15 years one-stop China custom CNC machining parts factory

181 |

Published by VMT at Jul 11 2025 | Reading Time:About 7 minutes

181 |

Published by VMT at Jul 11 2025 | Reading Time:About 7 minutes

Navigating the world of material selection for CNC machining can often feel like deciphering a complex code, especially when terms like 18/8 stainless steel and 304 stainless steel are used interchangeably. Businesses and individuals seeking a reliable CNC machining shop often find themselves asking: what exactly is the distinction between these two common stainless steel types? Is one superior to the other for my specific application? Misunderstanding these nuances can lead to suboptimal material choices, potentially compromising product durability, corrosion resistance, and overall performance.

This confusion isn't merely academic; it has tangible implications for the success of manufacturing projects. An incorrect material selection can result in components that fail prematurely, exhibit undesirable surface finishes, or incur unexpected costs due to rework or material waste. Furthermore, if your chosen CNC machining services provider lacks a deep understanding of these material properties, you might encounter delays in delivery, inconsistencies in quality control, or inadequate post-machining support. This article aims to demystify the relationship between 18/8 stainless steel and 304 stainless steel, providing clarity on their compositions, properties, and the practical implications for stainless steel CNC machining. By understanding these fundamental differences, you can make informed decisions, ensuring your CNC machining parts meet the highest standards of quality and performance.

18/8 stainless steel is a common informal designation for 304 stainless steel, indicating it contains approximately 18% chromium and 8% nickel. While 18/8 highlights the key alloying elements, 304 stainless steel is the official ASTM grade with precise compositional limits for all elements, ensuring consistent performance. Both are widely used in stainless steel CNC machining due to excellent corrosion resistance and formability.

Having established the fundamental relationship between these two widely used stainless steel designations, you might naturally wonder about the specific characteristics that define each, and how these attributes impact their suitability for various applications, especially within the realm of CNC machining. Therefore, we will now delve deeper into the defining aspects of 18/8 and 304 stainless steel, exploring their unique advantages, potential limitations, and the precise chemical compositions that underpin their performance. This detailed examination will undoubtedly aid in making more informed decisions when collaborating with a CNC machining shop for your next project.

The term "18/8 stainless steel" is a widely recognized informal designation, particularly prevalent in the consumer goods sector, especially for kitchenware and cutlery. This nomenclature directly refers to the approximate percentages of its two primary alloying elements: around 18% chromium (Cr) and 8% nickel (Ni). Chromium is the cornerstone of stainless steel's corrosion resistance. It reacts with oxygen in the environment to form an incredibly thin, yet remarkably stable and self-repairing, passive layer of chromium oxide on the surface. This protective film acts as a formidable barrier, preventing rust and resistance to staining. The addition of nickel significantly enhances the material's overall corrosion resistance, particularly in acidic and alkaline environments, while also improving its ductility, toughness, and formability. These characteristics are crucial for various manufacturing processes, including bending, deep drawing, and the intricate operations involved in CNC machining parts.

18/8 stainless steel belongs to the austenitic family of stainless steels. This classification signifies that it possesses a face-centered cubic (FCC) crystal structure at room temperature, which largely contributes to its non-magnetic properties in its annealed state. However, it is worth noting that some slight magnetism can be induced through cold working or extensive deformation. This material is highly valued for its excellent combination of corrosion resistance, weldability, and workability. Its non-toxic nature and ease of cleaning make it a preferred choice for applications involving contact with food, such as sinks, cooking utensils, and food processing equipment. Beyond culinary uses, it finds extensive application in architectural ornamentation, automotive components, and medical instruments, where its aesthetic appeal and durability are beneficial. For CNC machining shops, understanding the precise properties of 18/8 stainless steel is paramount for optimizing machining parameters, selecting appropriate tooling, and devising effective cutting strategies. This meticulous approach ensures the dimensional accuracy, surface finish, and overall quality of 18/8 stainless steel CNC machining parts, helping to mitigate common issues like poor surface finish and delays in delivery.

304 stainless steel stands as one of the most widely used and versatile grades within the austenitic stainless steel family globally. Unlike the informal "18/8" designation, 304 is an official standard grade, specifically categorized under the ASTM (American Society for Testing and Materials) standards as UNS S30400. While its core composition also features approximately 18% chromium and 8% nickel—hence the frequent informal reference as 18/8 stainless steel—the defining characteristic of 304 stainless steel lies in its precisely controlled chemical composition for all constituent elements. This includes specific maximum limits for carbon (typically 0.08%), manganese (2%), silicon (1%), phosphorus (0.045%), and sulfur (0.03%). This rigorous control over elemental percentages ensures consistent mechanical properties, corrosion resistance, and predictable performance across various applications, making it a reliable choice for stainless steel CNC machining.

304 stainless steel is renowned for its exceptional balance of properties. Its superior corrosion resistance makes it highly effective in a broad range of atmospheric, freshwater, and moderately aggressive chemical environments. This resistance is due to the formation of a robust, passive chromium oxide layer. Furthermore, 304 stainless steel exhibits excellent formability, allowing it to be easily deep-drawn, bent, and stretched into complex shapes, which is a significant advantage for manufacturing intricate CNC machining parts. Its superb weldability, without the need for extensive preheating or post-weld heat treatment, simplifies fabrication processes and reduces manufacturing complexity. The material also boasts commendable strength and toughness, maintaining its mechanical integrity even at cryogenic temperatures, making it suitable for low-temperature applications like liquefied natural gas (LNG) storage. Its non-magnetic nature in the annealed condition further expands its applicability in sensitive electronic and medical equipment. For CNC machining services, a thorough understanding of 304 stainless steel's characteristics is fundamental to producing high-quality 304 stainless steel CNC machining parts. Reputable CNC machining shops leverage these attributes with advanced CNC machining techniques to deliver components that meet stringent precision and performance requirements, thereby addressing client concerns regarding quality control and product reliability.

18/8 Stainless Steel: Advantages and Disadvantages

18/8 Stainless Steel Advantages

18/8 stainless steel, largely synonymous with 304 stainless steel, offers numerous benefits for diverse applications, particularly in stainless steel CNC machining:

18/8 Stainless Steel Disadvantages

Despite its strengths, 18/8 stainless steel has certain limitations that need consideration, especially in specialized CNC machining contexts:

304 Stainless Steel: Advantages and Disadvantages

304 Stainless Steel Advantages

304 stainless steel, recognized globally as a standard, offers a comprehensive set of advantages for stainless steel CNC machining and beyond:

304 Stainless Steel Disadvantages

Despite its widespread utility, 304 stainless steel has specific limitations that are important for CNC machining shops and clients to acknowledge:

18/8 and 304 Stainless Steel: Chemical Composition

Understanding the chemical composition is paramount to distinguishing between 18/8 stainless steel and 304 stainless steel. As previously discussed, 18/8 stainless steel is largely an informal designation for 304 stainless steel, particularly prevalent in consumer-facing descriptions. This means that virtually all stainless steel marketed as "18/8" will broadly conform to the compositional requirements of 304 stainless steel. However, 304 stainless steel itself is a precisely defined grade under international standards, which specify tighter ranges for its constituent elements, ensuring consistent mechanical and corrosion-resistant properties. The exact percentages of these elements are critical for stainless steel CNC machining as they directly influence the material's machinability, weldability, and ultimate performance as CNC machining parts.

The primary elements in both 18/8 and 304 stainless steel are chromium and nickel, which lend them their characteristic corrosion resistance and austenitic structure. Chromium is the star player, forming the passive oxide layer that protects against rust and staining. Nickel enhances ductility, toughness, and resistance to various acids. Beyond these two, other elements like carbon, manganese, silicon, phosphorus, and sulfur are present in controlled amounts, each playing a role in the material's overall properties. For instance, carbon impacts strength and weldability, while silicon and manganese act as deoxidizers during steelmaking. The table below outlines the typical compositional ranges, highlighting the close relationship between the informal "18/8" description and the standardized "304" grade. This detailed breakdown aids CNC machining shops in verifying material quality and predicting how it will behave during complex CNC machining services, preventing common issues such as poor quality control or unexpected material reactions during fabrication.

| Element |

18/8 Stainless Steel (Typical) |

304 Stainless Steel (ASTM A240 Standard Range) |

Primary Role |

| Chromium |

~18% | 17.5% - 20% | Forms passive layer for corrosion resistance. |

| Nickel |

~8% | 8% - 10.5% | Enhances ductility, toughness, and corrosion resistance. |

| Carbon |

<0.08% | 0.08% max | Influences strength and weldability. |

| Manganese |

<2% | 2% max | Deoxidizer, contributes to strength. |

| Silicon |

<1% | 1% max | Deoxidizer, improves strength. |

| Phosphorus |

<0.045% | 0.045% max | Can cause brittleness if too high. |

| Sulfur |

<0.03% | 0.03% max | Improves machinability (can reduce corrosion resistance). |

| Iron |

Balance | Balance | Base metal. |

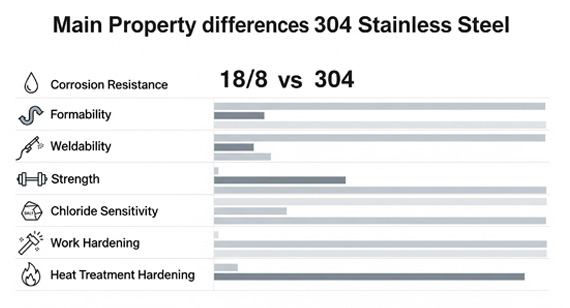

While their chemical compositions are almost identical, small variations within the standard ranges and the specific processing methods can lead to subtle differences in their mechanical and physical properties. For stainless steel CNC machining, these properties dictate how the material behaves under cutting forces, its finished quality, and its suitability for specific applications. Understanding these nuances helps CNC machining shops optimize their processes to produce high-quality CNC machining parts and meet stringent client specifications.

This comparison focuses on key properties that influence material selection and CNC machining services. The density affects part weight; tensile strength indicates resistance to breaking under tension; melting point is crucial for high-temperature applications; modulus of elasticity relates to stiffness; resistivity impacts electrical applications; thermal conductivity influences heat dissipation during machining; thermal expansion is important for dimensional stability; elongation at break indicates ductility; hardness affects wear resistance and machinability; corrosion resistance defines durability in various environments; magnetic properties are relevant for sensitive instruments; formability relates to ease of shaping; and machinability impacts the efficiency of CNC machining.

| Property |

18/8 Stainless Steel (Typical) |

304 Stainless Steel (Typical Range) |

Relevance to CNC Machining/Application |

| Density (g/cm³) |

7.93 | 7.93 - 8.03 | Influences part weight; important for weight-sensitive applications. |

| Tensile Strength (MPa) |

520 - 720 | 515 - 700 | Resistance to breaking under tension; critical for load-bearing CNC machining parts. |

| Melting Point (°C) |

1400 - 1450 | 1400 - 1450 | Relevant for high-temperature applications and welding. |

| Modulus of Elasticity (GPa) |

193 - 200 | 193 - 200 |

Stiffness of the material; important for structural integrity. |

| Resistivity (Ω·m) |

7.2 x 10⁻⁷ | 7.2 x 10⁻⁷ - 7.5 x 10⁻⁷ | Electrical resistance; relevant for electrical components. |

| Thermal Conductivity (W/mK) |

16.2 | 16.2 - 17.0 | How well it conducts heat; impacts heat dissipation during CNC machining. |

| Thermal Expansion (1/K) |

17.3 x 10⁻⁶ | 16.9 x 10⁻⁶ - 17.3 x 10⁻⁶ | How much it expands with temperature changes; crucial for dimensional stability in varying temperatures. |

| Elongation at Break (%) |

40 - 60 | 40 - 60 | Indication of ductility; impacts formability and resistance to cracking during CNC machining. |

| Hardness (Rockwell B) |

70 - 90 | 70 - 92 | Resistance to indentation; affects wear resistance and ease of cutting in stainless steel CNC machining. |

| Corrosion Resistance |

Excellent (general) | Excellent (general) | Critical for durability in corrosive environments, especially for 18/8 and 304 stainless steel CNC machining parts. |

| Magnetic Properties |

Non-magnetic (annealed) | Non-magnetic (annealed) | Important for magnetically sensitive applications. |

| Formability |

Excellent | Excellent | Ease with which it can be shaped; key for complex CNC machining parts. |

| Machinability (Annealed) |

Good (prone to work hardening) | Good (prone to work hardening) | How easily it can be cut by CNC machining services; work hardening can increase tool wear. |

When considering materials for stainless steel CNC machining, the cost of 18/8 and 304 stainless steel is a significant factor for CNC machining shops and their clients. Generally, since "18/8" is a common informal way to refer to 304 stainless steel, their market prices are essentially the same. The cost is primarily influenced by several factors, which can cause fluctuations.

Here are the main factors affecting the cost of 18/8 and 304 stainless steel:

| Cost Factor |

Description |

| Raw Material Prices |

Nickel and Chromium are major cost drivers, with nickel's price being particularly volatile and a significant portion of the total material cost. Iron ore prices also contribute. |

| Market Supply & Demand |

Global demand across industries like construction, automotive, and appliances directly impacts pricing. Supply shortages or surpluses can cause significant price swings. |

| Form & Finish |

The material's form (sheet, plate, bar, tube) and specialized finishes (e.g., polished, brushed) will affect cost. More processed forms or custom finishes typically increase the price. |

| Supplier & Quantity |

Prices vary between suppliers. Larger bulk purchases often lead to lower per-unit costs for CNC machining factories due to economies of scale. |

| Global Economic Factors |

Broader economic trends, energy costs for production, and international trade policies (like tariffs and quotas) can all influence the overall pricing of raw materials. |

Raw Material Prices:

Market Supply and Demand:

Form and Finish:

Supplier and Quantity:

Global Economic Conditions and Trade Policies:

While 18/8 and 304 stainless steel are generally considered cost-effective options among austenitic stainless steels due to their widespread availability and versatility, they are typically more expensive than plain carbon steels or lower-grade stainless steels like 430. This higher initial material cost is an important consideration for CNC machining services when budgeting for 18/8 stainless steel CNC machining parts or 304 stainless steel CNC machining parts. However, their superior performance, longevity, and reduced maintenance in applications where corrosion resistance and durability are critical often justify the investment, potentially leading to lower long-term costs through reduced maintenance and replacement. VMT always provides transparent pricing and material sourcing to ensure clients receive the best value for their CNC machining projects.

18/8 stainless steel and 304 stainless steel are essentially two names for the same material. Widely used across industries, they are favored for their excellent corrosion resistance, good formability, and ease of machining. For customers seeking a reliable CNC machining partner, understanding the typical applications and part examples of these materials is essential for better project planning and execution.

Below are the primary application sectors and specific part examples of 18/8 and 304 stainless steel across various industries:

| Industry |

Typical Applications |

CNC Machining Use Cases |

Key Performance Benefits |

| Food & Beverage |

Valves, pump housings, fittings, mixer components, tank accessories | Precision valve cores, pump shafts, pipe flanges, clamps, nozzles, filter brackets | Excellent corrosion resistance (especially against food acids and bases), non-toxic, easy to clean and sanitize—ensuring food safety and hygiene compliance. |

| Medical & Pharmaceutical |

Surgical instruments (non-cutting), diagnostic equipment housings, syringe pump parts, reactor vessel internals | Precision fixtures, connectors, sensor housings, fluid channels, metering pump pistons | Biocompatibility, high cleanliness, easy sterilization, and corrosion resistance (disinfectants)—ensuring reliability and purity in medical environments. |

| Architecture & Construction |

Curtain wall anchors, connectors, handrail brackets, door/window hardware | Structural connectors, custom brackets, decorative fasteners, precision-sized components | Weather resistance, atmospheric corrosion protection, attractive surface finish—ensures long-term appearance with minimal maintenance and modern aesthetic appeal. |

| Automotive & Transportation |

Exhaust system components, sensor housings, fuel system fittings, decorative parts | Exhaust flanges, oxygen sensor mounts, fuel injector bodies, brackets, custom bolts | High-temperature resistance, corrosion protection, mechanical strength—ensuring durability and safety in vehicle systems. |

| Chemical & Petrochemical |

Pump bodies, pipe joints, flanges, heat exchanger parts | Precision valve bodies, flange plates, pipe connectors, seals, instrument housings | Resistance to various chemical media, high strength, good weldability—ensures safety and efficiency in fluid handling and chemical processing. |

| General Industry & Consumer Goods |

Bearing housings, bushings, fasteners, electronic housings, appliance components | Precision shafts, dowel pins, custom nuts, electronics panels, internal appliance brackets | Good mechanical strength, durability, broad usability, ease of machining—offering great cost-performance balance for diverse applications. |

Food & Beverage Industry

Examples:

Image Suggestion: Close-up of a stainless steel kitchen sink or food processing equipment showing the smooth surface finish.

Medical & Pharmaceutical Industry

Features: Biocompatibility, easy sterilization, and corrosion resistance for sterile environments and product purity.

Applications: Used in clean, high-precision medical devices and pharmaceutical equipment.

Examples:

Image Suggestion: Shiny stainless steel instruments or pharmaceutical processing lines with sterile equipment.

Architecture & Construction

Features: Aesthetic appeal, weather resistance, low maintenance, long service life.

Applications: Widely used in both decorative and structural elements.

Examples:

Image Suggestion: Stainless steel building façade or modern architecture with stainless steel handrails.

Features: Corrosion resistance, high strength, heat resistance, attractive appearance.

Applications: Manufacturing parts that require durability and long-term performance.

Examples:

Image Suggestion: Close-up of a stainless steel exhaust pipe or automotive part with stainless trim.

Chemical & Petrochemical Industry

Features: Corrosion resistance, resistance to various chemicals, high strength.

Applications: Processing and storing corrosive chemicals.

Examples:

Image Suggestion: Large stainless steel chemical tanks or complex chemical piping systems.

General Industry & Consumer Goods

Features: Cost-effective, versatile, good mechanical properties and durability.

Applications: From daily-use items to heavy-duty machinery.

Examples:

Image Suggestion: A variety of stainless steel fasteners or small precision-machined components.

VMT specializes in producing high-precision CNC machined parts using 18/8 and 304 stainless steel for all the applications listed above. With deep expertise in the material's characteristics and advanced CNC machining capabilities, we ensure every part meets your strict technical and performance requirements. Whether you need a complex prototype or high-volume production, our CNC machining services deliver professional solutions that help you avoid common issues like delivery delays, quality control concerns, surface finishing inconsistencies, and post-sale challenges.

To ensure global consistency and interchangeability, both 18/8 and 304 stainless steel are recognized under various national and international standards. While “18/8” is a general descriptor, 304 stainless steel is a precisely defined grade in many specifications. For CNC machining manufacturers working with international clients or sourcing materials globally, understanding these equivalent grades is critical for accurate material selection and quality control of stainless steel CNC machined parts.

Below is a list of major national and international standards and their equivalent designations for 304 stainless steel:

| Country/Region |

Standards Organization |

Equivalent 304 Stainless Steel Grades |

| United States |

ASTM (American Society for Testing and Materials) | 304 (UNS S30400), ASTM A240, ASTM A312 |

| Europe |

EN (European Norm) | X5CrNi18-10, 1.4301 |

| Japan |

JIS (Japanese Industrial Standards) | SUS 304 |

| China |

GB (National Standards of China) | 06Cr19Ni10, 0Cr18Ni9 (older standard) |

| International |

ISO (International Organization for Standardization) | X5CrNi18-10 (per ISO 15510, similar to EN designation) |

| Germany |

DIN (Deutsches Institut für Normung) | 1.4301 |

| United Kingdom |

BS (British Standards) | 304S15, 304S16, 304S31 (depending on specific product form) |

| India |

IS (Indian Standards) | X4CrNi18-10 (per IS 6911) |

Why Equivalent Grades Matter in CNC Machining

Understanding these equivalent designations allows CNC machining service providers to ensure that the required material—regardless of origin—meets the exact chemical composition and performance standards needed for the project. When a customer requests CNC machined parts made from 18/8 or 304 stainless steel, a knowledgeable CNC machining company like VMT can confidently source and machine the correct material based on global standards. This helps avoid discrepancies that could lead to production delays or performance issues.

Standardization is essential for consistent quality, especially in global trade and international manufacturing collaborations. By recognizing these equivalents, CNC machining factories can maintain high reliability and compliance across all customer specifications.

This question often arises due to the common misconception that 18/8 stainless steel and 304 stainless steel are entirely distinct materials. As we've clarified, 18/8 stainless steel is fundamentally a descriptive term for 304 stainless steel, indicating its approximate chromium and nickel content. Therefore, it's more accurate to say that they possess very similar, if not identical, strength characteristics because they are effectively the same material grade.

Here's a breakdown of their strength properties:

In essence, when comparing the strength, you are comparing 304 stainless steel to itself, just described by a different nomenclature. Any perceived difference in strength would likely stem from variations in manufacturing processes (e.g., degree of cold work) rather than inherent material distinctions based solely on the "18/8" or "304" label. Reputable CNC machining factories understand this equivalence and will apply the same rigorous quality control standards to both descriptions.

The question of which is "better" between 18/8 stainless steel and 304 stainless steel is a common point of confusion, primarily because, for all practical purposes, they refer to the same material. The term "18/8" is simply a shorthand for the approximate composition of 304 stainless steel, denoting 18% chromium and 8% nickel. Therefore, in terms of material properties, performance, and suitability for various applications, there is no functional difference between them.

Here's why they are considered equivalent in most contexts:

The choice between using the term "18/8" or "304" often comes down to industry jargon or consumer branding. In technical specifications and engineering drawings, 304 stainless steel is the precise and preferred term because it refers to a specific, standardized ASTM grade with defined compositional limits for all alloying elements, not just the two primary ones. This standardization ensures consistency and predictable performance.

So, when a CNC machining factory specifies 304 stainless steel, it is confirming adherence to a recognized international standard that guarantees the material's properties. When a product is labeled "18/8," it's generally communicating that it has the desirable corrosion resistance and durability associated with 304 stainless steel. Neither is "better" than the other; they are two ways of referring to the same, highly versatile, and widely used stainless steel grade in stainless steel CNC machining and beyond.

At VMT, we specialize in providing high-precision, high-quality 18/8 stainless steel CNC machining parts and 304 stainless steel CNC machining parts. We understand that clients often face concerns regarding delivery deadlines, quality control issues, poor surface finish, and inadequate after-sales service when seeking a reliable CNC machining factory. That's why we've established a comprehensive service framework designed to address these pain points and ensure the seamless execution of your projects.

1. Rigorous Material Sourcing and Quality Control:

We recognize that the quality of raw material is the bedrock of superior CNC machining parts. At VMT, our procurement of 18/8 and 304 stainless steel strictly adheres to international standards, partnering only with reputable suppliers. Every batch of incoming material undergoes stringent chemical composition analysis and physical property testing to ensure full compliance with ASTM and other industry standards. This meticulous approach eliminates the risk of poor quality control from the outset. We verify original Material Test Certificates (MTCs) and conduct in-house validation to ensure the material meets all requirements for stainless steel CNC machining. This includes comprehensive checks on density, tensile strength, yield strength, and hardness, ensuring optimal machinability.

2. Advanced CNC Machining Technology and Equipment:

VMT boasts a state-of-the-art arsenal of CNC machining equipment, including multi-axis machining centers and precision turn-mill machines. These advanced machines are specifically chosen for their ability to accurately process the unique characteristics of 18/8 and 304 stainless steel. Our team of highly skilled engineers possesses deep expertise in the machining properties of these materials. They meticulously optimize cutting parameters, select appropriate tooling, and employ effective cooling lubricants to prevent issues such as work hardening, premature tool wear, and suboptimal surface finishes. Whether your project demands intricate geometries or tight dimensional tolerances, our advanced CNC machining services deliver precise results. We utilize cutting-edge CAD/CAM software for meticulous programming, ensuring accurate and repeatable machining operations while minimizing human error. Regular maintenance and calibration of our equipment guarantee consistent and reliable performance.

3. Expert Surface Finishing Processes:

For stainless steel CNC machining parts, the surface finish is critical to both aesthetics and performance. VMT offers a diverse range of custom surface finishing solutions, including brushing, polishing, bead blasting, electropolishing, and passivation. We rigorously control the parameters of each surface treatment step to ensure a uniform, flawless finish that enhances the part's corrosion resistance and visual appeal, eliminating concerns about poor surface finish. For example, passivation treatment actively strengthens the passive layer on the stainless steel surface, significantly boosting its corrosion resistance. Our expert team recommends the most suitable surface finish based on the part's end use and your specific requirements, ensuring standardized and traceable processes.

4. Comprehensive Quality Management System and Inspection:

VMT places immense emphasis on quality control. We operate under an ISO 9001 certified comprehensive quality management system that spans every phase, from raw material procurement to final product shipment. All 18/8 stainless steel CNC machining parts and 304 stainless steel CNC machining parts undergo multiple stages of rigorous in-process inspection. This includes precise dimensional measurements using advanced equipment like Coordinate Measuring Machines (CMMs), thorough visual inspections for surface defects, hardness testing, and selective corrosion resistance checks. We utilize cutting-edge inspection tools such as optical comparators and spectrophotometers to verify that every single part conforms precisely to engineering drawings and industry standards. Before dispatch, all products undergo a final quality assurance check, accompanied by detailed inspection reports. This unwavering commitment to quality control ensures that every CNC machining part you receive from VMT is flawless.

5. Efficient Production Management and On-Time Delivery:

We recognize the critical impact that delivery deadlines can have on your project timelines. VMT prioritizes efficiency through optimized production workflows, the implementation of lean manufacturing principles, and advanced production planning systems. We maintain substantial manufacturing capacity and flexible scheduling capabilities, allowing us to respond quickly to client demands and consistently adhere to promised delivery dates. Even for urgent orders, we proactively allocate resources to ensure our CNC machining services are completed on schedule, helping you avoid costly production delays and capitalize on market opportunities. We maintain transparent communication channels with our clients, providing regular updates on production progress, ensuring you are always informed about your project status.

6. Holistic After-Sales Service and Technical Support:

VMT is founded on a customer-centric philosophy. We provide extensive after-sales service to ensure our clients have complete peace of mind after receiving their CNC machining parts. Should any issues arise during use, our dedicated technical support team responds promptly, offering expert consultation, troubleshooting, and effective solutions to ensure your concerns are resolved swiftly and efficiently, eliminating any worries about inadequate after-sales service. We aim to build enduring partnerships with our clients, providing continuous support. Regardless of the technical challenges you encounter, our experienced team is ready to provide professional advice and assistance, guaranteeing the ongoing success of your projects.

Choosing VMT means partnering with a CNC machining shop that delivers a complete solution – from expert material consultation and high-precision stainless steel CNC machining to comprehensive after-sales service. We are committed to being your most trusted manufacturing partner, jointly achieving excellence in product fabrication. To learn more about our CNC machining services or to discuss your specific requirements for 18/8 stainless steel CNC machining parts and 304 stainless steel CNC machining parts, please contact us today. Our expert team is ready to assist you.

In this comprehensive exploration, we've clarified the fundamental relationship between 18/8 stainless steel and 304 stainless steel: they are, for all practical purposes, the same material, with "18/8" serving as a descriptive shorthand for the chromium and nickel content of the officially standardized 304 stainless steel grade. Both are celebrated for their exceptional corrosion resistance, favorable formability, and widespread applicability across various industries, making them indispensable in both industrial and everyday contexts.

However, for clients seeking high-quality CNC machining parts, understanding the material alone is insufficient. The true key to success lies in selecting a CNC machining factory that not only comprehends the intricate properties of these materials but also possesses advanced CNC machining technology, implements stringent quality control protocols, offers efficient CNC machining services, and provides robust after-sales support.

VMT exemplifies such a reliable CNC machining shop. We not only possess a profound understanding of the chemical compositions and physical characteristics of both 18/8 and 304 stainless steel but also command the expertise to transform these materials into precision-engineered 18/8 stainless steel CNC machining parts and 304 stainless steel CNC machining parts. Our commitment is to alleviate client concerns regarding delivery deadlines, quality control issues, poor surface finish, and inadequate after-sales service. By partnering with VMT for your stainless steel CNC machining needs, you are assured of receiving products that deliver superior performance and unwavering reliability, ensuring the successful fruition of your projects. We sincerely invite you to contact us to discuss your CNC machining requirements and experience the unparalleled quality of our service.

Is 18-8 Stainless Steel Magnetic?

Generally, 18-8 stainless steel (which is essentially 304 stainless steel) is non-magnetic in its annealed state. However, cold working processes like bending, deep drawing, or extensive cutting can induce a slight magnetism due to martensitic transformation. This induced magnetism is usually weak and does not typically affect its primary performance.

Is 18/8 Stainless Steel Safe?

Yes, 18/8 stainless steel is considered safe. It is free from harmful substances and exhibits excellent corrosion resistance, meaning it will not react with food or water to leach out toxic compounds. Consequently, it is widely used in food contact applications such as cutlery, cookware, and food processing equipment, meeting international food safety standards.

Is 18/8 Professional Grade Stainless Steel?

Yes, 18/8 stainless steel (effectively 304 stainless steel) is widely recognized as a professional-grade stainless steel. It is extensively utilized in industrial and commercial sectors, including food processing, medical, chemical, and construction industries, where its performance and reliability are universally accepted.

Are 18/8 and 304 Stainless Steel Food Grade Stainless Steel?

Yes, both 18/8 and 304 stainless steel are considered food-grade stainless steel. Their properties, including good corrosion resistance, non-toxicity, and ease of cleaning, comply with hygienic requirements for food contact materials, making them suitable for kitchenware, food storage, and processing equipment.

Are 18-8 and 304 Stainless Steel the Same?

For most practical purposes, 18-8 and 304 stainless steel are the same. "18-8" is an informal term describing a stainless steel with 18% chromium and 8% nickel, a composition that aligns with the official ASTM standard for 304 stainless steel.

Which is Better, 18-8 Stainless Steel or 304 Stainless Steel, for Food Grade Applications?

Since 18-8 stainless steel is essentially the same as 304 stainless steel, both are equally suitable for food-grade applications. They offer identical benefits in terms of non-toxicity, corrosion resistance, and ease of cleaning, making them excellent choices for kitchen and food processing environments.

What is Stronger Than 304 Stainless Steel?

Certain stainless steel grades are stronger than 304 stainless steel. These include some martensitic stainless steels (e.g., 440C) and precipitation-hardening stainless steels (e.g., 17-4PH), which can achieve higher strength and hardness through heat treatment. Additionally, some duplex stainless steels (e.g., 2205) offer a combination of higher strength and enhanced corrosion resistance compared to 304.

Is 18/8 Stainless Steel Good Quality?

Yes, 18/8 stainless steel is considered good quality. It offers a beneficial combination of excellent corrosion resistance, good formability, weldability, and aesthetic appeal, making it a reliable and widely used material for numerous applications.

How Long Does 304 Stainless Steel Last?

304 stainless steel has an exceptionally long lifespan, often lasting for several decades under normal service conditions. Its exact longevity depends on the corrosiveness of its environment, maintenance practices, and whether it incurs physical damage.

What is the Highest Quality Stainless Steel?

There isn't a single "highest quality" stainless steel; quality depends on the specific application requirements. For extreme corrosion resistance, grades like 316L or super austenitic stainless steels (e.g., 904L) might be considered higher quality than 304. For high strength, martensitic or duplex stainless steels could be superior. Each grade offers a unique balance of properties for different needs.

What Grades of Cheap Stainless Steel are There?

Some relatively cheaper stainless steel grades include 430 stainless steel (a ferritic stainless steel that contains no nickel and is magnetic) and certain low-nickel 200-series austenitic stainless steels. However, it's crucial to balance cost with performance, as these cheaper alternatives typically offer lower corrosion resistance compared to 304 stainless steel.

What is 18-8 Stainless Steel Equivalent To?

18-8 stainless steel is typically equivalent to ASTM 304 stainless steel in the United States. In the European system (EN), its common equivalent is X5CrNi18-10 or 1.4301. In Japanese Industrial Standards (JIS), it is known as SUS 304.

Why Choose 304 Stainless Steel?

304 stainless steel is chosen for many reasons: its excellent general corrosion resistance, good formability, ease of welding, appealing surface finish, and its relatively economical cost compared to higher-alloyed grades. It provides a highly versatile and cost-effective solution for a vast majority of applications where a balance of these properties is desired.

How Do I Tell If My Stainless Steel is 304 or 316?

Visually distinguishing between 304 and 316 stainless steel is nearly impossible. The most reliable method is through chemical composition analysis, such as using an X-ray Fluorescence (XRF) analyzer. This device can detect the presence of molybdenum (typically 2-3%) in 316 stainless steel, an element absent in 304 stainless steel.

Which is Better, SS 304 or 316?

SS 316 is generally considered better than SS 304 when enhanced corrosion resistance, particularly against chlorides, is required. The addition of molybdenum in 316 stainless steel significantly improves its resistance to pitting and crevice corrosion in harsh environments like marine or acidic conditions. However, 304 stainless steel is typically more cost-effective and perfectly adequate for a wide range of less aggressive applications.

Which is Stronger, 303 or 304 Stainless Steel?

304 stainless steel is generally stronger than 303 stainless steel. 303 stainless steel has added sulfur to improve its machinability, but this addition compromises its strength, toughness, and corrosion resistance compared to 304. Therefore, for applications requiring higher strength and better corrosion resistance, 304 is the superior choice.

Which is Better, 304 Stainless Steel or 430 Stainless Steel?

304 stainless steel is generally better than 430 stainless steel in terms of overall performance. 304 (an austenitic grade) contains nickel, offering superior corrosion resistance across a broader range of chemicals and better weldability. 430 (a ferritic grade) is nickel-free, making it cheaper and magnetic, but its corrosion resistance is significantly lower than 304, and its weldability is generally poorer.

Is 301 Stainless Steel Better Than 304 Stainless Steel?

Neither 301 stainless steel nor 304 stainless steel is universally "better"; each excels in different areas. 301 stainless steel has a higher carbon content and can achieve significantly higher strength and hardness through cold working, making it ideal for springs or structural components requiring high formability and strength. However, 301 has slightly lower corrosion resistance than 304 and can be prone to intergranular corrosion after welding. 304 stainless steel offers superior general corrosion resistance, better weldability, and is more widely versatile for a broader range of applications. The choice depends on the specific balance of strength, formability, and corrosion resistance required for the application.