15 years one-stop China custom CNC machining parts factory

Machining Material Inventory

VMT is committed to delivering high-quality CNC machined parts by using the best raw materials. For over 14 years, we have manufactured parts and collaborated with clients across various industries. To ensure prototypes and small-batch precision-machined parts are produced within 24 hours, we maintain an inventory of 40+ materials, including plastics and metals, some of which are IMDS-approved. For any prototyping or production project, our experienced team can recommend the optimal material based on properties and cost requirements.

We can customize CNC machined parts to your material specifications, and we are your trusted material selection experts. Explore our available materials below. If you're unsure about the best material for your part, contact our CNC machining and manufacturing team today.

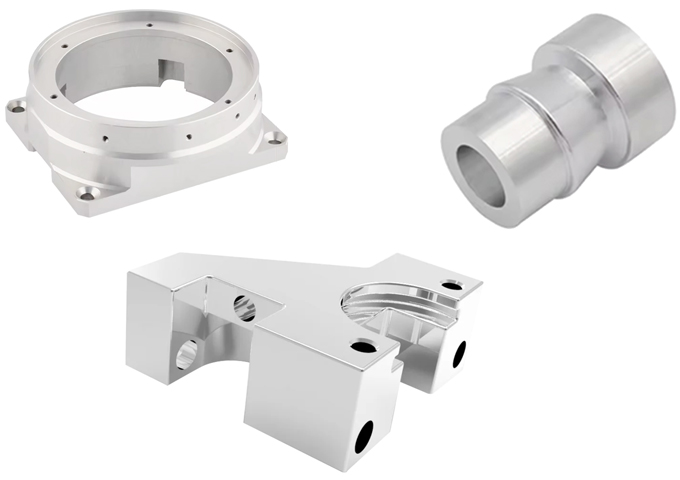

CNC Metal Manufacturing Materials

VMT is equipped to machine various metal materials and employ a wide range of manufacturing techniques. We are dedicated to delivering each project with high quality to meet our customers' specific requirements.

Aluminum

Materials: AL6061, AL7075, AL2014, AL2024, AL5052, AL6063, AL1060, AL1070/, AL1080 etc.

Advantages: low density, high hardness, high strength, good electrical and thermal conductivity, excellent corrosion resistance and chemical resistance, easy processing, recyclability, widely used in the production of structural parts, housings, heat sinks, etc.

Manufacturing Processes: Sheet metal fabrication, CNC machining, die casting, and extrusion.

Application industries: aerospace, automotive, electronics, etc.

Stainless Steel

Materials: 304L, 316L, 301, 304, 430, etc.

Advantages: Chemical and electrochemical corrosion resistance, heat and high-temperature resistance, high hardness, oxidation resistance, excellent plasticity, and good weldability with minimal thermal cracking tendency.

Manufacturing Processes: Machining, welding, extrusion, etc.

Application industries: aerospace, automotive, medical, food machining, building and construction, etc.

Steel

Grades: 1015, 1045, 1020 etc.

Advantages: good machinability, excellent electrical conductivity, widely used in the manufacture of machine parts, molds, etc.

Manufacturing Processes: Forging, extrusion, CNC machining, welding, and stamping.

Application industries: Automotive, marine, aerospace, construction, etc.

Titanium

Grades: GR1, GR2, GR4 etc.

Advantages: low density, high strength, good corrosion resistance, widely used in the production of aerospace parts, artificial joints, etc.

Manufacturing Processes: Sheet metal fabrication, laser cutting, CNC machining, friction welding, and profile extrusion.

Application industries: Aerospace, medical devices, etc.

Brass

Grades: C37700, C38500, C38600, C10200, C11000 etc.

Advantages: Conduction, heat conduction, corrosion resistance, widely used in the production of electrical components, heat exchangers, etc.

Manufacturing Processes: CNC machining, die casting, bending, extrusion, etc.

Application industries: Automotive, aerospace, construction, electronics, semiconductors, marine, home appliances, kitchenware, musical instruments, and decor.

Copper

Materials: T1, T2, T3, TU1, TU2, TUP, TUMn, etc.

Advantages: High ductility, excellent thermal and electrical conductivity, easy welding and machining, and high corrosion resistance.

Manufacturing Processes: CNC machining, extrusion, hot rolling, and friction welding.

Applications: Automotive, aerospace, medical, construction, and more.

Bronze

Materials: ZCuAl10Fe3, ZCuAl10Fe3Mn2, ZCuAl9Fe4Ni4Mn2, etc.

Advantages: High corrosion resistance, excellent wear resistance, superb casting qualities, high strength and hardness, elasticity, and fatigue resistance; ideal for marine environments or chemical processing equipment.

Manufacturing Processes: Die casting, CNC machining, extrusion, and stamping.

Applications: Bearings, gears, bushings, connectors, bolts and nuts, aerospace, automotive, machinery, power, and oil & gas industries.

Iron

Materials: 4140, Q235, Q345B, 20#, 45#, etc.

Advantages: Iron and its alloys, such as steel, offer high strength, good ductility, corrosion resistance, heat resistance, and high mechanical strength.

Manufacturing Processes: Sheet metal fabrication, CNC machining, welding, and forging.

Applications: Used for manufacturing various mechanical parts, tools, equipment, automotive frames, engine components, wheels, and more.

Magnesium Alloy

Materials: AZ series, AM series, ZK series, WE series, etc.

Advantages: Lightweight, high strength-to-weight ratio, good machinability, damping properties, and recyclability.

Manufacturing Processes: Casting, extrusion, forging, and CNC machining.

Applications: Used for manufacturing wheels, engine blocks, transmissions, laptop cases, smartphone frames, and camera bodies.

Alloy Material

Grades: Nickel Alloy, Cobalt Alloy, Tungsten Alloy etc.

Advantages: high-temperature resistance, high strength, good corrosion resistance, widely used in the production of high-temperature parts, corrosion resistant parts, etc.

Disadvantages: higher cost.

Application industries: aerospace, energy, chemical industry, etc.

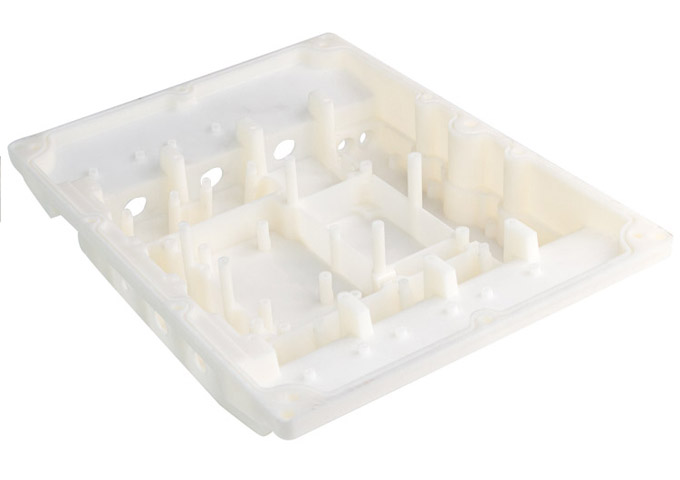

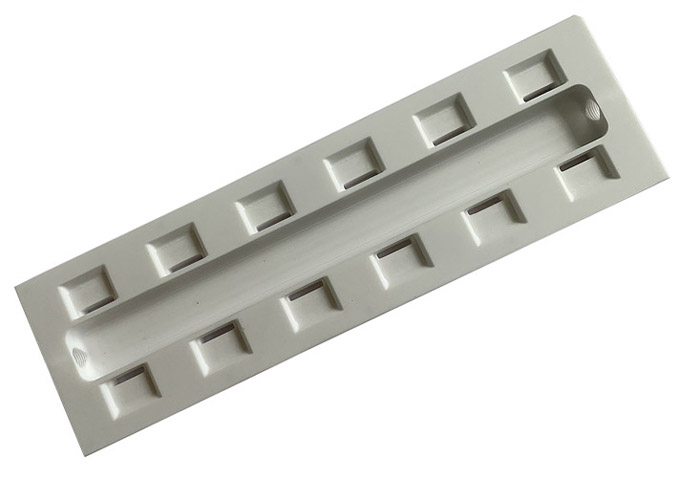

CNC Plastic Manufacturing Materials

Plastic materials are becoming increasingly popular in CNC machining due to their versatility, cost-effectiveness, and ease of processing. Let’s dive into some commonly used plastic CNC machining materials and their unique properties.

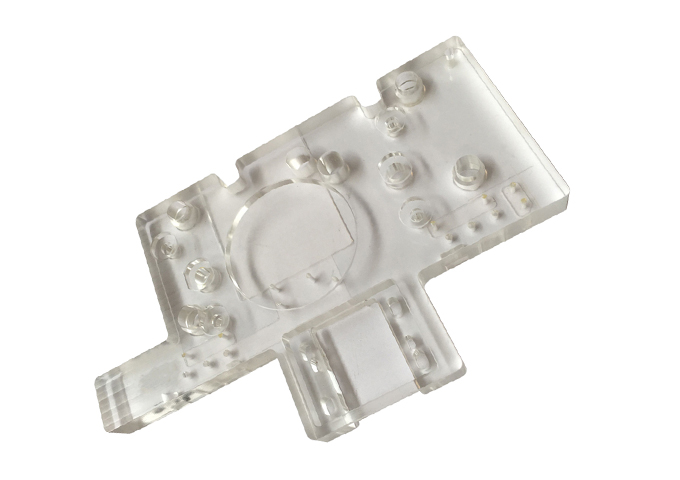

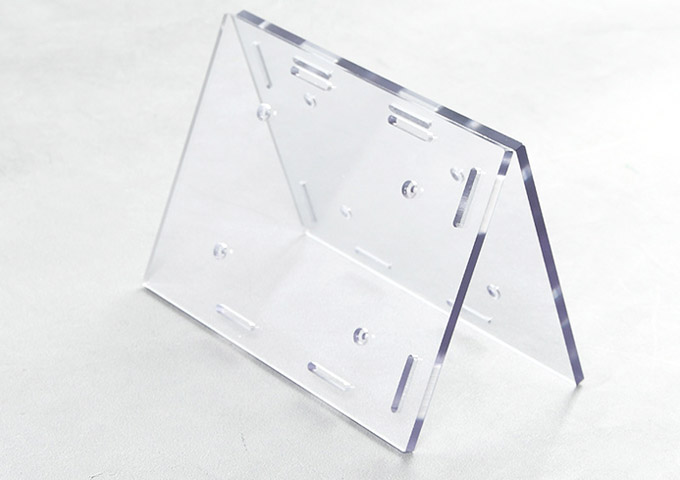

Acrylic (PMMA)

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent plastic material that offers excellent optical clarity and is commonly used in applications where transparency and aesthetics are important.

Advantages: Excellent optical clarity and transparency, lightweight, easy processing, good impact resistance, UV resistance, easy polishing and bonding.

Manufacturing Processes: CNC machining, extrusion, laser cutting, and injection molding.

Application: Signage and display cases, lighting fixtures and lenses, automotive components, point-of-purchase displays, medical equipment, etc.

Polycarbonate (PC)

Polycarbonate is a tough and durable plastic material with high impact resistance, making it ideal for applications requiring impact and abrasion protection.

Advantages: high impact resistance, good heat resistance, transparent and easy to process, excellent electrical insulation properties, UV resistance.

Manufacturing Processes: CNC machining, extrusion, laser cutting, and injection molding.

Application: Goggles and face shields, automotive and aerospace parts, electrical and electronic components, machine guards and shields, medical equipment.

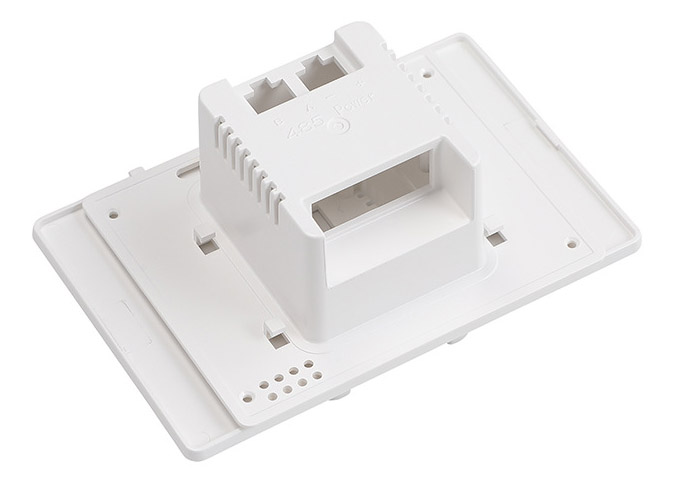

ABS

ABS is a versatile and versatile plastic material that offers a good balance of strength, impact resistance and processability.

Advantages: Good balance of strength and impact resistance, durable, easy to machine, glue, and paint, cost-effective.

Manufacturing Processes: CNC machining, extrusion, laser cutting, and injection molding.

Application: Toys, home appliances, dashboards and interior automotive parts, electronic device housings, pipes, and fittings, sports, and recreational equipment.

Nylon (PA)

Nylon is a strong and durable plastic material with excellent mechanical properties such as high tensile strength and impact resistance.

Advantages: High tensile strength and impact resistance, low friction coefficient, excellent wear resistance, easy to machine, and good chemical resistance.

Manufacturing Processes: CNC machining, extrusion, casting, and injection molding.

Application: Gears, bearings, bushings, automotive and aerospace parts, industrial machinery components, ski bindings, and gears, electrical and electronic connectors.

PEEK

PEEK is a high-performance polymer material with excellent properties for a variety of demanding applications.

Advantages: High-temperature resistance, chemical resistance, high mechanical performance, electrical insulation, and biocompatibility.

Manufacturing Processes: CNC machining, profile extrusion, and injection molding.

Application: Bushings, bearings, piston parts, pump impellers, valves, and cable insulators.

Polyacetal (POM)

Polyacetal (POM), also known as acetal or Delrin®, is a high-performance engineering plastic known for its excellent mechanical properties and dimensional stability.

Advantages: High stiffness, low friction, excellent dimensional stability, and good wear resistance, making it ideal for precision parts.

Manufacturing Processes: CNC machining, extrusion into solid profiles, etc.

Application: Ideal for plastic gears, bushings, rollers, electrical insulators, and panels.

PTFE

PTFE (Polytetrafluoroethylene), commonly known by the brand name Teflon®, is a synthetic fluoropolymer known for its non-stick, low-friction, and chemically resistant properties.

Advantages: Extremely low friction, high heat resistance, excellent chemical resistance, ideal for non-stick applications.

Manufacturing Processes: CNC machining, mold pressing, and extrusion.

Application: Used for seals, gears, bearings, manifolds, valve components, gaskets, fittings, bushings, washers, O-rings, insulators, etc.

Polypropylene (PP)

Polypropylene (PP) is a versatile thermoplastic polymer known for its toughness, chemical resistance, and affordability, making it popular across various industries.

Advantages: Chemical resistance, excellent fatigue resistance, low density, good heat resistance, easy to machine.

Manufacturing Processes: CNC machining, injection molding, and extrusion.

Application: Suitable for food packaging, pharmaceutical packaging, household packaging, medical syringes, and test tubes.

Bakelite

Bakelite is a thermosetting phenol-formaldehyde resin and one of the first synthetic plastics. Known for its electrical insulation properties and heat resistance, it is widely used in applications requiring durability and safety.

Advantages: Excellent insulation, heat resistance, corrosion resistance, high mechanical strength, and strong plasticity.

Manufacturing Processes: CNC machining, injection molding, and extrusion.

Application: Suitable for switches, sockets, lamp holders, headphones, telephone casings, instrument casings, and insulation gaskets.

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red