Product / Industrial Industry /

VMT is a manufacturing facility for various industrial CNC machining parts. With 13 years of experience in CNC processing industrial parts and various types of CNC industrial parts samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of industrial CNC machining product services to meet your customized CNC machining needs.

Product Specification:

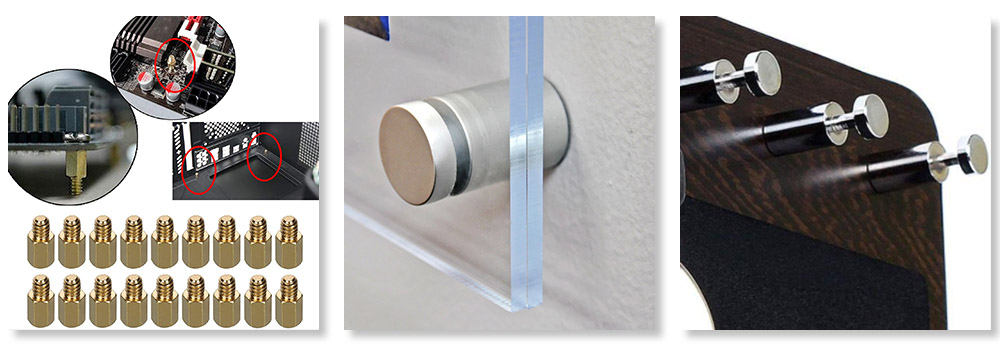

Custom Precision CNC Machining Metal Stainless Steel Aluminum Threaded Standoff Screws Home Depot

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Our Custom CNC Metal Standoff Screws Home Depot Services Manufacturer

| Our custom CNC metal bracket screws are a reliable and versatile solution for a variety of applications. With our expertise in CNC prototyping, a wide selection of materials and superior surface finishes, we can manufacture standoff screws to your exact specifications. Our commitment to quality, customization, and customer satisfaction has made us an industry-leading manufacturer. |

Custom CNC Metal Standoff Screws Home Depot Prototyping Machining

CNC machining prototyping plays an important role in the development and production of custom CNC metal Standoff Screws Home Depot. Accurate and fully functional prototypes are created for testing and refinement before final manufacturing. CNC prototyping allows us to verify the design, function and performance of standoff screws, ensuring they meet our customers' exact specifications and requirements. |

|

|

|

|

||

Custom CNC Metal Standoff Screws Home Depot Surface Treatment |

Custom CNC Metal Standoff Screws Home Depot Material |

||

|

In order to meet the diverse needs of our customers, we offer a variety of material options for custom CNC metal standoff screws home depot. Standoff screws home depot can be manufactured in a variety of materials to meet specific application requirements such as corrosion resistance, weight considerations or electrical conductivity. |

Surface treatments are essential to enhance the performance and aesthetics of CNC metal standoff screws home depot. We provide comprehensive surface treatment options, 12 quality control procedures, and a professional surface treatment engineering team to control for you. |

Custom CNC Metal Standoff Screws Home Depot Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

Custom CNC Metal Standoff Screws Home Depot Application

| Below are the different application scenarios of customized CNC metal standoff screws home depot, various metal standoff screws home depot can meet the needs of professionals and DIY enthusiasts. Whether you work on electronic, architectural, automotive, mechanical or household projects, our custom standoff screws can meet your specific application needs. |

Custom CNC Metal Standoff Screws Home Depot Material

| When custom your CNC metal standoff screws home depot, a variety of material options are available to meet your specific project requirements. These screws are designed to provide stability, durability and precise spacing between components. Learn how important material selection is for optimal performance and reliability. Different material options for custom CNC metal standoff screws home depot: |

|

|

Stainless Steel CNC Standoff Screws Home Depot

Stainless Steel: Stainless steel is a popular choice for CNC metal standoff screws home depot due to its excellent corrosion resistance, strength, and versatility. It is ideal for applications that require durability and resistance to harsh environmental conditions.

More Details>> |

|

|

|

Aluminum CNC Standoff Screws Home Depot

Aluminum: Aluminum CNC standoff screws home depot are lightweight and offer good strength-to-weight ratio. They are commonly used in projects where weight reduction is a priority without compromising on structural integrity. More Details>> |

|

|

|

Brass CNC Standoff Screws Home Depot

Brass: Brass CNC standoff screws home depot are known for their excellent electrical conductivity and corrosion resistance. They are often used in electrical and electronic applications where conductivity and aesthetics are important.

More Details>> |

|

|

|

Titanium CNC Standoff Screws Home Depot

Titanium: Titanium CNC standoff screws home depot are renowned for their exceptional strength, lightweight nature, and corrosion resistance. They are commonly used in industries such as aerospace, automotive, and medical, where high strength and reliability are crucial.

More Details>> |

|

|

These are just a few examples of the material options available at custom CNC metal standoff screws home depot. The best material can be selected according to the specific needs of the project. We ensure that all materials meet strict quality standards and provide material reports. |

|

The finish of CNC metal standoff screws home depot plays a vital role in enhancing its performance, durability and aesthetics. We offer a variety of surface treatment options to ensure your standoff screws not only meet your functional requirements. |

|

1. Anodizing

Anodizing: Anodizing can be customized with multiple color options.Anodizing is a widely used surface treatment Anodizing is widely used in CNC machining parts, which can enhance the corrosion resistance and wear resistance of the surface of CNC metal standoff screws home depot. |

|

|

2. Plating

Plating: Electroplated CNC metal standoff screws home depot enhances corrosion resistance, and the surface is smooth and reflective. Electroplating is the coating of a surface with a metal such as zinc, nickel or chromium. |

|

|

|

3. Powder Coating

Powder coating: Powder coating can be customized in a variety of colours, textures and finishes with a matte finish. Powder coating is to apply dry powder on the surface of CNC metal standoff screws home depot and then cure under heat. This process creates a durable, protective and decorative finish. |

|

|

|

4. Painting

Painting: Painting is a versatile option that can be customized in color and appearance to the specific requirements of your project. Painting is to apply liquid paint on the surface of CNC metal standoff screws home depot. The process provides a decorative finish and enhances corrosion resistance. |

|

|

|

These are just a few examples of the finish options available at CNC metal standoff screws home depot. Each finishing technique offers unique benefits, selected by a team of professionals based on the functional and aesthetic needs of your project. |

| Precision quality and reliability are priorities in the manufacturing of custom CNC metal standoff screws home depot. Our state-of-the-art facility and skilled technicians ensure that every standoff screw is made to the highest standards. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The manufacturing process begins with design and engineering. Our team of experts works closely with clients to understand their specific requirements and create detailed designs for the custom CNC metal standoff screws home depot. This stage involves considering factors such as dimensions, tolerances, materials, and surface treatments. |

|

2. Material Selection

Material Selection: After engineering design analysis, cost-effective materials are selected according to the customer's product performance and appearance requirements. Carry out material testing and obtain material reports before CNC machining. |

|

3. CNC Machining

CNC Machining: At the beginning of a project, CNC machining is generally used for prototyping, and solid blocks or bars of selected materials are precisely formed into CNC metal standoff screws home depot. CNC machining ensures accuracy, consistency and repeatability in the production process. |

|

4. Secondary Operations

Secondary Operations: Secondary operations after CNC machining to improve CNC metal standoff screws home depot. This can include processes such as drilling, tapping, threading or deburring, depending on the specific requirements of the project. These actions ensure that the standoff screws meet the required specifications and functional requirements. |

|

4. Surface Treatment

Surface Treatment: CNC metal standoff screws home depot undergoes surface treatment after machining and finishing, surface treatment is selected according to customer requirements. For example, if customers need bright light and mirror effect, they can choose electroplating or polished surface treatment for more materials. |

|

5. Quality Control

Quality Control: Each custom CNC metal standoff screws home depot undergoes rigorous inspection and testing to ensure it meets specified standards. This includes checking dimensions, tolerances, surface finish and other critical parameters. Delivery is only possible after passing strict quality control. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: Packaging and transportation can be carried out according to customer requirements. If there is any problem, we will communicate with the customer to change the packaging requirements and transportation method to prevent any damage during transportation and ensure that they reach the customer in the best condition. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Metal Standoff Screws Home Depot FAQs

|

Here are some frequently asked questions (FAQs) about custom CNC metal standoff screws home depot:

1. Can I order custom CNC metal standoff screws home depot in a non-standard size or shape?

2. What is the typical lead time for ordering custom CNC metal standoff screws home depot?

3. Can you assist in considering design considerations for custom CNC metal standoff screws home depot?

4. Can CNC metal standoff screws home depot customize those surface treatments?

5. How much is custom CNC metal standoff screws home depot?

|

| If you have any other questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.