15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

465 |

Published by VMT at Oct 30 2024 | Reading Time:About 2 minutes

465 |

Published by VMT at Oct 30 2024 | Reading Time:About 2 minutes

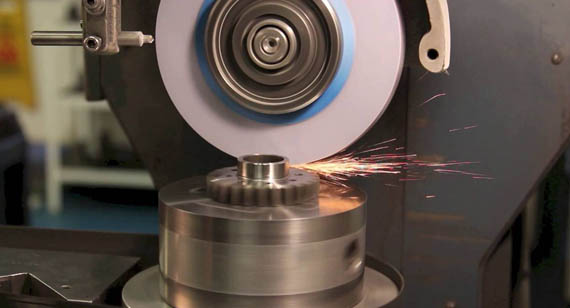

Are you struggling to achieve tight tolerances and flawless surface finishes in your machining operations? Precision grinding offers the perfect solution. This technique provides high accuracy and superior finishes, making it ideal for industries where perfection matters, such as aerospace, automotive, and medical manufacturing.

Precision grinding is a machining process that removes material from a workpiece with high precision using rotating abrasive wheels. It ensures tight tolerances, smooth finishes, and enhanced durability, making it a vital technique in CNC machining services for creating precision components like bearings, fasteners, and gears. With multiple grinding types available, this process delivers superior performance across various industries.

Now, let’s explore the principles of precision grinding, its types, and how it applies to modern manufacturing.

Precision grinding is one of the most accurate and essential processes in custom CNC machining. It is a finishing process used to achieve micron-level tolerances and smooth surfaces. Grinding ensures parts meet strict quality standards required in industries such as aerospace, automotive, and medical device manufacturing. This guide offers a deep dive into the grinding process, types, applications, and precautions that ensure precision in every operation.

Precision grinding is a subtractive manufacturing process that uses abrasive wheels to remove small amounts of material from a workpiece. Unlike other machining techniques, grinding provides highly accurate surface finishes, achieving tolerances as tight as ±0.001 mm. This process is ideal for CNC machining parts that require superior surface finishes or specific shapes, such as shafts, bearings, and precision gears.

The precision grinding process can be applied to both internal and external surfaces of a part, providing flexibility in machining components of varying geometries. Using high-quality grinding tools and machines, manufacturers achieve consistent results even for complex designs, which is essential in prototype machining and large-scale production.

Cost-Effectiveness and Accuracy

Precision grinding ensures cost-effective machining by reducing the need for post-processing. The high level of accuracy and precision minimizes errors and rework, saving both time and material costs.

Additionally, this method enables manufacturers to produce identical parts consistently, which is critical in large production runs where small dimensional deviations can impact product performance.

A Reliable Machining Alternative

Precision grinding is the go-to process when tight tolerances or specific surface finishes are needed—especially when standard CNC machining services cannot deliver the required results.

This method is especially suitable for:

1. Surface Grinding

Surface grinding ensures flat and smooth surfaces, making it ideal for parts like plates, mold components, and tooling. A rotating abrasive wheel removes material from the surface until the desired smoothness is achieved.

2. Cylindrical Grinding

Cylindrical grinding focuses on circular parts, such as shafts, pipes, and rollers.

3. Centerless Grinding

Centerless grinding removes material without using centers to hold the part. It is often used for high-volume production of parts like rods, tubes, and fasteners.

4. Coordinate Grinding

Coordinate grinding machines are used for complex geometries and high-precision holes, making them essential in aerospace and medical manufacturing.

5. Creep Feed Grinding

Creep feed grinding removes material in one deep pass rather than multiple shallow passes, making it ideal for producing large and heavy components.

6. Single and Double Disc Grinding

This grinding type uses one or two abrasive discs to machine flat surfaces. Single-disc grinding works on one surface, while double-disc grinding processes both sides of a part simultaneously, ensuring parallel surfaces.

7. Super Abrasive Grinding

This technique employs advanced abrasives such as diamond or cubic boron nitride (CBN) to grind extremely hard materials, including ceramics and high-strength alloys.

8. Thread Grinding

Thread grinding machines specialize in cutting precise screw threads for applications like taps, ball screws, and worm gears, ensuring tight tolerances and smooth finishes.

Precision grinding is essential for CNC prototype machining and large-scale production of components requiring high precision. It is widely used for:

Precision grinding plays a vital role in various industries:

Aerospace: Ensures critical components, such as turbine blades, meet precise dimensions.

Automotive: Used to grind shafts, gears, and engine components for maximum performance.

Medical Equipment: Achieves the smooth finishes required for surgical tools and implants.

Industrial Tools: Provides the perfect finish for dies, molds, and cutting tools.

Precision grinding machines operate by rotating abrasive wheels at high speeds to remove material from a workpiece. This ensures smooth, accurate surfaces. However, it’s essential to follow these precautions to ensure safe and effective operation:

A typical precision grinding machine consists of the following parts:

Grinding Wheel: The abrasive tool that removes material.

Wheel Guard: Protects the operator from sparks and debris.

Grinding Head: Houses the motor and grinding wheel.

Traverse Wheel: Controls the movement of the grinding head across the part.

Table and Column: Support and align the workpiece during grinding.

Coolant Supply Nozzle: Delivers coolant to reduce heat and improve grinding precision.

At VMT, we specialize in precision grinding CNC machining parts to meet the strictest quality standards. Whether you need prototype machining or large-scale production, our CNC machining factory ensures that every part meets the desired tolerance and surface finish.

Precision grinding is a critical process in modern manufacturing, delivering high accuracy, tight tolerances, and smooth finishes for a wide range of components. With multiple grinding types available, manufacturers can produce custom CNC machining parts that meet stringent industry requirements. Whether for aerospace, automotive, or medical applications, precision grinding plays an essential role in ensuring high-performance products.

What is the accuracy of precision grinding?

Precision grinding can achieve tolerances as tight as ±0.001 mm.

What is the cutting speed of a grinder?

Cutting speeds vary depending on the material and wheel, typically between 30–50 m/s.

What is the difference between manual grinding and precision grinding?

Manual grinding relies on operator skill, while precision grinding offers automated, repeatable results.

What is the tolerance of precision grinding?

Precision grinding machines can maintain tolerances of ±0.001 to ±0.005 mm.

What is non-precision grinding?

Non-precision grinding focuses on rough material removal without high accuracy or surface finish requirements.

What is the tolerance of CNC grinding?

CNC grinding achieves tolerances as fine as ±0.001 mm, ensuring consistent quality in large-scale production.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!