15 years one-stop China custom CNC machining parts factory

Home / Product / Industrial Industry /

VMT is a manufacturing facility for various industrial CNC machining parts. With 13 years of experience in CNC processing industrial parts and various types of CNC industrial parts samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of industrial CNC machining product services to meet your customized CNC machining needs.

Product Specification:

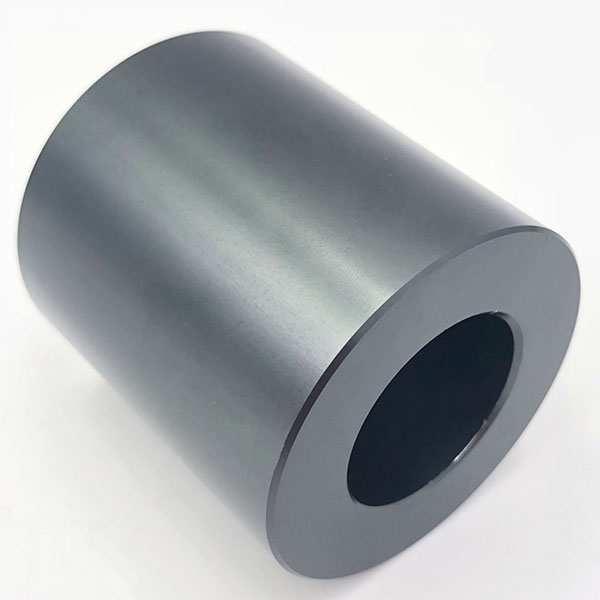

Custom Precision CNC Machining Plastic Stainless Steel Aluminum Bronze Flange Sleeve Bushings Factory

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

|

Welcome to the world of custom CNC machining flange sleeve bushings, where precision engineering meets versatility. Our comprehensive services encompass prototyping, surface treatment, and material selection, ensuring that you receive a tailored solution that meets your unique needs. Let's explore these services in detail: |

Custom CNC Flange Sleeve Bushing Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing. We can complete and deliver the flange sleeve bushing prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom CNC Flange Sleeve Bushing Surface Treatment |

Custom CNC Flange Sleeve Bushing Material |

||

|

We offer a variety of surface treatment services for your flange sleeve bushing project: polishing, anodizing, powder coating, and more. 12 quality inspection procedures guarantee your CNC machining parts. |

We have our own material library, which can provide you with a series of materials, and professional flange sleeve and bushing project engineers can choose the correct material for you. |

|

|

|

||

|

|

|||

|

|

|

|

Surface treatments for custom CNC machined flange sleeve bushings are essential for enhancing their performance, durability, and resistance to wear and tear. Here are some common surface treatments and coatings that can be applied to flange sleeve bushings: |

|

1. Polished

Characteristics: A polished finish provides a smooth, mirror-like surface. It reduces friction and improves the bushing's ability to resist wear.

|

|

|

2. Anodized

Characteristics: Anodizing is an electrochemical process that adds a protective oxide layer to the surface. It improves corrosion resistance and can be colored for aesthetic purposes.

|

|

|

|

3. Teflon Coating (PTFE)

Characteristics: PTFE coatings offer exceptional low-friction properties, making them ideal for self-lubrication.

|

|

|

|

4. Nickel Plating

Characteristics: Nickel plating adds a layer of nickel to the bushing's surface, improving its resistance to corrosion and wear.

|

|

|

|

5. Black Oxide Coating

Characteristics: Black oxide coating provides a dark, matte finish that enhances corrosion resistance and reduces glare.

|

|

|

|

6. Custom Coatings

Characteristics: Custom coatings can be tailored to specific requirements. They may include specialized materials or processes to meet unique performance criteria.

|

|

|

| The choice of surface treatment should be based on the specific requirements of your application, including factors like load, speed, environmental conditions, and lubrication. Properly selected and applied surface treatments can significantly extend the life and performance of your custom CNC machined flange sleeve bushings. |

| When it comes to custom CNC machining for flange sleeve bushings, the choice of material is crucial to achieving the desired balance of strength, durability, and performance. We offer a range of materials, each with its unique properties to meet your specific requirements. Here are some commonly used materials for flange sleeve bushings: |

|

|

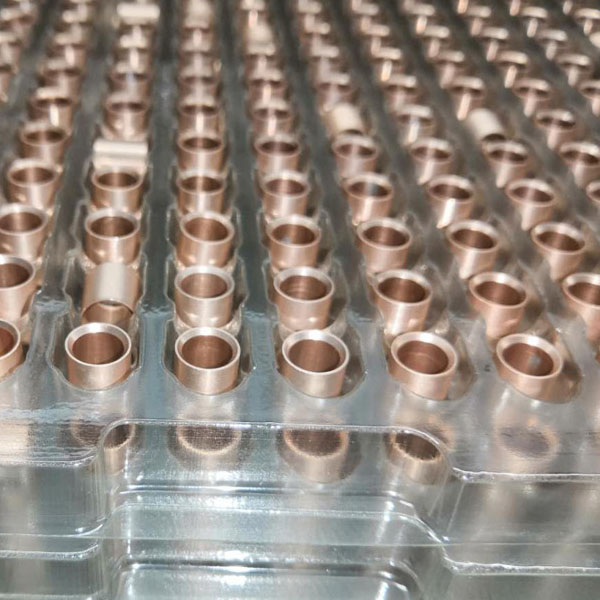

CNC Machining Bronze Flange Sleeve Bushing

Characteristics: Bronze is a popular choice for sleeve bushings due to its excellent lubricity and wear resistance. It is often impregnated with oil or graphite for self-lubricating properties.

More Details>> |

|

|

|

CNC Machining Brass Flange Sleeve Bushing

Characteristics: Brass offers good corrosion resistance and has a bright, golden appearance. It is often used in applications where aesthetics are a consideration.

More Details>> |

|

|

|

CNC Machining Steel Flange Sleeve Bushing

Characteristics: Steel bushings are known for their high strength and excellent wear resistance. They are often used in applications with heavy loads and high temperatures.

More Details>> |

|

|

|

CNC Machining Stainless Steel Flange Sleeve Bushing

Characteristics: Stainless steel combines strength with corrosion resistance. It is an excellent choice for applications exposed to moisture or harsh environments.

More Details>> |

|

|

|

CNC Machining PTFE (Polytetrafluoroethylene) Flange Sleeve Bushing

Characteristics: PTFE is a self-lubricating, low-friction material known for its chemical resistance and low moisture absorption.

More Details>> |

|

|

|

CNC Machining Nylon Flange Sleeve Bushing

Characteristics: Nylon bushings are lightweight, corrosion-resistant, and self-lubricating. They offer good wear resistance and are often used in conveyor systems and automotive applications.

More Details>> |

|

| The choice of material should be based on factors such as load capacity, operating temperature, environmental conditions, and budget constraints. Each material has its advantages, and selecting the right one will ensure optimal performance and longevity for your custom CNC machined flange sleeve bushings. |

| The manufacturing process for custom CNC machined flange sleeve bushings is a meticulously executed series of steps designed to achieve precision, durability, and consistent quality. Here's an overview of the typical manufacturing process: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: Create detailed CAD drawings or 3D models to define the precise dimensions and specifications of your flange sleeve bushings. These digital designs serve as blueprints for the machining process. Recreated prototypes can bring your ideas to life, allowing you to visualize the final product before production begins. |

|

2. Material Selection

Material Selection: The process begins with the selection of the appropriate material based on the specific requirements of the bushing, such as load capacity, operating environment, and durability. Common materials include bronze, brass, steel, stainless steel, PTFE, and nylon. |

|

3. CNC Machining

CNC Machining: CNC (Computer Numerical Control) machining is the core of the manufacturing process. The selected material is loaded into CNC machines equipped with cutting tools and programmed with the CAD data.

|

|

4. Surface Treatment

Surface Treatment: After the machining process, surface treatments are applied to enhance the performance and durability of the bushing. These treatments can include polishing, anodizing, lubrication groove machining, PTFE coating, and more, as discussed in previous responses. |

|

5. Quality Control

Quality Control: Quality control is a critical step to ensure that each flange sleeve bushing meets the specified tolerances, dimensions, and finish quality. Measurements and inspections are conducted to verify accuracy and quality. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

6. Packaging and Delivery

Once the flange sleeve bushings pass quality control inspections and meet the required standards, they are carefully packaged to prevent damage during transit. They are then shipped to the customer's location. |

|

Throughout the manufacturing process, precision and attention to detail are paramount. CNC machining ensures that each bushing is manufactured with high accuracy and consistency. Surface treatments are applied to improve functionality and longevity, while quality control checks guarantee that the bushings meet strict standards. The end result is a custom CNC machined flange sleeve bushing that not only meets but often exceeds the performance expectations of various applications, from industrial machinery to automotive components. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your machining requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Machining Flange Sleeve Bushing FAQs

| Certainly, here are some frequently asked questions (FAQs) related to custom CNC machining flange sleeve bushings: |

|

1. What is a flange sleeve bushing, and what are its primary functions?

A flange sleeve bushing is a cylindrical component with a flange at one end. It is designed to provide support, reduce friction, and enable smooth motion between two parts. The flange offers stability and prevents axial movement.

Common materials include bronze, brass, steel, stainless steel, PTFE (Polytetrafluoroethylene), and nylon. The choice of material depends on factors like load capacity, operating environment, and specific application requirements.

It depends on the material and design of the bushing. Some materials, like bronze and brass, may require external lubrication to reduce friction. However, self-lubricating options, such as PTFE-coated bushings, eliminate the need for additional lubrication.

CNC machining offers precision and consistency in manufacturing. It ensures that each bushing is produced with high accuracy, tight tolerances, and uniform quality. This results in reliable and durable bushings.

Yes, custom flange sleeve bushings can be precisely tailored to meet the unique requirements of a particular application. CAD design and CNC machining allow for precise control over dimensions and tolerances.

Surface treatments can include polishing, anodizing, lubrication groove machining, PTFE coating, nickel plating, and custom coatings. These treatments enhance the bushing's performance and longevity.

Flange sleeve bushings find applications in various industries, including automotive, aerospace, industrial machinery, agriculture, and more. They are used in components like bearings, hinges, pivots, and linkages.

To select the right bushing, consider factors such as load capacity, operating temperature, environmental conditions, required dimensions, and lubrication preferences. Consulting with a knowledgeable manufacturer can help you make an informed choice.

Custom flange sleeve bushings can be cost-effective, especially when tailored to specific requirements. They minimize the need for modifications and reduce downtime in your application.

Lead times can vary depending on factors like complexity, quantity, and material availability. It's advisable to discuss lead times with the manufacturer when placing an order.

|

| These FAQs provide a basic overview of custom CNC machined flange sleeve bushings and their applications. For more detailed information and specific inquiries, it's best to consult with a trusted manufacturer or supplier with expertise in flange sleeve bushings production. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.