15 years one-stop China custom CNC machining parts factory

299 |

Published by VMT at Feb 21 2025 | Reading Time:About 8 minutes

299 |

Published by VMT at Feb 21 2025 | Reading Time:About 8 minutes

Problem: If you are looking to understand casting and its role in manufacturing, you may be overwhelmed by the variety of casting methods and technical terms associated with the process. Whether you are a novice or an experienced professional, understanding how casting works is crucial for selecting the right method for your needs.

Agitation: There’s a lot of confusion surrounding casting processes—how they are carried out, when to use them, and what the key benefits and limitations are. With various types of casting, each suited for different applications, it’s vital to know which one aligns best with your project requirements.

Solution: In this article, we will guide you through the essentials of casting—defining it, exploring the types, and discussing the process from start to finish. We will also highlight the key benefits and common applications, ensuring you gain a solid understanding of how casting can be applied to manufacturing.

Casting is a manufacturing process where molten material is poured into a mold to create a desired shape. The types of casting include sand casting, die casting, investment casting, and more. Each method has its unique advantages, such as cost-effectiveness, precision, and versatility, making it ideal for different applications like automotive parts, sculptures, and industrial components.

Casting is one of the oldest manufacturing methods, but it remains relevant today due to its versatility and ability to create complex shapes. To understand how casting works, let’s first define the process and then take a deeper dive into its different types. From sand casting to die casting, each method has its own set of benefits that makes it ideal for specific use cases. Let’s explore how casting is carried out and the steps involved.

Casting is a manufacturing process where molten material, typically metal, is poured into a mold to solidify and form a specific shape. It is widely used in the production of complex shapes that would be difficult or expensive to create using other methods, such as machining. The process involves heating a metal to its molten state, pouring it into a pre-designed mold, and allowing it to cool and solidify into the desired shape.

Why use casting? Casting is an essential part of industries that require durable, high-precision parts. From engine blocks and components for the aerospace sector to artistic sculptures and decorative elements, casting offers the flexibility and versatility needed to meet the demands of various sectors.

The origins of casting date back to ancient times, with evidence of casting as far back as 3000 BC in Mesopotamia and Egypt. Initially, casting was performed with simple molds made of sand or clay, and metals such as bronze and iron were used to create tools, weapons, and ceremonial objects. Over time, the process evolved, with more sophisticated methods such as investment casting and die casting emerging in the 19th and 20th centuries. Today, casting is integral to industries like automotive manufacturing, aerospace, medical devices, and consumer goods, thanks to advancements in material science and casting techniques.

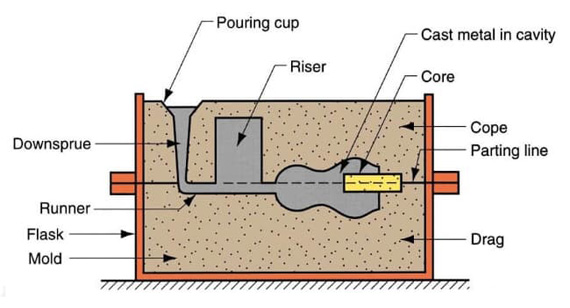

The casting process involves several critical steps. First, a pattern is made based on the design of the object being produced. The pattern can be created using materials like wax, sand, or metal. Afterward, the pattern is placed in a mold made from a material that can withstand the molten metal's temperature. Here's how the process generally works:

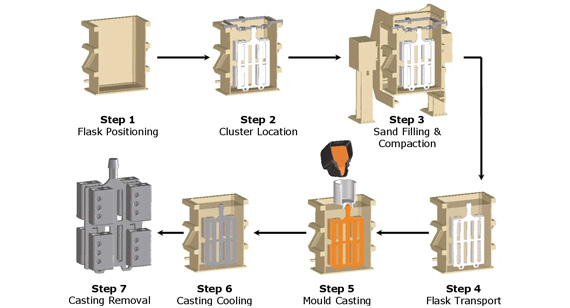

Casting is a fundamental manufacturing technique used across various industries to produce parts in a wide range of materials and sizes. By pouring molten material into a mold and allowing it to cool and solidify, casting allows for the creation of complex shapes with high precision. Understanding the different types of casting processes can help industries select the most suitable method for producing custom CNC machining parts and other components. Here’s an overview of the most common casting methods, including their benefits and typical applications.

Consumable Casting Technology

Consumable casting refers to casting processes where the mold is destroyed after the casting has been made, making it ideal for small production runs or complex parts. This section introduces various consumable casting technologies.

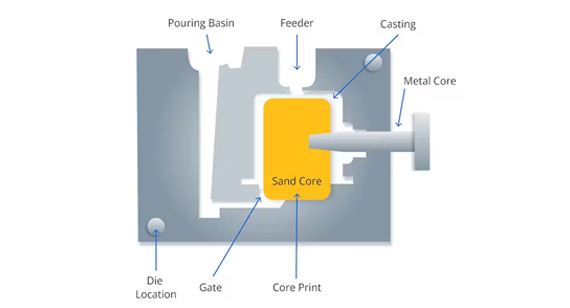

Sand Casting

What is Sand Casting?

Sand casting is one of the oldest and most versatile casting methods, where sand is used to create the mold. It is often employed for large, simple, or complex parts that don’t require the finest surface finishes.

Advantages:

Typical Applications:

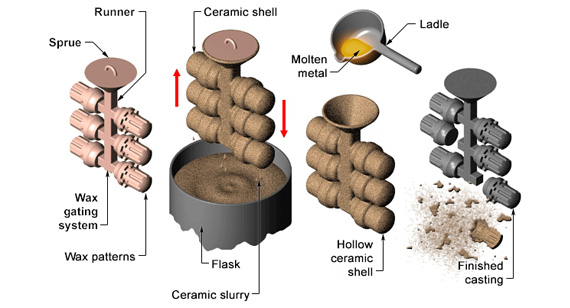

Investment Casting (Lost Wax Casting)

What is Investment Casting?

Investment casting involves creating a wax model of the part, coating it in a ceramic shell, and then heating it to remove the wax before pouring molten metal into the mold.

Advantages:

Typical Applications:

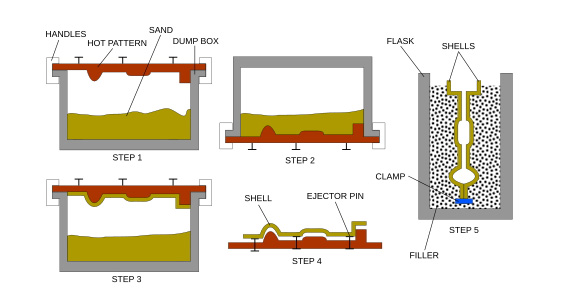

Shell Molding

What is Shell Molding?

Shell molding is similar to investment casting but uses a metal pattern to create the shell. This process is suitable for parts requiring fine detail and high precision.

Advantages:

Typical Applications:

Lost Foam Casting

What is Lost Foam Casting?

Lost foam casting is a process where a foam pattern is used instead of traditional sand. The foam pattern is vaporized as molten metal is poured into the mold.

Benefits:

Typical Applications:

Gypsum Casting

What is Gypsum Casting?

Gypsum casting is often used for artistic purposes, where a gypsum-based material is used to create molds for intricate designs.

Benefits:

Typical Applications:

Ceramic Mold Casting

What is Ceramic Mold Casting?

Ceramic mold casting uses a ceramic shell mold to cast metals, ideal for producing high-strength components that need excellent dimensional stability.

Benefits:

Typical Applications:

Full Mold Casting

What is Full Mold Casting?

Full mold casting involves creating a part using a pattern made from materials that decompose easily, leaving no trace behind. It’s particularly useful for complex shapes.

Benefits:

Typical Applications:

Electroslag Casting

What is Electroslag Casting?

Electroslag casting is a specialized casting process used primarily to produce large ingots of high-quality metal. In this process, molten slag surrounds the material being cast and provides heat to maintain the necessary temperature for melting and forming the metal. The method is particularly useful for producing materials with exceptional strength and structural integrity.

Benefits:

Typical Applications:

Permanent and Semi-Permanent Mold Casting Technology

Permanent and semi-permanent mold casting techniques involve creating molds that are reused multiple times, as opposed to consumable mold methods. These methods are particularly well-suited for mass production of precise, durable parts.

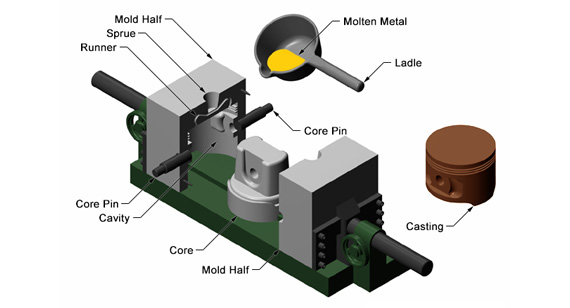

What is Die Casting?

Die casting is a method where molten metal is injected into a reusable metal mold under high pressure. It is commonly used to produce parts with complex geometries in high volumes.

Advantages:

Typical Applications:

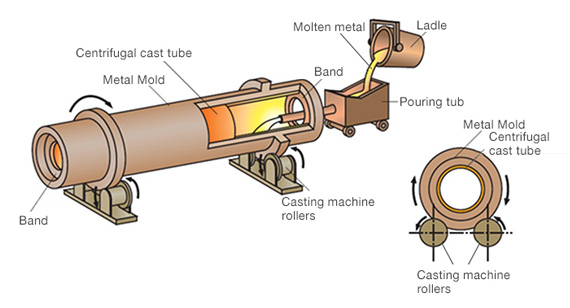

Centrifugal Casting

What is Centrifugal Casting?

Centrifugal casting involves pouring molten metal into a rotating mold, utilizing centrifugal force to distribute the metal evenly. This method is often used for cylindrical or ring-shaped components.

Advantages:

Typical Applications:

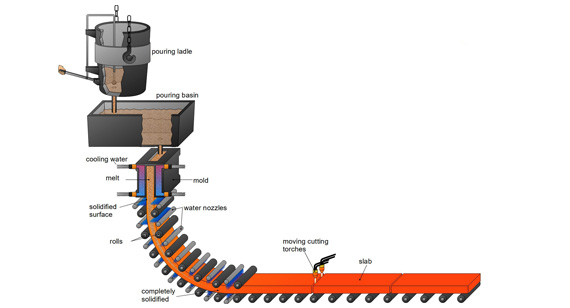

Continuous Casting

What is Continuous Casting?

Continuous casting is a process used to solidify metal continuously as it flows through a mold, often used for producing large quantities of uniform material like billets or slabs.

Advantages:

Typical Applications:

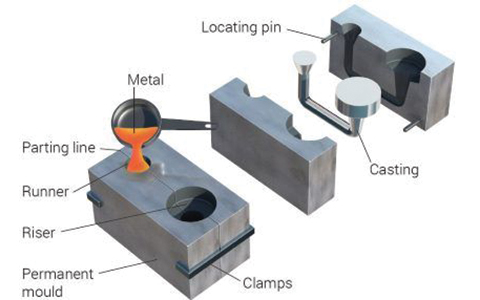

Permanent Mold Casting

What is Permanent Mold Casting?

Permanent mold casting uses a reusable mold, typically made from metal, to cast materials such as aluminum and zinc. It is known for producing high-strength parts with excellent surface finishes.

Advantages:

Typical Applications:

Gravity Die Casting

What is Gravity Die Casting?

Gravity die casting is a type of permanent mold casting in which molten metal is poured into a metal mold using gravity rather than pressure.

Advantages:

Typical Applications:

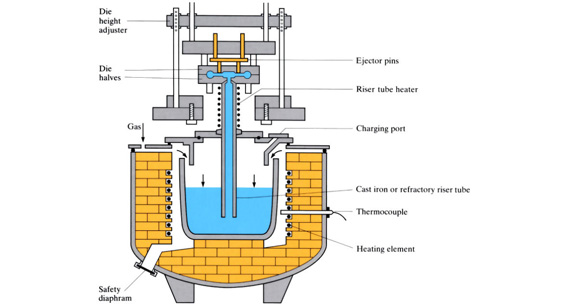

Low Pressure Casting

What is Low Pressure Casting?

Low pressure casting involves introducing molten metal into a mold under low pressure, allowing for high-quality parts with minimal defects.

Benefits:

Typical Applications:

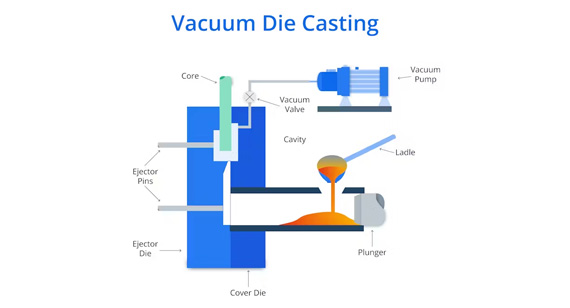

Vacuum Casting

What is Vacuum Casting?

Vacuum casting uses a vacuum environment to ensure that air is removed from the mold, improving the quality of the final part by preventing air pockets and other defects.

Benefits:

Typical Applications:

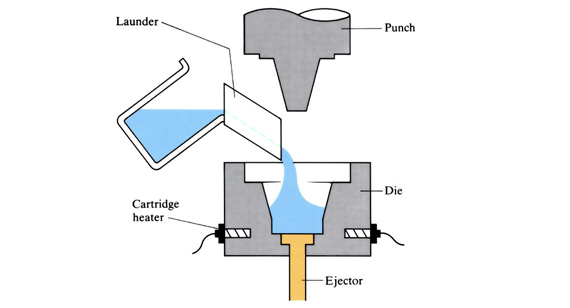

Squeeze Casting

What is Squeeze Casting?

Squeeze casting is a process where molten metal is injected into a mold under high pressure, which compacts the metal and solidifies it under controlled conditions. This method combines the benefits of casting and forging, providing high-strength components with excellent surface quality.

Benefits:

Typical Applications:

Slime Casting

What is Slime Casting?

Slime casting is a relatively simple and cost-effective casting method often used for decorative or lightweight products. In this process, a slurry of material is poured into a mold to create hollow or intricate components with minimal weight.

Benefits:

Typical Applications:

Rotational Casting

What is Rotational Casting?

Rotational casting is a process in which a mold is rotated while molten material is poured into it, allowing the material to coat the inner walls of the mold. This process is ideal for creating hollow and uniform thickness components.

Benefits:

Typical Applications:

Hot Isostatic Pressing (HIP)

What is Hot Isostatic Pressing (HIP)?

Hot Isostatic Pressing is a process in which metal powders or castings are subjected to high temperature and pressure in a chamber to remove voids and improve material properties. It is primarily used to enhance the strength and density of the material.

Benefits:

Typical Applications:

Metal Casting

What is Metal Casting?

Metal casting is a manufacturing process where molten metal is poured into a mold to form a part. Once the metal cools and solidifies, the mold is removed, and the part is ready for further processing.

Advantages:

Typical Applications:

Resin Casting

What is Resin Casting?

Resin casting involves pouring liquid resin into a mold, where it hardens to form a solid part. This process is often used for creating detailed prototypes or decorative items and can be highly accurate.

Advantages:

Typical Applications:

These casting processes offer a broad spectrum of benefits and are adaptable to a range of industries and applications, from aerospace and automotive to art and consumer products.

The casting process involves various machines and tools that work in tandem to transform raw materials into finished components. From melting metals to shaping them into complex forms, these tools ensure precision, efficiency, and quality in the final product. Here's a detailed look at the essential machines and tools used in casting.

1. Furnace

Purpose:

The furnace is used to melt metal or alloy to a liquid state before it is poured into molds. The type of furnace used depends on the material being cast (e.g., electric arc furnaces for steel, induction furnaces for aluminum).

Types:

Function:

Melts the metal at precise temperatures, ensuring consistency and preventing oxidation.

2. Molds

Purpose:

Molds are the shapes into which molten metal is poured to solidify into the desired form. They are crucial in determining the final shape, surface finish, and detail of the cast part.

Types:

Function:

Provide the structure and form needed for casting the molten material into the desired shape.

3. Ladle

Purpose:

A ladle is used to transport molten metal from the furnace to the mold. It must be able to withstand high temperatures and handle large amounts of molten material.

Types:

Function:

Ensures the controlled transfer of molten metal without contamination or loss of material.

4. Die Casting Machine

Purpose:

A die casting machine is specifically designed for die casting processes. It forces molten metal into a mold under high pressure, allowing for high precision and smooth surface finishes.

Types:

Function:

Applies high pressure to inject molten metal into a die to produce high-quality parts with fine details.

5. Core Making Machine

Purpose:

Core making machines are used to produce the cores that create internal cavities or hollow sections in the casting. The core material is typically sand, which is hardened using binders and heat.

Types:

Function:

Produces the core inside the mold that determines the internal shape of the casting.

6. Sand Dropping Machine

Purpose:

A sand dropping machine is used in sand casting to automate the process of adding sand into molds and compaction. The machine ensures even distribution of sand and consistent mold quality.

Function:

Automates the filling and compaction of sand, ensuring a high-quality mold with uniform density for better casting results.

7. Edge Trimming Machine

Purpose:

The edge trimming machine is used to remove excess material or flash (the thin, unwanted material around the edges of the casting) after the casting has cooled and solidified.

Function:

Clears excess metal or mold material from the casting to ensure proper dimensional accuracy and appearance.

8. Shot Blasting Machine

Purpose:

Shot blasting machines are used to clean the surface of castings by shooting abrasive materials at them. This process removes sand, oxides, and other impurities, preparing the part for finishing.

Function:

Cleans and polishes the surface of the casting to remove any impurities and improve its surface finish.

9. Heat Treating Furnace

Purpose:

A heat treating furnace is used to subject castings to controlled heating and cooling cycles, which alters the metal's properties. This process can improve the strength, hardness, and durability of the casting.

Types:

Function:

Heat treatment processes like annealing, quenching, or tempering improve the physical properties of the metal, making it stronger or more durable.

10. Finishing Equipment

Purpose:

Finishing equipment is used to further refine and perfect the castings. This may include machines like grinders, polishers, and lathes.

Types:

Function:

Provides the final touches to the casting, ensuring it meets required specifications and surface finish quality before being sent for assembly or packaging.

Conclusion

The tools and machines used in the casting process are essential for ensuring precision, quality, and efficiency. Each machine serves a specific purpose, whether it’s melting the metal, shaping it into molds, or providing the final finish. Proper utilization and maintenance of these machines are crucial to achieving high-quality castings that meet the desired standards across various industries.

Materials Commonly Used in Casting

Casting is a versatile manufacturing process that involves pouring molten material into a mold to produce components with specific shapes and properties. The material used in casting depends on factors such as the application, desired strength, thermal properties, and corrosion resistance. Below are the 20 most commonly used materials in casting processes:

1. Aluminum

Properties:

Lightweight, corrosion-resistant, and excellent for heat conduction.

Common Uses:

Automotive parts, aerospace components, and electrical housings.

2. Cast Iron

Properties:

High wear resistance, good castability, and excellent vibration damping.

Common Uses:

Engine blocks, pipes, and heavy machinery components.

3. Steel

Properties:

Strong, versatile, and highly durable. It can be alloyed with other elements for improved properties.

Common Uses:

Automotive parts, construction equipment, and machinery components.

4. Copper

Properties:

Excellent electrical and thermal conductivity, corrosion resistance.

Common Uses:

Electrical components, plumbing fixtures, and heat exchangers.

5. Bronze

Properties:

Corrosion-resistant, high strength, and good wear resistance.

Common Uses:

Marine components, bearings, and sculptures.

6. Zinc

Properties:

Low melting point, good corrosion resistance, and excellent castability.

Common Uses:

Die-cast components for automotive, hardware, and decorative items.

7. Magnesium

Properties:

Lightweight, high strength-to-weight ratio, and good for applications requiring strength without heavy mass.

Common Uses:

Automotive components, aerospace parts, and military applications.

8. Nickel

Properties:

Excellent corrosion resistance, high-temperature strength, and toughness.

Common Uses:

Aerospace components, turbine blades, and marine applications.

9. Tin

Properties:

Malleable, non-toxic, and resistant to corrosion.

Common Uses:

Soldering, decorative items, and pewter alloys.

10. Lead

Properties:

Heavy, malleable, and resistant to corrosion.

Common Uses:

Batteries, shielding for radiation, and lead-based alloys.

11. Titanium

Properties:

High strength-to-weight ratio, corrosion resistance, and biocompatibility.

Common Uses:

Aerospace components, medical implants, and military applications.

12. Silicon Bronze

Properties:

Good corrosion resistance, especially in marine environments.

Common Uses:

Marine hardware, valves, and industrial machinery.

13. Brass

Properties:

Corrosion-resistant, malleable, and has a golden appearance.

Common Uses:

Musical instruments, plumbing fittings, and decorative components.

14. Gold, Silver, Platinum

Properties:

Excellent ductility, high corrosion resistance, and aesthetic appeal.

Common Uses:

Jewelry, coins, and high-end electronics.

15. Bismuth

Properties:

Low melting point, non-toxic, and has good casting properties.

Common Uses:

Soldering materials, alloys for fire safety, and as a replacement for lead in certain applications.

16. Pewter

Properties:

Low melting point, malleable, and corrosion-resistant.

Common Uses:

Decorative items, jewelry, and small household goods.

17. Cobalt

Properties:

High-temperature strength, wear resistance, and corrosion resistance.

Common Uses:

Cutting tools, aerospace components, and medical implants.

18. Ceramics

Properties:

High heat resistance, good electrical insulating properties, and wear resistance.

Common Uses:

Aerospace components, electrical insulators, and medical applications.

19. Graphite

Properties:

High thermal conductivity, self-lubricating, and heat-resistant.

Common Uses:

Foundry applications (core sand for molds), electrodes, and heat exchangers.

20. Polyurethane, Silicone Rubber, and Plaster of Paris

Properties:

Flexible, moldable, and capable of producing high-detail molds.

Common Uses:

Prototype modeling, molds for low-volume production, and artistic sculptures.

Conclusion

The materials selected for casting processes are critical to ensuring that the final product meets the desired mechanical, thermal, and chemical properties. From lightweight metals like aluminum and magnesium to specialized alloys like titanium and cobalt, the casting process is a key manufacturing method that provides flexibility in materials and designs across a wide range of industries.

The casting process involves various critical parameters that influence the quality, accuracy, and performance of the final casted product. Proper control of these parameters ensures that the cast component meets the desired material properties, dimensional accuracy, and surface finish. Below are the key parameters that impact the casting process:

1. Mold Materials

Definition:

Mold materials are the substances used to create the mold cavity in which the molten metal is poured.

Importance:

The choice of mold material affects heat resistance, mold strength, and the ability to produce intricate shapes. Common mold materials include sand, metal, ceramic, and shell mold materials.

2. Melt Temperature

Definition:

Melt temperature refers to the temperature at which the metal is heated until it becomes molten before pouring it into the mold.

Importance:

The melt temperature directly affects fluidity, casting integrity, and the ease of pouring. If the temperature is too low, the metal may not fill the mold completely. If it's too high, excessive oxidation or evaporation may occur.

3. Pouring Temperature

Definition:

Pouring temperature is the temperature at which the molten metal is poured into the mold.

Importance:

It determines the metal's fluidity and ability to fill the mold cavities. Pouring at too high a temperature can cause defects such as burn-on or excessive shrinkage, while pouring at too low a temperature may result in incomplete filling and defects.

4. Mold Design

Definition:

Mold design includes the shape, size, and structure of the mold cavity, gating system, and core.

Importance:

A well-designed mold ensures the proper flow of molten metal, minimizes the occurrence of defects, and maintains uniform cooling. Key design considerations include wall thickness, draft angle, and gating system configuration.

5. Cooling Rate

Definition:

Cooling rate refers to how quickly the molten metal cools down and solidifies inside the mold.

Importance:

The cooling rate influences the microstructure and mechanical properties of the casting. A controlled cooling rate can prevent internal stresses, porosity, and cracking. Faster cooling can increase hardness but may also lead to brittleness.

6. Pouring Rate

Definition:

Pouring rate is the speed at which molten metal is poured into the mold.

Importance:

A controlled pouring rate ensures proper filling and reduces turbulence in the mold. Too fast a pouring rate can cause splashing, air entrapment, or turbulence, while too slow a rate may lead to incomplete mold filling.

7. Vibration

Definition:

Vibration refers to the use of mechanical vibrations to help improve mold filling and minimize air pockets.

Importance:

Vibration can enhance the density of the casting, reduce porosity, and promote uniform distribution of the molten metal, especially in complex mold designs or thin-walled sections.

8. Pressure

Definition:

Pressure refers to the application of force, either during the pouring process (pressure casting) or as a separate step to improve casting quality (such as in investment casting or die casting).

Importance:

Using pressure can help achieve finer details, reduce porosity, and improve the overall strength of the casting, particularly for high-performance applications.

9. Draft Angle

Definition:

Draft angle is the slight taper applied to the sides of the mold to facilitate the removal of the casting from the mold.

Importance:

Proper draft angles reduce friction and the risk of mold damage during extraction. The angle typically ranges from 1° to 5° depending on the material and complexity of the part.

10. Parting Line

Definition:

The parting line is the line formed where the two halves of the mold meet.

Importance:

The parting line affects the casting’s surface finish, and a well-designed parting line is essential for easy mold separation and minimizing the risk of defects. Careful consideration is required to ensure no imperfections, like seams, are formed at this location.

11. Venting

Definition:

Venting refers to the provision of small channels or holes in the mold to allow air or gases to escape during pouring and solidification.

Importance:

Proper venting prevents air pockets, gas traps, and porosity in the casting. Without venting, trapped gases can create defects like bubbles or voids.

12. Riser Design

Definition:

Risers are reservoirs designed into the mold to compensate for metal shrinkage during solidification.

Importance:

Proper riser design ensures that the mold remains full of molten metal during solidification, which helps eliminate shrinkage cavities. The size and placement of risers are essential to achieve high-quality castings without defects.

Conclusion

Each of these parameters plays a crucial role in determining the quality, strength, and overall performance of the cast product. By controlling and optimizing these parameters, manufacturers can achieve high-precision components with minimal defects, ensuring cost-effective and high-quality production. Understanding how to adjust and balance these factors for specific materials and applications is key to mastering the casting process.

Casting is a versatile manufacturing process used to produce a wide range of products across various industries. The process involves pouring molten metal or other materials into molds to form a specific shape. Its adaptability allows it to be applied in numerous sectors, each with unique requirements. Below are some key industrial applications of casting:

Casting Applications:

Why casting?

2. Aerospace Industry

Casting Applications:

Why casting?

3. Architecture Industry

Casting Applications:

Why casting?

4. Healthcare Industry

Casting Applications:

Why casting?

Casting Applications:

Why casting?

6. Art and Sculpture

Casting Applications:

Why casting?

Conclusion

Casting is an essential manufacturing process that serves a wide range of industries, from automotive and aerospace to healthcare and art. The process allows for the production of components with complex geometries, high precision, and material versatility. Its applications are critical in industries requiring durability, strength, and detailed design, making it an indispensable technology across multiple sectors.

Casting is a versatile and widely used manufacturing process that offers several key benefits across various industries. These advantages make casting an ideal choice for producing complex parts and components efficiently, cost-effectively, and with high precision. Below are the main advantages of casting:

1. Versatility

Why it’s important: Casting can be used to create parts from a wide range of materials, including metals, polymers, and ceramics, allowing it to meet diverse industry needs. It is especially advantageous for manufacturing parts with intricate designs, complex geometries, and internal cavities.

Key benefits:

2. Cost-Effectiveness

Why it’s important: Casting is generally more cost-effective than other manufacturing methods, especially for high-volume production. The process minimizes material waste and energy consumption, which helps reduce overall production costs.

Key benefits:

3. Material Diversity

Why it’s important: Casting allows the use of a wide variety of materials, making it suitable for a broad spectrum of industries, including automotive, aerospace, and healthcare.

Key benefits:

4. Mass Production

Why it’s important: Casting is highly efficient for mass production, where large numbers of identical parts need to be manufactured quickly and with consistent quality.

Key benefits:

5. Strength and Durability

Why it’s important: Casting processes create parts with excellent mechanical properties, including high strength and durability, making it ideal for parts that must withstand heavy loads or extreme conditions.

Key benefits:

6. Precision and Accuracy

Why it’s important: Casting allows for high precision and accuracy, which is crucial for parts that must fit together perfectly or meet stringent performance standards. Advanced casting techniques like investment casting achieve fine details and tight tolerances.

Key benefits:

7. Minimum Waste

Why it’s important: Casting is a process that generates minimal material waste, especially when compared to subtractive methods like machining. This contributes to environmental sustainability and cost savings.

Key benefits:

Conclusion

Casting offers numerous advantages, making it an ideal solution for a wide range of industries. From its versatility in material use and ability to produce intricate shapes, to its cost-effectiveness, strength, and minimal waste, casting is a powerful manufacturing process that provides efficient, high-quality solutions for large-scale production needs. The precision and accuracy offered by advanced casting techniques also contribute to its widespread use in critical applications where performance is key.

The casting process, while versatile and efficient, is susceptible to certain defects that can affect the quality and performance of the final product. Understanding these defects, their causes, and prevention methods is essential for producing high-quality castings. Below are the common defects found in casting processes and considerations for maintaining quality.

1. Gas Porosity

What is gas porosity?

Gas porosity refers to the presence of gas bubbles trapped inside a casting. These bubbles can weaken the material and create voids within the casting, leading to structural issues.

Causes:

Prevention:

2. Shrinkage Defects

What are shrinkage defects?

Shrinkage defects occur when the metal contracts as it cools and solidifies, leading to voids or cavities within the casting. These defects are typically found in the thick sections of the casting.

Causes:

Prevention:

3. Mold Material Defects

What are mold material defects?

Mold material defects refer to problems related to the mold itself, such as cracks, sand inclusions, or weak molds that may compromise the casting process.

Causes:

Prevention:

4. Casting Metal Defects

What are casting metal defects?

Casting metal defects refer to issues with the metal itself, such as contamination, incorrect alloy composition, or poor metal quality.

Causes:

Prevention:

5. Metallurgical Defects

What are metallurgical defects?

Metallurgical defects are related to the physical properties and structure of the metal itself, including issues like segregation, cracking, or grain structure abnormalities.

Causes:

Prevention:

6. Casting Shape Defects

What are casting shape defects?

Casting shape defects occur when the casting does not conform to the intended design, leading to misalignment, distortion, or incomplete features.

Causes:

Prevention:

Conclusion

Casting is a complex process that requires careful attention to detail in order to avoid defects that could affect the performance and integrity of the final product. By understanding common casting defects such as gas porosity, shrinkage, mold material defects, casting metal defects, metallurgical issues, and shape defects, manufacturers can implement prevention techniques to improve casting quality. Effective prevention measures include controlling material quality, optimizing mold design, ensuring proper metal pouring conditions, and applying appropriate heat treatment processes. By focusing on these quality considerations, casting processes can produce reliable, durable, and high-precision components.

Minimizing defects in the casting process is essential to producing high-quality products that meet design specifications and performance standards. By addressing potential issues at various stages of the casting process, manufacturers can significantly reduce the occurrence of defects and improve the overall quality of their castings. Here are some effective strategies to minimize casting defects:

1. Using Simulation Software

Casting simulation software can predict potential defects before they occur, allowing manufacturers to optimize the design and manufacturing process. By simulating the casting process, engineers can analyze factors like mold filling, solidification, and cooling rates.

Benefits:

2. Controlling Material Quality

Material quality plays a significant role in the final properties of the casting. Using high-quality materials and ensuring that they are free from contaminants is essential to prevent defects.

Best Practices:

3. Regular Equipment Maintenance

Casting defects can often arise from poorly maintained equipment, such as furnaces, molds, and pouring systems. Regular maintenance ensures that the equipment is in optimal working condition and can perform consistently.

Maintenance Tips:

4. Training Personnel

Skilled and knowledgeable operators play a crucial role in preventing defects. Proper training ensures that personnel understand the casting process and can identify and address potential issues before they lead to defects.

Training Focus Areas:

5. Performing Quality Inspections

Regular quality inspections throughout the casting process can identify defects early, preventing the production of substandard parts. Inspections can be visual or involve more advanced testing methods depending on the complexity of the casting.

Inspection Methods:

Quality control is critical in the casting process to ensure that products meet required specifications. Various tests can be performed at different stages of production to detect defects and assess the material properties of the casting.

1. Visual Inspection

Visual inspection is the first and simplest method of detecting defects in castings. It involves examining the surface of the casting for visible imperfections, such as cracks, porosity, or irregularities in the shape.

Benefits:

Limitations:

2. X-Ray Inspection

X-ray inspection is a non-destructive testing (NDT) method that uses X-rays to detect internal flaws like voids, cracks, and porosity within the casting.

Benefits:

Limitations:

3. Dye Penetrant Testing

Dye penetrant testing is a surface inspection method that involves applying a liquid dye to the casting surface. The dye penetrates cracks or voids, which are then revealed under ultraviolet light.

Benefits:

Limitations:

4. Tensile Testing

Tensile testing measures the strength of a material by pulling a specimen until it fractures. It helps determine the material's tensile strength, ductility, and overall structural integrity.

Benefits:

Limitations:

5. Hardness Testing

Hardness testing measures the resistance of a material to indentation. It helps determine the casting's ability to withstand wear and deformation.

Benefits:

Limitations:

6. Spectroscopic Analysis

Spectroscopic analysis involves analyzing the composition of the casting material by measuring the light emitted from a sample when exposed to heat. This technique is used to ensure that the correct alloy composition is used in the casting.

Benefits:

Limitations:

Conclusion

Minimizing defects and maintaining high quality in the casting process requires a comprehensive approach, involving simulation tools, quality material control, proper maintenance, personnel training, and regular inspections. By performing typical quality tests like visual inspections, X-ray analysis, tensile and hardness testing, manufacturers can detect and address defects early, ensuring that cast products meet the necessary standards for performance, durability, and functionality.

The cost of casting can vary significantly based on several factors that affect both the raw material and production processes. Understanding these factors is crucial for manufacturers and businesses to estimate casting costs accurately and optimize production efficiency. Here’s a breakdown of the main cost drivers involved in casting:

1. Material Costs

The type of material used in the casting process directly impacts the cost. More expensive metals and alloys, like titanium or precious metals, will drive up the overall cost of casting. Conversely, less expensive materials like aluminum or cast iron will lower the cost.

Factors to Consider:

2. Mold Complexity

The complexity of the mold used in casting is a significant factor that influences production cost. Complex molds, which may require intricate designs, advanced features, or multi-part molds, often take more time and resources to produce, increasing the overall cost.

Factors to Consider:

3. Production Volume

Casting is generally more cost-effective for high-volume production runs. The cost per unit decreases as the production volume increases, as the initial setup costs (e.g., mold creation) are spread over a larger number of units.

Factors to Consider:

4. Machining Requirements

Many cast parts require additional machining after the casting process to achieve precise dimensions, surface finishes, or features. The more extensive the machining requirements, the higher the total cost.

Factors to Consider:

5. Finishing Operations

Finishing operations are often necessary to improve the final appearance and functionality of cast products. This includes processes like surface polishing, painting, coating, and heat treatment.

Factors to Consider:

6. Energy Costs

Casting requires significant energy for melting the metal, maintaining the right pouring temperatures, and other operations. Energy costs, including electricity or fuel for furnaces and other equipment, can account for a significant portion of the total cost.

Factors to Consider:

7. Labor Costs

Labor costs depend on the skills and expertise required to operate casting machines, maintain equipment, and supervise the process. Highly skilled workers can command higher wages, and manual operations may require more labor hours.

Factors to Consider:

8. High Volume Production

High-volume production is generally more cost-effective for casting because it amortizes the fixed costs associated with mold design, machine setup, and labor across a larger number of parts. As production increases, the per-unit cost decreases.

Factors to Consider:

9. Complex Geometries

Parts with complex geometries—such as intricate internal features, thin sections, or complex external shapes—are more difficult and expensive to cast. These designs may require special mold configurations, higher precision, or additional post-processing.

Factors to Consider:

10. Minimum Finishing Requirements

Some cast parts require little to no finishing, which can significantly reduce the overall cost. On the other hand, products that require detailed finishing—such as polishing, cleaning, or coating—will have higher costs.

Factors to Consider:

Conclusion

The cost of casting is influenced by a variety of factors, including material costs, mold complexity, production volume, machining, finishing requirements, and energy consumption. To optimize casting costs, manufacturers need to carefully balance these variables, considering factors like economies of scale, part complexity, and labor costs. By managing these aspects efficiently, businesses can reduce the overall cost of casting while maintaining the required product quality.

The time required for the casting process can vary depending on several factors, including the complexity of the part, the casting method used, and the size of the production run. Below is a breakdown of the key stages in the casting process and the typical time they require:

1. Mold Design and Fabrication

Before the actual casting can begin, a mold must be designed and fabricated. This stage can take time based on the complexity and size of the part being cast, as well as the type of mold used.

Factors Affecting Time:

Typical Time Frame:

2. Material Selection and Preparation

Selecting and preparing the right materials for the casting process is crucial to achieving the desired properties in the final part. This phase involves sourcing and processing the raw material to prepare it for melting and casting.

Factors Affecting Time:

Typical Time Frame:

3. Casting Methods

The casting method selected plays a significant role in the overall timeline of the process. Some casting methods are quicker, while others, especially those requiring more precision or specialized equipment, can take longer.

Factors Affecting Time:

Typical Time Frame:

4. Solidification and Cooling Times

Once the mold is filled with molten metal, it must solidify and cool before it can be removed from the mold. Cooling times depend on the material used, the size and shape of the part, and the casting method.

Factors Affecting Time:

Typical Time Frame:

5. Post-Processing Requirements

After the casting is removed from the mold, post-processing steps such as cleaning, trimming, machining, and finishing are often required to achieve the desired shape and surface quality.

Factors Affecting Time:

Typical Time Frame:

6. Inspection and Testing

Once the casting is finished, it undergoes inspections and testing to ensure it meets quality standards. This may include visual inspection, dimensional checks, non-destructive testing (such as X-ray or ultrasonic testing), or mechanical testing.

Factors Affecting Time:

Typical Time Frame:

Conclusion

The total time for the casting process can vary depending on the casting method, part complexity, and post-processing requirements. On average, casting takes from a few days to several weeks, with die casting being one of the fastest methods and investment casting often taking the longest due to its multi-step process.

To streamline production, manufacturers should consider factors such as material selection, method efficiency, and post-processing needs. Balancing these elements can help optimize the casting timeline and improve production efficiency.

The casting process involves various high-temperature and potentially hazardous steps that require strict adherence to safety protocols. Additionally, casting operations can have significant environmental impacts, which must be mitigated through responsible practices. Below are key safety and environmental factors to consider in casting operations.

Safety Procedures in Casting Operations

1. Personal Protective Equipment (PPE)

Workers involved in casting operations must wear appropriate PPE to protect themselves from the hazards associated with molten metals, machinery, and chemicals. The specific PPE will depend on the casting method and materials used, but common safety gear includes:

2. Ventilation Systems

Casting operations, especially those that involve high temperatures, produce fumes and gases that can be harmful if inhaled. Adequate ventilation systems are critical for maintaining safe air quality in the workplace. This includes:

3. Training and Drills

Proper training is essential to ensure that workers understand the risks associated with casting operations and know how to handle emergencies. This includes:

4. Equipment Maintenance

Casting operations involve the use of heavy machinery, such as furnaces, molds, and cooling systems. Regular maintenance of these machines is crucial for safe operations. Maintenance practices include:

The Environmental Impact of Casting

1. Recycling Initiatives

The casting process generates significant amounts of waste, including scrap metal, sand, and other by-products. Recycling initiatives can help reduce the environmental footprint of casting operations by:

2. Energy Efficiency

Casting processes, particularly those that involve melting metals at high temperatures, require substantial amounts of energy. Implementing energy-efficient practices can significantly reduce the environmental impact of casting operations. Some strategies include:

3. Emission Control

The casting process produces emissions that can harm the environment if not properly managed. These emissions include fumes from molten metal, volatile organic compounds (VOCs), and particulate matter. Effective emission control is essential for compliance with environmental regulations. Solutions include:

4. Water Management

Water is often used in casting for cooling and other purposes. Managing water usage and discharge is crucial to minimize environmental impact, particularly in areas facing water scarcity. Effective water management strategies include:

Conclusion

Safety and Environmental Responsibility in Casting

Casting operations are inherently hazardous, requiring strict safety protocols and environmental management. Ensuring the safety of workers and minimizing the environmental impact of casting requires careful planning and the implementation of best practices, such as the use of proper PPE, efficient ventilation, equipment maintenance, and recycling initiatives. By adopting these safety and environmental strategies, casting facilities can maintain high standards of worker protection and sustainability, ensuring both human and environmental well-being in the casting process.

Casting is a widely used manufacturing process where a liquid material, usually metal, is poured into a mold and allowed to solidify. It is distinct from other manufacturing processes such as forging and machining, each of which offers unique advantages for different applications. Understanding the differences between casting and other manufacturing methods, as well as the trends shaping its future, is key to selecting the best process for any given project.

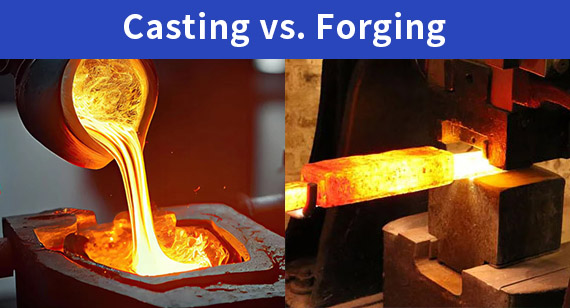

What is the Difference Between Casting and Forging?

Casting and forging are both metalworking processes, but they differ in how the material is shaped:

Key Differences:

What is the Difference Between Casting and Machining?

While casting and machining are both used to create parts, they are fundamentally different processes:

Key Differences:

What Are the Future Trends and Innovations in Casting?

The casting industry continues to evolve, with technological advancements shaping the future of the process. Key trends and innovations include:

Metal casting offers numerous advantages, which make it an ideal choice for producing a wide range of components across various industries:

Metal casting is a cornerstone of modern manufacturing due to its ability to meet the demands of a wide range of industries. It is critical for:

Metal casting serves as a foundation for innovation and advancement in these sectors, ensuring that high-quality, cost-effective components are produced in large volumes to meet global demand.

Casting stands out as one of the most versatile and efficient manufacturing processes, capable of producing complex, high-quality metal parts. While it differs from other manufacturing methods like forging and machining, it offers significant advantages, particularly in terms of shape complexity, cost-effectiveness, and material versatility. The future of casting looks promising, with innovations such as additive manufacturing, automation, and sustainable practices enhancing its capabilities. Understanding why metal casting is important and how it compares to other processes is essential for selecting the right method for any given application, ensuring the production of reliable, high-performance components across industries.

What are the 4 Steps in Casting?

The basic steps in the casting process are:

What are the 4 Main Types of Casting?

The four main types of casting processes are:

Does the Casting Process Contain 5 Steps?

While some variations of the casting process may include additional steps, the traditional casting process typically involves the following key stages:

Some might consider the post-casting operations, such as finishing and testing, as an additional "step," but the core process generally contains the four key stages listed above.

How is Casting Performed?

Casting is performed by first preparing a mold that mirrors the shape of the desired part. Molten metal is then poured into the mold, where it cools and solidifies. The mold is then removed, and the solidified metal casting is cleaned and finished as needed. This process can be applied to a variety of materials, from metals to certain plastics and resins.

What are the Basics of the Casting Process?

The casting process involves:

Casting is a highly versatile method that can create complex shapes, large parts, or high-precision components, depending on the technique used.

How Long Does the Casting Process Take?

The casting process duration depends on several factors, including:

In general, the actual pouring and solidification stages may take minutes to hours, but the full process can take several hours to days when including mold preparation and post-processing.

What is the Casting Cycle?

The casting cycle refers to the sequence of operations involved in producing a casting, which includes:

The cycle time can vary based on the casting method, material, and part complexity.

What is the Post-Casting Process?

The post-casting process involves several steps after the metal has solidified and the casting has been removed from the mold. Common post-casting operations include:

What are the Most Common Casting Processes?

The most common casting processes include:

Each of these processes has its own advantages, such as cost-effectiveness, precision, or the ability to produce complex shapes.

What are the Advantages and Disadvantages of Casting?

Advantages of Casting:

Disadvantages of Casting: