15 years one-stop China custom CNC machining parts factory

Home / Product / Automotive Industry /

13 years of experience in CNC machining auto parts, different processing and manufacturing techniques, reducing processing costs. There are 2000+ automotive CNC machining parts samples, you can view the factory online, contact us immediately to get discounts and samples.

Product Specification:

New Design CNC Machining Aluminum motorcycle adjustable footrest for Harley Davidson

| Machining process | Contens | Description | Standard |

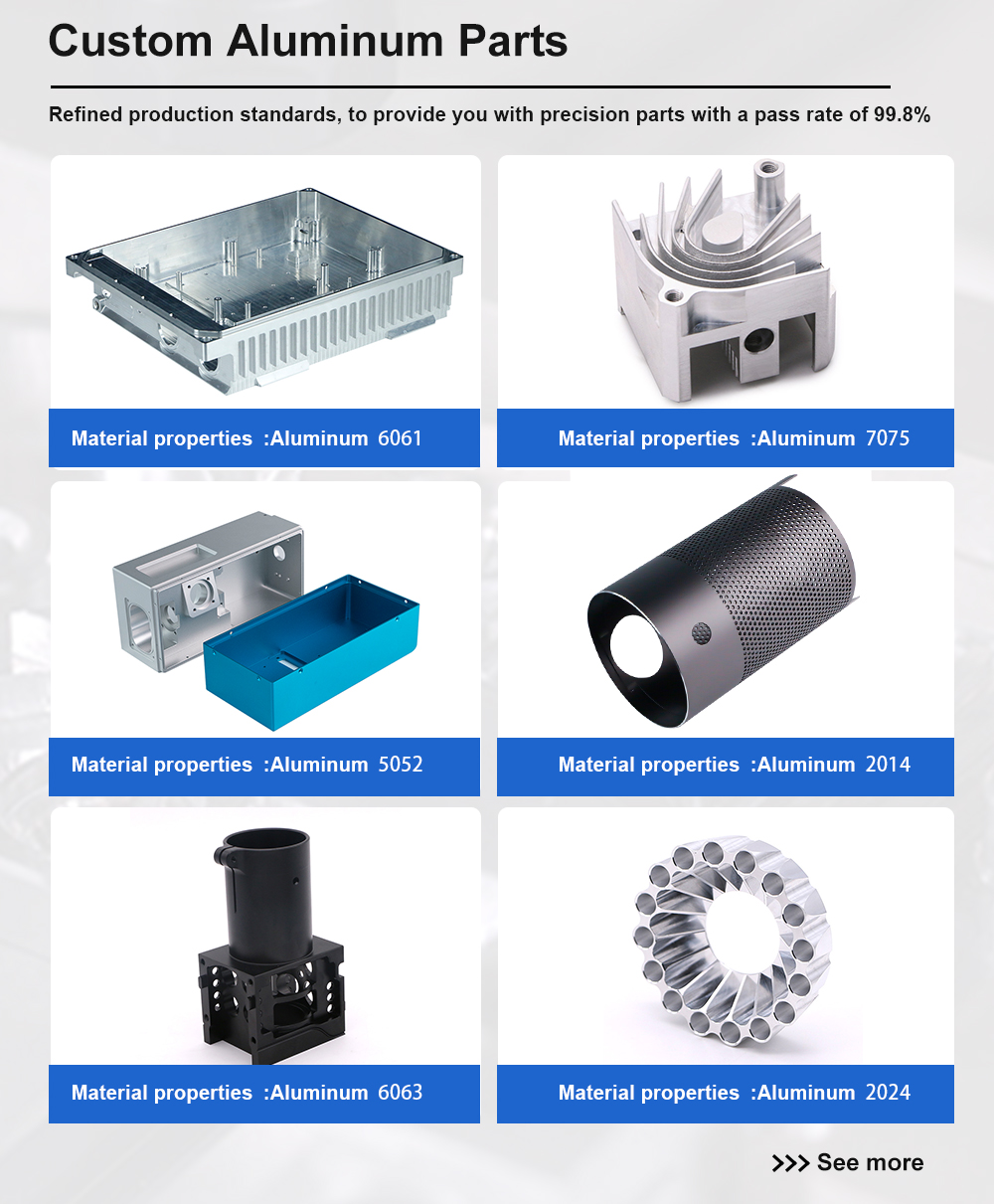

| Materia | Aluminum | AL 6061-T6, 6063, 7075-T 2014 2017 2011 etc | SUS,ASTM,DTM |

| Copper | C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | SUS,ASTM,DTM | |

| Iron | 4140, Q235, Q345B,20# ,45# etc. | SUS,ASTM,DTM | |

|

Stainless Steel |

303,304,316L, 17-4(SUS630) etc | SUS,ASTM,DTM | |

| Titanium | TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | SUS,ASTM,DTM | |

| Surface treatment | Plating | Galvanized, Gold Plating, Nickel,Plating, Chrome Plating, Zinc nickel alloy, Titanium Plating | ML-STD-810G |

| PVD | Golden TiN; Black:TiC, Silver:CrN | ASTM B117 ASTM D3359 | |

| Anodized | Hard oxidation ,Clear Anodized,Color Anodized |

ASTM B117 ASTM D3360 ASTM G154-2006 |

|

| Tolerance | Circularity | +/-0.01mm | ISO 4292:1985 |

| Planarity | +/-0.05mm | ISO 4292:1985 | |

| Surface roughness | Ra0.1 3.2 |

ISO 468-1982 ISO 8502-3-1993-05

|

Our goal is to help more small and medium-sized enterprides quickly verify their new product designs

New Design CNC Machining Aluminum motorcycle adjustable footrest for Harley Davidson

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!