15 years one-stop China custom CNC machining parts factory

1617 |

Published by VMT at Jul 22 2024

1617 |

Published by VMT at Jul 22 2024

Cast aluminum, a crucial member of the metal casting processes, refers to the process of injecting molten aluminum or aluminum alloy into molds, cooling and solidifying it to form aluminum parts of the desired shape. Due to its unique physical and chemical properties, cast aluminum is widely used in various industrial fields. This article provides an in-depth guide for experts and practitioners in the CNC machining parts manufacturing industry, covering the definition of cast aluminum, its advantages, comparison with other metal materials, different casting processes, common casting aluminum alloys, methods for choosing casting processes, surface treatments for cast aluminum parts, application fields, and common issues.

In simple terms, cast aluminum refers to aluminum parts produced using the casting process. In this process, molten aluminum or aluminum alloy is poured into a pre-designed mold and then cooled and solidified to form aluminum products with specific shapes and sizes. The aluminum materials used for casting are known as casting aluminum alloys, which typically contain various alloying elements to enhance properties such as strength, corrosion resistance, and fluidity.

Ability to Create Complex Designs:

The casting process can produce parts with complex shapes and intricate structures without requiring complex machining or assembly processes. This ability makes cast aluminum highly advantageous in designing and producing complex components.

Lightweight and Strong:

The density of aluminum is only about one-third that of steel, yet its strength is comparable to or exceeds many alloy steels. Therefore, cast aluminum parts can significantly reduce the overall weight of structures while maintaining sufficient strength, which is particularly important in the aerospace and automotive industries.

Excellent Corrosion Resistance:

Aluminum has good corrosion resistance and can maintain stable performance in humid, acidic, or alkaline environments. This makes cast aluminum products widely applicable in fields such as chemical engineering and marine engineering.

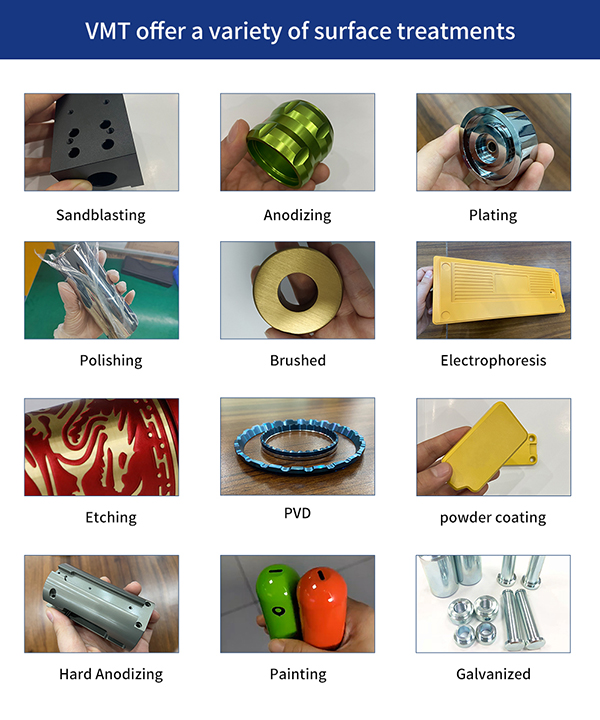

Fine Surface Treatment:

The surface quality of cast aluminum parts can be finely treated through various methods such as sandblasting and anodizing to enhance their appearance and durability. These treatments not only improve the appearance of the castings but also enhance their corrosion and wear resistance.

Faster Production Speed:

Compared to other metal processing methods, the casting process can quickly produce large quantities of parts. This advantage makes cast aluminum highly favored in applications requiring mass production.

Cost-Effective in Manufacturing:

Aluminum is abundant and relatively inexpensive, and the casting process has high material utilization and low scrap rates. These factors collectively reduce the production cost of cast aluminum products, making them competitive in price.

Porosity:

Porosity is a common defect in cast aluminum parts, caused by trapped gases during the casting process. Solutions include optimizing the mold design, controlling the pouring temperature, and using degassing techniques.

Shrinkage:

Shrinkage occurs when the aluminum part contracts during cooling, leading to dimensional inaccuracies. Solutions include proper gating and riser design, controlling the cooling rate, and using appropriate casting methods.

Cold Shuts:

Cold shuts occur when two streams of molten aluminum fail to fuse properly, resulting in weak joints. Solutions include increasing the pouring temperature, improving mold design, and ensuring proper gating and venting.

Hot Cracking:

Hot cracking occurs during the solidification process when the aluminum part is under tensile stress. Solutions include using alloys with lower susceptibility to hot cracking, optimizing the cooling rate, and minimizing casting stress.

Surface Defects:

Surface defects, such as roughness, pits, and inclusions, can affect the appearance and performance of cast aluminum parts. Solutions include proper mold preparation, controlling the pouring process, and applying surface treatments.

In conclusion, cast aluminum offers a wide range of advantages and applications across various industries. By understanding the different casting processes, choosing the appropriate casting method, and addressing common issues, manufacturers can produce high-quality cast aluminum parts that meet specific requirements and standards.

Cast aluminum and conventional aluminum materials differ in performance and application. Cast aluminum refers to aluminum parts produced by casting, with shapes and sizes determined by molds. Conventional aluminum materials are usually products formed by rolling, extrusion, and other processes. Cast aluminum offers higher design flexibility and a broader range of applications but at a relatively higher cost. Conventional aluminum materials are less expensive but have more limited shapes and sizes.

Weight:

Cast aluminum's density is much lower than cast iron's, giving cast aluminum parts a significant weight advantage. In applications where weight reduction is essential, cast aluminum is a more suitable choice.

Dimensional Tolerance:

Cast aluminum and cast iron have different characteristics regarding dimensional tolerance. Cast aluminum parts typically have higher dimensional accuracy and can meet stricter tolerance requirements. In contrast, cast iron parts have relatively lower dimensional accuracy.

Precision and Accuracy:

The casting process can produce parts with higher precision and accuracy, suitable for applications with high precision requirements. In comparison, cast iron parts may be somewhat lacking in precision and accuracy.

Thermal Resistance:

Aluminum has much better thermal conductivity than iron, so cast aluminum parts perform better in heat dissipation. In applications requiring rapid heat dissipation, cast aluminum is a more suitable choice.

Different Product Forms:

Cast aluminum parts are produced by casting, with shapes and sizes determined by molds. Forged aluminum parts are formed by forging and have higher density and strength.

Different Alloying Elements:

Cast aluminum and forged aluminum differ in their choice of alloying elements. Cast aluminum alloys typically contain various alloying elements to improve fluidity, strength, and corrosion resistance. Forged aluminum alloys focus more on enhancing strength and toughness.

Different Product Characteristics:

Cast aluminum parts are lightweight with good corrosion resistance while maintaining sufficient strength. Forged aluminum parts have higher strength and toughness but are relatively heavier.

1. Die Casting:

Advantages:

High Production Efficiency: Die casting can produce large quantities of parts in a short time.

High Precision: Die cast parts have high dimensional accuracy and surface quality.

Low Cost: Die casting molds can be reused, reducing production costs.

Disadvantages:

High Mold Cost: The design and manufacture of die casting molds are complex and costly.

Limited Applicability: Die casting is suitable for producing relatively simple-shaped parts.

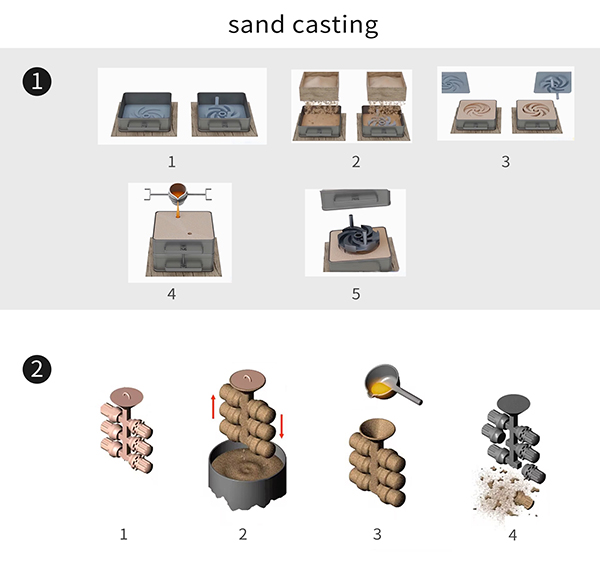

2. Sand Casting:

Advantages:

Low Cost: The materials used for sand casting molds are inexpensive and easy to obtain.

Simple Process: Sand casting is relatively simple and suitable for producing various complex-shaped parts.

Disadvantages:

Lower Surface Quality: Sand-cast parts have higher surface roughness and require post-processing to improve surface quality.

Limited Dimensional Accuracy: Due to the limitations of sand casting molds, the dimensional accuracy of sand-cast parts is relatively low.

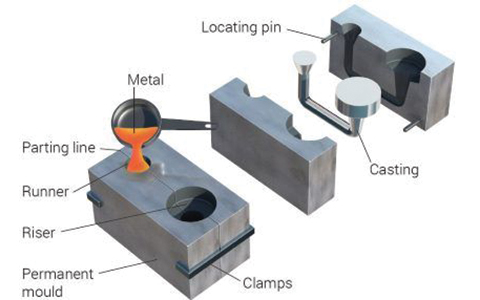

3. Permanent Mold Casting:

Advantages:

High Precision: Permanent mold casting can produce parts with high dimensional accuracy and surface quality.

Reusability: Permanent molds can be used multiple times, reducing long-term production costs.

Disadvantages:

High Mold Cost: The design and manufacture of permanent molds are costly and time-consuming.

Poor Flexibility: Once the mold is made, changing the design or producing different parts is expensive.

4. Shell Mold Casting:

Advantages:

High Precision: Shell mold casting can produce parts with very high dimensional accuracy and surface quality.

Suitable for Complex Shapes: Shell mold casting can produce parts with complex shapes and thin-walled structures.

Disadvantages:

Complex Process: The manufacturing process of shell molds is complex and requires precise control.

High Cost: The manufacturing cost of shell molds is high, and they are not suitable for mass production.

5. Plaster Mold Casting:

Advantages:

Low Cost: Plaster mold materials are inexpensive, making it suitable for small-batch or prototype production.

Good Reproducibility: Plaster molds can replicate complex shapes well.

Disadvantages:

Low Strength: Plaster molds have lower strength and are unsuitable for producing large or heavy parts.

Poor Durability: Plaster molds have limited durability and need frequent replacement.

A356 Aluminum Alloy:

A common casting aluminum alloy with excellent casting performance, high strength, and good corrosion resistance. It is widely used in automotive, motorcycle, and aerospace industries.

A360 Aluminum Alloy:

A casting aluminum alloy with good fluidity and low thermal cracking tendency. It is suitable for producing parts with complex shapes and varying wall thicknesses, such as engine blocks.

A380 Aluminum Alloy:

A casting aluminum alloy with high silicon content, offering good wear resistance and thermal cracking resistance. It is commonly used for parts that need to withstand high temperatures and wear, such as engine pistons.

A383 Aluminum Alloy (ADC12):

A commonly used die casting aluminum alloy with excellent fluidity and filling properties. It can produce die-cast parts with complex shapes and high surface quality.

Design Complexity:

The design complexity of the part is the primary consideration when choosing a casting process. For parts with complex shapes and intricate structures, high-precision processes such as shell mold casting or die casting may be needed.

Production Speed:

Production speed is also a crucial factor. If large quantities of parts need to be produced quickly, die casting or sand casting may be more suitable.

High Quantity:

For mass production, choosing a cost-effective casting process is critical. Sand casting is suitable for large-scale production due to its low cost and flexibility.

Material Properties and Performance:

Different casting processes affect the performance of the material. For example, shell mold casting can produce parts with high strength and toughness, while die casting is suitable for complex shapes that do not require particularly high strength.

Prototype Design:

In the product development stage, plaster mold casting is favored for its low cost and rapid prototyping capabilities.

Strength and Surface Treatment:

Choose the appropriate casting process based on the required strength and surface treatment of the part. For example, parts requiring high strength and good surface treatment may be suitable for shell mold casting.

Cost Considerations:

The final choice of casting process also needs to consider cost factors, including mold cost, production cost, and post-processing cost.

Powder Coating:

An environmentally friendly and durable surface treatment method. Powder coating is applied to the aluminum part's surface using electrostatic spraying and then cured to form a hard coating. This method improves the corrosion resistance and aesthetics of the aluminum part.

Painting:

A simple and flexible surface treatment method. Suitable paints and colors can be selected as needed for coating. However, the durability and corrosion resistance of the paint coating may not be as good as other methods.

Electroplating:

A process of plating a layer of metal (such as chromium, nickel, etc.) onto the aluminum part's surface. The electroplated layer improves corrosion resistance and aesthetics and provides specific surface properties (such as conductivity, reflectivity, etc.).

Anodizing:

An electrochemical process that forms an oxide film on the surface of the aluminum part. The anodized layer improves the part's corrosion resistance, wear resistance, and aesthetics, and can also provide various colors.

Sandblasting:

A surface treatment method that removes surface contaminants and forms a uniform surface using high-speed sand grains. Sandblasting can improve the adhesion of the subsequent coating and provide a matte surface finish.

Cast aluminum is widely used in producing various automotive parts, such as engine blocks, cylinder heads, intake manifolds, and wheels. The lightweight and corrosion-resistant properties of cast aluminum contribute to improving vehicle performance and fuel efficiency.

Aerospace Industry:

Cast aluminum plays a crucial role in the aerospace industry, where lightweight and high-strength materials are essential. It is used in manufacturing aircraft structural components, engine parts, and landing gear components.

Construction Industry:

Cast aluminum is used in producing building materials and structural components, such as doors, windows, curtain walls, and handrails. Its lightweight and corrosion resistance make it ideal for architectural applications.

Marine Industry:

In the marine industry, cast aluminum is used to manufacture ship components, such as hulls, propellers, and deck fittings. Its corrosion resistance and lightweight properties make it suitable for marine environments.

Cast aluminum is used in producing electronic enclosures, heat sinks, and components for various electronic devices. Its excellent thermal conductivity and electrical properties make it valuable in the electronics industry.

Consumer Goods:

Cast aluminum is used in producing various consumer goods, such as cookware, furniture, and sports equipment. Its lightweight, durability, and aesthetic appeal make it a popular choice for consumer products.

Medical Equipment:

Cast aluminum is used in manufacturing medical equipment and devices, such as surgical instruments, imaging equipment, and mobility aids. Its biocompatibility, lightweight, and corrosion resistance make it suitable for medical applications.

As an important metal casting material, cast aluminum demonstrates its unique advantages and broad application prospects in various industrial fields. From precision instruments in the medical industry to power cores in the automotive sector, from cookware in the culinary industry to flight equipment in the aerospace industry, cast aluminum is recognized for its lightweight, robust, corrosion-resistant, and flexible design properties. With continuous technological advancements and innovations in the manufacturing process, cast aluminum will play an increasingly significant role in more fields, contributing more to the development of modern industries.

What is the difference between cast aluminum and aluminum?

Cast aluminum refers to aluminum parts produced using the casting process, with shapes and sizes determined by molds. Conventional aluminum materials usually refer to aluminum products formed through processes such as rolling and extrusion. Cast aluminum offers greater design flexibility and a broader range of applications, but it is relatively more expensive. Conventional aluminum materials are less costly but have more limited shapes and sizes.

What is the most precise aluminum casting method?

One of the most precise aluminum casting methods is shell mold casting, also known as precision casting or investment casting. Shell mold casting can produce parts with high dimensional accuracy and excellent surface quality, making it suitable for applications requiring extremely high precision.

Which is better, cast iron or cast aluminum?

Cast iron and cast aluminum each have their own advantages and disadvantages. The choice between the two depends on the specific application and requirements. Cast iron offers higher strength and wear resistance, making it suitable for applications that need to withstand heavy loads and wear. Cast aluminum, on the other hand, is lighter, more corrosion-resistant, and more flexible in design, making it suitable for applications that require weight reduction, improved fuel efficiency, or aesthetic appeal.

Why is cast aluminum so expensive?

The relatively high cost of cast aluminum can be attributed to two main reasons: first, the casting process is complex and requires high-precision molds and specialized production equipment. Second, cast aluminum alloys often contain various alloying elements to enhance performance, and these elements can be relatively expensive.

Is cast aluminum better than steel?

Cast aluminum and steel each have unique advantages and application areas, and it is not straightforward to say which is better. Cast aluminum is lightweight, corrosion-resistant, and flexible in design, making it ideal for applications that require weight reduction, improved fuel efficiency, or aesthetic appeal. Steel, on the other hand, offers higher strength and toughness, making it suitable for applications that need to withstand heavy loads and impacts.

How many aluminum casting processes are there?

The main aluminum casting processes include die casting, sand casting, permanent mold casting, shell mold casting, and plaster mold casting. Each method has its unique advantages and suitable applications, and the choice of process depends on the specific application and requirements.

Is die-cast aluminum the same as cast aluminum?

Die-cast aluminum is a specific form of cast aluminum, produced using the die-casting process. Die-cast aluminum parts are known for their high production efficiency, high dimensional accuracy, and good surface quality. However, die-casting molds are costly and are typically used for producing relatively simple-shaped parts. Thus, while die-cast aluminum is a type of cast aluminum, they are not entirely the same.