15 years one-stop China custom CNC machining parts factory

Home / Product / Industrial Industry /

VMT is a manufacturing facility for various industrial CNC machining parts. With 13 years of experience in CNC processing industrial parts and various types of CNC industrial parts samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of industrial CNC machining product services to meet your customized CNC machining needs.

Product Specification:

Water Quality Detection Sensor Alarm Instrument Case CNC Machining

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

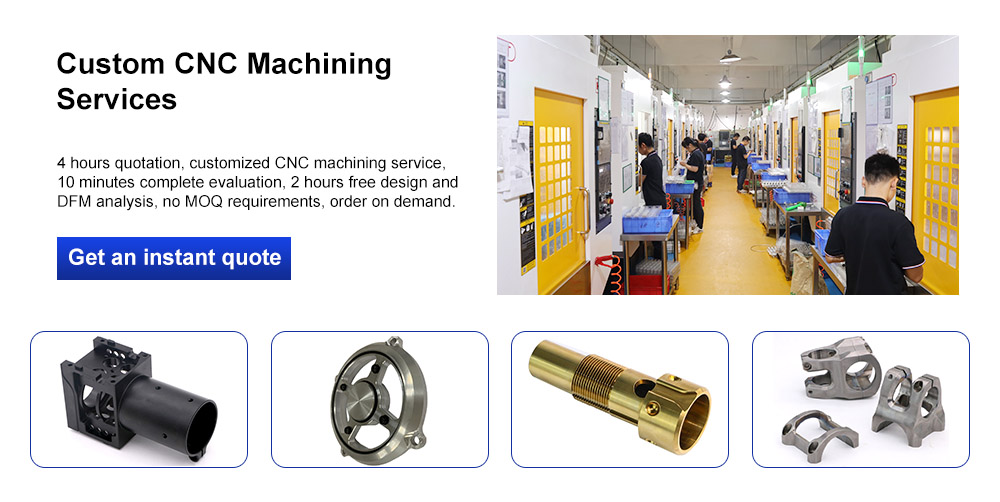

Our Custom CNC Machining Services

| We are a professional custom CNC machining manufacturer, we can custom manufacture a variety of complex design parts, provide you with drawing design analysis and prototype manufacturing, material selection, surface treatment. VMT can provide a variety of additional custom CNC machining machining services to better assist you in completing your project. Such as CNC prototype machining, extrusion + CNC machining, die-casting + CNC machining, etc.There are professional engineers to provide you with guidance. |

|

|

|

||

CNC Machining |

CNC Turning |

||

|

300 CNC machining machines more than 40 kinds of metal materials and 15 kinds of surface treatments the appearance is carried out according to the Apple appearance standard. Various processes combined with CNC machining free evaluation DFM analysis quality control. |

CNC machining components service with monthly output up to 300000 pieces free review drawing optimization quotation and DFM within 4 hours.Complete CNC prototype machining manufacturing and delivery within 24 hours. |

Custom Cooperation Process

|

|

|

|

||||

|

|

||||||

Upload CAD files and Quotes |

Confirm Specifications and Production |

Quality Inspection and Delivery |

||||

| Send your part design to our email: inquiry@vimetal.com.cn, we will give you a quotation within 24 hours. |

Analyze your part specifications and choose a lead time that fits your schedule, and start production immediately. |

We take full responsibility for ensuring your parts are manufactured to our standards. Choose the shipping and packing method according to your requirements. |

||||

|

|

|

|

||||

Company Profile

|

|

SHENZHEN VMT METAL PRODUCT CO.,LIMITED.

VMT is located in shenzhen, china, with 13 years experience to manufacture China customized CNC machining metal parts and assembly. We are certificated by ISO9001 and 16949, also get 11 patents. Our business has grown to now cover 62 countries worldwide. We strictly control the quality from the initial engineering review DFM, pre-production, IQC, first article, in-process to final inspection to ensure the quality. To achieve zero defect, we utilize automatic inspection machines, 2D and 3D projector to check dimension and surface. Our machines include high speed CNC lathes, Automatic Lathes, CNC milling, Drilling, tapping, grinding, Welding machine, Tube bending machine. And working with a wide range of materials including steel, aluminum, stainless steel, copper, bronze, brass and aircraft alloys. To offer competitive price, VMT combine diverse processes for various designs, such as CNC Machining, stamping, forged, extrusion, castings, bending, welding etc. |

| We have all kinds of CNC machining equipment and testing equipment to provide you with CNC machining parts services. |

|

CNC machining equipment:

Testing Equipment:

|

|

|

|

|

|

|

||||

|

|

||||||

|

|

|

|

||||

|

|

|

CNC Machining Materials

We can generate instant machining quotes for 50+ metals and plastics.

|

|

|

|

|||||

|

Aluminum |

Brass | Stainless Steel | |||||

|

|

|

For more materials, click this link: |

|||||

| Titanium | Plastic |

Custom CNC Machining Surface Treatments

We can do the following surface treatment:

|

|

|

|

|

||||||

|

As machined |

Brushed + Anodized | Powder coating+Anodizing | Sand blasting+Anodizing | ||||||

|

|

|

|

|

||||||

| Polishing |

Hard Anodizing |

Chrome Plating | Color Anodizing |

CNC Machining Components Tolerance

|

During the production process, we will implement the stricter standards than ISO Tolerances DIN ISO 2768-1 for the unrequired parts, and the CNC machining components standard tolerances of our machines. |

|

Nominal linear range tolerance (mm) |

Linear dimensions DIN ISO 2768-F |

Our CNC machining parts |

Our plastic parts |

|---|---|---|---|

|

0.5 up to 3 |

±.0.05 | ±.0.02 | ±0.05 |

|

over 3 up to 6 |

±.0.05 | ±.0.03 | ±0.05 |

|

over 6 up to 30 |

±0.1 | ±0.05 | ±0.1 |

|

over 30 up to 120 |

±0.15 | ±0.05 | ±0.15 |

|

over 120 up to 400 |

±0.2 | ±0.1 | ±0.2 |

|

Nominal angle range tolerance (mm) |

Linear dimensions DIN ISO 2768-F | Our metal parts | Our plastic parts |

|

≦10 |

±1° | ±1° | ±1° |

|

10~50 |

±0°30′ | ±0°30′ | ±0°30′ |

|

50~120 |

±0°20 | ±0°20 | ±0°20 |

|

120~400 |

±0°10 | ±0°10 | ±0°10 |

|

|

|||

|

Text and color |

VMT can use CNC engraving or laser carving to create standard text based on customers’requirements. VMT can customize any color according to customers' requirements. |

||

|

|

|||

| Lead Time | Simple CNC machining componeents parts: 1 day prototype machining delivery. Complex CNC machining componeents parts: 3 days prototype machining delivery. |

||

Custom CNC Machining Manufacturing Process

| Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way. |

|

|

|

|

||||

| DFM Analysis | Dimensional Tolerance | Material Testing | ||||

|

|

|

|

||||

| CNC Machining Production | FQC detection | SPC / CKP | ||||

|

|

|

|

||||

| Problem Found | Problem Solving | OQC Detection | ||||

|

|

|

|

||||

| Surface Treatment | Full Inspection | Package |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

Our Certificate

|

|

|

Custom CNC Machining FAQs

|

Here are some frequently asked questions (FAQs) about custom CNC metal standoff screws home depot:

1. Can I order custom CNC metal standoff screws home depot in a non-standard size or shape?

2. What is the typical lead time for ordering custom CNC metal standoff screws home depot?

3. Can you assist in considering design considerations for custom CNC metal standoff screws home depot?

4. Can CNC metal standoff screws home depot customize those surface treatments?

5. How much is custom CNC metal standoff screws home depot?

We offer competitive prices for custom CNC machining speaker spikes feet shoes. Pricing depends on factors such as material, size, quantity, and additional requirements such as surface treatment. We strive to provide affordable solutions without compromising product quality and performance. According to your project needs, send an email to us for an immediate quotation for you.

These frequently asked questions should give you a better understanding of custom CNC machined speaker spikes and their applications. If you have any other questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

Water Quality Detection Sensor Case CNC Machining - Aluminum Stainless Steel Water Quality Detection Alarm Instrument Shell Manufactur

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.