15 years one-stop China custom CNC machining parts factory

VMT offers personalized custom machining services, with flexible solutions tailored to meet your specific requirements, ensuring each product aligns precisely with your expectations.

Get an Instant Quote

We have professional equipment and a team. We have accumulated 6582 models for customers and cumulative production models: 9628 models. Our business has spread to 62 countries. such as medical automotive plumbing and performance parts agriculture electronics electron hardware video and audio control systems oil & gas industrial energy lighting pressure & filtration systems cooling and heating system.

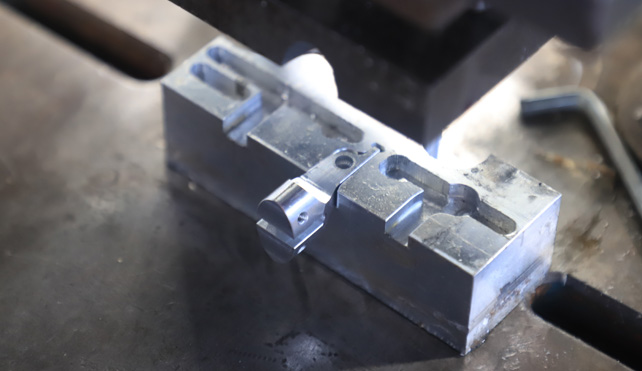

We will complete different processing designs based on customers' processing needs and combine different processing techniques to give customers the best solutions such as CNC machining turning milling stamping forging extrusion casting bending welding etc.

As long as we can do it you only need to provide your project drawings and samples and we can customize and manufacture for you.

Customized processing can be obtained within 1 day to obtain prototypes and small batch production parts to provide customers with high-quality and low-cost CNC machined products.

We provide CNC machining turning milling parts assembly. We have a wide range of applications, it is recommended that you communicate with our sales so that we can understand your exact needs.

For example, you want to complete some CNC machining parts by welding. We can provide. you need to contact us for more details.

We can choose the appropriate packaging method for high-precision machining turning parts to ensure that the product is in good condition before shipping, during shipping and when it reaches your hand.

Usually, the sheet stamping is made of sheet into a specified shape, and it is operated with a cutting machine or a bending machine, but custom CNC machining is more complicated. high precision machining turning parts raw material is block, not simply bending and deforming. Compared with stamping, CNC machining turning milling parts is more precise.

We can reduce your manufacturing cost through the combination of two different processing. For some structures, we can also reduce the cost by 50% on the basis of the original.

Punching is a stamping method that separates the blank from the blank with a closed curve to obtain the part to be holed. Compared with sheet punching, pipe punching has many similarities in terms of deformation properties, deformation characteristics, etc., but because the pipe is a hollow cylindrical blank, the pipe wall that the convex and concave molds contact during punching is an isolated surface. Unlike the plate, which is flat, special process measures and die structure are required. The traditional method of punching is to use punching dies to process through holes on the plate.

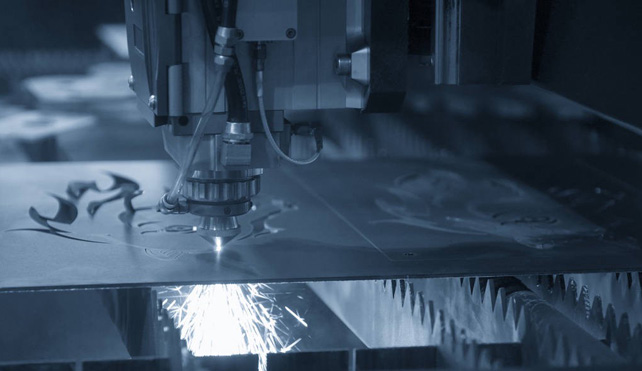

The high-speed rotating grinding wheel is used to cut the steel, and the raw material is simply cut or separated according to the shape to obtain the blank. Common metal cutting methods include: saw cutting, plasma cutting, laser cutting and waterjet cutting.

Stamping is a production technology that uses a mold installed on a press to apply pressure to the sheet material in the mold to deform the sheet material in the mold, so as to obtain a production technology of product parts with a fixed shape, size and performance.

To make the sheet blank or other blanks bend and deform along a straight line (bending line) is to bend the flat blank into an angle shape. There are many different forms depending on the shape, precision and production volume of the part. The mold thus obtains a mold of a certain angle and shape of the workpiece.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!