15 years one-stop China custom CNC machining parts factory

199 |

Published by VMT at Nov 18 2024 | Reading Time:About 3 minutes

199 |

Published by VMT at Nov 18 2024 | Reading Time:About 3 minutes

Are you facing challenges with your CNC machined parts not meeting the exact specifications required for your projects? Frustrated by inconsistencies that lead to costly delays and reworks in your custom CNC machining operations? You're not alone. Many manufacturers grapple with the nuances of accuracy and precision in CNC machining, which can significantly impact the quality and reliability of their products. But what if understanding the critical differences between accuracy and precision could transform your CNC machining services, ensuring superior quality and customer satisfaction?

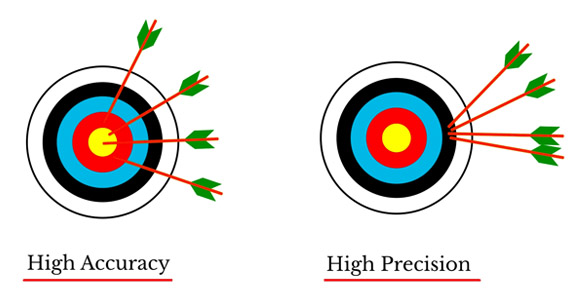

Accuracy refers to how close a measurement is to the true or intended value, while precision indicates the consistency of repeated measurements. In CNC machining, understanding the difference between accuracy and precision is essential for producing high-quality parts that meet exact specifications and function reliably in their intended applications.

Now that we've highlighted the importance of distinguishing between accuracy and precision in CNC machining, let's delve deeper into their definitions, significance, and how they impact the manufacturing process. By gaining a comprehensive understanding of these concepts, you can enhance your CNC machining plant's operations, improve product quality, and achieve greater customer satisfaction.

Foreword

In the world of CNC machining, the terms accuracy and precision are often used interchangeably, yet they represent distinct concepts that are crucial to the manufacturing process. These terms define the quality and reliability of CNC machined parts, affecting everything from functionality and fit to safety and aesthetics. For professionals in the CNC machining plant, understanding the difference between accuracy and precision is not just a matter of semantics but a foundational aspect of producing high-quality components.

The rise of custom CNC machining and CNC prototype machining has intensified the need for manufacturers to grasp these concepts thoroughly. As clients demand tighter tolerances and more complex geometries, the stakes for achieving both accuracy and precision have never been higher. This article will explore the definitions, importance, and differences between accuracy and precision in CNC machining, providing valuable insights for anyone involved in CNC machining services.

Accuracy in CNC machining refers to how close a machined part's dimensions are to the true or intended design specifications. It measures the degree of conformity of a measured or produced value to its actual or desired value. In other words, accuracy is about hitting the target—producing a part that matches the dimensions and tolerances specified in the engineering drawing.

For example, if a component is designed to be 100 mm in length, and the machined part measures exactly 100 mm, the machining process is considered highly accurate. If the part measures 100.05 mm or 99.95 mm, the accuracy decreases, depending on the tolerances allowed.

Accuracy is critical in CNC machining because it ensures that parts will fit together correctly in assemblies, function as intended, and meet regulatory and safety standards. In industries such as aerospace, automotive, and medical devices, where the margin for error is minimal, high accuracy is non-negotiable.

Factors affecting accuracy in CNC machining include machine calibration, tool wear, thermal expansion, machine rigidity, and operator skill. Regular maintenance and calibration of CNC machines are essential to maintain accuracy over time.

The Importance of Precision

Precision refers to the consistency or repeatability of measurements or machining processes. It indicates how closely multiple measurements or produced parts are to each other, regardless of whether they are close to the intended target value. Precision is about producing the same result repeatedly under unchanged conditions.

In CNC machining, precision is vital for mass production, where thousands or millions of identical parts are manufactured. High precision ensures that each part is virtually identical, allowing for interchangeability and consistent performance across all units.

Precision is influenced by factors such as machine stability, environmental conditions, tool quality, and process control. For example, a CNC machine that produces parts with dimensions consistently at 99.98 mm, when the intended dimension is 100 mm, is precise but not accurate. The parts are all the same size but not to specification.

The importance of precision cannot be overstated in industries where consistency is critical. For instance, in the automotive industry, components like engine parts must be precisely the same to ensure proper function and safety across all vehicles.

Machining Accuracy

Machining accuracy in CNC machining refers to the degree to which the actual machined dimensions match the design specifications. It encompasses not only linear dimensions but also geometric aspects like flatness, roundness, and surface finish. Machining accuracy is a measure of the machine's capability to produce parts within the specified tolerances.

Achieving high processing accuracy involves controlling various elements of the machining process:

Machining accuracy is crucial for custom CNC machining projects, where unique or complex parts require tight tolerances and exact dimensions. It directly impacts the functionality and quality of the final product.

Precision and Tolerance

Tolerance is the allowable deviation from a specified dimension, representing the range within which a part is considered acceptable. Precision relates closely to tolerance, as it measures how consistently parts fall within the specified tolerances.

High precision in CNC machining means that the variations between parts are minimal, and they consistently meet the tolerance requirements. Precision ensures that even if there are minor deviations from the nominal dimensions, the parts remain within acceptable limits and function as intended.

Understanding the relationship between precision and tolerance is essential for:

Precision in CNC machining is defined as the degree to which repeated measurements or produced parts under unchanged conditions show the same results. It is a measure of consistency and repeatability in the manufacturing process.

Precision is not concerned with how close the measurements are to the intended value (that's accuracy) but rather how close the measurements are to each other. A highly precise process will produce parts with very little variation between them, even if they are not exactly to the specified dimensions.

For example, if a CNC machine produces ten parts with lengths measuring 99.97 mm, 99.98 mm, 99.99 mm, 99.97 mm, and so on, it demonstrates high precision because the measurements are very close to each other. However, if the intended length is 100 mm, the process is not accurate.

Precision is essential for:

Importance of Accuracy

Accuracy is crucial in CNC machining because it ensures that the produced parts meet the exact specifications required for their intended function. High accuracy is vital for several reasons:

Functional Performance: Parts must meet design dimensions to function correctly within assemblies or systems.

Achieving high accuracy requires meticulous attention to all aspects of the machining process, from initial setup and programming to tool selection and machine maintenance.

Machining Precision

Machining precision refers to the ability of the CNC machining process to produce parts with minimal variation between them. It is a reflection of the machine's repeatability and the control over the manufacturing process.

Key factors influencing machining precision include:

Machining precision is particularly important in CNC prototype machining, where producing consistent parts allows for accurate testing and validation of designs.

Accuracy vs Tolerance

While accuracy measures how close a part's dimensions are to the intended value, tolerance defines the acceptable range of variation from that value. Tolerance is essentially the permissible limit of variation, and accuracy is how well the machining process stays within that limit.

For example, if a part is designed with a dimension of 50 mm and a tolerance of ±0.02 mm, the acceptable range is from 49.98 mm to 50.02 mm. If the machined part measures 50.015 mm, it is accurate because it falls within the tolerance.

Understanding the relationship between accuracy and tolerance is vital for:

While accuracy and precision are related concepts, they have distinct meanings in CNC machining. Understanding the differences is essential for optimizing manufacturing processes, ensuring product quality, and meeting client expectations.

1. Descriptions Are Different

In CNC machining, a process can be accurate but not precise, precise but not accurate, both, or neither.

2. Types of Errors Indicated

Identifying whether errors are due to accuracy or precision issues helps in diagnosing and correcting problems in the machining process.

3. Number of Measurements

In practice, ensuring both high accuracy and high precision involves monitoring individual parts for conformity and analyzing data from multiple parts for consistency.

Illustrating the concepts of accuracy and precision through examples helps clarify their differences and significance in CNC machining.

1. Accurate and Precise

Imagine a CNC machine programmed to drill holes at exactly 10 mm apart. If the machine consistently drills holes at 10 mm intervals, matching the design specifications exactly, it is both accurate and precise.

This scenario represents the ideal situation in CNC machining, where parts meet specifications and show consistent quality across production runs.

2. Not Precise, but Accurate

Suppose the same CNC machine drills holes at intervals of 10 mm, 10.05 mm, 9.95 mm, and so on, but the average interval is 10 mm. Over time, the deviations average out to the intended specification.

In this case, the process is accurate (on average) but not precise, as the individual measurements vary significantly. This lack of precision can cause problems in assemblies where consistent spacing is required.

3. Precise but Not Accurate

Now, imagine the CNC machine drills all holes at intervals of 10.05 mm consistently. The measurements are tightly clustered but do not match the intended 10 mm specification.

This scenario represents a process that is precise but not accurate. All parts are consistent, but they do not meet the design requirements, potentially causing issues in functionality or assembly.

4. Imprecise, Inaccurate

If the machine drills holes at intervals of 10.1 mm, 9.9 mm, 10.05 mm, and so on, with significant deviations and an average that does not match the intended 10 mm, the process is neither accurate nor precise.

This situation is undesirable in CNC machining, leading to parts that are unreliable and likely unusable.

Achieving high accuracy and precision in CNC machining offers numerous benefits, impacting the overall quality, functionality, and success of manufactured parts.

1. Safety Considerations

2. Smooth Testing and Prototyping

3. Easier Equipment Calibration

Measuring accuracy and precision in CNC machining involves several methods and tools:

Implementing these measurement techniques helps maintain high levels of accuracy and precision, ensuring that the CNC machining process produces quality parts consistently.

Improving accuracy and precision in CNC machining involves several strategies:

By focusing on these areas, manufacturers can significantly enhance the performance of their CNC machining operations, delivering superior products to their clients.

At VMT, we specialize in providing high-quality CNC machining services that prioritize both accuracy and precision. Our state-of-the-art CNC machining plant is equipped with advanced machinery and technology, enabling us to meet the most demanding specifications.

Why Choose VMT?

Our Services Include:

Contact Us Today

If you're looking for a reliable partner to deliver CNC machined parts with exceptional accuracy and precision, VMT is here to help. Contact us to discuss your project requirements and discover how we can contribute to your success.

Understanding the difference between accuracy and precision is fundamental in CNC machining. These concepts play a critical role in ensuring that machined parts meet design specifications, function correctly, and are produced efficiently.

By focusing on both accuracy and precision, manufacturers can deliver high-quality products that meet the exacting demands of today's industries. Implementing best practices in machine maintenance, process control, and quality assurance enables the production of parts that are both accurate and precise.

For businesses involved in custom CNC machining, investing in understanding and improving accuracy and precision is not just beneficial—it's essential for competitiveness and customer satisfaction.

Why Are Accuracy and Precision So Important for Machined Parts?

Accuracy and precision are crucial for machined parts because they ensure that components meet design specifications and function correctly within assemblies. High accuracy ensures that parts are made to the correct dimensions, while high precision ensures consistency across multiple parts. Together, they contribute to product quality, reliability, safety, and customer satisfaction.

Which Manufacturing Process Produces Higher Precision?

CNC machining is known for producing high-precision parts due to its automated control and ability to execute complex tool paths with minimal human intervention. Processes like CNC milling and turning can achieve tight tolerances and consistent results, making them ideal for applications requiring high precision.

What Is Precision Tolerance?

Precision tolerance refers to the allowable variation in dimensions for parts requiring high precision. It defines the tight limits within which a part must be manufactured to be considered acceptable. Precision tolerances are typically tighter than general tolerances and are specified for critical dimensions where small deviations can impact functionality or performance.

What Is the Difference Between Accuracy, Precision, and Reliability?

In CNC machining, reliability refers to the machine's ability to consistently produce accurate and precise parts over extended periods.

What Is the Difference Between Accuracy and Precision in EMI?

In the context of Electromagnetic Interference (EMI), accuracy refers to the closeness of a measured or calculated value to its true value, while precision refers to the repeatability or consistency of measurements under the same conditions. In EMI testing, high accuracy ensures that the measurements reflect the true electromagnetic emissions, while high precision ensures that repeated tests yield consistent results.

By mastering the concepts of accuracy and precision, and implementing strategies to improve them, manufacturers can enhance their CNC machining operations, delivering superior products that meet the highest standards of quality and performance.