15 years one-stop China custom CNC machining parts factory

426 |

Published by VMT at Nov 19 2024 | Reading Time:About 6 minutes

426 |

Published by VMT at Nov 19 2024 | Reading Time:About 6 minutes

Are you struggling to find a manufacturing process that offers high precision, excellent surface finish, and cost-effectiveness for producing complex metal parts? Frustrated by methods that don't meet the demands of mass production without compromising on quality? You're not alone. Many manufacturers face the challenge of selecting the right process that balances efficiency with superior product characteristics. But what if die casting could be the solution that revolutionizes your production line, delivering intricate components with unmatched accuracy and consistency?

Die casting is a metal casting process that forces molten metal under high pressure into a mold cavity, allowing for the mass production of complex, high-precision metal parts with excellent surface finishes and dimensional accuracy. It's widely used in industries requiring large quantities of small to medium-sized parts with fine details.

Now that we've introduced die casting as a potential game-changer for your manufacturing needs, let's delve deeper into what die casting is, why it's used, and how it works. Understanding the intricacies of die casting will empower you to make informed decisions for your production processes, ensuring you achieve the quality and efficiency your projects demand.

Foreword

In the competitive landscape of modern manufacturing, the demand for high-quality, intricate metal parts produced efficiently and cost-effectively is ever-increasing. Industries such as automotive, aerospace, electronics, and consumer goods rely heavily on components that meet strict specifications and performance standards. Traditional manufacturing methods often fall short when it comes to balancing complexity, precision, and scalability. This is where die casting emerges as a pivotal technology. By leveraging advanced techniques and materials, die casting enables manufacturers to produce complex shapes with tight tolerances and excellent surface finishes, all while maintaining cost efficiency. In this comprehensive exploration, we'll uncover the fundamentals of die casting, its processes, types, materials, and diverse applications, providing valuable insights for professionals seeking to optimize their production capabilities.

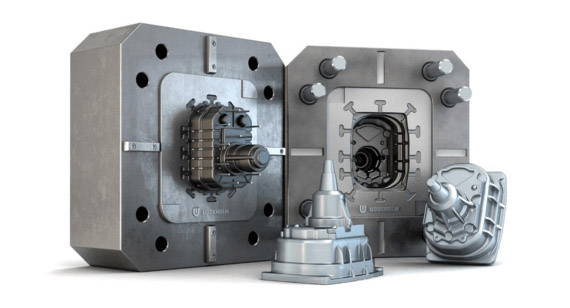

Die casting is a versatile and efficient metal casting process where molten metal is injected under high pressure into a hardened steel die or mold cavity. The molds, known as dies, are precision-machined to form complex shapes with high accuracy and repeatability. Once the molten metal solidifies within the die, the casting is ejected, and the process repeats, making it highly suitable for mass production.

This manufacturing method is renowned for producing parts with excellent dimensional accuracy, defined external shapes, and smooth or textured surfaces, reducing the need for additional machining or finishing. Die casting is particularly advantageous for producing large quantities of small to medium-sized parts that require intricate details and consistent quality.

Die casting can be performed using various metals, including aluminum, zinc, magnesium, copper, and lead alloys. The choice of material depends on the desired mechanical properties, weight, corrosion resistance, and other application-specific requirements.

The process is widely used across multiple industries due to its ability to produce complex components efficiently. It integrates seamlessly with other manufacturing techniques like CNC machining services for post-processing and finishing, enhancing the versatility and application scope of die-cast parts.

Die casting offers several compelling advantages that make it a preferred manufacturing method for many applications:

High Precision and Accuracy: Die casting produces parts with tight tolerances and precise dimensions, reducing or eliminating the need for secondary machining processes. This precision aligns with the demands of CNC machining parts and ensures components fit and function as intended.

Complex Geometries: The process allows for the creation of intricate shapes and complex geometries that would be difficult or impossible with other casting methods. Features like thin walls, fine details, and internal structures can be achieved with ease.

Excellent Surface Finish: Die-cast parts typically have smooth surfaces and can be cast with textures or patterns directly from the die, reducing the need for additional finishing. This enhances the aesthetic appeal and functional properties of the components.

High Production Efficiency: Die casting is ideal for mass production due to its rapid cycle times and automation capabilities. The process can produce a large number of identical parts quickly, making it cost-effective for high-volume manufacturing.

Material Versatility: A range of metals can be used in die casting, each offering different mechanical and physical properties. This flexibility allows manufacturers to select materials that best suit the application's requirements.

Strength and Durability: Die-cast parts generally have high strength and are more durable compared to parts made through other casting methods. The rapid cooling and solidification under pressure enhance the mechanical properties of the metal.

Reduced Waste: The precise control over material usage in die casting minimizes waste, contributing to cost savings and environmental sustainability.

Integration with Other Processes: Die casting can be combined with processes like custom CNC machining and CNC prototype machining for finishing operations or to produce prototypes before full-scale production.

By leveraging these advantages, manufacturers can achieve higher quality products, streamline production processes, and reduce overall costs, making die casting an attractive option for a wide range of applications.

The primary purpose of die casting is to manufacture metal parts that are complex in shape, precise in dimension, and suitable for mass production. Die casting fulfills several key objectives:

Efficiency in Mass Production: Die casting is designed for high-volume production runs, enabling manufacturers to produce large quantities of parts consistently and efficiently.

Complexity and Precision: It allows for the creation of intricate designs with tight tolerances, meeting the demands of modern engineering and design.

Cost-Effectiveness: By reducing the need for secondary operations and minimizing material waste, die casting offers a cost-effective solution for producing metal parts.

Material Properties: The process enhances the mechanical properties of metals, resulting in strong, durable components suitable for demanding applications.

Versatility: Die casting accommodates a variety of metals and alloys, providing flexibility in meeting specific application requirements.

Integration with Advanced Manufacturing: The compatibility of die casting with CNC machining services and other advanced manufacturing techniques allows for further refinement and customization of parts.

In essence, die casting serves as a critical manufacturing method that bridges the gap between design complexity and production efficiency, enabling the realization of innovative products across various industries.

Die casting is a highly efficient manufacturing process that transforms molten metal into precisely shaped solid parts through the use of molds called dies. The process involves several critical steps, each contributing to the quality and characteristics of the final product. Understanding how die casting works is essential for manufacturers, designers, and engineers looking to leverage this technology for their projects.

The Die Casting Process Involves Several Steps:

Step 1 – Mold Design

The die or mold is the foundation of the die casting process. It is typically made from hardened steel and precision-machined to form the exact shape of the desired part. Mold design involves:

Step 2 – Metal Preparation

The chosen metal or alloy is prepared by melting it to the appropriate temperature in a furnace. Key considerations include:

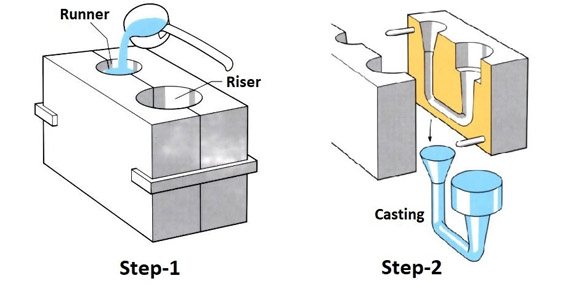

Step 3 – Injection Process

Molten metal is injected into the die using one of two primary methods:

High pressure is applied to force the molten metal into the die cavities, ensuring it fills all areas and replicates the mold's details.

Step 4 – Casting Process

As the molten metal enters the die, it begins to cool and solidify. The pressure is maintained during this phase to:

Step 5 – Cooling

The casting is allowed to cool within the die until it solidifies completely. Cooling time depends on factors like:

Step 6 – Ejection

Once solidified, the die opens, and ejector pins push the casting out of the mold. Care is taken to:

Step 7 – Finishing Process

After ejection, the casting undergoes finishing operations, which may include:

By meticulously following these steps, manufacturers produce high-quality die-cast parts that meet precise specifications and performance criteria.

Die casting encompasses various methods, each tailored to specific materials, part designs, and production requirements. Understanding the different types of die casting enables manufacturers to select the most suitable process for their applications, optimizing efficiency, quality, and cost-effectiveness. The main types of die casting include:

Each type has unique characteristics, advantages, and limitations, which we'll explore in detail.

| Type of Die Casting |

Suitable Materials |

Advantages |

Disadvantages |

Applications |

| Cold Chamber Die Casting |

Aluminium, Magnesium, Copper Alloys |

High-strength parts, suitable for high-melting point metals |

Slower cycle times due to metal transfer |

Automotive components (engine blocks, gear housings) |

| Vacuum Die Casting |

Aluminium, Magnesium, Zinc |

Reduces porosity, improves mechanical properties |

Higher cost, more complex process |

Automotive parts requiring high strength and tight tolerances (engine parts) |

| High-Pressure Die Casting |

Aluminium, Zinc, Magnesium |

Excellent surface finish, fast production, highly precise |

Higher tooling cost, porosity issues |

Automotive, electronics, appliances |

| Hot Chamber Die Casting |

Zinc, Lead Alloys |

Fast production, low melting point metals |

Fast production, low melting point metals |

Electrical components, consumer products |

| Gravity Die Casting |

Aluminium, Zinc, Copper |

Better mechanical properties than sand casting, low-cost tooling |

Less precision compared to high-pressure casting |

Medium complexity parts (valve bodies, pipes) |

| Low-Pressure Die Casting |

Aluminium |

Better structural integrity, good for large parts |

Slower process, more suited to lower production volumes |

Wheels, large structural components |

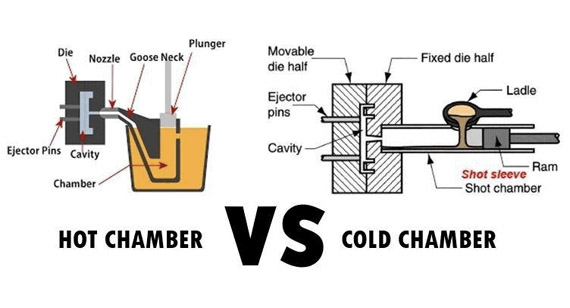

What Is Cold Chamber Die Casting?

Cold Chamber Die Casting is a process where molten metal is poured into a cold chamber or shot sleeve and then injected into the die cavity using a hydraulic piston. The injection system is not submerged in the molten metal, differentiating it from the hot chamber process.

Applicable Materials

Advantages

Disadvantages

Applications

What Is Hot Chamber Die Casting?

Hot Chamber Die Casting involves a machine where the injection mechanism is submerged directly in the molten metal. A plunger forces the metal through a gooseneck into the die cavity.

Applicable Materials

Advantages

Disadvantages

Applications

What Is Vacuum Die Casting?

Vacuum Die Casting incorporates a vacuum system to remove air and gases from the die cavity before and during the injection of molten metal. This process reduces porosity and enhances the quality of the casting.

Applicable Materials

Advantages

Disadvantages

Applications

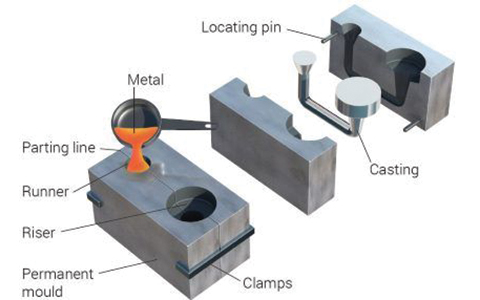

What Is Gravity Die Casting?

Gravity Die Casting, also known as Permanent Mold Casting, involves pouring molten metal into a metal die under the force of gravity without applying external pressure.

Applicable Materials

Advantages

Disadvantages

Applications

What Is High Pressure Die Casting?

High Pressure Die Casting uses significant pressure to inject molten metal into the die cavity, ensuring rapid filling and solidification.

Applicable Materials

Advantages

Disadvantages

Applications

What Is Low Pressure Die Casting?

Low Pressure Die Casting involves applying a low pressure (usually between 0.7 to 1.5 bar) to force molten metal upward into the die cavity from a sealed furnace.

Applicable Materials

Advantages

Disadvantages

Applications

What Is Semi-Solid Die Casting (SSDC)?

Semi-Solid Die Casting (SSDC) utilizes metal alloys that are partially solid and partially liquid, allowing for thixotropic flow into the die cavity.

Applicable Materials

Advantages

Disadvantages

Applications

What Materials Are Suitable for Die Casting?

The choice of material in die casting significantly influences the properties of the final product, including strength, weight, corrosion resistance, and thermal conductivity. Selecting the appropriate alloy is crucial for meeting specific application requirements. Common materials used in die casting include:

Each material group offers distinct characteristics, advantages, and applications.

|

Die Casting Material |

Alloy Examples |

Characteristics |

Applications |

| Aluminum Alloys |

A380, A383, ADC12 |

Lightweight, corrosion-resistant, high strength, excellent machinability |

Automotive parts, aerospace components, consumer electronics |

| Lead Alloys |

Lead, Tin-Lead Alloys |

Dense, excellent shielding properties, easy to cast |

Battery components, radiation shielding, small intricate parts |

| Zinc Alloys |

Zamak 3, Zamak 5 |

Excellent casting properties, high precision, good electrical conductivity |

Electrical components, small consumer products, automotive parts |

| Magnesium Alloys |

AZ91D, AM60B, AS41B |

Ultra-lightweight, good strength-to-weight ratio, moderate corrosion resistance |

Lightweight automotive parts, electronics, aerospace |

| Copper Alloys |

Brass (C85700), Bronze |

High corrosion resistance, excellent thermal and electrical conductivity |

Plumbing fixtures, electrical connectors, industrial machinery |

Aluminum Alloys

Models

Features

Applications

Magnesium Alloys

Models

Features

Applications

Zinc Alloys

Models

Features

Applications

Copper Alloys

Models

Features

Applications

Lead Alloys

Models

Features

Applications

Die casting offers numerous benefits that make it a popular choice for manufacturing metal parts. However, it also has limitations that must be considered when selecting the appropriate manufacturing process.

Advantages of Die Casting

Excellent Accuracy

Die casting produces parts with high dimensional accuracy and stability. Tolerances as tight as ±0.1 mm are achievable, reducing the need for secondary machining. This precision is essential for components that require exact fit and function, aligning with the capabilities of CNC machining services.

Complex Shapes

The process allows for the creation of complex geometries, including intricate details, thin walls, and internal features that would be challenging or impossible with other methods. This versatility enables designers to innovate without being constrained by manufacturing limitations.

Versatility

Die casting accommodates a wide range of metals and alloys, providing flexibility in meeting specific mechanical and physical property requirements. It supports various surface finishes and textures directly from the mold.

Fast Delivery of Large Quantities

With rapid cycle times and automation potential, die casting is ideal for mass production. It efficiently produces large volumes of identical parts, making it cost-effective for high-demand products.

Cost-Effective

By minimizing material waste and reducing the need for secondary operations, die casting offers economic advantages. The initial investment in tooling is offset by the low per-unit cost in large production runs.

Repeatability

Die casting ensures consistent quality and dimensions across all parts in a production run. This repeatability is crucial for applications requiring high reliability and interchangeability.

Smooth Surface Finish

Parts produced through die casting typically have smooth surfaces, reducing the need for additional finishing processes. This characteristic enhances both the aesthetic and functional aspects of the components.

Long Die Life

Dies made from hardened steel can withstand a high number of cycles before needing replacement. This longevity contributes to the cost-effectiveness of the process over time.

Limitations of Die Casting

Limited Material Usage

Die casting is generally restricted to non-ferrous metals with specific melting points. Materials like steel and iron are not suitable due to their high melting temperatures, limiting the range of applications.

High Die Cost

The initial investment in die design and manufacturing is substantial. This cost is justifiable only for large production volumes, making die casting less suitable for small-scale projects.

Labor Intensive

Despite automation potential, die casting still requires skilled labor for die design, machine setup, and quality control. Training and labor costs can impact overall expenses.

Unchangeable Die

Once a die is manufactured, making changes or corrections is challenging and costly. This rigidity necessitates thorough design validation before die creation.

Susceptible to Defects

Die casting can be prone to defects like porosity, cold shuts, and flow lines if not properly managed. Controlling process parameters is essential to minimize these issues.

Unsuitable for Small Projects

Due to the high initial costs and setup time, die casting is not economical for low-volume production or one-off prototypes.

Selecting the appropriate manufacturing process depends on various factors, including material requirements, production volume, part complexity, and cost considerations. Comparing die casting with other methods like injection molding and forging provides insights into the strengths and limitations of each process.

Differences Between Die Casting and Injection Molding

While both die casting and injection molding involve injecting material into a mold to form parts, they use different materials and have distinct processes.

| Differences |

Die Casting |

Injection Molding |

| Process |

Metal injection into a predesigned steel mold under pressure |

Molten plastic injection into a predesigned steel or aluminum mold under pressure |

| Material |

Non-ferrous metal alloys (e.g., aluminum, zinc, magnesium) |

Thermoplastic or thermosetting plastics |

| Mold materials |

Steel |

Steel or aluminum |

| Cooling time |

Longer cooling times |

Shorter cooling times |

| Production Speed |

Slower |

Faster |

| Tooling cost |

Higher die casting tooling costs due to the use of steel molds |

Lower tooling cost due to the use of aluminum molds |

| Part cost |

Higher part costs due to longer production times |

Lower part cost due to faster production times |

Manufacturing Process

Materials

Mold Materials

Cooling Time

Production Speed

Mold Cost

Part Cost

Differences Between Forging and Die Casting

Forging and die casting are both methods of shaping metal but differ significantly in process and part properties.

| Differences |

Forging |

Die Casting |

| Process |

Involves shaping the metal by applying compressive forces |

Injection of the metal in a molten state into a mold under pressure |

| Material |

Suitable for ferrous and non-ferrous metals e.g., steel and aluminum |

Suitable for only non-ferrous metals like aluminum, zinc, magnesium |

| Mold Material |

Does not require a mold. But it uses a die |

Steel molds |

| Production Speed |

Slower |

Faster |

| Tolerance Control |

Moderate tolerance |

High tolerance control due to the precision mold manufacturing process |

| Final Part Properties |

Improved mechanical properties due to the forging process |

Mechanical properties depend on the casting material |

Manufacturing Process

Materials

Mold Materials

Production Speed

Tolerance Control

Final Part Properties

Effective die casting design requires careful consideration of geometric features to ensure manufacturability, quality, and performance. Key factors include:

Draft

Incorporating draft angles (typically 1-3 degrees) facilitates the ejection of the part from the die without damage. Adequate draft reduces friction and wear on the die surfaces.

Ribs

Adding ribs strengthens thin sections without increasing wall thickness. Properly designed ribs enhance rigidity and structural integrity.

Bosses

Bosses provide mounting points or attachment features. Ensuring they have appropriate draft and are supported by ribs prevents defects and enhances strength.

Pockets

Designing pockets with uniform wall thickness and sufficient draft prevents issues like porosity and sink marks.

Wall Thickness Uniformity

Maintaining consistent wall thickness avoids stress concentrations and reduces the risk of defects. Sudden changes in thickness can lead to uneven cooling and warping.

Fillets and Corners

Rounding internal and external corners with fillets distributes stress more evenly and improves metal flow during casting.

Corner Radius

Adding appropriate corner radii minimizes stress concentrations and reduces the likelihood of cracking or other defects.

Parting Lines

Positioning parting lines thoughtfully minimizes their impact on the part's functionality and appearance. It also simplifies the die design.

Holes and Windows

Incorporating holes and windows requires careful planning to ensure they fill correctly and do not compromise the die's integrity. Core pins and slides may be necessary.

Producing high-quality die castings involves optimizing several aspects of the process, from material selection to mold design and quality control.

Using High-Quality Metals

Selecting the appropriate alloy with consistent composition ensures the desired mechanical properties and reduces defects related to impurities or inconsistencies.

Optimizing Mold Design

Implementing rigorous quality assurance measures, including:

Enhancing the surface finish of die castings can improve aesthetic appeal, corrosion resistance, and functional properties. Several finishing options are available.

Deburring

Removing excess material and smoothing edges ensures parts are safe to handle and function correctly.

Secondary Finishing Options

Powder Coating

Applying a powder coat provides a durable, attractive finish with excellent corrosion resistance. It offers a wide range of colors and textures.

Plating

Electroplating with metals like chrome, nickel, or zinc enhances corrosion resistance, electrical conductivity, and appearance.

Painting

Applying liquid paint allows for specific colors and finishes. It provides additional protection against environmental factors.

Die casting is utilized across various industries due to its ability to produce complex, high-quality metal parts efficiently.

Appliance Industry

Furniture Industry

Start Your Die Casting CNC Machining Service Project: Choose VMT

At VMT, we specialize in providing comprehensive CNC machining services that complement the die casting process. Our expertise in custom CNC machining allows us to offer:

By choosing VMT, you gain access to a team of experienced professionals dedicated to delivering high-quality products and exceptional customer service. We work closely with you to understand your needs and provide tailored solutions that drive success.

Die casting is a versatile and efficient manufacturing process that enables the production of complex metal parts with high precision and excellent surface finishes. Understanding the various processes, types, materials, and applications of die casting empowers manufacturers and designers to make informed decisions that optimize production efficiency and product quality.

While die casting offers numerous advantages, it also presents challenges that must be carefully managed. By considering factors like material selection, mold design, and process control, and by integrating complementary services like CNC machining, businesses can leverage die casting to meet the evolving demands of modern industries.

Whether you're looking to produce high-volume automotive components, intricate electronics housings, or robust industrial parts, die casting provides a pathway to achieve your goals with efficiency and excellence.

What Is Die Casting GCSE?

In the context of GCSE (General Certificate of Secondary Education) studies, die casting is introduced as a manufacturing process where molten metal is forced into a mold cavity under high pressure. It's taught as part of design and technology courses to explain industrial manufacturing methods used to produce metal components with complex shapes and fine details.

Why Is Die Casting Better Than Sand Casting?

Die casting offers several advantages over sand casting:

However, die casting has higher initial tooling costs, making sand casting more economical for low-volume or large parts.

Are Die Casting Products Durable?

Yes, die casting products are durable. The process produces parts with good mechanical properties, including strength and hardness. The rapid cooling and solidification under pressure enhance the metal's grain structure, resulting in components that can withstand mechanical stress and have a long service life.

What Are the Types of Die Casting Molds?

Die casting molds, or dies, can be categorized based on their construction:

The choice depends on production requirements and part design.

What Is the Die Casting Die Lifespan?

The lifespan of a die casting die depends on factors like:

On average, a well-maintained die can produce tens of thousands to millions of parts before needing replacement.

By understanding die casting in depth, from its processes and types to materials and applications, manufacturers and designers can harness its full potential to create high-quality, complex metal parts efficiently and cost-effectively. Whether integrating with CNC machining services or exploring innovative design possibilities, die casting remains a cornerstone of modern manufacturing.