15 years one-stop China custom CNC machining parts factory

281 |

Published by VMT at May 26 2025 | Reading Time:About 9 minutes

281 |

Published by VMT at May 26 2025 | Reading Time:About 9 minutes

Precision. Strength. Durability. In industries where parts must endure harsh conditions, resist corrosion, and maintain tight tolerances, stainless steel die casting is the answer. Many manufacturers, however, struggle to find a material and process that balance performance, longevity, and cost. That’s where stainless steel die casting offers a solution: combining advanced material properties with high-precision forming capabilities to meet the demands of modern engineering.

Stainless steel die casting is a manufacturing process that injects molten stainless steel into molds under high pressure. It offers high corrosion resistance, heat resistance, and strength, making it ideal for complex components in aerospace, marine, medical, and industrial applications. It supports CNC machining services for enhanced precision, making it popular in stainless steel CNC machining parts production.

In this guide, we’ll explore everything you need to know about stainless steel die casting—from how it works and why it’s used, to the grades of stainless steel best suited for casting, the types of casting processes, and the advantages of combining die casting with CNC machining. We’ll also cover real-world applications and how you can partner with professional CNC machining factories like VMT to get high-quality stainless steel die casting CNC machining parts.

Stainless steel die casting is a high-pressure metal casting process that involves injecting molten stainless steel into hardened steel molds called dies. This method allows for the rapid and repeatable creation of high-precision, complex parts with tight tolerances. It is especially favored in sectors where strength, corrosion resistance, and visual appeal are critical.

Unlike traditional casting methods, die casting provides exceptional surface finishes and eliminates the need for extensive post-processing. When combined with CNC machining services, this process results in stainless steel CNC machining parts that are not only functional but also meet high aesthetic and dimensional standards.

Stainless steel die casting is commonly used in industries such as aerospace, marine, automotive, food processing, and medical device manufacturing. These industries demand materials that can withstand extreme conditions and still deliver consistent performance. Stainless steel, with its inherent corrosion resistance and durability, becomes the material of choice for such environments.

By leveraging CNC machining services alongside stainless steel die casting, manufacturers can enhance the dimensional accuracy, smoothness, and quality of cast parts. This integration is vital for producing components like valve bodies, engine parts, surgical tools, and marine hardware—where reliability and performance are non-negotiable.

Choosing the right material for casting is critical to the performance, longevity, and cost-effectiveness of your product. Stainless steel castings stand out as a top-tier solution, particularly when performance under stress and in corrosive environments is non-negotiable. But what exactly makes stainless steel die casting a superior choice?

1. Exceptional Corrosion Resistance

Stainless steel is renowned for its ability to resist rust, oxidation, and chemical degradation—even in the most aggressive environments. This makes stainless steel castings ideal for marine, chemical, and medical applications where exposure to moisture, saltwater, or acidic compounds is constant. Unlike other materials, stainless steel does not require heavy surface treatments or coatings to withstand corrosion.

2. Superior Mechanical Strength

Stainless steel castings deliver high tensile strength, hardness, and impact resistance. This strength makes them suitable for high-stress mechanical components in automotive, aerospace, and heavy equipment manufacturing. When combined with CNC machining services, the resulting stainless steel CNC machining parts offer both strength and precision.

3. Excellent Heat and Wear Resistance

Stainless steel maintains structural integrity under high temperatures, making it ideal for engine parts, exhaust systems, and heat exchangers. It also resists wear from friction and abrasive forces, making it reliable for moving parts or high-contact surfaces.

4. Hygienic and Food-Safe

Stainless steel’s non-reactive surface is safe for contact with food, beverages, and pharmaceuticals. That’s why stainless steel die casting is widely used for producing food-grade equipment such as grinders, coffee machine components, and valves in medical or laboratory settings.

5. Precision Casting Compatibility

The die casting process enables manufacturers to create complex geometries with consistent dimensions. Stainless steel, despite its high melting point, performs well in investment casting and pressure die casting when processed by expert CNC machining factories like VMT.

6. Recyclability and Sustainability

Stainless steel is 100% recyclable without loss of quality, making it an environmentally responsible material. This aligns with sustainability goals in modern manufacturing and reduces waste across the product lifecycle.

From high-performance to high sanitation, the versatility of stainless steel castings makes them essential in numerous industries. When processed through CNC machining services, their advantages are even further enhanced—resulting in durable, corrosion-resistant, and precision-finished stainless steel die casting CNC machining parts.

When it comes to stainless steel die casting, understanding the elemental makeup is essential to selecting the right grade for your application. The performance of stainless steel CNC machining parts—especially their resistance to corrosion, wear, and heat—depends directly on the alloy composition.

Introduction to Stainless Steel Composition

At its core, stainless steel is primarily composed of iron (Fe). However, what sets it apart from ordinary steel is the addition of at least 11% chromium (Cr). This chromium forms a passive oxide layer on the surface of the metal, which gives stainless steel its hallmark corrosion resistance.

Most stainless steels used in die casting and CNC machining also include nickel (Ni), which stabilizes the austenitic structure and enhances both corrosion resistance and ductility. In some grades, elements like molybdenum (Mo), manganese (Mn), silicon (Si), and carbon (C) are also introduced to improve hardness, machinability, or resistance to pitting and crevice corrosion.

Let’s break down the primary roles of each alloying element:

| Element |

Function in Stainless Steel |

| Chromium (Cr) |

Enhances corrosion and oxidation resistance; essential for forming a passive surface layer |

| Nickel (Ni) |

Improves ductility and toughness; stabilizes the austenitic structure |

| Molybdenum (Mo) |

Increases resistance to localized corrosion such as pitting |

| Carbon (C) |

Increases strength and hardness but can reduce corrosion resistance in higher amounts |

| Manganese (Mn) |

Improves hot-working properties and wear resistance |

| Silicon (Si) |

Increases oxidation resistance and strength at high temperatures |

These elemental combinations allow stainless steel die castings to meet a wide range of industrial requirements—from marine hardware that withstands saltwater corrosion to high-temperature components in automotive exhaust systems.

For example, 316 stainless steel, known for its high molybdenum content, offers superior resistance to chlorides and is a popular choice in marine and medical applications. Meanwhile, 304 stainless steel, with a balanced mix of chromium and nickel, is a cost-effective option for general use.

If you're not sure which composition fits your product's needs, consult with experienced CNC machining factories like VMT, which offer expert guidance and precision stainless steel die casting CNC machining services.

Surface treatment is a vital process in stainless steel die casting and CNC machining. While stainless steel inherently resists corrosion and oxidation due to its chromium content, additional surface treatments enhance its functionality, appearance, and longevity. These treatments improve wear resistance, prevent surface contamination, and increase product performance across various environments—especially in industries like marine, food processing, and medical device manufacturing.

When producing high-quality stainless steel CNC machining parts, especially for high-end or critical-use applications, the right surface finish not only boosts performance but also creates a polished, professional appearance. At VMT CNC machining factories, surface finishing is tailored to your specific needs, ensuring both visual appeal and superior function.

Here are the most common surface treatment methods for stainless steel die castings:

Shot Peening

Shot peening involves bombarding the surface of stainless steel components with small spherical media. This process induces compressive stress, increasing fatigue resistance and reducing the risk of cracking under repeated loading. It’s commonly used in aerospace and automotive applications to extend part life.

Painting

Although stainless steel is corrosion-resistant, painting can provide an added layer of protection, especially in chemically aggressive environments. Specialty primers and topcoats ensure adhesion and longevity without compromising the natural properties of stainless steel.

Satin Polishing

Also called brushed or matte finishing, satin polishing gives the stainless steel a soft, low-gloss appearance. This finish hides fingerprints and scratches, making it popular in architectural and consumer goods applications.

Electrolytic Polishing

Also known as electropolishing, this method smooths and brightens the surface by selectively removing high points at the microscopic level. It improves corrosion resistance and is widely used in the food, pharmaceutical, and semiconductor industries where hygiene is critical.

Chrome Plating

Chrome plating deposits a layer of chromium on the stainless steel surface, offering enhanced hardness, wear resistance, and a mirror-like appearance. It’s ideal for decorative or high-friction applications, including automotive parts.

Mirror Polishing

Mirror polishing produces a highly reflective, ultra-smooth surface. It’s often applied to parts in the food, beverage, and medical sectors for aesthetic appeal and easy cleaning.

Dacromet Coating

This zinc- and aluminum-rich coating provides outstanding corrosion resistance. Dacromet is environmentally friendly and often used for fasteners, clamps, and components exposed to harsh outdoor environments.

Galvanizing

Although more common with carbon steels, galvanizing (usually hot-dip zinc coating) can also be applied to certain stainless steel components to enhance corrosion protection in specific industrial settings. However, compatibility must be evaluated due to potential metallurgical reactions.

Each of these surface treatments can be customized based on your stainless steel grade and application needs. When choosing a finish, factors like operating environment, wear resistance, and desired aesthetics must all be considered. If you're unsure which finish suits your product, VMT offers expert CNC machining services with surface treatment consulting tailored to your application.

The stainless steel casting process is a precision-oriented sequence that transforms raw stainless steel into high-performance components used in industries ranging from aerospace to medical devices. Each step must be executed with accuracy to ensure dimensional consistency, structural integrity, and aesthetic appeal—especially when preparing parts for secondary CNC machining services.

At VMT CNC machining factories, the casting process is tightly controlled to minimize defects, enhance surface quality, and meet exacting client specifications. Whether you need stainless steel die casting or investment casting for CNC-finished parts, understanding each production stage will help you make informed choices.

Step 1: Pattern Making

The casting journey begins with the creation of a precise pattern, which forms the mold cavity. Patterns replicate the exact shape of the final part and are crucial for maintaining dimensional accuracy during casting.

Types of Patterns Include:

Each pattern type serves a specific purpose based on casting technique, volume, and required tolerances.

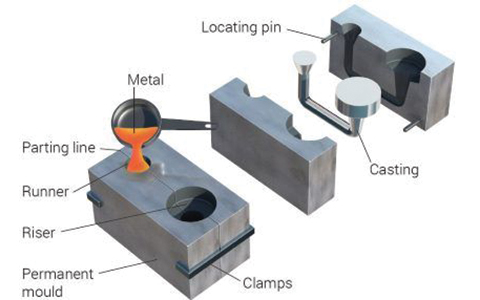

Step 2: Casting Process

Once a pattern is prepared, it's used to create the mold that will shape the molten stainless steel. Several casting processes are used depending on the part’s complexity, required surface finish, and performance needs.

Common Stainless Steel Casting Processes:

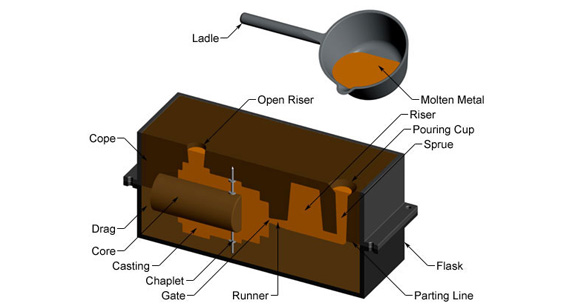

Sand Casting: Steps

Sand casting is a traditional and flexible method widely used for large or simple stainless steel parts.

Steps Include:

Shell Mold Casting: Steps

Shell mold casting uses a resin-coated sand to form a hard, smooth mold. It provides better surface finishes and dimensional accuracy than traditional sand casting, making it ideal for precision parts that require stainless steel CNC machining.

Ceramic Mold Casting: Steps

This process uses ceramic material to create high-detail molds, suitable for complex shapes and fine surface finishes. It’s frequently used for aerospace and medical components where tight tolerances are essential.

Step 3: Melt and Pour

Melting and pouring the stainless steel requires strict control to ensure uniform composition and fluidity.

Furnace Types Include:

After melting, the molten metal is carefully poured into the mold to prevent turbulence and inclusions.

Step 4: Finishing

Once the casting solidifies, it undergoes various post-processing steps to prepare it for final use or CNC machining:

At VMT CNC machining factories, we specialize in finishing stainless steel castings with tight-tolerance CNC machining services, delivering precision parts that meet both functional and aesthetic requirements.

Stainless steel is prized in manufacturing for its unique combination of mechanical and chemical properties, making it indispensable for both die casting and subsequent CNC machining services. Key properties include:

These properties are tailored by alloy composition and heat treatment, ensuring each stainless steel die casting part meets the demands of its application. For expert guidance on selecting the right grade and achieving optimal performance through precise machining, consult VMT’s experienced CNC machining factories.

Here is a clear and professional table summarizing the key properties of stainless steel relevant to die casting and CNC machining:

| Property |

Description |

Relevance to Die Casting & CNC Machining |

| Corrosion Resistance |

Stainless steel forms a passive chromium oxide layer that resists oxidation, rust, and chemical attack. | Extends product lifespan in harsh environments; essential for food, marine, and medical components. |

| Mechanical Strength |

High tensile and yield strength, especially in martensitic and duplex grades. | Supports load-bearing applications and resists mechanical stress in automotive and aerospace components. |

| Heat Resistance |

Maintains strength and resists scaling at high temperatures, particularly austenitic and high-chromium grades. | Suitable for high-temperature parts like exhaust manifolds and engine components. |

| Wear Resistance |

Enhanced by alloying elements like carbon and molybdenum for better hardness and abrasion resistance. | Improves performance and durability of moving or high-friction parts. |

| Formability |

Austenitic stainless steels are highly formable, allowing complex shapes and tight bends. | Facilitates design flexibility and reduces secondary machining during die casting. |

| Weldability |

Good weldability, especially in austenitic and duplex grades, with minimal risk of cracking or deformation. | Allows easy post-casting assembly and integration into welded structures. |

| Machinability |

While tougher than carbon steel, grades like 303 are optimized for machining with proper tools and techniques. | Enables efficient production of precise stainless steel CNC machining parts. |

| Recyclability |

100% recyclable with no degradation of quality, making it environmentally sustainable. | Ideal for eco-conscious industries and aligns with global sustainability standards. |

| Hygienic Properties |

Non-porous and easy to sterilize, meeting regulatory standards in food and medical applications. | Required for components in pharmaceutical, food processing, and medical devices. |

| Aesthetic Appeal |

Naturally glossy and available in multiple surface finishes such as mirror, satin, and brushed. | Suitable for visible or decorative parts in architecture, appliances, and consumer products. |

This table helps engineers, purchasers, and product designers clearly understand why stainless steel is so widely used in die casting and CNC machining services. For custom stainless steel die casting CNC machining parts, VMT offers expert support and advanced machining capabilities.

Stainless steels are categorized by their crystal structure and alloying elements. The five primary types are:

Martensitic Stainless Steel

High-carbon alloys that can be hardened by heat treatment, offering exceptional strength and moderate corrosion resistance. Commonly used in cutlery and turbine blades.

Austenitic Stainless Steel

The most widely used type, characterized by its face-centered cubic structure and high nickel content. It provides excellent corrosion resistance, formability, and weldability—ideal for stainless steel die casting CNC machining parts.

Ferritic Stainless Steel

Lower-nickel, body-centered cubic alloys with good stress corrosion cracking resistance and moderate toughness. Often selected for automotive trim and industrial equipment.

Precipitation Hardening Stainless Steel

Alloys that achieve high strength through controlled heat treatments, balancing corrosion resistance with ultra-high mechanical properties. Used in aerospace fittings and fasteners.

Duplex Stainless Steel

A hybrid of austenitic and ferritic structures, duplex grades combine high strength with superior resistance to stress corrosion cracking. Suited for offshore, chemical, and pulp-and-paper applications.

Each type presents a distinct balance of corrosion resistance, strength, and machinability. By choosing the appropriate type and grade, manufacturers can optimize both performance and cost in their die casting and machining workflows.

Here is a detailed and easy-to-read table summarizing the types of stainless steel, their key features, and typical applications — ideal for understanding material selection in stainless steel die casting and CNC machining services:

| Stainless Steel Type |

Structure |

Key Characteristics |

Typical Applications |

| Austenitic |

Face-Centered Cubic (FCC) | Non-magnetic, excellent corrosion resistance, good weldability, excellent formability | Food processing, marine components, medical tools, architectural parts, stainless steel CNC machining parts |

| Ferritic |

Body-Centered Cubic (BCC) | Magnetic, moderate corrosion resistance, less ductile than austenitic, good thermal conductivity | Automotive trim, industrial equipment, kitchenware |

| Martensitic |

Body-Centered Tetragonal | Magnetic, high strength and hardness, moderate corrosion resistance | Cutlery, surgical instruments, turbine blades, pump parts |

| Duplex |

Mixed Austenitic + Ferritic | High strength, improved corrosion and stress corrosion resistance, magnetic | Offshore structures, pressure vessels, chemical tanks |

| Precipitation Hardening |

Austenitic or Martensitic | High strength after heat treatment, good corrosion resistance | Aerospace parts, nuclear reactors, precision components |

Key Takeaways:

This table guides material selection for CNC machining services, helping you choose the right type of stainless steel for your die casting and precision machining projects.

Selecting the right stainless steel grade ensures that each part meets specific environmental and mechanical requirements. Below is an overview of the most common grades used in die casting and CNC machining services.

Austenitic Stainless Steel

Austenitic grades are the backbone of die-cast parts and precision machining:

Ferritic Stainless Steel

Ferritic grades provide cost advantages and good resistance to stress corrosion:

Martensitic Stainless Steel

Martensitic grades are chosen for their hardness and strength:

Duplex Stainless Steel

Duplex grades marry strength with corrosion resistance:

By understanding these properties, types, and grades, you can select the ideal stainless steel for die casting and ensure that your finished parts—whether standard castings or precision stainless steel die casting CNC machining parts—perform flawlessly in their intended environment.

Here is a comprehensive table summarizing common grades of stainless steel, their structure type, notable features, and typical applications. This table is especially useful for selecting the right material for stainless steel die casting, stainless steel CNC machining parts, and CNC machining services offered by professional CNC machining factories.

Stainless Steel Grades Comparison Table

| Grade |

Type |

Structure |

Notable Features |

Common Applications |

| 304 |

Austenitic | FCC | Excellent corrosion resistance, weldability, and formability | Kitchen equipment, piping, tanks, food processing, stainless steel CNC machining parts |

| 304L |

Austenitic | FCC | Low carbon version of 304; better weldability, less carbide precipitation | Welded components, pressure vessels |

| 316 |

Austenitic | FCC | Superior corrosion resistance (especially to chlorides), excellent marine durability | Marine hardware, chemical equipment, food machinery, CNC machining factories |

| 316L |

Austenitic | FCC | Lower carbon version of 316, excellent weldability and resistance to sensitization | Biomedical implants, marine fasteners, pharmaceutical applications |

| 303 |

Austenitic | FCC | Free-machining, contains sulfur for improved machinability, slightly lower corrosion resistance | Fasteners, gears, shafts, CNC prototype parts |

| 321 |

Austenitic | FCC | Titanium-stabilized for high temperature resistance and weldability | Aircraft exhausts, thermal insulation, heat exchangers |

| 347 |

Austenitic | FCC | Niobium-stabilized, excellent in high heat environments | Aerospace, pressure vessels, high-temp piping |

| 310 |

Austenitic | FCC | High chromium and nickel content, excellent oxidation resistance at high temperatures | Furnace components, heat treatment equipment |

| 317 |

Austenitic | FCC | Higher molybdenum than 316 for enhanced corrosion resistance | Chemical processing, marine applications |

| 302 |

Austenitic | FCC | Similar to 304 but with higher strength and less corrosion resistance | Springs, washers, wire products |

| 409 |

Ferritic | BCC | Basic stainless steel, moderate corrosion resistance | Automotive exhaust systems |

| 430 |

Ferritic | BCC | Good corrosion resistance, magnetic, more affordable | Kitchen appliances, decorative trim |

| 444 |

Ferritic | BCC | High corrosion resistance, improved weldability | Water heaters, solar panels |

| 410 |

Martensitic | BCT | Hard, strong, moderate corrosion resistance | Cutlery, valves, surgical instruments |

| 416 |

Martensitic | BCT | Free-machining version of 410, excellent machinability | Fasteners, gears, automotive parts |

| 420 |

Martensitic | BCT | High hardness, wear resistance, moderate corrosion resistance | Surgical tools, scissors, knives |

| 431 |

Martensitic | BCT | Good toughness, corrosion resistance, and high strength | Marine equipment, pump shafts |

| 440 |

Martensitic | BCT | High carbon, very hard, wear-resistant | Knife blades, ball bearings, valve components |

| 2205 |

Duplex | FCC + BCC | High strength, excellent chloride stress corrosion resistance | Offshore platforms, chemical tanks |

| 2304 |

Duplex | FCC + BCC | Lean duplex grade, cost-effective, high strength | Storage tanks, structural applications |

Key Insights:

This table supports engineers, designers, and purchasing teams in selecting the most appropriate stainless steel grade for die casting and CNC machining services.

Choosing the best grade of stainless steel for casting is crucial to ensure optimal performance, durability, and cost-efficiency of the final product. Stainless steel die casting demands materials that offer excellent corrosion resistance, mechanical strength, and ease of casting and machining. Among the many stainless steel grades available, 304 and 316 stainless steels stand out as the most widely used and trusted choices in the casting industry. Each has unique properties making them suitable for different applications in stainless steel die casting and CNC machining parts manufacturing.

304 Stainless Steel

304 stainless steel is often considered the workhorse of stainless steel casting due to its excellent combination of corrosion resistance, mechanical properties, and affordability. It contains about 18% chromium and 8% nickel, which gives it robust resistance against oxidation and many corrosive environments. This grade is highly versatile, making it suitable for general-purpose applications such as food processing equipment, architectural components, and household appliances.

In terms of casting, 304 stainless steel exhibits good fluidity and solidification properties, allowing for precise and complex shapes. Additionally, its weldability and machinability are favorable, which aligns well with secondary operations like CNC machining services. However, 304 may not perform optimally in highly corrosive environments, especially those containing chlorides or marine atmospheres, where pitting corrosion can occur.

316 Stainless Steel

316 stainless steel is a premium grade widely regarded as the best choice for demanding casting applications where corrosion resistance is critical. It contains an increased amount of nickel (about 10-14%) and added molybdenum (2-3%), which dramatically improves resistance to chloride-induced corrosion, making it ideal for marine, chemical processing, and pharmaceutical industries.

When it comes to stainless steel die casting, 316 offers superior durability and longevity in harsh environments. It is also commonly used for specialized CNC machining parts, such as medical instruments, food machinery components, and marine hardware. Though 316 is generally more expensive than 304 due to its alloying elements, its superior performance often justifies the higher cost, especially in critical applications where failure or corrosion could have severe consequences.

In summary, 304 stainless steel is typically the best cost-effective option for general casting applications, offering good performance and ease of manufacturing. In contrast, 316 stainless steel excels in aggressive environments requiring enhanced corrosion resistance and durability. Selecting the right grade depends on the specific needs of your project, environment, and budget, making consultation with professional stainless steel die casting CNC machining factories like VMT CNC essential for the best outcomes.

Choosing between 304 and 316 stainless steel can be a challenging decision for many industries and customers seeking the right material for their stainless steel die casting and CNC machining parts. Both grades are austenitic stainless steels with excellent corrosion resistance and mechanical properties, but they have distinct differences that impact their performance, cost, and suitability for specific applications. Understanding these differences is essential to selecting the best stainless steel grade that meets your project’s requirements without overspending or compromising quality.

Comparing Corrosion Resistance

The key advantage of 316 stainless steel over 304 lies in its superior corrosion resistance. Thanks to the addition of molybdenum (2-3%) in 316, it provides enhanced protection against chlorides, saltwater, and harsh chemical environments. This makes 316 the preferred choice for marine applications, chemical processing equipment, and medical instruments that must withstand aggressive corrosion. In contrast, 304 stainless steel performs well in most general environments but is more prone to pitting and crevice corrosion when exposed to chlorides or salty conditions.

Mechanical Properties and Durability

Both 304 and 316 stainless steels offer good strength and toughness, suitable for a wide range of industrial applications. However, 316 generally exhibits slightly better resistance to high temperatures and has a marginally higher tensile strength. For heavy-duty applications requiring long service life and high durability, 316 stainless steel is often recommended. On the other hand, 304 is easier to process and machine, making it an excellent option for projects requiring complex designs and quicker turnaround times.

Cost Considerations

Cost is another major factor in deciding between 304 and 316 stainless steel. Because of its alloy composition, including molybdenum, 316 stainless steel is more expensive than 304. For projects where extreme corrosion resistance is not necessary, 304 stainless steel offers a highly cost-effective solution without sacrificing essential performance. It is widely used in food processing, kitchen equipment, and architectural components where moderate corrosion resistance suffices.

Application Suitability

Choose 316 stainless steel if your application involves exposure to saltwater, harsh chemicals, or requires medical-grade materials with superior corrosion resistance and durability. Common uses include marine parts, chemical tanks, pharmaceutical equipment, and surgical tools.

Choose 304 stainless steel for general-purpose applications where corrosion exposure is limited or controlled, such as household appliances, automotive trim, food service equipment, and indoor architectural structures.

Conclusion:

Neither 304 nor 316 stainless steel is universally “better”—the best choice depends on your specific application, environment, and budget. For stainless steel die casting and CNC machining parts that demand top-tier corrosion resistance and durability, 316 is the ideal choice. For cost-effective, versatile solutions in less aggressive environments, 304 stainless steel remains a reliable and widely used option. To ensure you make the optimal selection, consulting with experienced stainless steel CNC machining factories like VMT CNC can help tailor the material choice to your exact needs.

Stainless steel casting is a critical manufacturing process that transforms molten stainless steel into complex, durable parts for various industries. Selecting the right casting method is vital to achieving the desired quality, precision, and cost-effectiveness. Different casting techniques offer unique advantages and challenges, making them suitable for specific applications. In this section, we explore the main stainless steel casting methods, outlining their principles, advantages, and disadvantages to guide manufacturers and customers in making informed decisions for their stainless steel die casting CNC machining parts.

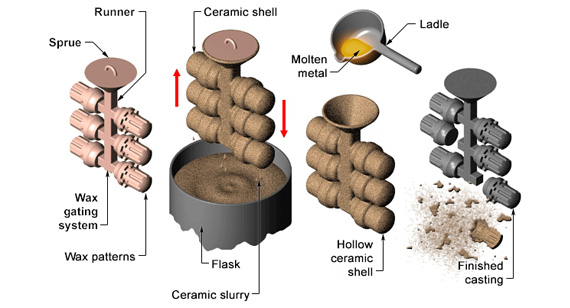

Stainless Steel Investment Casting

Investment casting, also known as lost-wax casting, involves creating a wax model coated with ceramic material to form a mold. The wax is melted away, and molten stainless steel is poured into the cavity.

Advantages:

Disadvantages:

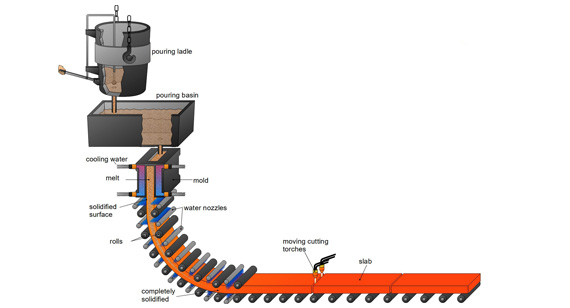

Stainless Steel Continuous Casting

Continuous casting involves the continuous solidification of molten stainless steel into semi-finished shapes like slabs, blooms, or billets.

Advantages:

Disadvantages:

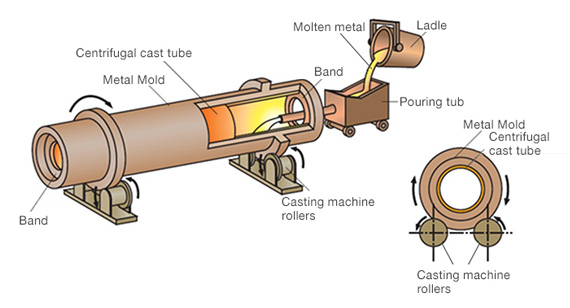

Stainless Steel Centrifugal Casting

In centrifugal casting, molten stainless steel is poured into a rotating mold, and centrifugal force distributes the metal evenly to form hollow cylindrical parts.

Advantages:

Disadvantages:

Stainless Steel Sand Casting

Sand casting uses a sand mold to shape molten stainless steel. It is one of the oldest and most versatile casting methods.

Advantages:

Disadvantages:

Stainless Steel Pressure Casting

Pressure casting forces molten metal into a mold under high pressure, improving mold filling and part density.

Advantages:

Disadvantages:

Stainless Steel Angle Casting

Angle casting involves casting metal at an angle in the mold to reduce turbulence and improve metal flow.

Advantages:

Disadvantages:

Stainless Steel Lost Wax Casting

Lost wax casting is similar to investment casting but typically used for very detailed and small-scale castings.

Advantages:

Disadvantages:

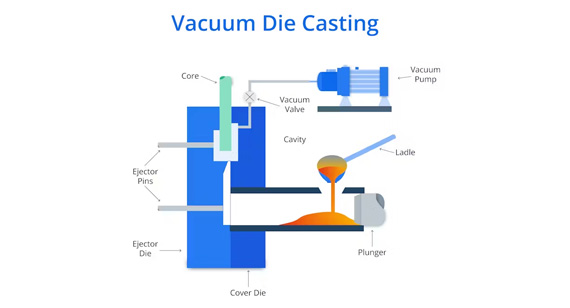

Stainless Steel Vacuum Casting

Vacuum casting uses a vacuum to remove air and gases during metal pouring to minimize defects.

Advantages:

Disadvantages:

Stainless Steel Die Casting

Die casting injects molten stainless steel under high pressure into reusable metal molds. It is widely used for precision parts with consistent quality.

Advantages:

Disadvantages:

Types of Die Casting Processes

Die casting processes vary mainly by how molten metal is introduced and solidified in the mold. Understanding these types helps in selecting the most suitable method for specific stainless steel CNC machining parts.

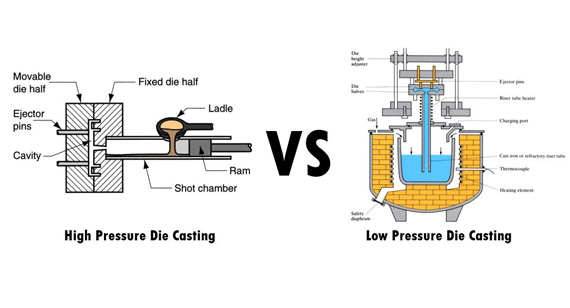

High Pressure Die Casting (HPDC)

Molten stainless steel is injected into the mold at very high pressure, allowing for rapid filling and precise control of the casting shape.

Advantages:

Disadvantages:

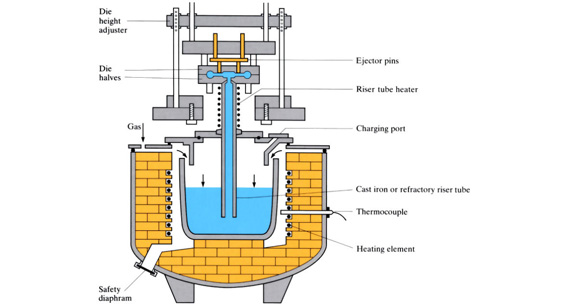

Low Pressure Die Casting (LPDC)

Molten metal is forced into the mold under low pressure, usually from the bottom up, reducing turbulence and improving casting integrity.

Advantages:

Disadvantages:

Choosing the right stainless steel casting method depends on your project’s size, complexity, production volume, and budget. Each method offers unique benefits and trade-offs, making consultation with expert CNC machining factories like VMT CNC essential to optimize your stainless steel die casting CNC machining parts production.

The following is a table of "Stainless steel casting methods and their advantages and disadvantages" to facilitate customers to compare and choose at a glance:

Stainless Steel Casting Methods: Pros and Cons Comparison Table

| Casting Method |

Introduction |

Advantages |

Disadvantages |

Typical Applications |

| Stainless Steel Investment Casting |

Uses wax patterns to create ceramic molds; wax is melted out before pouring molten steel | High dimensional accuracy, smooth surface, suitable for complex shapes and small batches | Higher cost, complex process, better for small parts | Small to medium-sized complex parts |

| Stainless Steel Continuous Casting |

Continuous pouring to form slabs, billets, etc. | High production efficiency, uniform quality, less material waste | Limited to simple shapes, requires high equipment investment | Large volume, simple-shaped semi-finished products |

| Stainless Steel Centrifugal Casting |

Molten metal poured into a rotating mold, using centrifugal force | High density, fewer defects, ideal for cylindrical parts | Limited to symmetrical parts, complex mold design | Pipes, rings, sleeves, and other cylindrical parts |

| Stainless Steel Sand Casting |

Uses sand molds; traditional and versatile method | Suitable for large, complex parts; low mold cost; easy design modification | Rough surface finish, lower precision, more machining needed | Large and complex components |

| Stainless Steel Pressure Casting |

Metal is injected into molds under high pressure | High precision, good surface finish, suitable for mass production | High mold and equipment costs, better for small parts | Small batch high-precision parts |

| Stainless Steel Tilt Casting |

Casting at an angle to reduce gas entrapment and improve metal flow | Fewer defects, smooth metal flow, improved quality | Requires specialized mold design, shape limitations | Complex parts demanding high-quality casting |

| Stainless Steel Lost Wax Casting |

Similar to investment casting, for highly detailed small parts | Extremely high detail and surface finish | High cost and long cycle times, size limitations | Very detailed, small components |

| Stainless Steel Vacuum Casting |

Uses vacuum to reduce gas pores and casting defects | Low porosity, high quality, superior surface and mechanical properties | Complex equipment, high cost | Critical high-quality components |

| Stainless Steel Die Casting |

High-pressure injection of molten steel into metal molds | High precision, excellent surface finish, fast production | High mold cost, limited part size | Small, precise parts for batch production |

| Die Casting Process Type |

Introduction |

Advantages |

Disadvantages |

Typical Applications |

| High Pressure Die Casting |

Molten metal injected under high pressure into molds | High precision, smooth surface, suitable for thin-walled, complex parts | High initial cost, limited size and shape | Small, high-precision batch parts |

| Low Pressure Die Casting |

Molten metal pushed from the bottom with low pressure | Lower porosity, better mechanical properties, longer mold life | Slower production, higher equipment cost | Medium to large parts with high quality requirements |

This table provides customers with an intuitive comparison, helping them select the most suitable casting process from the perspective of production needs and cost-effectiveness. In-depth communication is required based on specific product characteristics and factory capabilities to ensure project success.

Stainless steel die casting is a versatile manufacturing process widely used across many industries due to its excellent combination of strength, corrosion resistance, and precision. Understanding where stainless steel die castings are commonly applied can help you choose the right manufacturing solution for your project. Below are the key industries and typical parts made from stainless steel die castings.

Aerospace

In aerospace, stainless steel die castings are essential for components requiring high strength and resistance to extreme temperatures and corrosion. These include structural parts, engine components, and fastening elements that must withstand harsh flight conditions.

Architecture

Architectural applications leverage stainless steel die castings for decorative and structural elements, such as fixtures, handrails, and façade components. Their corrosion resistance ensures long-lasting performance even in outdoor environments.

Nuclear Industry

The nuclear sector demands materials that can endure radiation, heat, and corrosion. Stainless steel die cast parts are used in reactor components, shielding, and containment structures to meet these stringent requirements.

Chemical Industry

Chemical processing plants require highly corrosion-resistant parts like valves, pumps, and fittings. Stainless steel die castings offer durability and reliability when exposed to aggressive chemicals.

Vitality and Construction

From safety equipment such as seat belts to durable construction components, stainless steel die castings provide essential strength and longevity, ensuring safety and structural integrity.

Food Machinery (Using 316 Stainless Steel)

316 stainless steel die castings are commonly used in food processing equipment like coffee machine parts and metal grinders. The superior corrosion resistance and hygienic properties of 316 stainless steel make it ideal for these applications.

Pharmaceuticals

Pharmaceutical manufacturing requires sterile, corrosion-resistant parts for equipment used in drug production and packaging. Stainless steel die castings ensure compliance with strict hygiene standards.

Household Appliances

Many household appliances incorporate stainless steel die cast parts for durability and aesthetic appeal, including kitchen equipment, washing machines, and heating systems.

General Engineering

In general engineering, stainless steel die castings serve in machinery parts, brackets, and fasteners where precision and toughness are required.

Marine (Marine Grade Stainless Steel)

Marine-grade stainless steel die castings are used in anchors, bow wedges, hatches, and other ship hardware, benefiting from excellent corrosion resistance in harsh saltwater environments.

Critical medical devices such as implantable parts, dental and surgical tools, X-ray equipment, MRI machines, and wheelchairs utilize stainless steel die castings for biocompatibility and strength.

Railway Industry

Railway components made by stainless steel die casting include safety devices, couplings, and structural parts that require resilience and wear resistance.

Subsea Applications (Marine Grade Stainless Steel)

Underwater equipment demands robust materials. Stainless steel die castings provide corrosion resistance and mechanical strength for subsea valves, connectors, and protective housings.

Automotive parts such as decorative fender vents, exhaust manifolds, engine components, transmission parts, and hood emblems rely on stainless steel die castings for durability and fine detail.

Mechanical Industry

Mechanical systems benefit from stainless steel die cast components for gears, housings, and mounts, ensuring long service life under mechanical stress.

Petrochemical Industry

Stainless steel die castings are crucial for valves, pumps, and fittings exposed to high pressure and corrosive fluids in petrochemical plants.

Electrical enclosures, connectors, and terminals made by stainless steel die casting provide safety, conductivity, and corrosion resistance.

Valve and Pump Components

Key valve and pump parts such as valve discs, bodies, covers, pump bodies, valve glands, and impellers are manufactured using stainless steel die casting to withstand wear and corrosion.

Pipe Fitting Solutions

Elbows, bushings, tees, and other pipe fittings made from stainless steel die castings ensure leak-free, durable connections in various piping systems.

Stainless steel die casting provides the perfect combination of precision, durability, and corrosion resistance, making it a preferred choice across these diverse industries. Whether you require custom stainless steel die casting CNC machining parts or large-scale production, VMT CNC machining services are here to meet your manufacturing needs with high-quality standards and efficiency.

Here's a professional and clear table summarizing Stainless Steel Die Castings: Applications and Typical Parts for your article:

| Industry/Application |

Typical Parts and Components |

Key Benefits |

| Aerospace |

Structural parts, engine components, fastening elements | High strength, heat and corrosion resistance |

| Architecture |

Fixtures, handrails, façade components | Durability, corrosion resistance, aesthetics |

| Nuclear Industry |

Reactor components, shielding, containment structures | Radiation resistance, durability |

| Chemical Industry |

Valves, pumps, fittings | Corrosion resistance, chemical stability |

| Vitality and Construction |

Seat belts, safety equipment, construction components | Strength, safety, durability |

| Food Machinery (316 SS) |

Coffee machine parts, metal grinder parts | Hygiene, corrosion resistance |

| Pharmaceuticals |

Drug manufacturing equipment parts | Sterility, corrosion resistance |

| Household Appliances |

Kitchen equipment, washing machines, heating system parts | Durability, aesthetic appeal |

| General Engineering |

Machinery parts, brackets, fasteners | Precision, toughness |

| Marine (Marine Grade SS) |

Anchors, bow wedges, hatches, ship hardware | Saltwater corrosion resistance |

| Medical Equipment |

Implantable parts, dental/surgical tools, X-ray and MRI machines, wheelchairs | Biocompatibility, strength |

| Railway Industry |

Safety devices, couplings, structural parts | Wear resistance, durability |

| Subsea (Marine Grade SS) |

Valves, connectors, protective housings | Corrosion resistance, mechanical strength |

| Automotive |

Fender vents, exhaust manifolds, engine and transmission components, hood emblems | Durability, fine detail |

| Mechanical Industry |

Gears, housings, mounts | Long service life, mechanical strength |

| Petrochemical Industry |

Valves, pumps, fittings | High pressure resistance, corrosion resistance |

| Electrical Industry |

Enclosures, connectors, terminals | Safety, conductivity, corrosion resistance |

| Valve and Pump Components |

Valve discs, bodies, covers, pump bodies, valve glands, pump impellers | Wear resistance, corrosion resistance |

| Pipe Fitting Solutions |

Elbows, bushings, tees | Leak-free connections, durability |

Stainless steel die casting is widely used in many industries due to its unique combination of mechanical properties and corrosion resistance. Understanding the key advantages and potential drawbacks is essential for selecting the right manufacturing process and material for your application. Below is a detailed overview of the benefits and limitations of stainless steel die castings.

| Advantages of Stainless Steel Die Castings |

Disadvantages of Stainless Steel Die Castings |

| Corrosion Resistance: Stainless steel naturally forms a protective oxide layer that prevents rust and corrosion, making it ideal for harsh environments. | Brittleness: Stainless steel die castings can exhibit brittleness due to decreased ductility, especially compared to carbon steel, leading to potential cracking under impact or stress. |

| Durability and Long Service Life: These castings maintain strength and integrity over time, ensuring reliability even in demanding conditions. | Higher Cost: The raw materials and specialized casting processes can make stainless steel die casting more expensive than other metal casting options. |

| High Temperature Resistance: Stainless steel maintains mechanical properties at elevated temperatures, suitable for engine parts and exhaust systems. | Complex Casting Process: Achieving defect-free castings can be challenging due to stainless steel’s high melting point and solidification characteristics. |

| Environmentally Friendly: Stainless steel is 100% recyclable without loss of quality, supporting sustainable manufacturing practices. | Surface Finish Challenges: Additional finishing processes may be required to achieve smooth or decorative surfaces due to potential casting imperfections. |

| Wear and Damage Resistance: It offers good resistance to abrasion and mechanical wear, extending part lifespan. | Weight: Stainless steel is heavier than aluminum or magnesium alloys, which can be a limitation in weight-sensitive applications. |

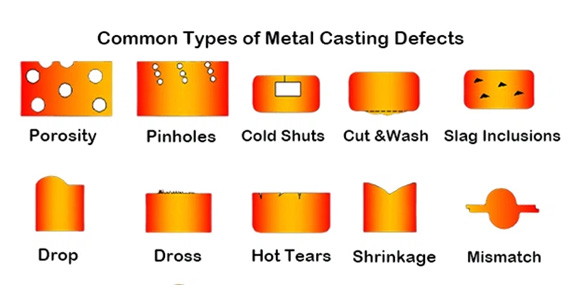

Stainless steel casting is a complex process that requires precise control to ensure high-quality parts. Various defects can arise during casting, affecting the performance, appearance, and structural integrity of the final product. Understanding these defects, their causes, and how to prevent them is crucial for manufacturers and customers alike to ensure reliable and precise stainless steel die casting CNC machining parts.

Casting Shrinkage Defects

Shrinkage defects occur when the metal contracts as it cools, potentially causing cavities or voids inside the casting. These defects can weaken parts and affect dimensional accuracy.

Causes

Solutions

Appearance Defects

Appearance defects, such as metal bulges and surface irregularities, compromise the aesthetic and sometimes functional quality of stainless steel parts.

Metal Bulges

Causes

Solutions

Discontinuities

Causes

Solutions

Incomplete Casting

Causes

Solutions

Inaccurate Casting Size or Shape

Causes

Solutions

Unqualified Surface

Causes

Solutions

Thermal Defects

Thermal defects arise due to improper heat management during casting, impacting structural integrity and surface quality.

Causes

Solutions

Filling Defects

Filling defects happen when the molten metal does not fill the mold cavity properly, causing surface or internal flaws.

Blowout Holes

Causes

Solutions

Sand Burning

Causes

Solutions

Cold Shut

Causes

Solutions

Leakage Welding

Causes

Solutions

Porosity Defects

Porosity defects are small holes or voids inside the casting, reducing mechanical strength and surface quality.

Causes

Solutions

This detailed guide ensures customers and manufacturers can identify, understand, and address common casting defects effectively, enhancing the quality of stainless steel die casting CNC machining parts. For more detailed guidance on specific processes and defect prevention, please refer to our related articles on Stainless Steel Casting Methods and Stainless Steel Surface Treatments.

Here's a clear, customer-friendly table summarizing the Control of Stainless Steel Defects During Casting with sections for Defect Type, Causes, and Solutions:

| Defect Type |

Causes |

Solutions |

| Casting Shrinkage |

- Inadequate feeding during solidification - Poor gating/riser design - Uneven cooling |

- Optimize gating and risers - Control cooling rates |

| Metal Bulges |

- Excessive mold temperature - Improper mold clamping - Overfilling |

- Maintain mold temperature - Ensure mold clamping - Control pouring volume |

| Discontinuities |

- Incomplete metal fusion - Gas/impurities entrapment - Poor solidification |

- Improve melting/pouring - Optimize mold design - Controlled solidification |

| Incomplete Casting |

- Insufficient metal volume - Restrictive mold design - Low pouring temperature |

- Increase molten metal - Redesign mold flow - Raise pouring temperature |

| Inaccurate Size/Shape |

- Mold wear/damage - Wrong mold dimensions - Thermal expansion |

- Maintain molds - Use precise molds - Account for shrinkage |

| Unqualified Surface |

- Surface oxidation - Metal contamination - Mold surface flaws |

- Use protective atmospheres - Clean metal - Polish molds |

| Thermal Defects |

- Uneven mold temperature - Rapid cooling causing cracks - Overheating |

- Uneven mold temperature - Rapid cooling causing cracks - Overheating |

| Blowout Holes |

- Excessive mold pressure - Weak mold structure - Poor venting |

- Reinforce molds - Improve venting - Control pressure |

| Sand Burning |

- High pouring temperature - Poor refractory coating - Low-quality sand |

- Lower temperature - Apply coatings - Use quality sand |

| Cold Shut |

- Poor fusion of metal streams - Low temperature or slow filling |

- Increase temperature - Speed up filling - Redesign gating |

| Leakage Welding |

- Cracks during solidification - Mold defects - Improper clamping |

- Use strong mold materials - Ensure clamping - Adjust solidification |

| Porosity Defects |

- Entrapped gases - Inadequate venting - Moisture in molds |

- Improve venting - Control moisture - Use vacuum or pressure casting |

This table is structured to help customers quickly understand the common defects, their main causes, and practical solutions in stainless steel casting. If you want, I can help format it for your website or brochure as well.

At VMT, we specialize in delivering high-precision stainless steel die casting CNC machining parts that meet the strictest quality standards and industry requirements. With years of experience in stainless steel casting and CNC machining, we combine advanced technology, expert craftsmanship, and a customer-centric approach to provide you with superior parts for diverse industries.

Why Choose VMT for Stainless Steel Die Casting & CNC Machining?

Industries Served

VMT’s stainless steel die casting CNC machining parts are trusted in aerospace, automotive, medical devices, food machinery, marine, electronics, and many other sectors demanding reliability and precision.

Partner with VMT to leverage our expertise in stainless steel die casting and CNC machining for parts that stand out in quality, durability, and performance. Contact us today to discuss your project requirements and receive a personalized quote.

Stainless steel die casting stands out as a highly versatile and reliable manufacturing method, offering exceptional benefits such as superior corrosion resistance, durability, and excellent performance in high-temperature environments. Whether in aerospace, automotive, medical, or food machinery industries, stainless steel die casting provides precisely engineered parts that meet demanding quality and safety standards.

Choosing the right stainless steel grade, such as 304 or 316, and employing advanced casting methods ensures optimal results tailored to your specific application. Although challenges like casting defects may arise, modern control techniques and expert craftsmanship effectively minimize these issues, delivering consistent, high-quality components.

At VMT, we understand the critical role that stainless steel die casting and CNC machining services play in your product’s success. Our comprehensive capabilities, combined with strict quality control and customer-focused solutions, guarantee parts that exceed expectations in both performance and reliability.

For manufacturers and engineers seeking top-tier stainless steel die casting CNC machining parts, VMT is your trusted partner. Explore our services to experience precision, efficiency, and innovation that drive your business forward.

Q1: Can stainless steel be used for die casting?

Yes, stainless steel can be used for die casting, especially when high strength, corrosion resistance, and durability are required. Stainless steel die casting offers precision parts with excellent mechanical properties suitable for many industries.

Q2: What is die casting stainless steel?

Die casting stainless steel is a manufacturing process where molten stainless steel is injected into molds under high pressure to produce complex shapes with high dimensional accuracy and smooth surfaces.

Q3: What are stainless steel castings?

Stainless steel castings refer to parts made by pouring molten stainless steel into molds. These castings can be produced by various methods such as sand casting, investment casting, or die casting, depending on the required shape and quality.

Q4: Can 316 stainless steel be cast?

Yes, 316 stainless steel is commonly cast because of its excellent corrosion resistance and mechanical properties, especially suitable for marine, chemical, and food processing applications.

Q5: Can 304 stainless steel be cast?

304 stainless steel can also be cast and is widely used due to its good corrosion resistance and cost-effectiveness, making it ideal for general-purpose applications.

Q6: Can 316L be cast?

Yes, 316L, a low-carbon version of 316, can be cast and is preferred when welding or further machining is required to reduce carbide precipitation and improve corrosion resistance.

Q7: What is the casting grade of SS316L?

The casting grade of SS316L corresponds to a low-carbon austenitic stainless steel with enhanced corrosion resistance, commonly used in chemical and marine environments.

Q8: Why use 316L instead of 316?

316L is used over 316 when better weldability and resistance to sensitization are needed, especially in castings subjected to heat treatment or welding.

Q9: What is the casting equivalent of 316L?

The casting equivalent of 316L stainless steel is often ASTM A743 CF-8M or similar grades designed for cast stainless steel components.

Q10: What is the best stainless steel for casting?

The best stainless steel for casting depends on application requirements, but 316 and 316L are widely regarded for their excellent corrosion resistance and mechanical properties.

Q11: Is 316L more expensive than 316?

Generally, 316L can be slightly more expensive due to its enhanced properties, but the cost difference is often justified by improved performance in demanding applications.

Q12: What is the ASTM standard for 316L stainless steel?

ASTM A240 is the standard specification covering 316L stainless steel plate, sheet, and strip for pressure vessels and general applications.

Q13: Is 1.4404 the same as 316L?

Yes, 1.4404 is the European standard (EN) designation equivalent to 316L stainless steel.

Q14: What is the ASTM equivalent standard for 316L?

ASTM A743 CF-8M is the cast stainless steel equivalent to 316L.

Q15: What is the difference between ASTM A312 and 316L?

ASTM A312 refers to seamless and welded stainless steel pipe, while 316L is a stainless steel grade commonly used in pipe, sheet, and castings.

Q16: What is the difference between duplex stainless steel 2205 and 316 SS?

Duplex 2205 offers higher strength and better resistance to stress corrosion cracking than 316 SS, making it suitable for more aggressive environments.

Q17: What is the composition of ASTM A312 316L?

ASTM A312 316L stainless steel typically contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, with low carbon content (<0.03%).

Q18: What is the difference between Nitronic 50 and 316L?

Nitronic 50 has higher strength and better wear resistance than 316L, often used in applications requiring superior mechanical performance.

Q19: Which metal is best for die casting?

Metals like aluminum, zinc, magnesium, and stainless steel are commonly used for die casting, with stainless steel chosen for high strength and corrosion resistance.

Q20: Can you use molds on stainless steel?

Yes, molds are essential in stainless steel die casting to shape molten metal accurately. Advanced mold materials and techniques are used to withstand high casting temperatures.

Q21: What are the casting materials for stainless steel?

Common casting materials include austenitic stainless steels (304, 316, 316L), ferritic, martensitic, duplex stainless steels, each selected based on required properties.