15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

570 |

Published by VMT at Jul 12 2024

570 |

Published by VMT at Jul 12 2024

In the CNC machined parts manufacturing field, grinding and polishing are essential surface treatment processes, each with specific tasks to achieve different surface qualities and aesthetic effects. This article aims to explore the differences between grinding and polishing, including their definitions, processes, applications on lathes, comparisons, and common issues, providing detailed references for professionals in the CNC machining industry.

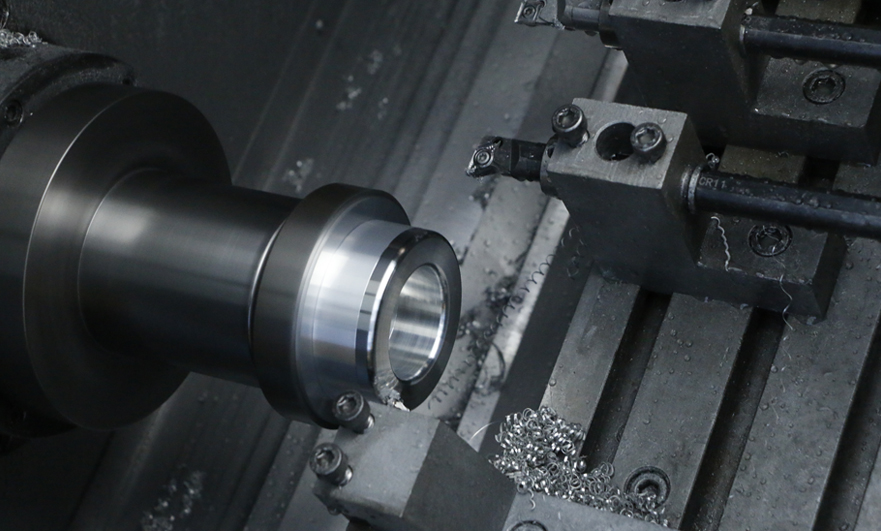

Grinding, the first step in surface treatment for CNC machined parts, involves using various grit sandpaper or abrasives to gradually refine the surface. This process removes machining marks, burrs, and uneven areas, making the surface relatively smooth. It sets the stage for subsequent polishing and is essential for improving the overall surface quality of the part.

Polishing is a more advanced surface treatment performed after grinding. It utilizes polishing tools (such as polishing wheels and cloths) and polishing compounds to further reduce surface roughness, achieving a bright, smooth, or even mirror-like finish. Polishing not only enhances the aesthetic appeal of the part but also improves its corrosion resistance, wear resistance, and fatigue strength.

Choosing Sandpaper: Select appropriate sandpaper based on the material, surface condition, and final requirements. Common grits range from 80 to 1000 and higher.

Initial Grit: Start with coarse sandpaper (e.g., 80 or 180 grit) to quickly remove large amounts of material, reducing processing time.

First Grinding: Apply uniform pressure to avoid deep or shallow spots, and ensure the sandpaper is flat to prevent scratching the part.

Alternating Sandpaper: Gradually switch to finer sandpaper, cleaning the surface thoroughly between each change to remove debris and scratches.

Dry or Wet Grinding: Choose dry or wet grinding based on material and needs. Wet grinding helps reduce heat buildup and deformation risk, improving efficiency.

Grinding Direction: Maintain a consistent direction to avoid cross-grinding marks, usually along the part's natural grain or machining direction.

Final Grit: Use the finest sandpaper for final grinding to achieve the desired surface roughness and smoothness.

Surface Cleaning: Thoroughly clean the part to remove all grinding residues, grease, and dirt to avoid affecting the polishing outcome.

Initial Grinding: Use coarse sandpaper or wheels to remove machining marks, burrs, and minor defects before polishing.

Choosing Polishing Tools: Select appropriate tools based on part shape, material, and polishing requirements, such as polishing wheels and cloths.

Coarse Polishing: Use coarse polishing media and higher pressure to quickly remove surface bumps and uneven areas.

Intermediate Polishing: Gradually reduce the polishing media grit and pressure for intermediate polishing, further refining the surface.

Fine Polishing: Use the finest polishing media and minimal pressure for fine polishing, achieving a near-mirror finish.

Mirror Polishing: For high gloss surfaces, use ultra-fine polishing compounds and clean polishing wheels to achieve the highest brightness.

Polishing Liquid Usage: Use suitable polishing liquids to reduce friction heat, improving polishing efficiency and results.

Polishing Speed Control: Adjust polishing speed to avoid overheating and deformation while maintaining efficiency.

Inspection During Polishing: Regularly check the surface to ensure no scratches or defects, adjusting polishing parameters as needed.

Removing Polishing Marks: After polishing, clean the part with suitable detergents and water to remove residues, preventing impact on subsequent processes.

Cleaning and Drying: Thoroughly clean and dry the part after polishing to remove polishing compound residues.

Quality Inspection: Inspect surface roughness, gloss, and flatness to ensure it meets design requirements.

Post-Treatment: Apply anti-rust or anti-corrosion treatments if needed based on part usage.

Recording and Feedback: Document polishing parameters and results for future reference and improvement.

Polishing on a lathe utilizes the lathe's rotational function, along with appropriate polishing tools and liquids, to efficiently and precisely polish parts. The controllable rotational speed and stable tool-part contact make it ideal for polishing cylindrical or conical parts.

Purpose: Grinding primarily removes rough layers, burrs, and machining marks to smooth the surface for subsequent processes. Polishing further refines the surface to achieve specific aesthetic or functional requirements.

Method: Grinding relies on physical friction using sandpaper or grinding wheels to remove material. Polishing involves both physical and chemical actions to form a thin, smooth layer on the surface.

Result: Grinding leaves the surface relatively smooth with some texture and marks. Polishing creates a smoother, glossy surface, potentially achieving a mirror finish.

Roughness: Grinding results in higher roughness compared to polishing. While grinding reduces roughness with finer grit, it can't achieve the ultra-low roughness of polishing.

Material Removal: Grinding removes more material, especially with coarse grit. Polishing focuses on fine surface refinement with minimal material removal.

Processing Depth: Grinding can address deeper surface issues, removing significant defects. Polishing refines only the top microns to tens of microns.

Surface Effect: Grinding improves smoothness but remains visually plain. Polishing yields a bright, glossy, and visually striking surface.

Process Order: Grinding typically precedes polishing, laying the foundation by removing most machining marks and unevenness.

Tools and Materials: Grinding uses sandpaper and grinding wheels with lubricants, while polishing uses wheels, cloths, and compounds for finer treatment.

Applications: Both are widely used in various CNC machining fields, including aerospace, automotive, precision machinery, and medical devices, with process parameters varying by field requirements.

What is the main purpose of grinding and polishing?

Primary Purpose: To improve surface quality, removing machining marks, burrs, and uneven areas, enhancing smoothness and gloss.

Is Pre-Grinding Necessary Before Polishing?

Generally, yes. Grinding prepares the surface by removing most rough layers and machining marks, providing a good base for polishing. Skipping grinding can make achieving the desired polish difficult.

What are the basic principles of polishing?

Basic Polishing Principle: Polishing creates a thin, uniform smooth layer through mechanical or chemical action. Polishing tools and compounds work together to remove micro-bumps and irregularities, resulting in a smooth, fine surface.

What should you avoid when sanding?

The following points should be avoided when grinding:

Excessive Force: Can cause deformation or surface scratches.

Cross Grinding: Creates new scratches and textures, affecting surface quality.

Incorrect Sandpaper Choice: Leads to inefficient grinding or poor surface quality.

Ignoring Cleaning: Residues must be cleaned during grinding to prevent impact on subsequent processing.

Grinding and polishing are crucial surface treatment processes in CNC machined parts manufacturing, each with specific tasks and effects. Grinding focuses on removing rough layers and machining marks, providing a good base for polishing. Polishing further refines the surface, enhancing smoothness and gloss. Together, they ensure high-quality and aesthetically pleasing CNC machined parts. Practical application requires selecting appropriate parameters and processes based on part requirements and material characteristics, with strict control over operation norms and quality inspection standards to meet design specifications.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!