15 years one-stop China custom CNC machining parts factory

Home / About / Quality Assurance /

Quality Management Systems for Machine Shop

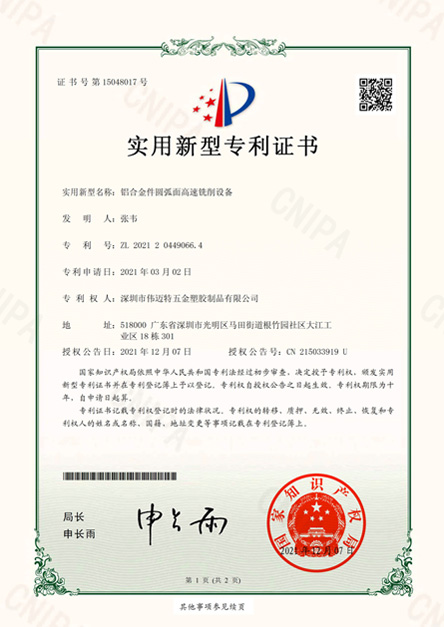

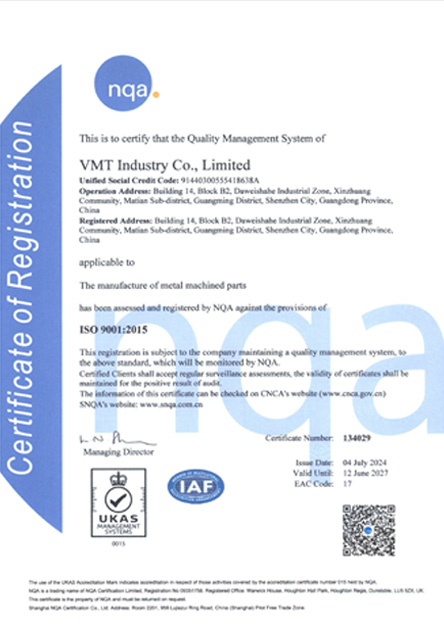

View Our ISO 9001:2015 Certification

90% Referrals

12 Quality Inspection Processes

98% Yield Rate

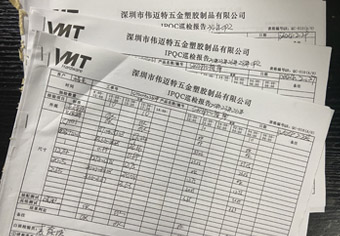

Full Size Inspection Report

VMT is dedicated to enhancing custom manufacturing capabilities, including CNC machining, rapid prototyping, and mold manufacturing, along with corresponding quality control processes.

We adhere to an ISO 9001-certified management system, utilizing standardized production procedures and work instructions alongside advanced testing equipment to ensure that every production stage meets strict quality standards, guaranteeing your project achieves the highest quality.

How to Ensure the Quality of CNC Machined Parts?

Strictly Vetted Suppliers

We own our CNC machining factory and have established solid partnerships with outsourcing suppliers, some of whom we have worked with for over 11 years. We maintain a comprehensive outsourcing supply chain management system with rigorous auditing standards, ensuring that every step from production to delivery meets our high-quality requirements.

High-Quality Materials

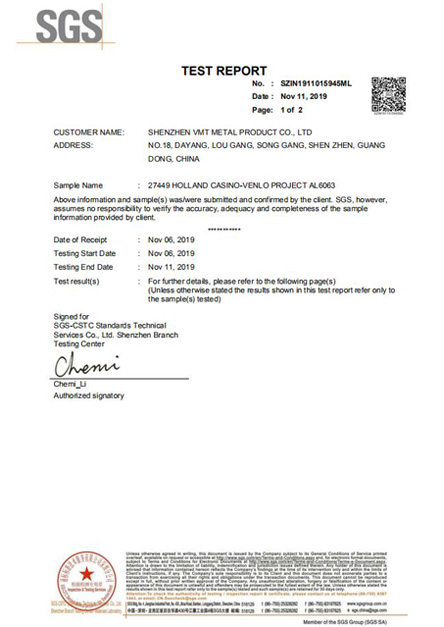

We strictly control material quality; each batch undergoes thorough testing upon arrival, with an SGS report provided to ensure that customers receive only premium raw materials.

Expert Project Engineers

Our team of experienced project engineers, with over 15 years of expertise, is dedicated to review and optimization processes to reduce CNC machining time and lower costs, offering competitive pricing without compromising on quality.

Precision CNC Machining and Manufacturing

We adhere to even stricter standards than ISO-2768-m and ISO-2768-c tolerances, with standard tolerances for our CNC machined parts as tight as 0.005 mm.

Rigorous Quality Inspection

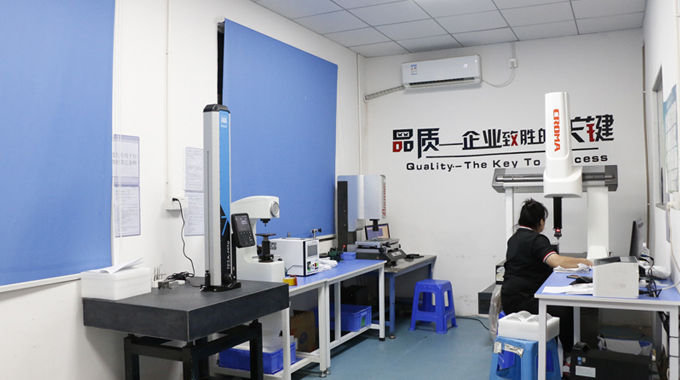

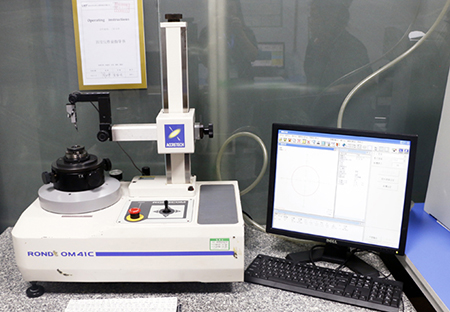

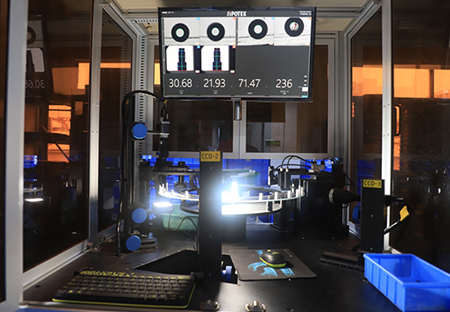

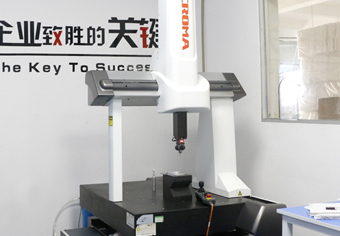

Throughout production, we perform strict quality checks at every stage to ensure that dimensions and appearance meet standards, accompanied by inspection reports. Our advanced quality control system combines manual and automated equipment, with first article, inspection, and shipment reports stored for two years. We assign dedicated personnel for full follow-up, ensuring transparent communication and providing usage support. Our measurement laboratory is equipped with high-precision 3D and 2D projectors.

Reliable Quality Driving Innovation

Discover how VMT ensures the highest quality standards.

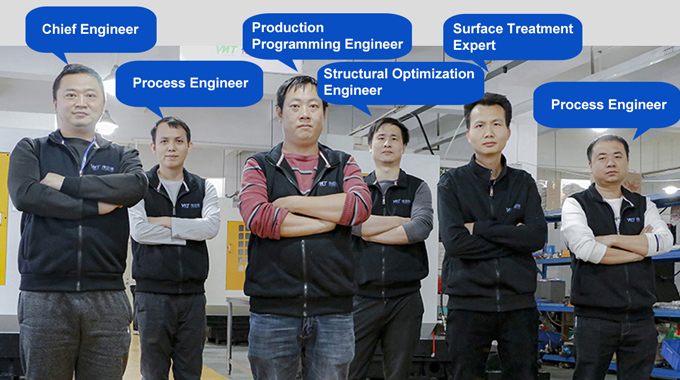

Engineering Team

Our engineering team includes six experts with over 20 years of experience, offering complimentary design services to ensure that parts meet an appearance standard comparable to that of an Apple iPhone, with machining precision akin to that of an atomic clock. We control process capability tolerances within 0.01 mm, and key process capabilities maintain a CPK of 1.68 or higher. Additionally, two surface treatment engineers oversee and control the surface treatment processes to ensure optimal quality.

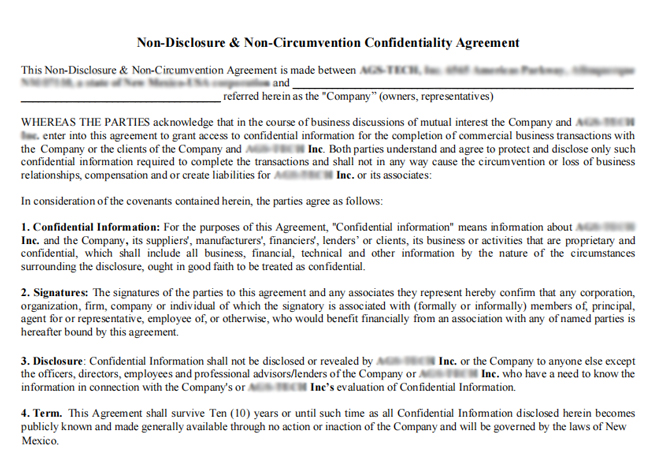

NDA

All customer drawings are kept in the business department and NDA is signed. Only disassembly drawings are used inside the factory, and there are regulations not to forward any videos and pictures of customers on public platforms. Do you have any other comments to add?

12 Quality Inspection Processes

We implement a stringent quality control process, divided into four stages: IQC,IPQC,FQC,and OQC. The sampling rate and frequency are determined by the acceptance criteria signed by the customer, with tailored quality control standards for each product to ensure it meets strict requirements.

Real-Time Transparent Sharing

Dedicated personnel follow the CNC machining production status from start to finish, sharing real-time photos and videos of the manufacturing process, allowing customers to monitor the progress of their products at any time.

We Ensure Quality in Every Step

Before CNC Machining Manufacturing

DFM Analysis

Before production begins, our engineering team conducts a comprehensive technical review of your part design. This includes detailed analysis of key factors like material selection, surface treatment, structural design, production processes, and 3D and 2D drawings. Our goal is to confirm the technical feasibility of the design and optimize the production process to meet your quality and cost-effectiveness requirements. Through this rigorous evaluation, we can identify and resolve potential issues in advance, ensuring smooth production.

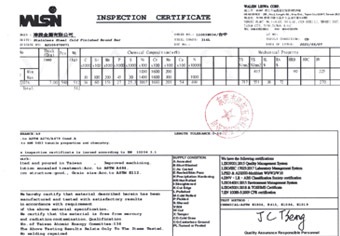

Material Verification

Upon request, we provide certification reports for the materials used, issued by the raw material manufacturer. These reports typically include information such as heat number, grade, dimensions, mechanical properties, and chemical analysis, ensuring the raw materials meet high-quality standards.

In Machining Production

In-Process Inspection

In precision machining, accurate material positioning is essential. We use an on-site inspection system that can automatically detect material positioning and make necessary adjustments. This system helps us identify and resolve issues promptly, reducing costs and shortening lead times. With this advanced inspection technology, we ensure process stability, product consistency, and improved production efficiency.

Process Quality Control

At VMT, we follow ISO 9001:2015 standards, ensuring every operation meets the highest quality requirements. Our quality control team performs thorough inspections of all work-in-progress parts every two hours. This regular review helps detect and resolve potential issues early, effectively mitigating risks and ensuring production continuity and product consistency.

Final Prototype Parts Production

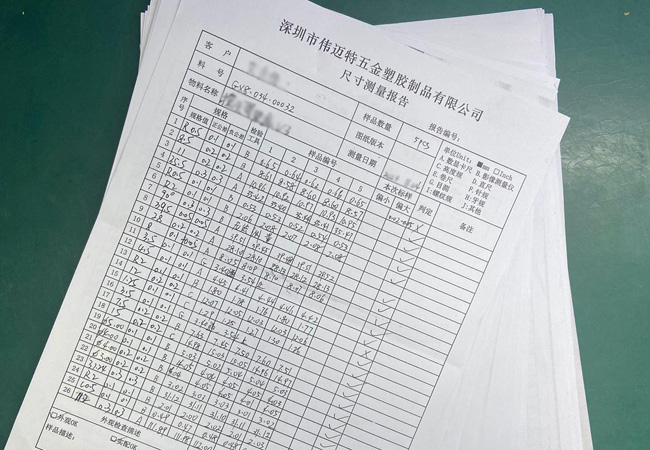

Full-Dimensional Inspection Report

For each order, we provide a detailed full-dimensional inspection report for transparency and accuracy. The report includes total part count, key dimensional data, thread specifications, tolerance ranges, thickness and depth measurements, and the visual condition of the parts.

Packaging and Shipping

We offer custom packaging based on client requirements, including branded packaging with the customer’s logo for premium products. For fragile or heavier items, we customize secure packaging options, such as cartons or wooden crates, to ensure the products remain intact during transport. Shipping methods can be tailored to client needs, with options for sea, air, or express delivery.

Quality Testing Equipment

100+

Machining Equipment

62+

Countries Shipped

100,000+

Parts Manufactured

All finished products, whether manufactured or procured, first undergo inspection at our IQC (Incoming Quality Control). During inspection, we review production orders, incoming part lists, and drawings. Sampling inspection is conducted per the AQL (Acceptable Quality Level) standard, while critical appearance and dimensional features are 100% inspected. Additionally, products with special surface treatments are subjected to relevant reliability testing, with inspection reports provided.

If defects are found, we issue a defect report and immediately notify the quality manager to recheck and determine acceptance or rejection. If the quality manager cannot make a decision, other departments are involved for a final decision. Approved products are stamped with a quality seal, then packaged and shipped to ensure every CNC machined part meets customer specifications.

VMT is certified in ISO 9001:2015 Quality Management System and IATF 16949, with all departments strictly adhering to these standards for production control:

Quality Inspection Reports

VMT provides certification for your order, including:

Read More Certificates Download Reports

Qualification Assessment Report

Visual Inspection

We conduct a thorough inspection of each part to assess surface smoothness, scratches, burrs, dents, dimensional accuracy, geometric accuracy, positional accuracy, surface roughness, markings, and color to ensure compliance with the customer's appearance standards.

Dimensional Inspection

We use calipers, micrometers, and height gauges to check the dimensions of simple CNC machined parts, ensuring quality and accuracy. For complex parts that require high precision, we employ a Coordinate Measuring Machine (CMM) for precise measurement.

Thread Inspection

For parts with threads, we utilize go/no-go gauges to inspect the threads, checking their dimensions, shape, and surface finish to ensure they meet customer assembly requirements.

If you require wear resistance for the part's surface, we can conduct film thickness testing and provide a report to enhance the quality, performance, and lifespan of the parts.

Air Tightness Test

If you have airtight requirements for the parts, we can perform leakage tests and provide reports accordingly.

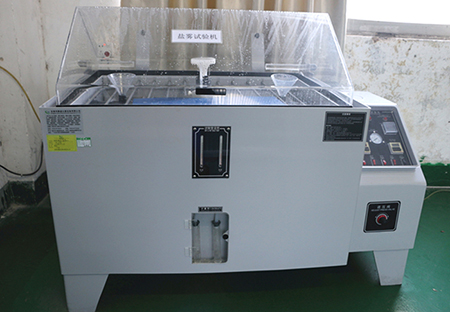

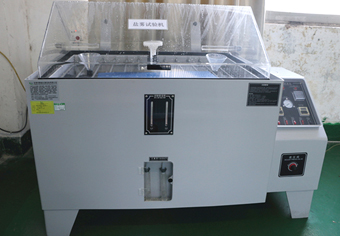

Salt Spray Testing

For parts with corrosion resistance requirements, we can simulate marine or salt spray environments to conduct accelerated corrosion tests as needed.

Full Inspection Report

Upon completion of CNC machining, we provide a final inspection report, archiving all reports for two years, including first article, in-process, and outgoing inspections. Dedicated personnel follow the progress from raw material to shipment, providing real-time updates.

RoHS Material Report

We can provide an RoHS report prior to processing, verifying the quality, performance, composition, and structure of materials to ensure compliance with RoHS standards and guarantee the authenticity of the raw materials.

Quality Resolution Solutions

VMT is committed to delivering high-quality prototypes and CNC machined parts to ensure they meet your specifications. If an order does not match what was ordered, we can either reprocess the part or issue a refund. Should you encounter quality issues within one month of receiving your order or have any questions, please feel free to contact our CNC experts, and we will respond promptly with a solution.

Rework Conditions

If issues arise during the CNC machining process, we will first identify the cause by reviewing the design files and samples, followed by a meeting to discuss potential solutions. If a problem occurs after receipt, we will promptly arrange a video conference upon receiving feedback, communicate with our experts, and quickly resolve the issue by sending new samples.

Refund Conditions

Upon receiving feedback, we will quickly confirm via video or phone whether the issue is due to our fault and is irreparable. We will then promptly process the refund or return.

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red