15 years one-stop China custom CNC machining parts factory

Home / Resources / Surface Finishing /

CNC Parts Surface Finishing Capabilities

Whether produced through CNC machining or 3D printing, achieving the final product's appearance requires strict post-processing. To meet the special surface application requirements of customer parts, enhance the durability, wear resistance, corrosion resistance, and aesthetics of CNC parts.

VMT offers comprehensive post-processing services for CNC parts to meet your diverse needs. Relying on our professional technical team, advanced equipment, and strong surface finishing supply chain, we are committed to achieving high standards in color, texture, gloss, and surface smoothness, aiming to exceed your expectations.

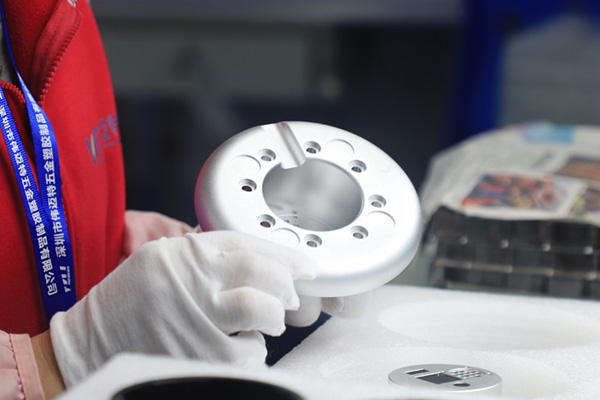

Surface Finishing Process Control

Have you encountered issues with the surface texture or defects in your CNC parts? Don't worry—VMT collaborates with surface finishing factories with over 10 years of experience. Two surface finishing engineers oversee the process control, and a dedicated SQE (Supplier Quality Engineer) closely monitors each stage at the surface finishing facility. Upon returning to the factory, we perform 100% inspection of the product's appearance to ensure quality.

VMT provides the best surface finishing services, according to customer requirements, according to different effects and materials, we provide customers with many kinds of surface finishings, such as oxidation, sandblasting, polishing, electroplating, powder spraying, baking paint, PVD, laser engraving, blackening, wire drawing, heat finishing, etching, etc. . In addition to the above conventional surface finishings, there are also a variety of special surface finishings. Please refer to the attached picture below.

Choosing the Right Surface Finish for Your Prototype Parts

As Machined

Standard surface finish with a surface roughness of 3.2 μm (126 μin), capable of removing sharp edges and cleanly deburring the parts.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metals, plastics

Color: None

Appearance: Slight visible surface scratches

Price: $

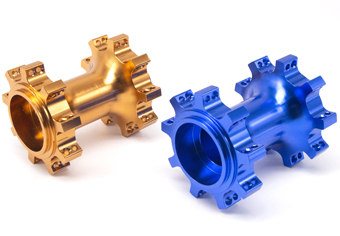

Anodizing

Anodizing is available in Type I, II, and III. It is an electrochemical process that forms a durable and corrosion-resistant oxide layer on the surface of metals, improving the durability of the parts and allowing for color customization.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Aluminum, Titanium

Color: Customizable colors available, including transparent, black, gray, red, blue, gold etc.

Appearance: Smooth matte finish

Price:$

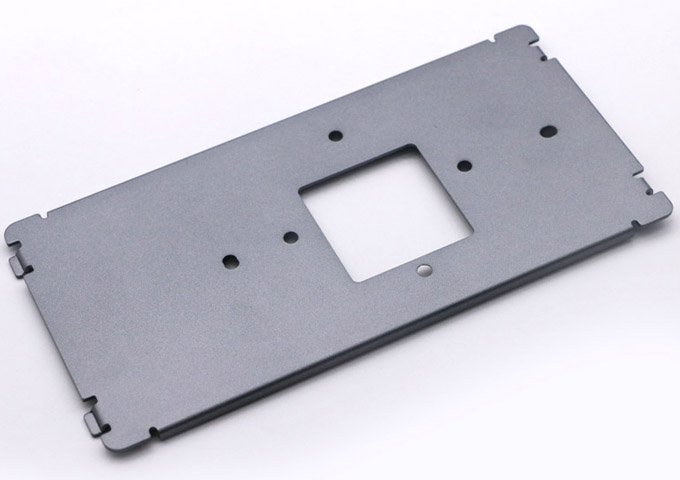

Hard Anodizing

Hard anodizing is a type of anodizing that produces a much thicker, harder, and more durable oxide layer on metal surfaces, typically used for industrial or high-wear applications.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Aluminum, Titanium

Color: Customizable upon request, including black, gray, brown, bronze etc.

Appearance:

Price:

Color Anodizing

Color anodizing is used primarily for aesthetic enhancement and product differentiation, while still offering corrosion protection and durability. It is commonly seen in consumer goods, architecture, and decorative applications.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Aluminum, Titanium

Color: Customizable upon request, including transparent, black, gray, red, blue, gold, etc.

Appearance:

Price:

Sandblasting

A powerful process that blasts abrasive media onto the surface to remove coatings and impurities.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metals, plastics

Color: None

Appearance: Smooth matte finish

Price:

Grinding and Polishing

The process of smoothing, polishing, and deburring metal surfaces to achieve a high gloss finish. Surface roughness can reach Ra0.6μm-Ra1.6μm.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metals

Color: natural color of the material

Appearance: Smooth and glossy

Price:$

Electroplating

Electroplating is a process that uses an electric current to deposit a thin layer of metal onto the surface of a workpiece, enhancing its properties such as corrosion resistance, wear resistance, or aesthetic appeal. It is commonly used in industries like automotive, electronics, and jewelry.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metal

Color: Chrome (silver, mirror-like), Nickel (silver-grey), Gold (yellow), Silver (bright white), Copper (reddish-brown), Zinc (silver, yellow, black or olive).

Appearance:

Price:$$$

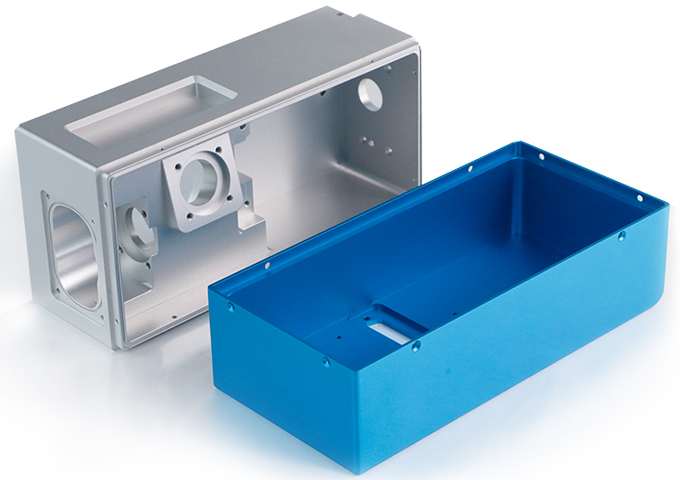

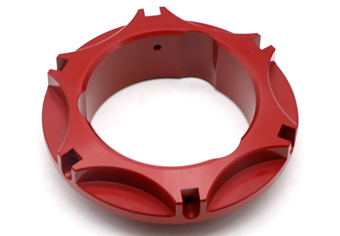

Powder Coating

Powder coating is a dry finishing process where powdered paint is electrostatically applied and then cured under heat to form a durable, protective layer.

Services: CNC machining, sheet metal fabrication

Applicable Materials: metal, some plastics

Color: Customizable colors as required, white, black, gray, red, blue, gold, green, etc.

Appearance:

Price:$$

Painting

Painting is the process of applying a liquid coating, typically paint, to a surface for protection, aesthetics, or both.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metals, plastics

Color: Customizable colors as required, white, black, gray, red, blue, gold, green, etc.

Appearance:

Price:$

PVD

PVD (Physical Vapor Deposition) is a vacuum coating process that deposits a thin film of material onto a substrate. It is widely used to enhance the durability, wear resistance, and appearance of components. The process involves vaporizing a solid material, such as metal, which then condenses onto the target surface, forming a highly durable coating.

Services: CNC machining, sheet metal fabrication

Applicable Materials: metal, some plastics

Color: Customizable colors as required, black, blue, silver, etc.

Appearance:

Price:$$$

Laser Engraving

Laser engraving is a precise, non-contact process that uses a laser beam to remove material from the surface, creating permanent designs, markings, or text.

Services: CNC machining, sheet metal fabrication

Applicable Materials: metal, plastic

Color: gray, white, black

Appearance:

Price:$$

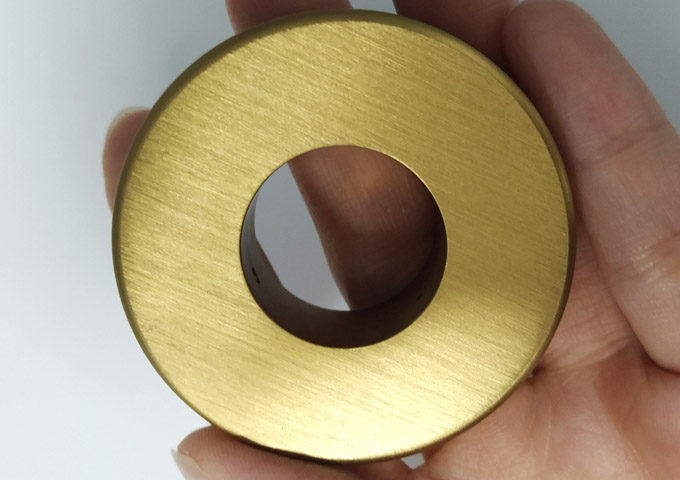

Brushing

Brushing is a surface finishing technique where a material is abraded using a brush to create a uniform, linear texture. It is often used for aesthetic purposes, giving materials a matte or satin finish with fine lines.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Aluminum, Titanium

Color: natural color of the material

Appearance:

Price:

Etching

Etching is a technique that uses chemicals, lasers, or acid to remove layers from the surface of a material to create patterns, designs, or text.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metal, Plastic

Color: Etching will usually bring out the natural color of the material.

Appearance:

Price:$

Silk Screen Printing

Silk screen printing is a printing technique where ink is forced through a fine mesh stencil onto a surface, creating vibrant, long-lasting designs. It’s known for its ability to produce bold, opaque prints.

Services: CNC machining, sheet metal fabrication

Applicable Materials: Metals, plastics

Color: Customizable colors as required, Available in a full range of colors, including metallic and fluorescent inks.

Appearance:

Price:

Electrophoresis

Electrophoresis (e-coating) is a process where a charged coating material is deposited onto a conductive surface using an electric current. It provides a uniform, corrosion-resistant coating, commonly used as a primer or final finish.

Services: CNC machining, sheet metal fabrication

Applicable Materials: metal

Color: Customizable colors as required, black, white, gray, black, blue, silver, etc.

Appearance:

Price:

Appearance Enhancement

Surface finishing is used for both functionality and aesthetics. When both aspects are taken into account, this finishing is especially suitable for beautifying parts. When manufacturing aesthetically pleasing components, we take extra measures to minimize scratches and marks that may occur during the machining process.

Major machining marks remain visible.

Finishing can be decorative or non-decorative based on requirements.

These finishes always have an aesthetic effect.

Cosmetic Acceptability Criteria

All cosmetic parts produced by VMT follow our Cosmetic Acceptability Criteria:

Consistency Requirements

Each part must be visually consistent across the same batch, meaning:

Manual brushing marks will be as unidirectional as possible. Please note that for rounded geometries, brushing marks may not be entirely unidirectional.

Visual Inspection Conditions

The surface quality of every part must meet the following conditions:

About Surface Finishing Standards

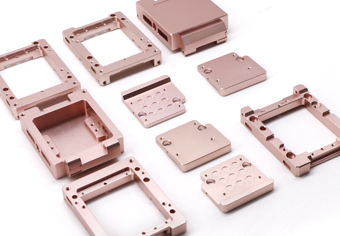

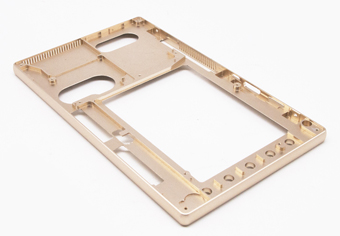

Gallery of Parts With Cosmetic Surface Finish

VMT works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their ideas to products.

Perfect Your Project's Finish

Your designs deserve the best. Enhance durability and appeal with our various finishing options. Part surfacing finishing techniques can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Step up the quality of your projects today!

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red